A vacuum preheating electron beam welding device for large thickness workpieces

An electron beam welding, large-thickness technology, applied in electron beam welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of reduced cooling rate, poor plastic toughness of welds, and large tendency of weld cracks to improve heating efficiency. , Guarantee welding quality, prevent oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

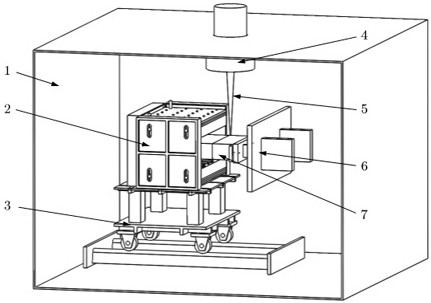

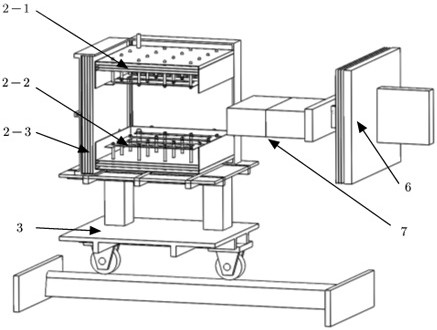

[0014] like Figure 1-2 As shown, the present invention provides a vacuum preheating electron beam welding device for high-strength alloy workpieces with large thickness, including: a vacuum chamber 1, a heating device 2, a mobile platform 3, an electron gun 5, a clamping tool 6 and a workpiece to be welded 7 , the workpiece to be welded 7 is composed of two large-thickness workpieces, and the thickness is more than 100mm.

[0015] Wherein, the heating device 2 includes an upper heating assembly 2-1, a lower heating assembly 2-2 and three side wall heat insulation protection assemblies 2-3, which are connected by bolts to form a box structure with an opening on one side, which can be welded according to the workpiece to be welded. The size is adjusted, and the heating assembly is composed of high-temperature heating devices, which are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com