Patents

Literature

33results about How to "Meet the requirements of engineering use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

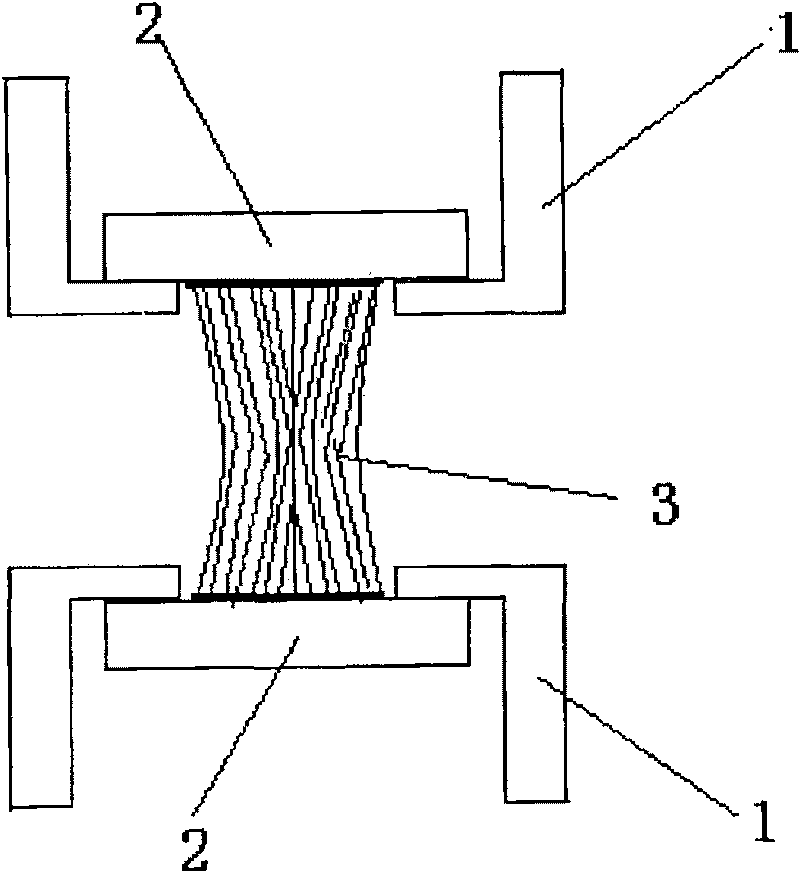

Graphene auxiliary brazing method for ceramic matrix composite material and metal material

ActiveCN103341674AImprove surface conditionReduce residual stressSoldering apparatusGas phaseShielding gas

A graphene auxiliary brazing method for a ceramic matrix composite material and a metal material elates to a brazing method for the ceramic matrix composite material and the metal material and solves the problem that a brazed connector obtained by brazing the ceramic matrix composite material and the metal material is poor in mechanical property. The brazing method comprises the steps of placing the ceramic matrix composite material into plasma reinforcing chemical vapor deposition equipment to carry out plasma surface treatment, adding CH4 gas to regulate flow, opening a radio frequency power supply, regulating the radio frequency to deposit for 10-30min, using Ar and H2 as protection gas, cooling to the room temperature, obtaining the ceramic matrix composite material with graphene growing on the surface, placing Ti brazing filler metal between faces to be connected, placing the Ti brazing filler metal into a vacuum brazing furnace to be brazed, and finally cooling to the room temperature to finish brazing. The shear strength of a connector formed by the ceramic matrix composite material and the metal material in the brazing method can reach to 35Mpa at the room temperature.

Owner:HARBIN INST OF TECH

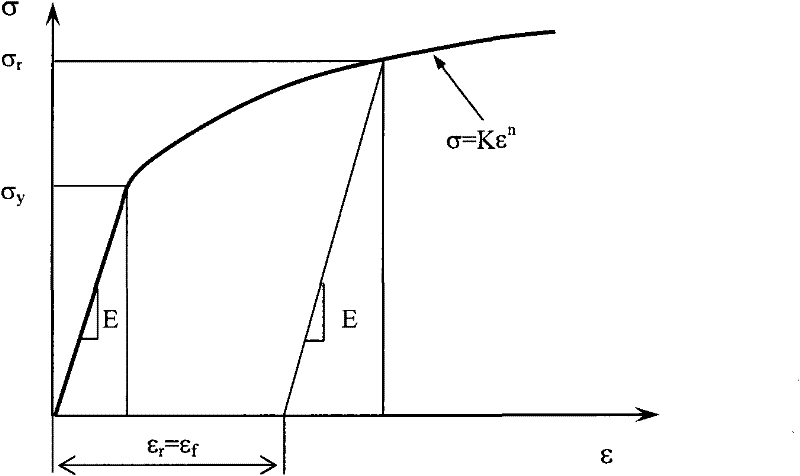

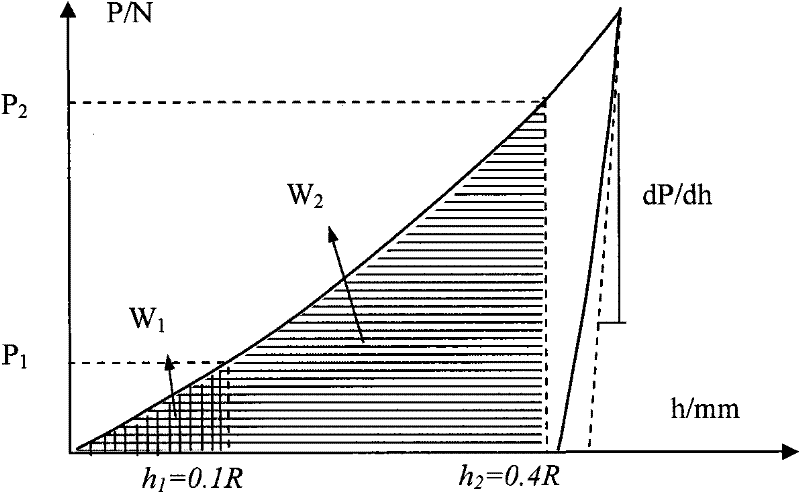

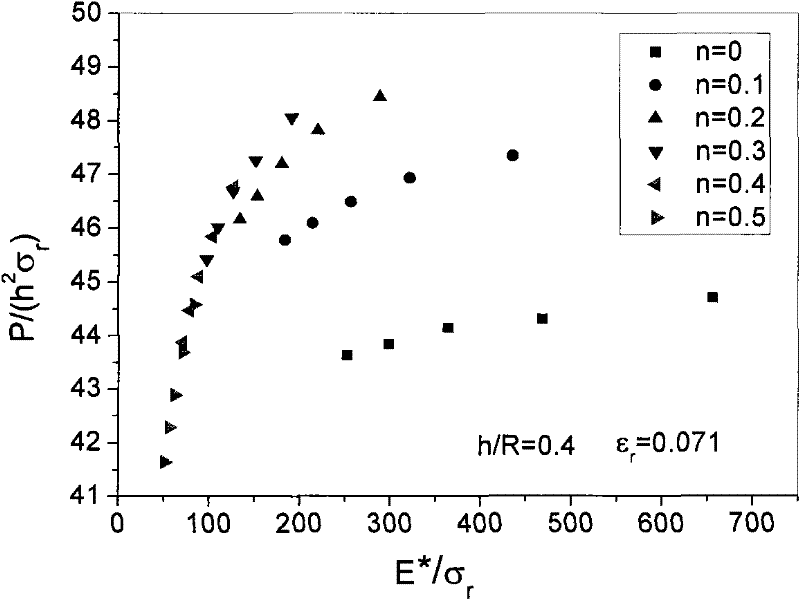

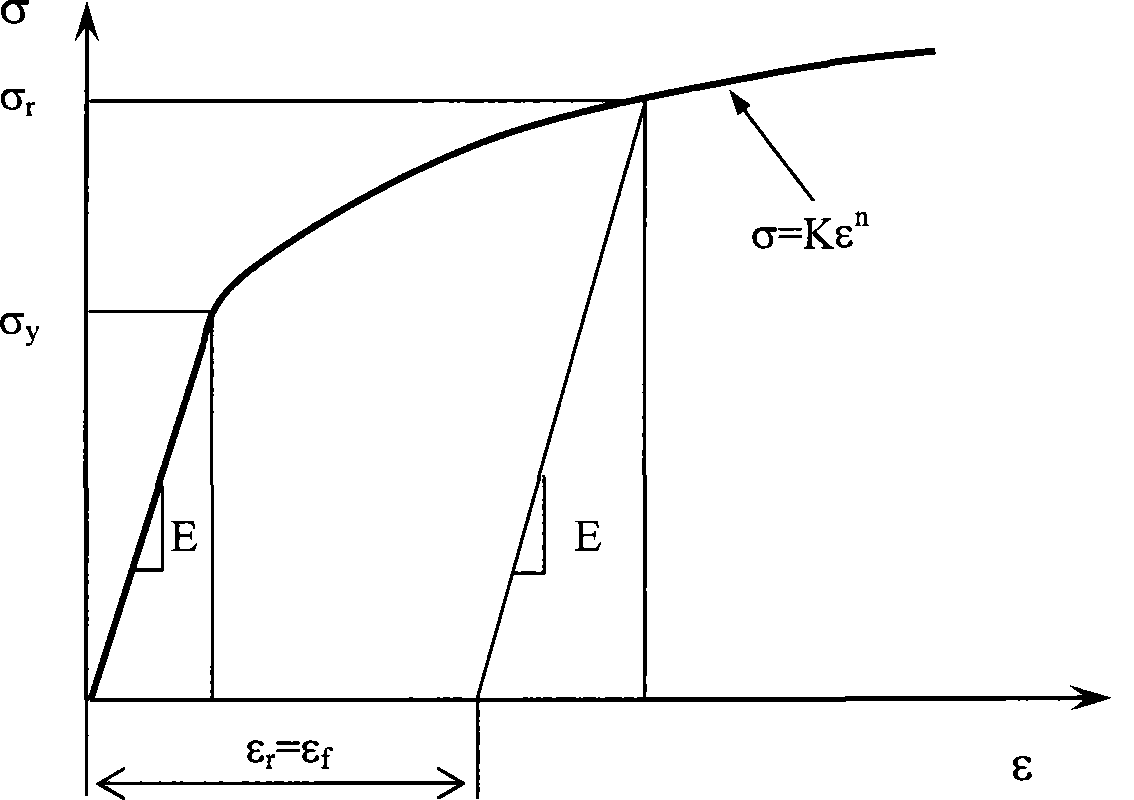

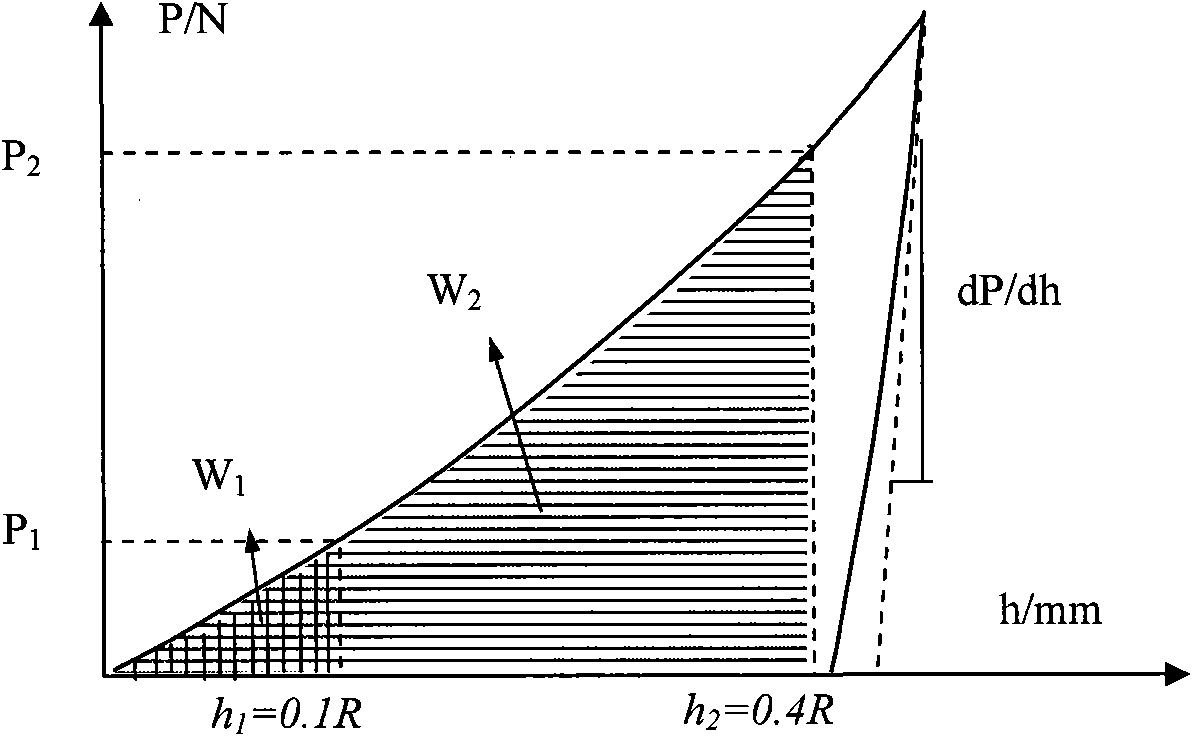

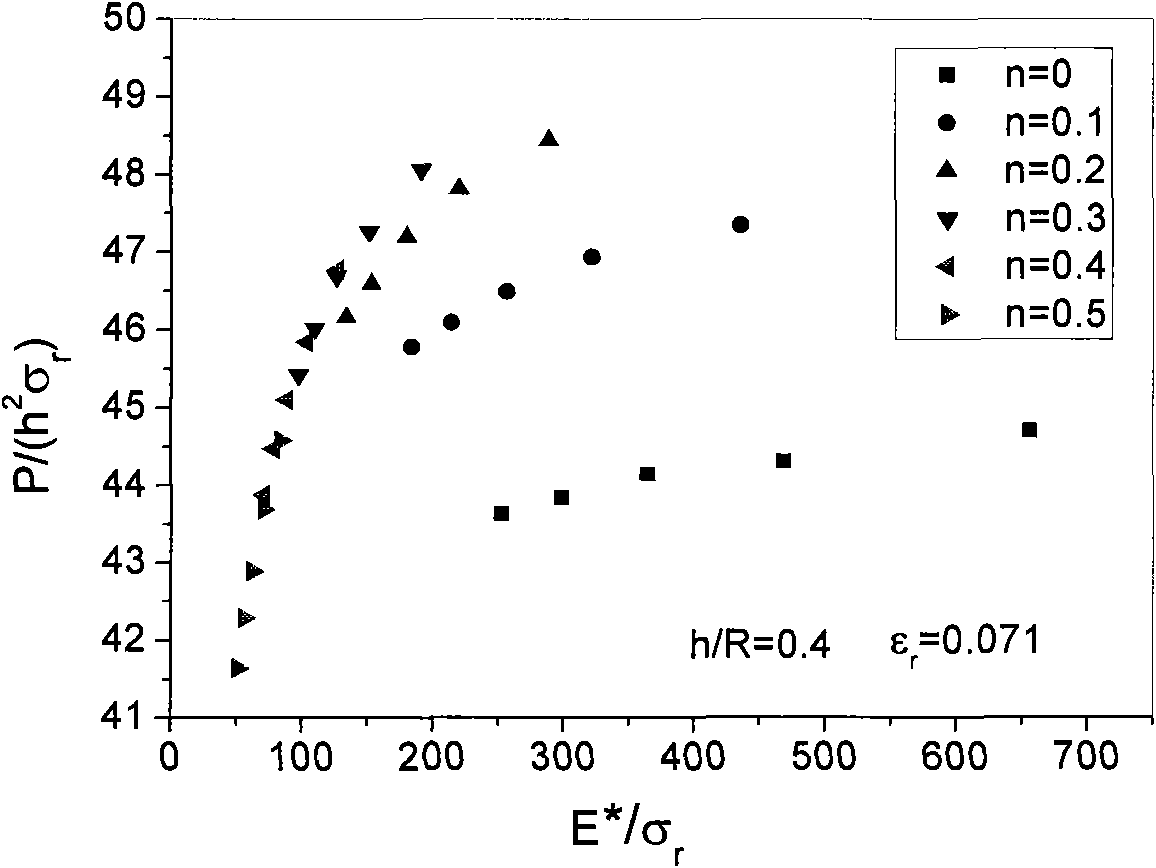

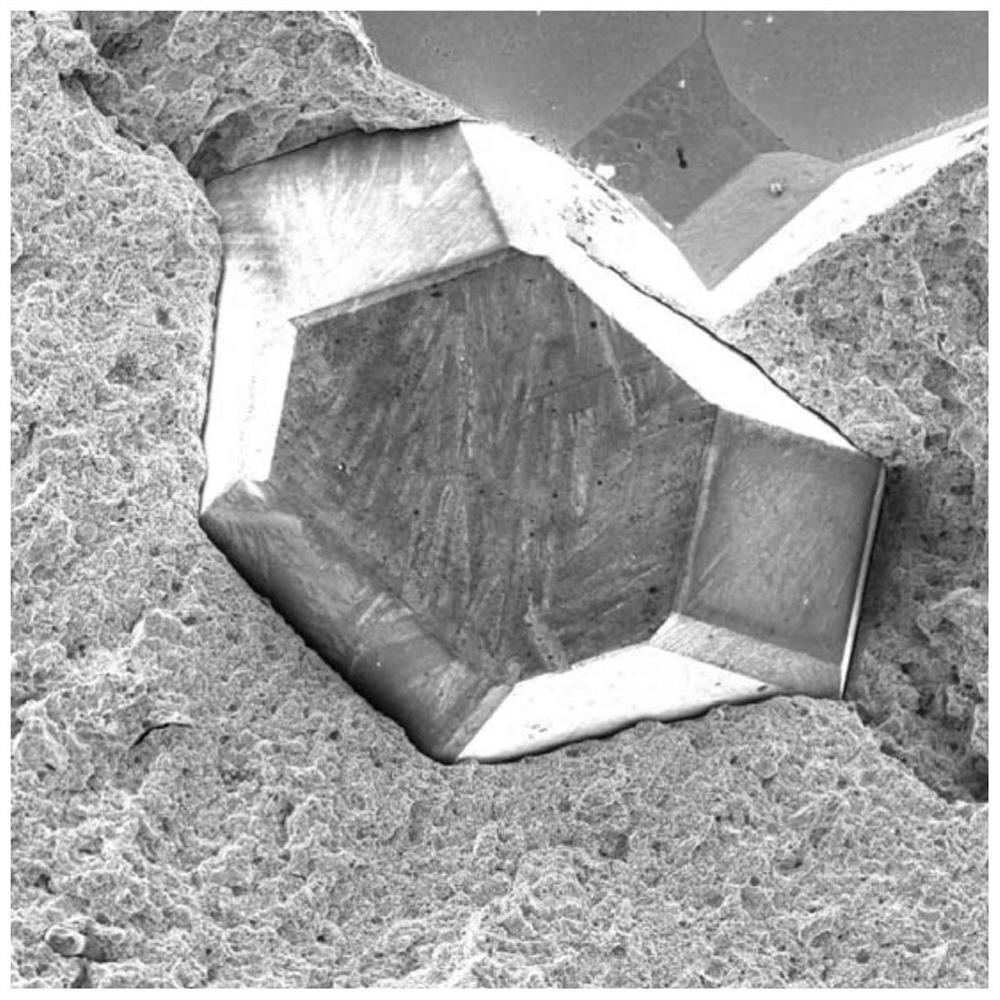

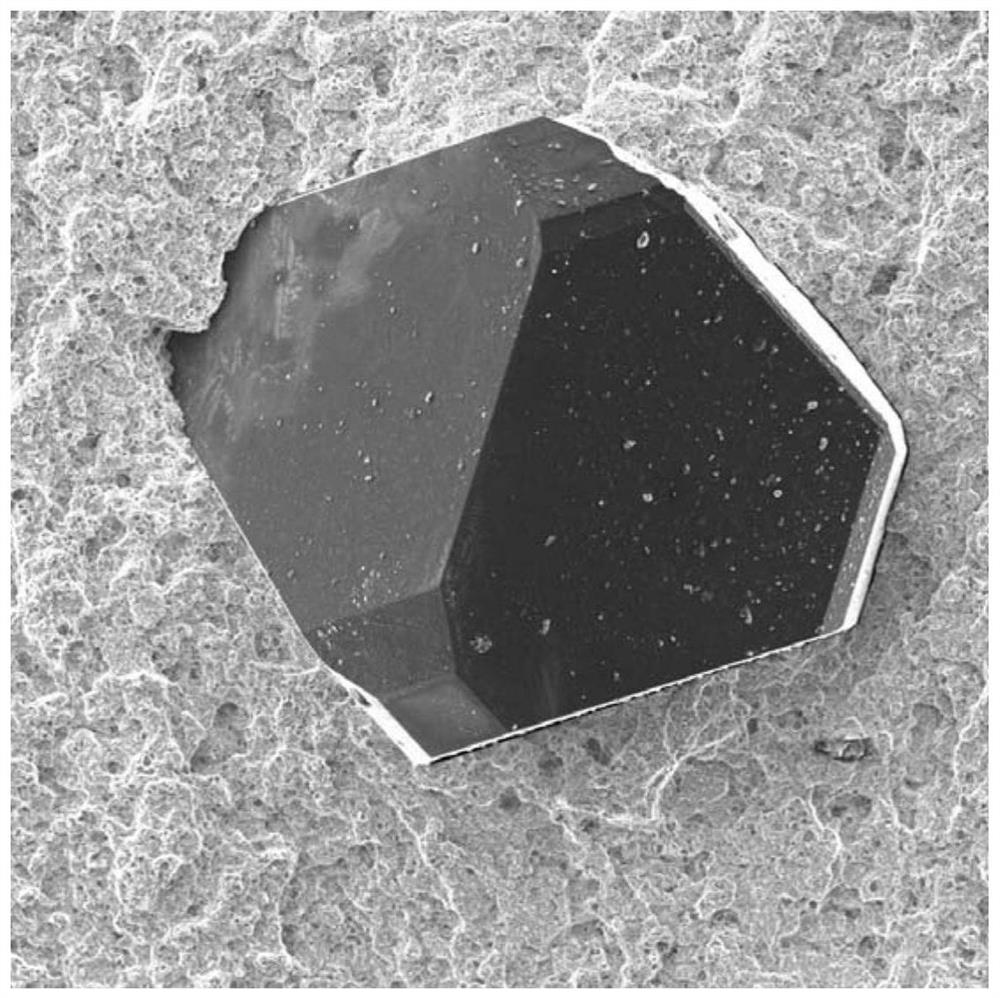

Method for obtaining mechanical property of metal material based on load-depth curve

ActiveCN102455263ARealize online detectionMeet the requirements of engineering useMaterial strength using tensile/compressive forcesInvestigating material hardnessTest materialTitanium alloy

The invention discloses a method for obtaining the mechanical property of a metal material based on a load-depth curve and belongs to the technical field of material property test. On the basis of determining to adopt a large pressed depth ratio (the depth h / the radius R of a pressing head), three kinds of engineering materials, namely alloy steel, aluminum alloy and titanium alloy, of which the elasticity modulus has remarkable difference are treated respectively by adopting two depth combinations (h1=0.1R and h2=0.4R) so as to obtain the respective material property coefficients; a ball factor S which reflects a hardening index effect is introduced so as to obtain a relational expression among a dimensionless function, W / (h3sigmarS ) and E* / (sigmarS); and the mechanical property of a tested material can be finally determined through constitutive relations, obtained by simulation by adopting finite element values, between the coefficients and the materials. By the method, the obtained result is more accurate; and the method is easy and quick and applicable to engineering structural materials in accordance with the power law.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

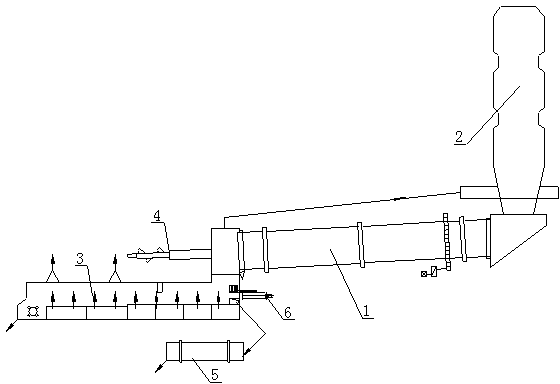

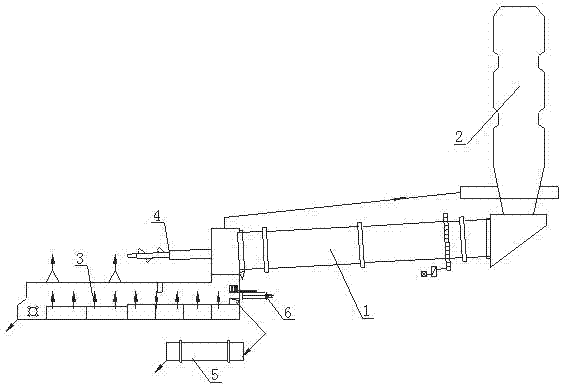

Material-distribution type cooling process of white cement clinker

ActiveCN103641345AIncrease productionReduce energy consumptionClinker productionCombustionDust control

The invention discloses a material-distribution type cooling process of white cement clinker. High-temperature clinker discharged from a rotary kiln is dropped into a grate type cooler, and a retractable material distributor is arranged on the front end part of the grate cooler in an interpenetrating manner; 20%-60% of granular clinker in the high-temperature clinker fallen from the rotary kiln is introduced by the material distributor to a discharging hole in the side part of the grate cooler to enter a rotary type bleaching machine to be cooled to 100 DEG C-300 DEG C by water spraying; the rest of the clinker particles are subjected to forced air cooling to 80 DEG C-100 DEG C by the grate cooler; high-temperature air preheated by the clinker and one part of medium-temperature air in the grate cooler are respectively provided for fuel combustion of the rotary kiln and a decomposing furnace as secondary air and tertiary air; the other part of the medium-temperature air enters a vertical type coal mill after entering a cyclone dust collector for collecting dust to provide drying hot air; low-temperature air and a vapor-containing gas exhausted by the bleaching machine are exhausted into atmosphere after entering a kiln-head electric dust collector for removing the dust. According to the invention, a material-distributing and cooling method of the white cement clinker can solve a defect that the conventional white cement clinker calcining is free from secondary air and tertiary air; meanwhile, whiteness requirements of the white cement can be ensured, and effects of increasing yield and saving energy can be obtained.

Owner:江西银杉白水泥股份有限公司

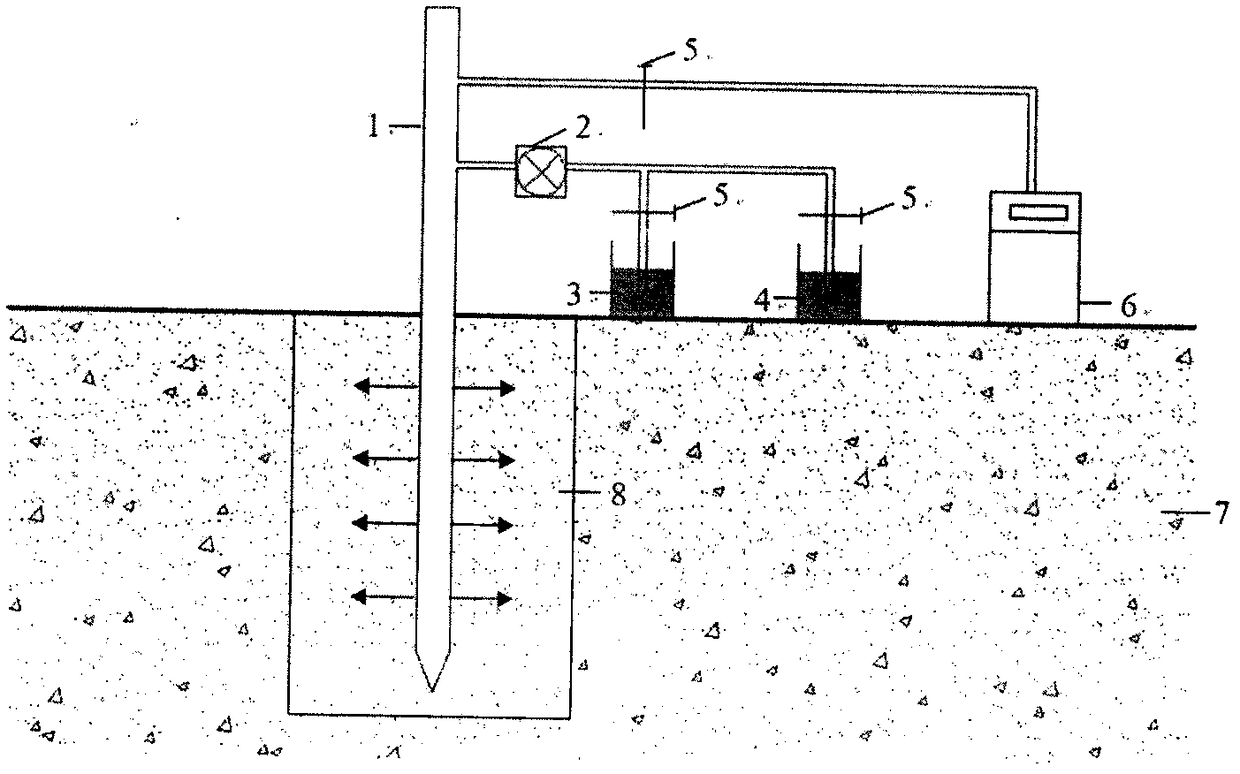

Microbial composite treatment for gold ore tailings and application method

InactiveCN108220197ANo cyanide accumulationNo secondary pollutionBacteriaMicroorganism based processesIonGold ore

The invention discloses a microbial composite treatment for gold ore tailings and an application method and belongs to the field of road engineering. According to the method, Bacillus pasteurii is compounded with one or more of Bacillus subtilis, Bacillus pumilus or Bacillus megaterium, so that by means of the Bacillus pasteurii, CaCO3 crystal is deposited and generated in the gaps in the gold oretailings, thus improving mechanical performance and stability and immobilizing heavy metal and noble metal ions in the gold ore tailings. The Bacillus pumilus or Bacillus megaterium can decompose thecyanides in the gold ore tailings. Through mechanical ploughing and multi-round slurry injection, the microorganisms, the gold ore tailings and a cemented liquid are fully mixed and contacted with each other, so that purposes of generating the CaCO3 crystal for reinforcing the gold ore tailings and degrading the cyanides can be achieved. The method has no secondary pollution, is low-cost, is simple and is high in resource utilization rate, and can achieve multi-channel large-scale recovery utilization of the tailings.

Owner:NANJING FORESTRY UNIV

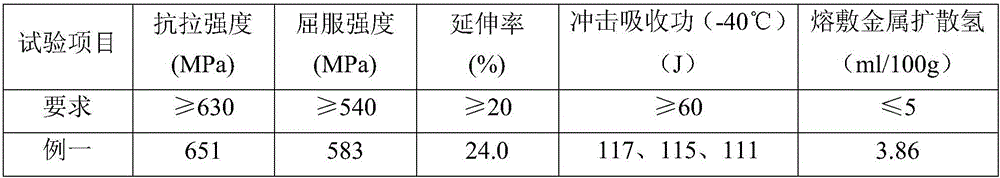

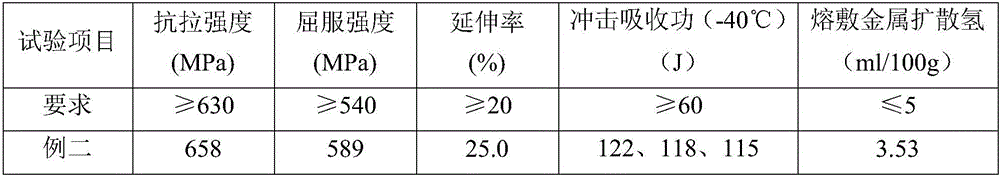

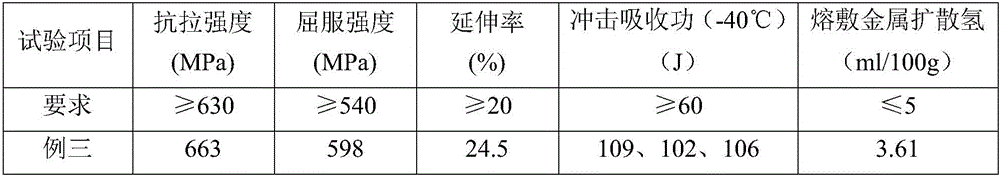

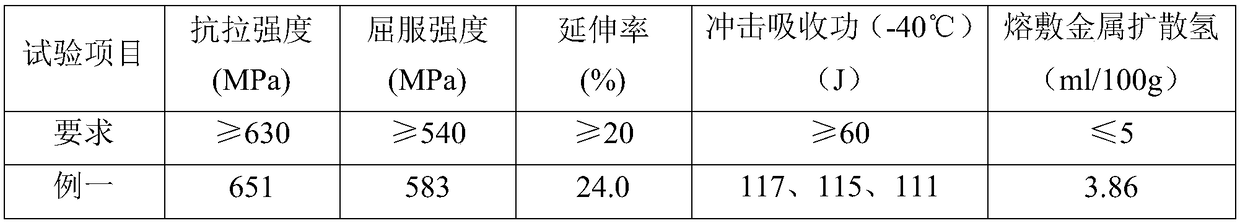

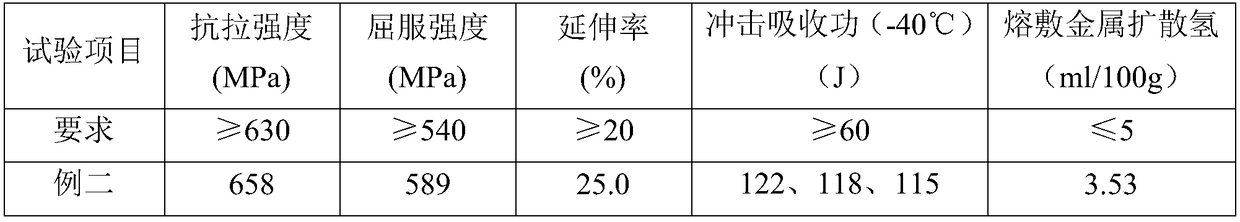

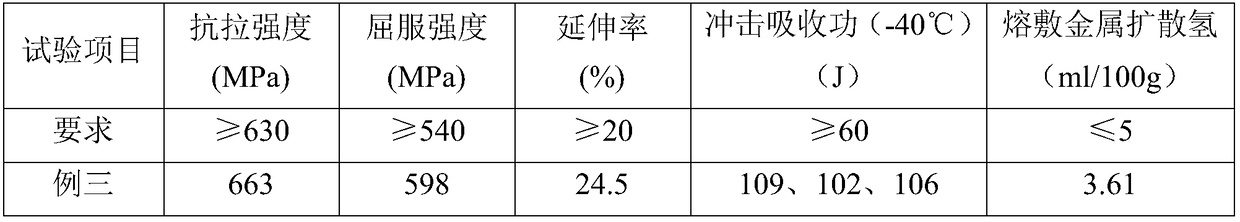

High-strength and high-toughness gas shielded flux-cored wire used for bridge steel

ActiveCN106334884AHigh tensile strengthHigh elongationArc welding apparatusWelding/cutting media/materialsManganeseZircon

The invention provides a high-strength and high-toughness gas shielded flux-core wire used for bridge steel. The high-strength and high-toughness gas shielded flux-core wire comprises a skin and a flux core wrapped by the skin. The flux core comprises, by weight, 30%-50% of rutile, 2%-8% of feldspar, 1%-6% of quartz, 0.5%-5% of zircon, 0.5%-5% of sodium fluoride, 0.1%-1.5% of lithium fluoride, 1%-8% of potassium-sodium arc stabilizers, 10%-25% of silicon-manganese alloys, 1%-8% of manganese metal, 1%-6% of magnesium powder, 5%-15% of nickel powder, 0.1%-1.5% of ferrotitanium, 0.05%-0.6% of ferroboron, and the balance iron powder, and the weight percents of the ingredients add up to 100%. According to the high-strength and high-toughness gas shielded flux-core wire used for the bridge steel, all the gradients and properties of the wire can meet the engineering using requirements of high-strength steel plates, and the wire is especially suitable for welding of Q500qE.

Owner:TIANJIN YONGCHANG WELDING WIRES +1

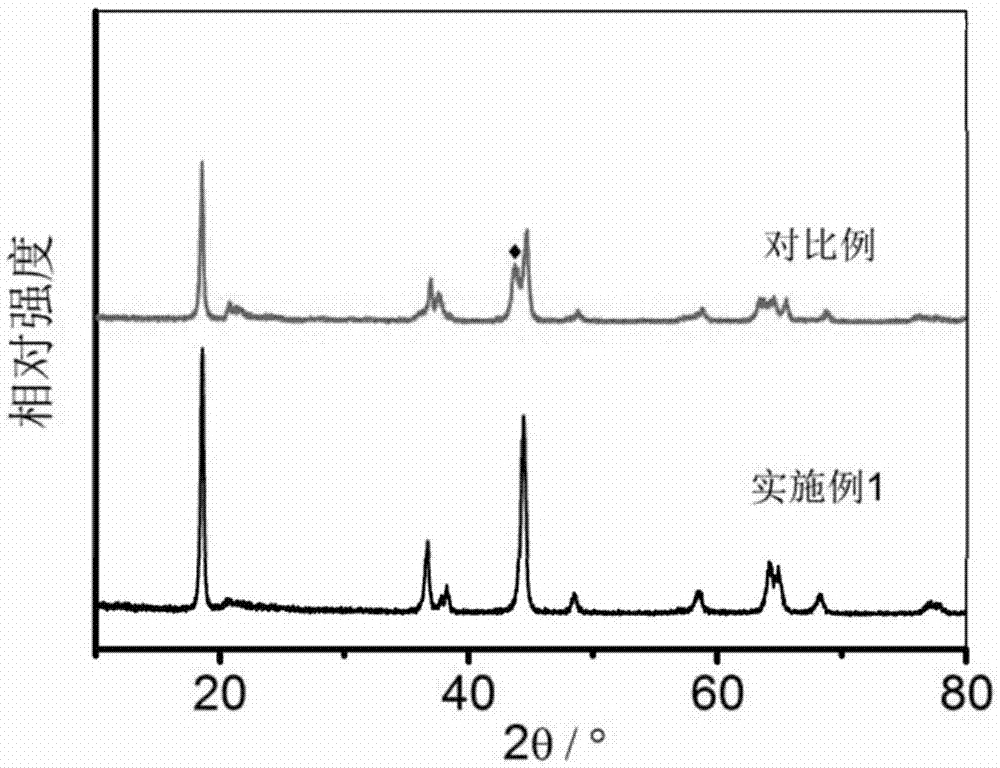

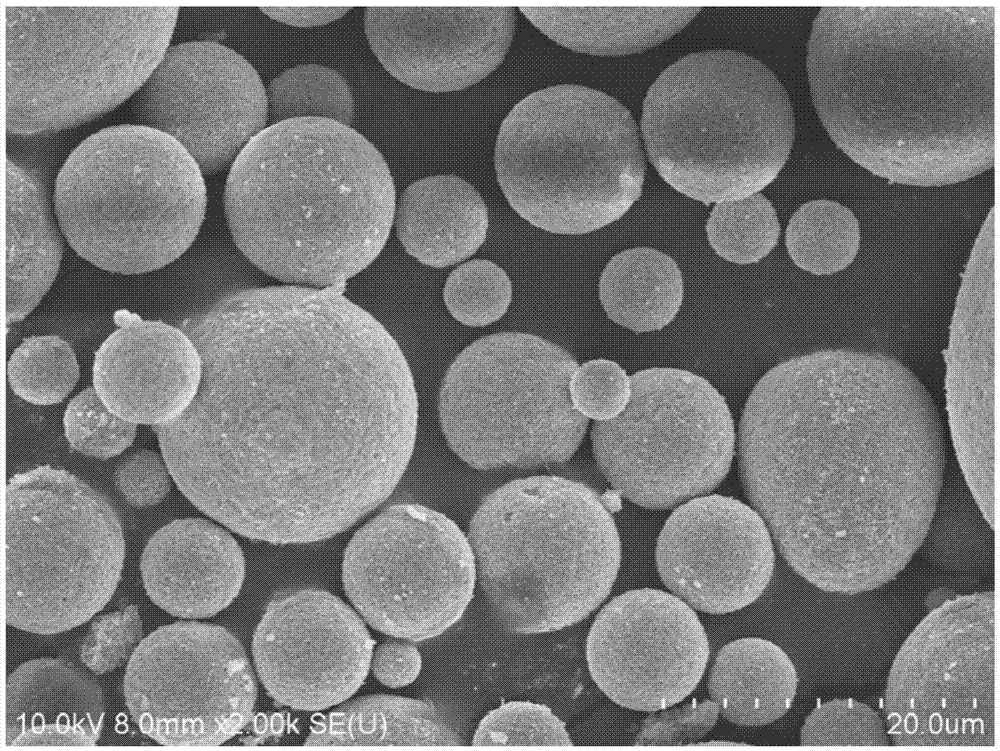

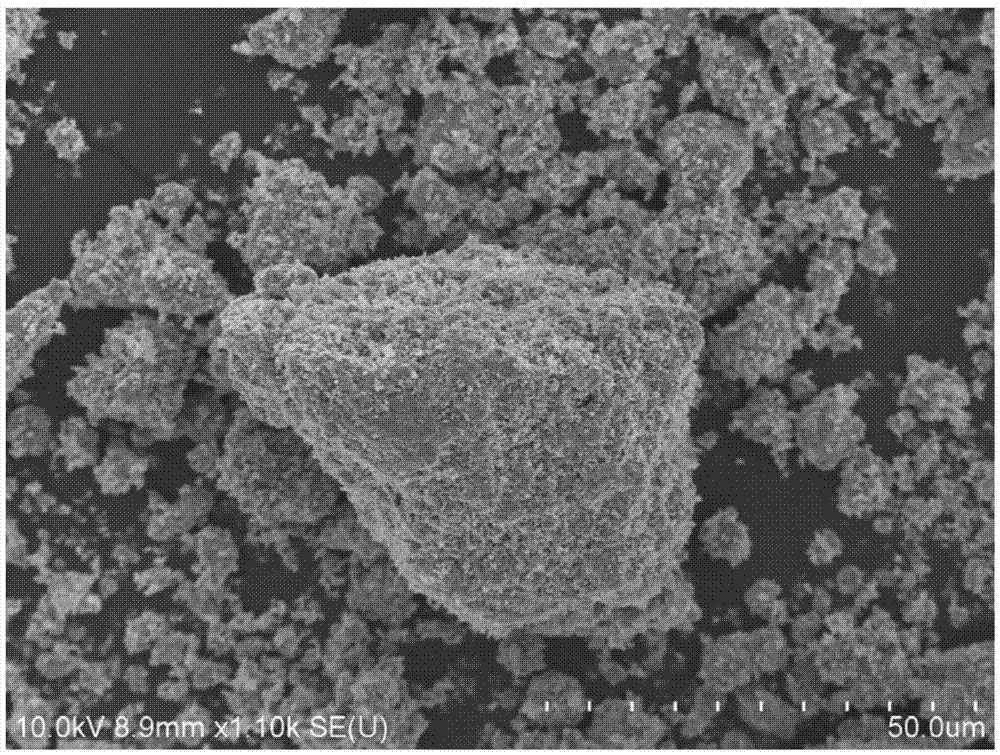

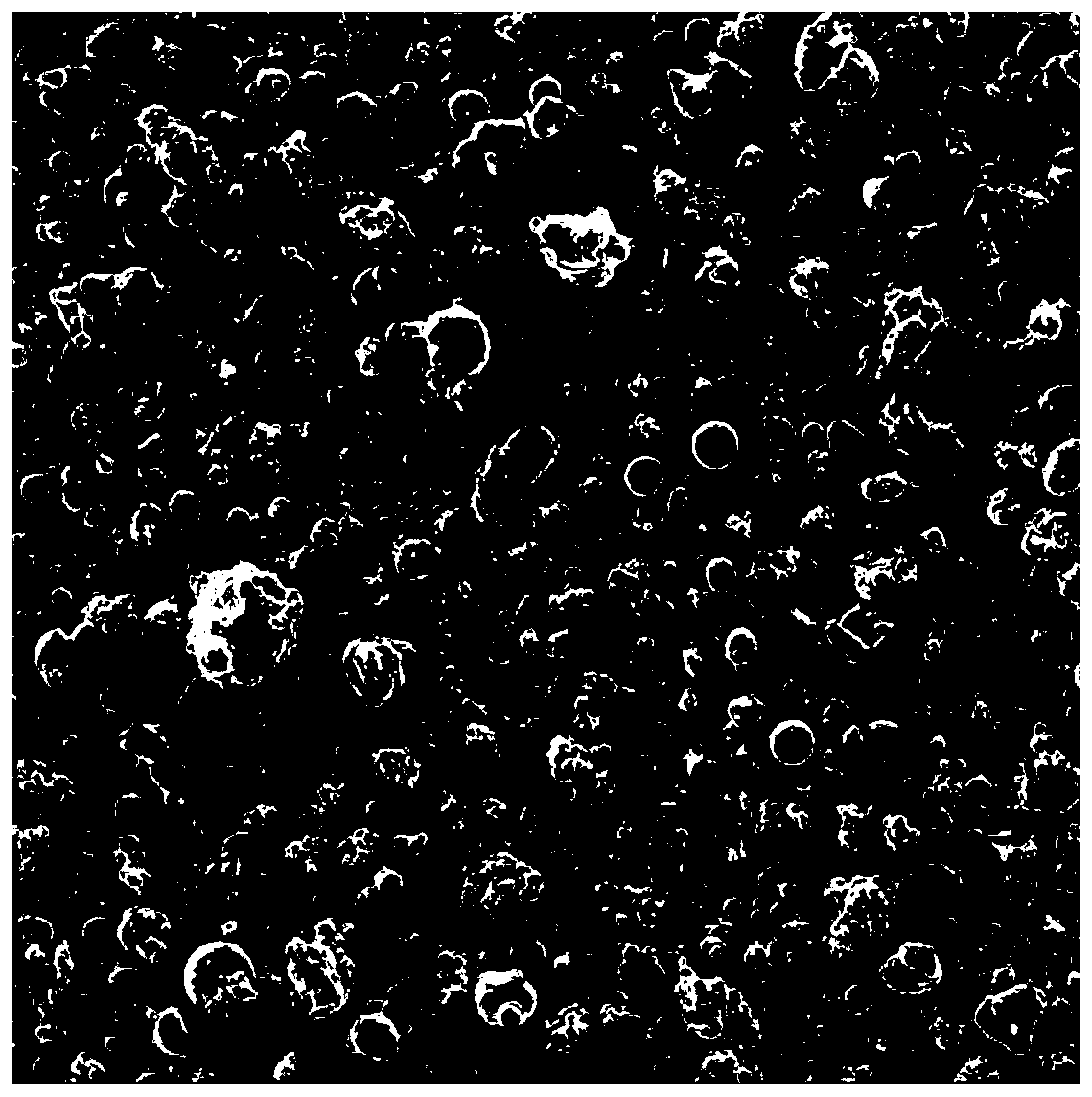

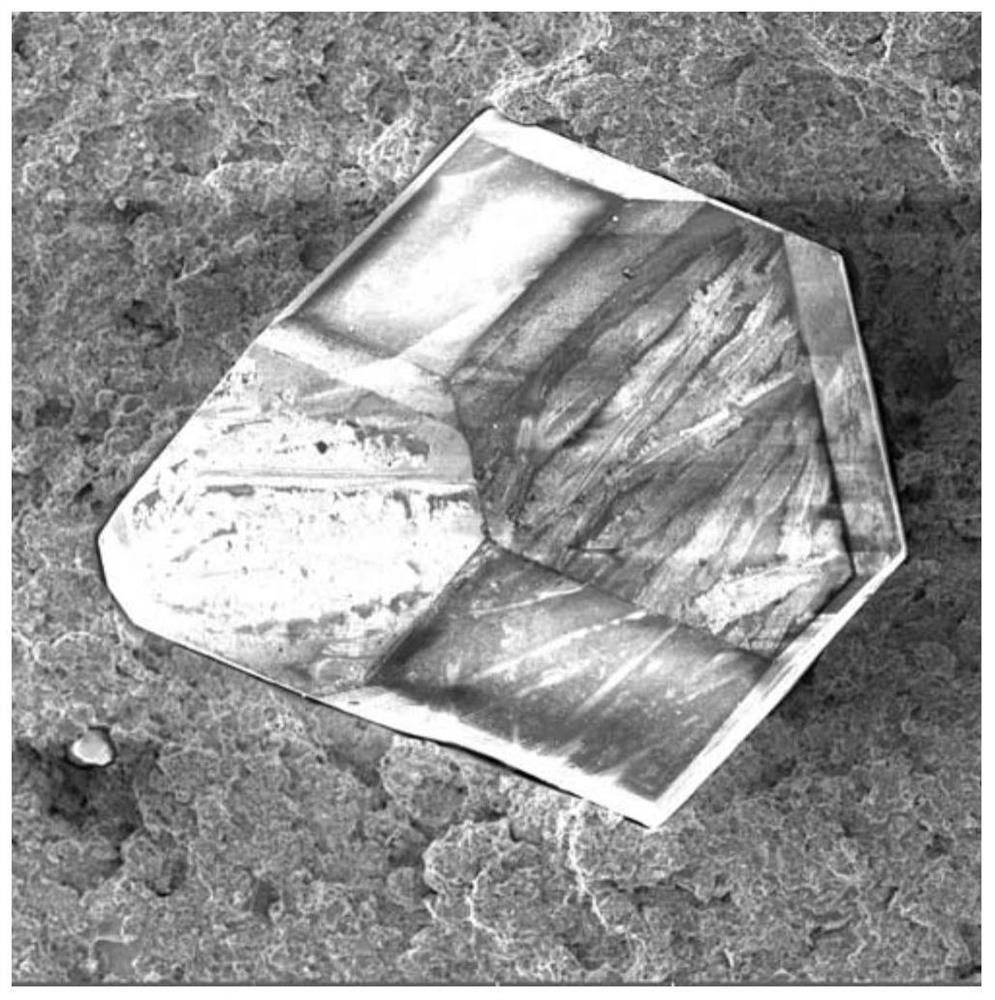

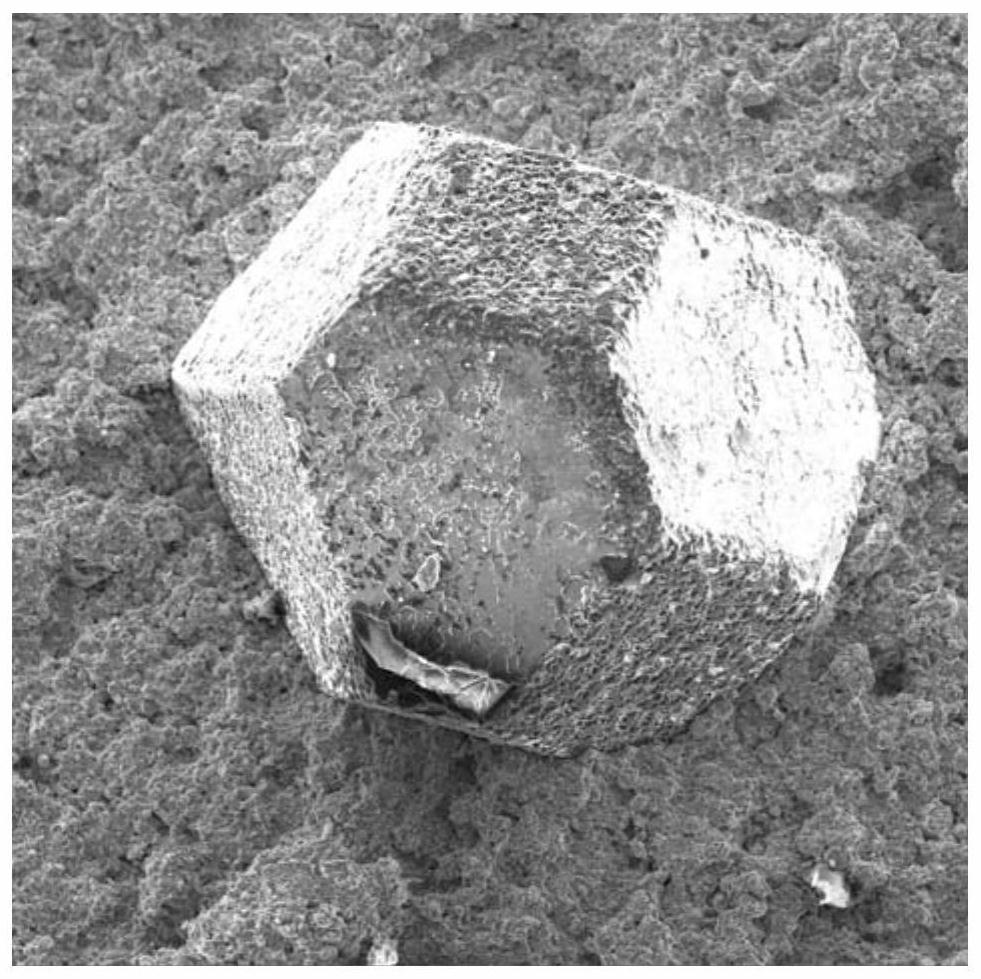

Lithium-rich manganese-based anode material, preparation method thereof and lithium ion battery containing anode material

ActiveCN106910887AThe problem of achieving compactionAchieve spherificationCell electrodesSecondary cellsManganeseLithium-ion battery

The invention discloses a lithium-rich manganese-based anode material, a preparation method thereof and a lithium ion battery containing the anode material. A chemical formula of the lithium-enrichment manganese-based anode material is Li1+xMnyMzAwOr, wherein the M is at least one of Ni, Co, Al, Mg, Ti, Fe, Cu, Cr, Mo, Zr, Ru and Sn; the A is at least one of S, P, B and F; the x is larger than 0 and smaller than or equal to 1, the y is larger than 0 and smaller than or equal to 1, the z is larger than or equal to 0 and smaller than 1, the w is larger than or equal to 0 and smaller than or equal to 0.2, and the r is larger than or equal to 1.8 and smaller than or equal to 3. The lithium-enrichment manganese-based anode material is prepared by methods of oxalate coprecipitation, spray drying and high-temperature roasting. The lithium-enrichment manganese-based anode material disclosed by the invention overcomes agglomeration of a material prepared through an oxalate coprecipitation method; a prepared material is controllable in particle size, meets requirements of engineering indexes and can achieve the purpose that transition metal ions are evenly mixed at an atom level; the particle size of the prepared lithium-enrichment manganese-based anode material is 3 to 25mu m, and the lithium-rich manganese-based anode material has good rate capability and circulation performance at the same time; furthermore, the lithium-enrichment manganese-based anode material has the advantages of simple preparation technology, low cost and wide application prospect.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD +1

Microbiological consolidation method and application method of bayer process red mud roadbed

InactiveCN108192623ARealize multiple rounds of groutingHigh strengthRoadwaysBuilding constructionsResource utilizationRed mud

The invention discloses a processing method and application method of a bayer process red mud roadbed, and belongs to the field of road engineering. The method comprises the following steps: fully mixing the paved bayer process red mud roadbed with microbiological bacterial liquid containing bacillus pasteurii according to a certain proportion in a way of mechanical plowing; supplying nutrient liquid and consolidating fluid to red mud in a way of several rounds of grouting. According to the processing method and application method of the bayer process red mud roadbed disclosed by the invention, the ways of mechanical plowing and grouting are innovatively adopted, so that three of the bacillus pasteurii, the red mud and the consolidating fluid are fully mixed and contact with each other; red mud particles are filled with calcium carbonate crystal produced by the bacillus pasteurii in pores of the red mud in a cementing manner, so that consolidation on the red mud is realized; the consolidated red mud can be used for roadbed filling engineering, and has the characteristics of no secondary pollution, low cost, simpleness in preparation method and high resource utilization ratio. In addition, the method disclosed by the invention also has the advantages that harmful components such as heavy metal in the red mud also can be consolidated, and multi-channel large-scale resource utilization of the red mud can be realized.

Owner:NANJING FORESTRY UNIV

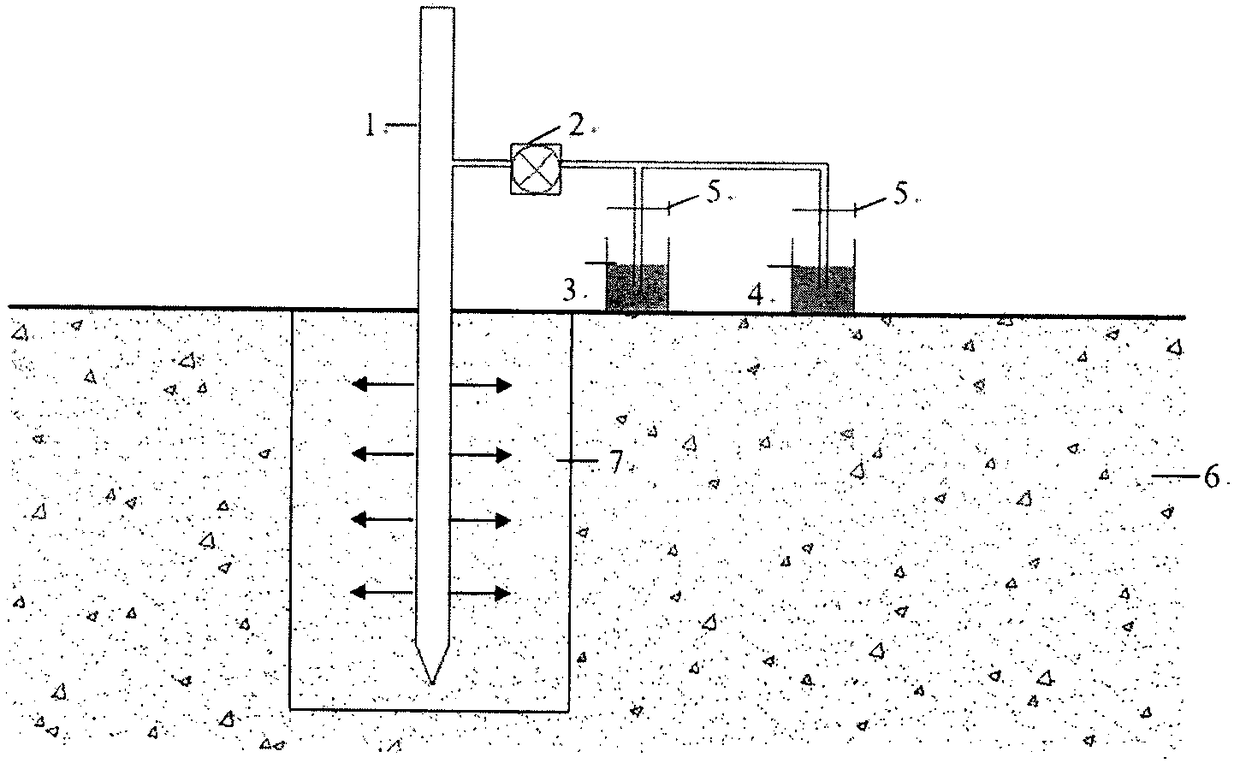

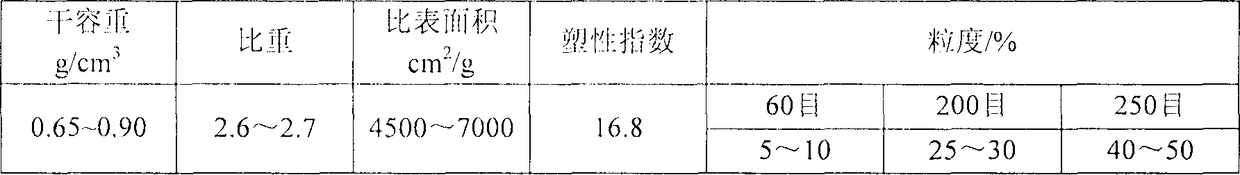

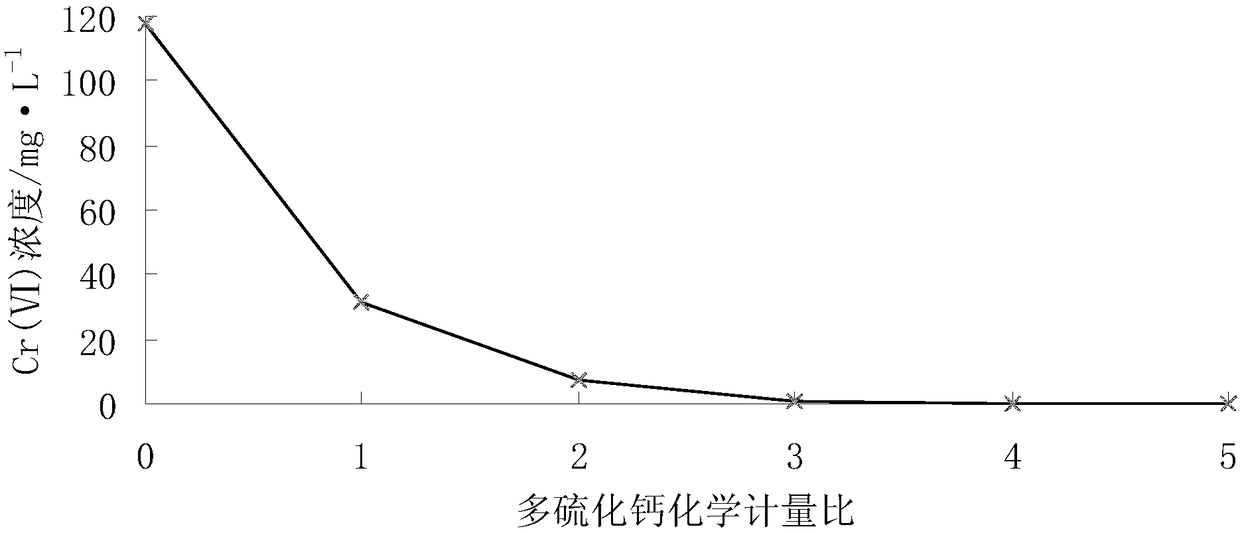

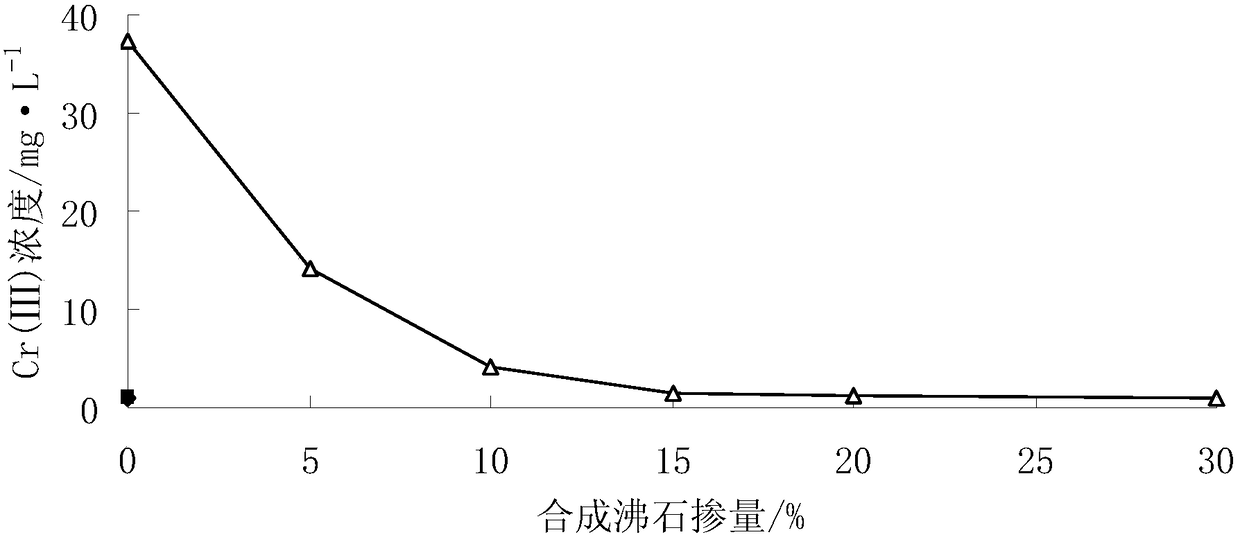

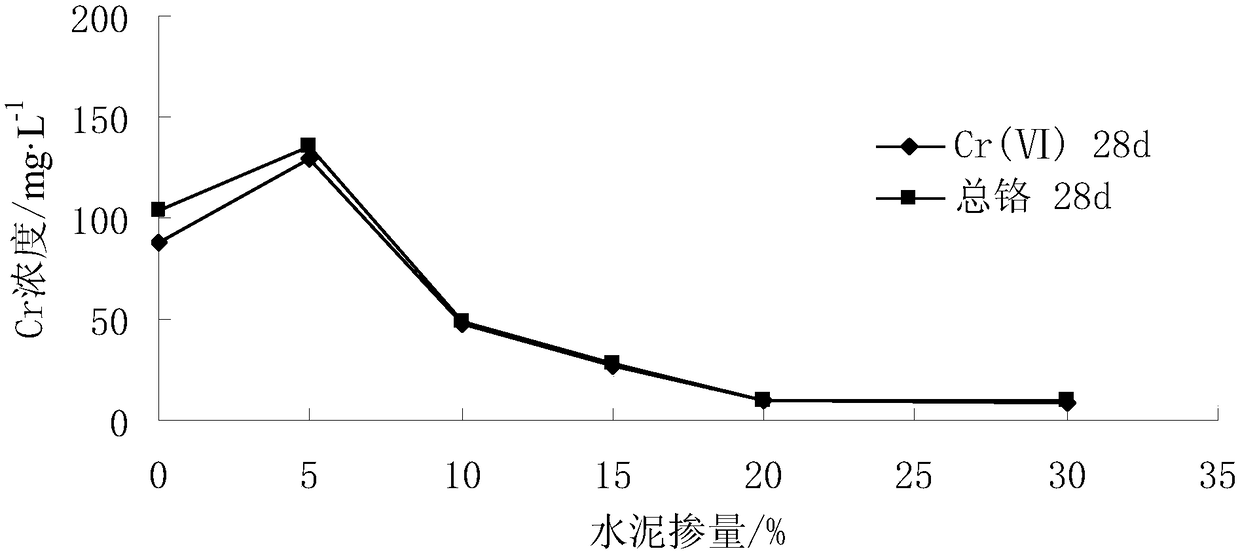

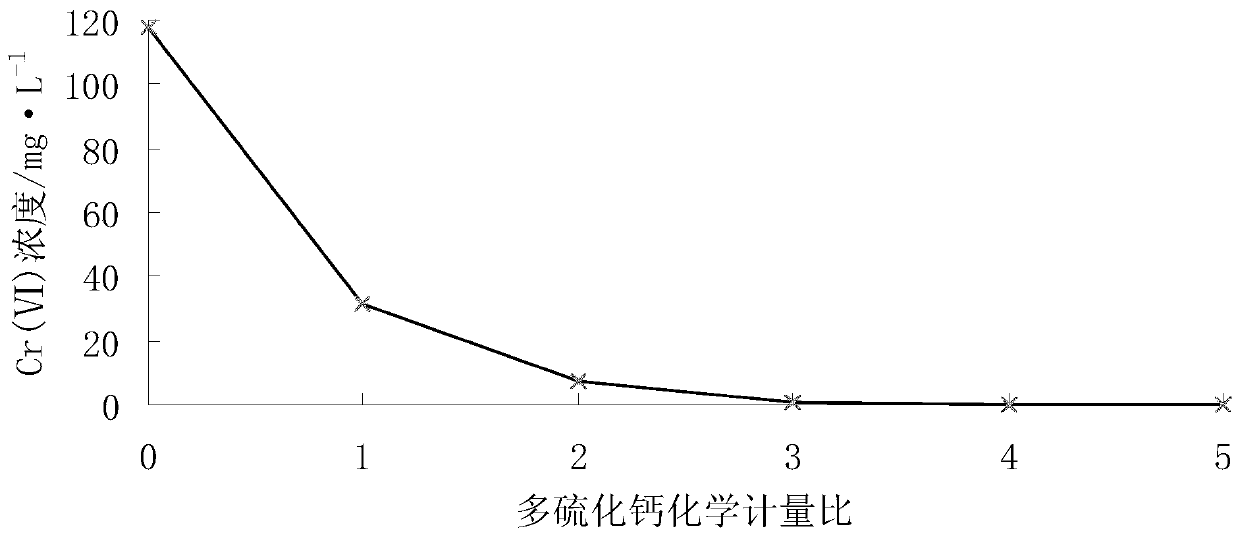

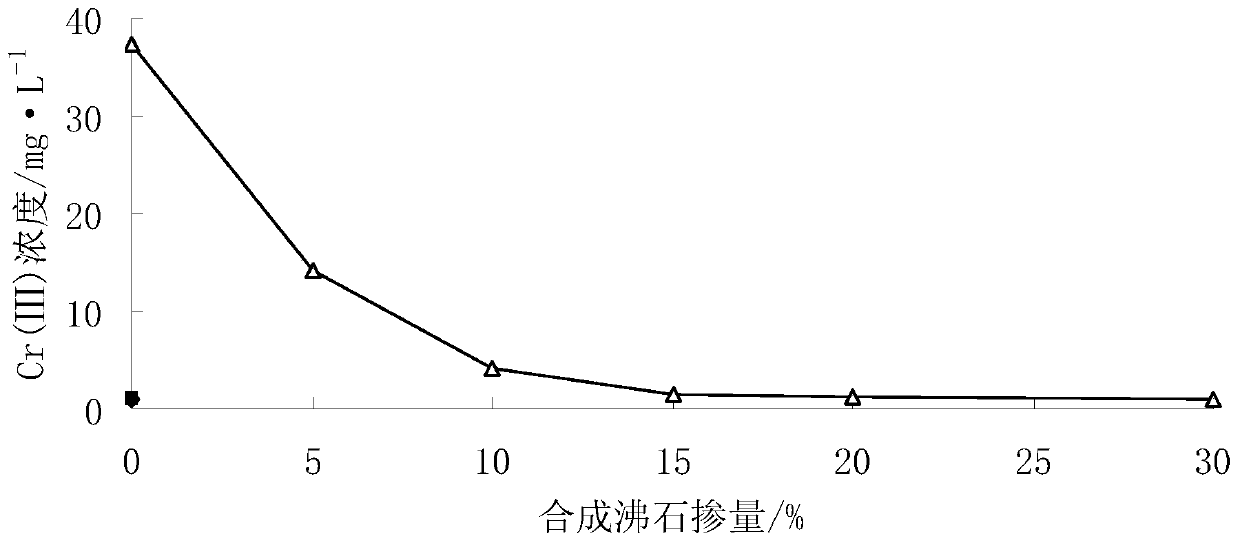

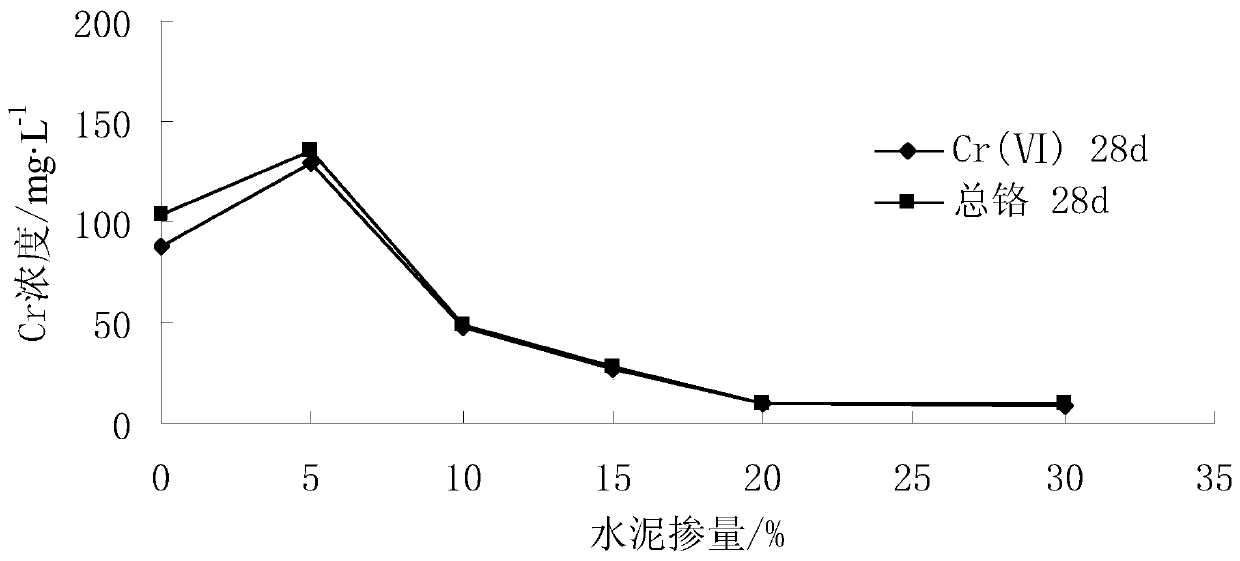

Chromium pollution soil combined remediation method

ActiveCN108160684ARaise the pHEnhance the ability to resist external environmental erosionOther chemical processesContaminated soil reclamationPollution soilMixed materials

A chromium pollution soil combined remediation method includes the steps that the concentration and the content of chromium and the optimum moisture content in chromium pollution soil are determined;a calcium polysulfide solution is selected, the chromium pollution soil and the calcium polysulfide solution are mixed and stirred according to a molar ratio of 2:1-3:1, and mixed material is added with water to maintain the optimum moisture content until the chromium of the chromium pollution soil is reduced from sexavalence to trivalence; coal ash is selected to compose zeolite, the amount of admixture is 10%-15%, the zeolite and the chromium pollution soil are mixed and stirred, mixed material is added with water to maintain the optimum moisture content until the steady absorption of the chromium of the chromium pollution soil is completed; and cement is selected, the amount of admixture is 5%-10% or 15%-20%, the cement is mixed and stirred with the chromium pollution soil, mixed material is added with water to maintain the optimum moisture content, and curing period is maintained for 7-28 days until the solidification of the chromium pollution soil is completed. The chromium pollution soil combined remediation method has the characteristics of good remediation effect, good long-term stability of the remediation effect, no secondary pollution, lower remediation cost and remediation mode reclamation.

Owner:LIAONING TECHNICAL UNIVERSITY

Red mud processing method

ActiveCN107487997AHigh strengthIncrease stiffnessSolid waste managementRed mudUltimate tensile strength

The invention discloses a red mud processing method. Red mud is mixed with a bacterial liquid containing Bacillus pasteurii to obtain a mixture 1. A consolidating solution is preferably added to the mixture 1, and the consolidating solution and the mixture 1 are mixed to obtain a mixture 2; and the mixture 2 is used in a civil engineering material, and the consolidating solution is sprinkled on the surface of the obtained civil engineering material after construction in order to complete the removal of the red mud from the civil engineering material. The Bacillus pasteurii is creatively compounded and contacted with the red mud to surprisingly obviously improve the strength and the rigidity of the red mud; the processed red can surprisingly meet requirements of roadbeds, base layers and sub-base layers of highways and port stockyards when used as a filling material; and heavy metals and other harmful components in the red mud also can be expectedly immobilized through the method. The method can realize the multi-channel and large-scale recycling of the red mud, and realize the purpose of changing red mud into valuables.

Owner:山东海逸生态环境保护有限公司

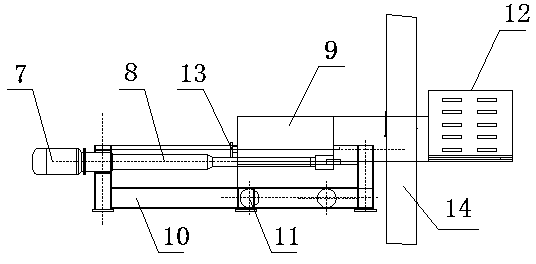

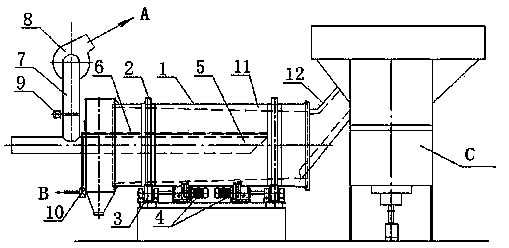

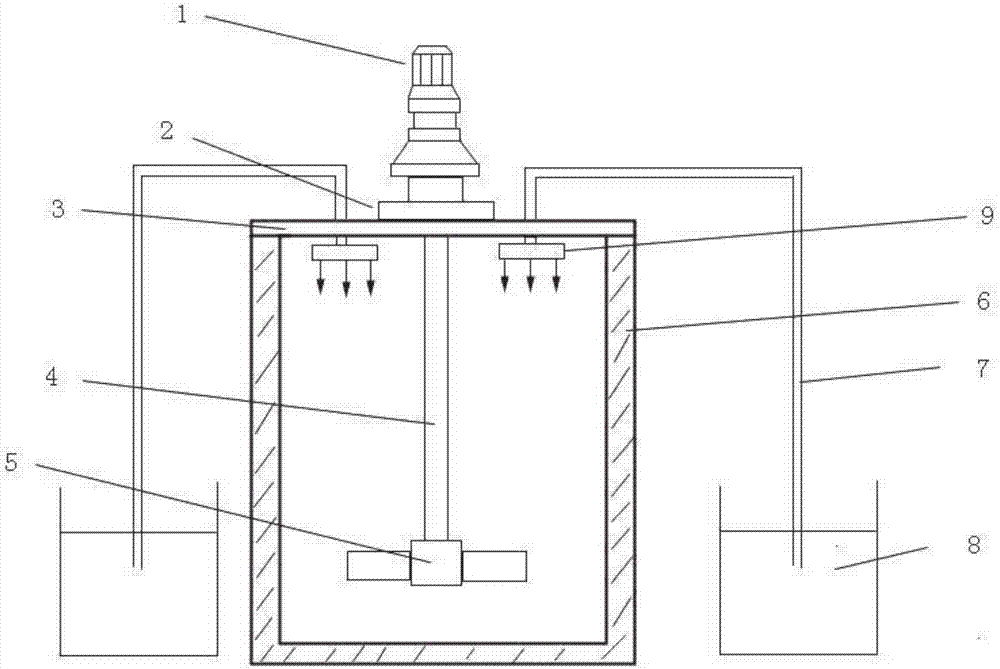

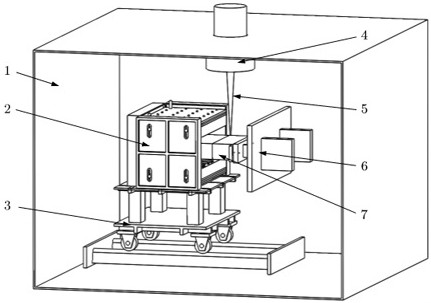

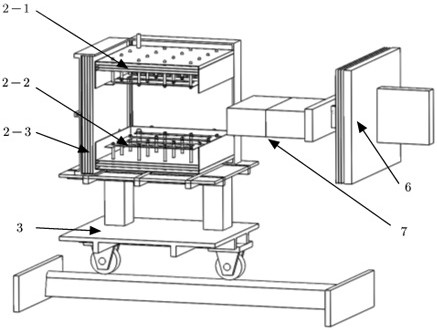

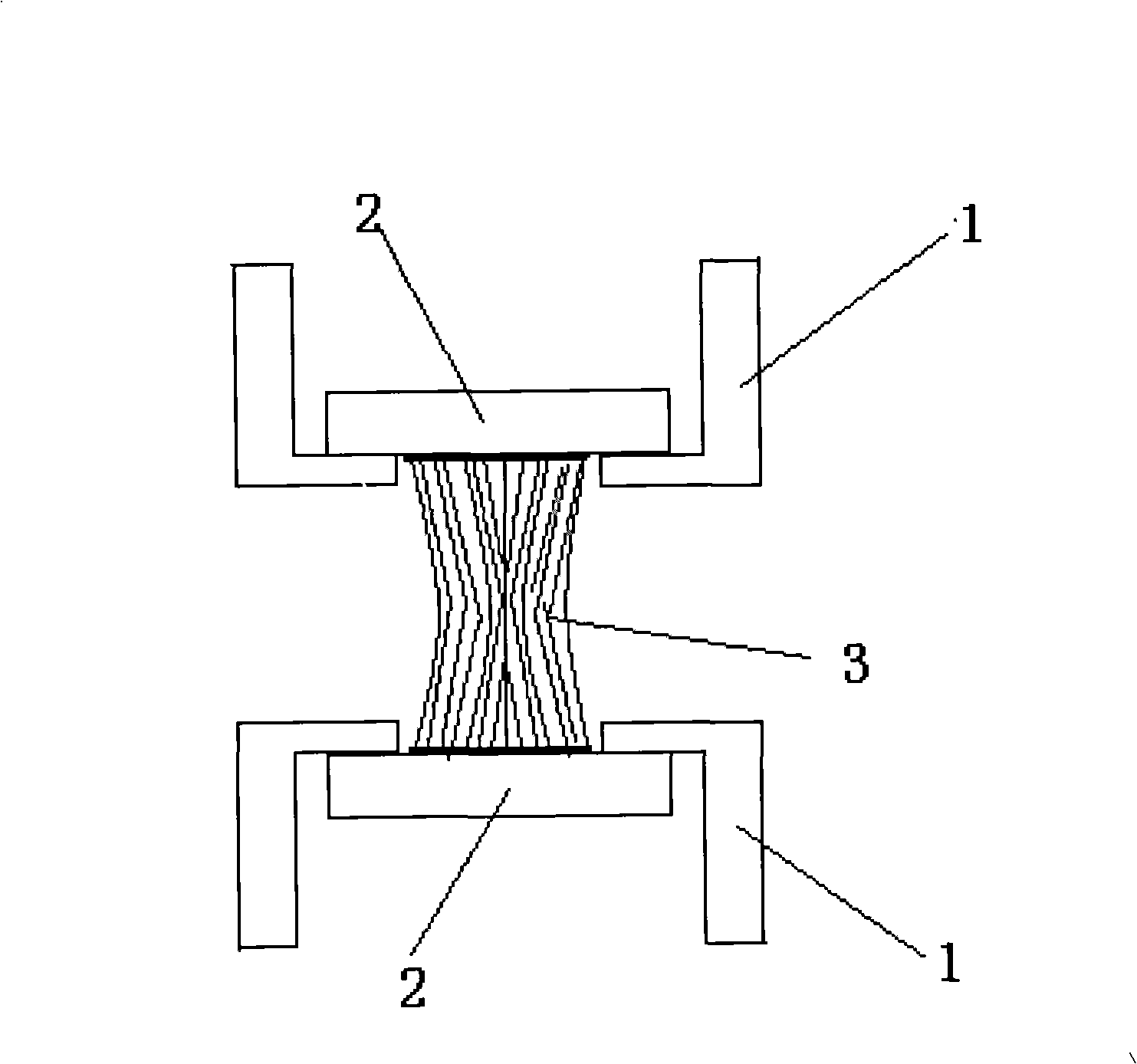

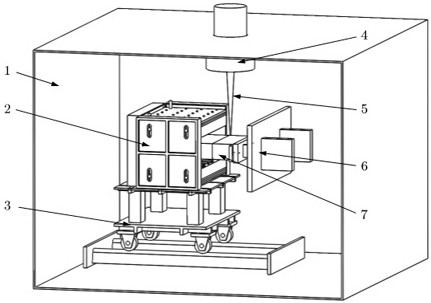

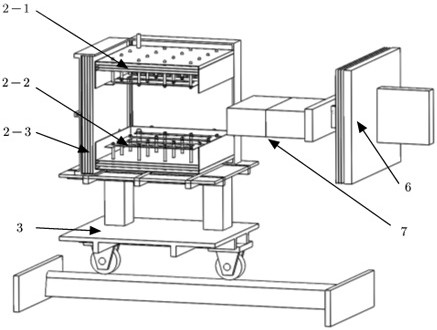

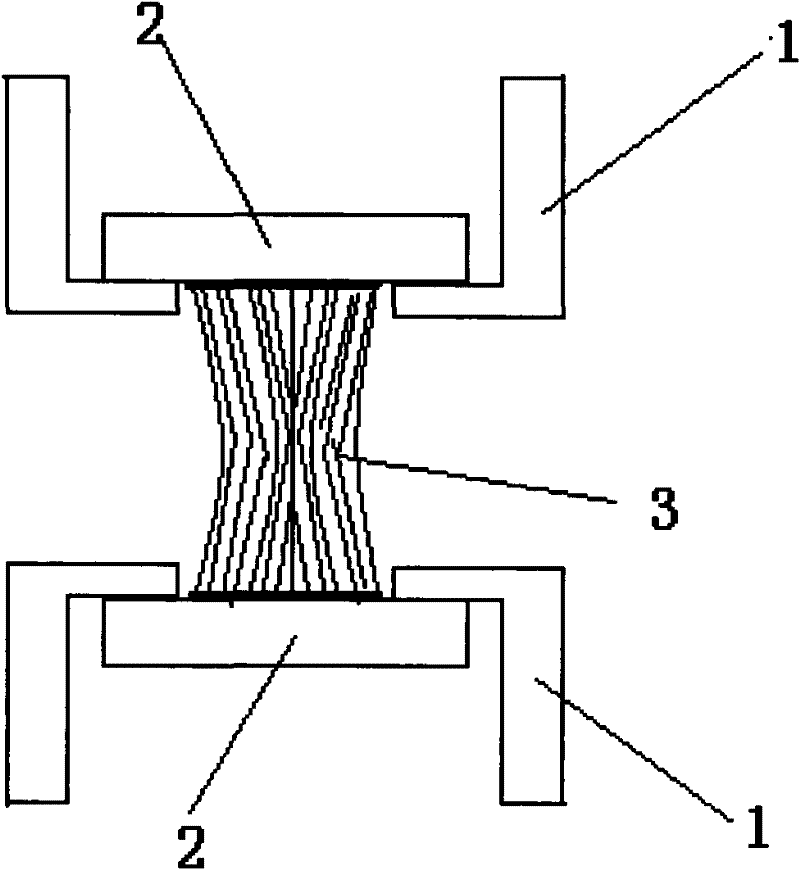

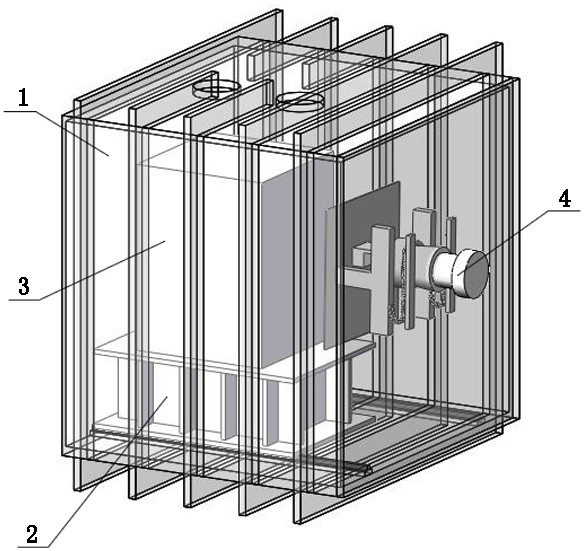

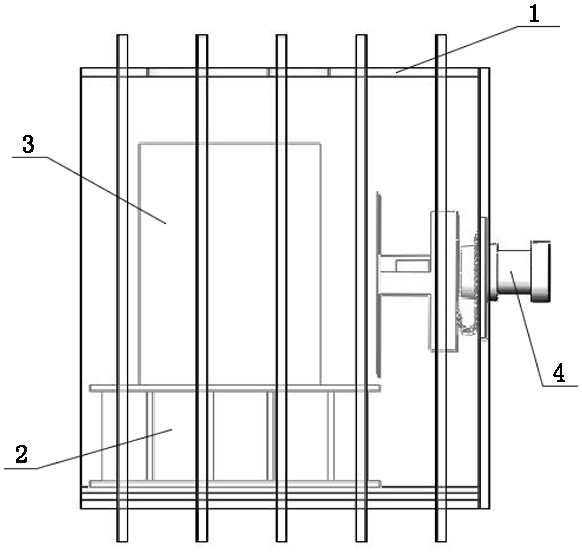

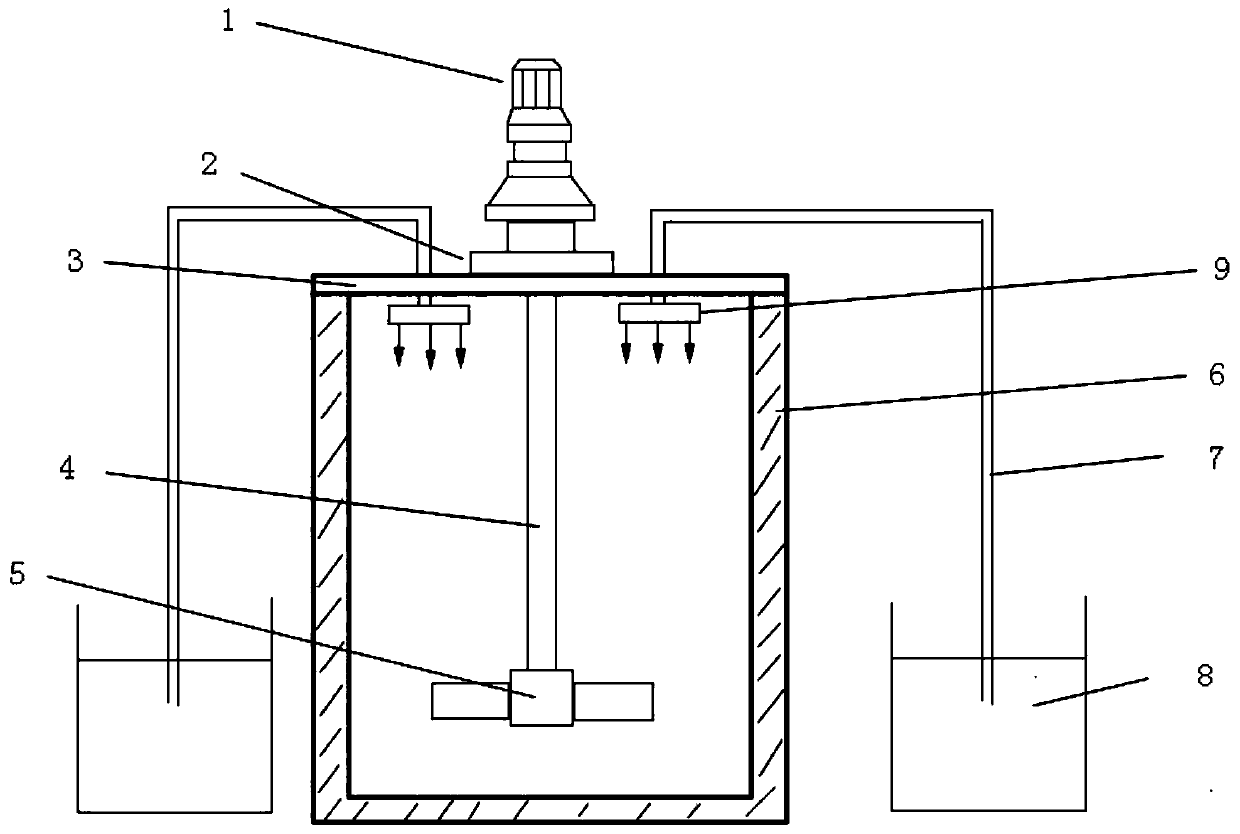

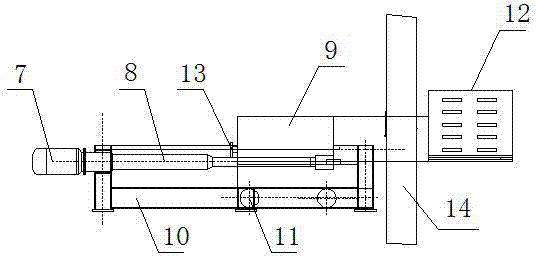

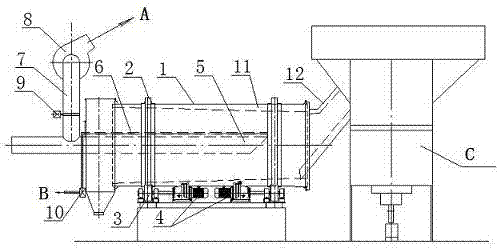

Large-thickness workpiece vacuum preheating and electron beam welding device

ActiveCN111761193AAvoid it happening againSolve the problems of large weld crack tendency and poor weld plasticity and toughnessElectron beam welding apparatusHeat-affected zoneWeld seam

The invention relates to a large-thickness workpiece vacuum preheating and electron beam welding device which comprises a vacuum chamber, a heating device, a moving platform, an electronic gun, a clamping tool and a to-be-welded workpiece. The to-be-welded workpiece is composed of two large-thickness workpieces. The heating device comprises an upper heating assembly, a lower heating assembly and three side wall heat insulation protection assemblies. In the vacuum environment, workpiece high-temperature preheating is achieved, the cooling speed is effectively reduced, generation of quenched structures in welding seams and heat affected zones is avoided, and the problems that the welding seam crack tendency of high-strength steel and high-strength titanium alloys and other products is large,and ductility and toughness of welding seams are poor are solved through a high-temperature preheating and electron beam welding method.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

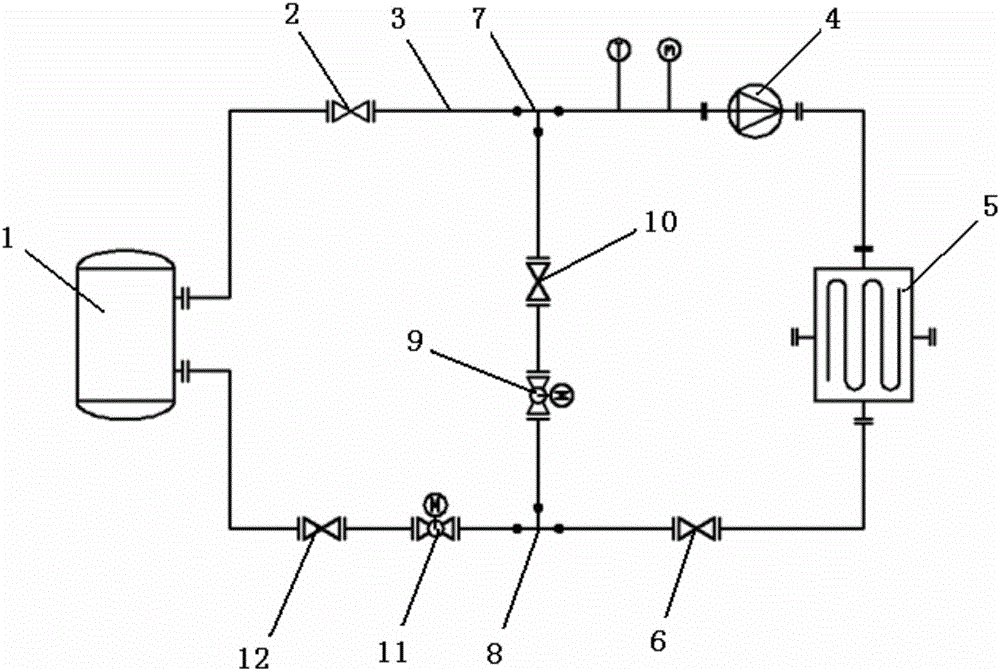

Liquid mixing and temperature adjusting method of cooling process of heat transformation

ActiveCN106524822AMeet the requirements of engineering useAchieve regulationHeat exchange apparatusTemperature differenceEngineering

The invention provides a liquid mixing and temperature adjusting method of a cooling process of heat transformation. According to the implementation mode of the method, a liquid return branch (7) is additionally arranged on an original circulation loop, so that part of liquid flows back to an inlet of a circulating pump (4) again after passing through a heat exchanger (5), the flow of returned cold liquid is adjusted through the opening degree of a flow regulating valve I (9) and a flow regulating valve II (11), thus different inlet temperatures of the different heat exchanger (5) are obtained, different outlet temperatures and temperature differences of the inlet temperatures and the outlet temperatures are obtained, adjustment of the heat exchange amount of the cold liquid is achieved finally, and requirements for engineering use are met.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP +1

Application of coal ash synthetic channel jointing material on damping interface or in water construction

InactiveCN101349045ASolve sticking problemsMeet the requirements of engineering useOther chemical processesMarine site engineeringCoalSystem construction

The invention discloses an application of a known impervious canal joint material synthesized by fly ash in the construction at a moist interface or in water. The proposer carries out an experiment to the material at the moisture interface or in the water; experiments show that the bonding strength of the construction of the canal joint material synthesized by the fly ash at the moisture interface or in the water achieves more than 80 percent of that at a dry interface, so the impervious canal joint material synthesized by the fly ash can fully solve problems of moist and water-contained bonding which are encountered during the actual engineering, and satisfy the operating requirement of the engineering.

Owner:NORTHWEST A & F UNIV

Automobile gear shaft and forging method thereof

The invention discloses an automobile gear shaft and a forging method thereof. The gear shaft comprises, by weight, 0.16-0.2% of carbon, 0.15-0.3% of silicon, 0.75-0.90% of manganese, 0-0.015% of phosphorus, 0-0.025% of sulfur, 0.5-1.1% of chromium, 0.01-0.03% of aluminum, 0-0.025% of copper, 0.12-0.28% of nickel, 2.98-3.58% of molybdenum and the balance iron. A raw material blank is subjected tocirculating heating and cooling many times, then subjected to surface treatment, cooled to 1100-1300 DEG C and kept warm; then, upsetting and drawing are carried out to reach the specification required by forge pieces, and the forging temperature is 850-1300 DEG C; the blank is drawn into an octagonal shape and distributed, small head drawing, rolling and finishing are carried out, and then the blank is subjected to thermal treatment and carburizing treatment. The hardness, fatigue resistance and overload resistance of the gear shaft are improved while the application stability of the gear shaft is ensured.

Owner:浙江恒利五金科技有限公司

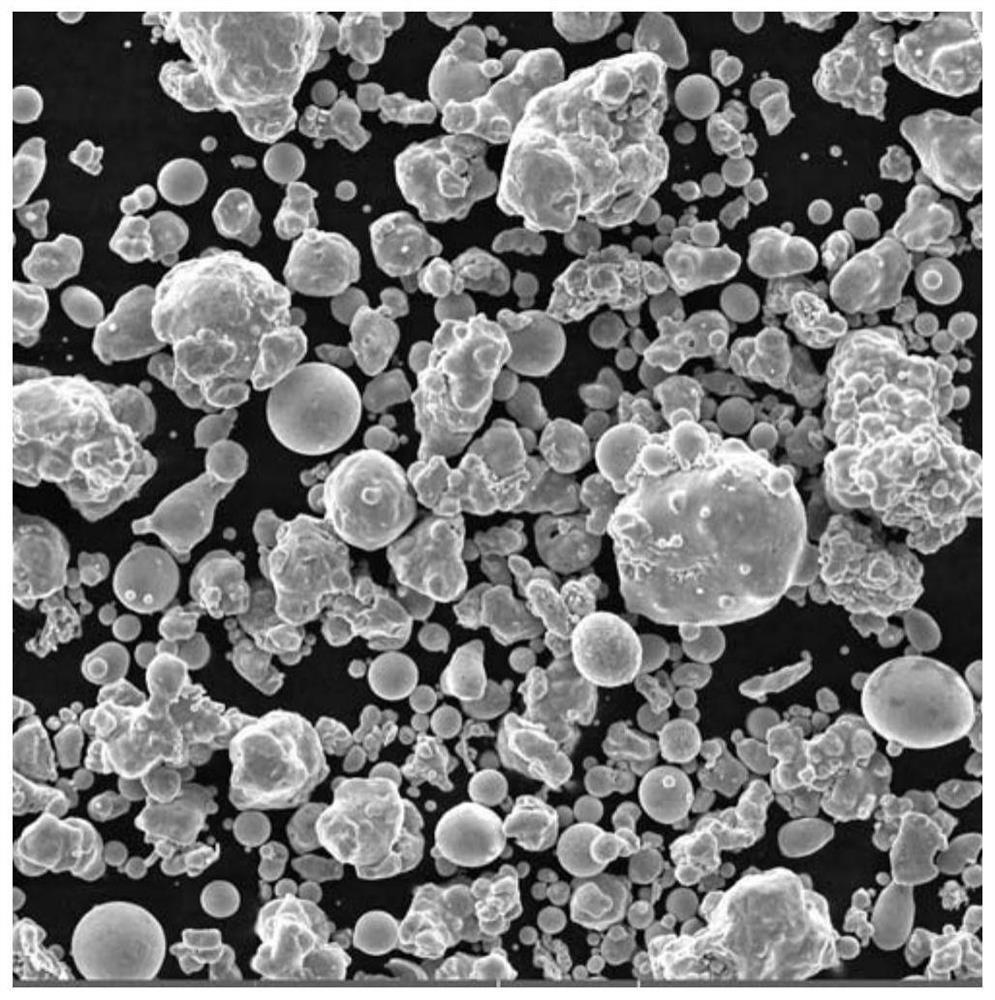

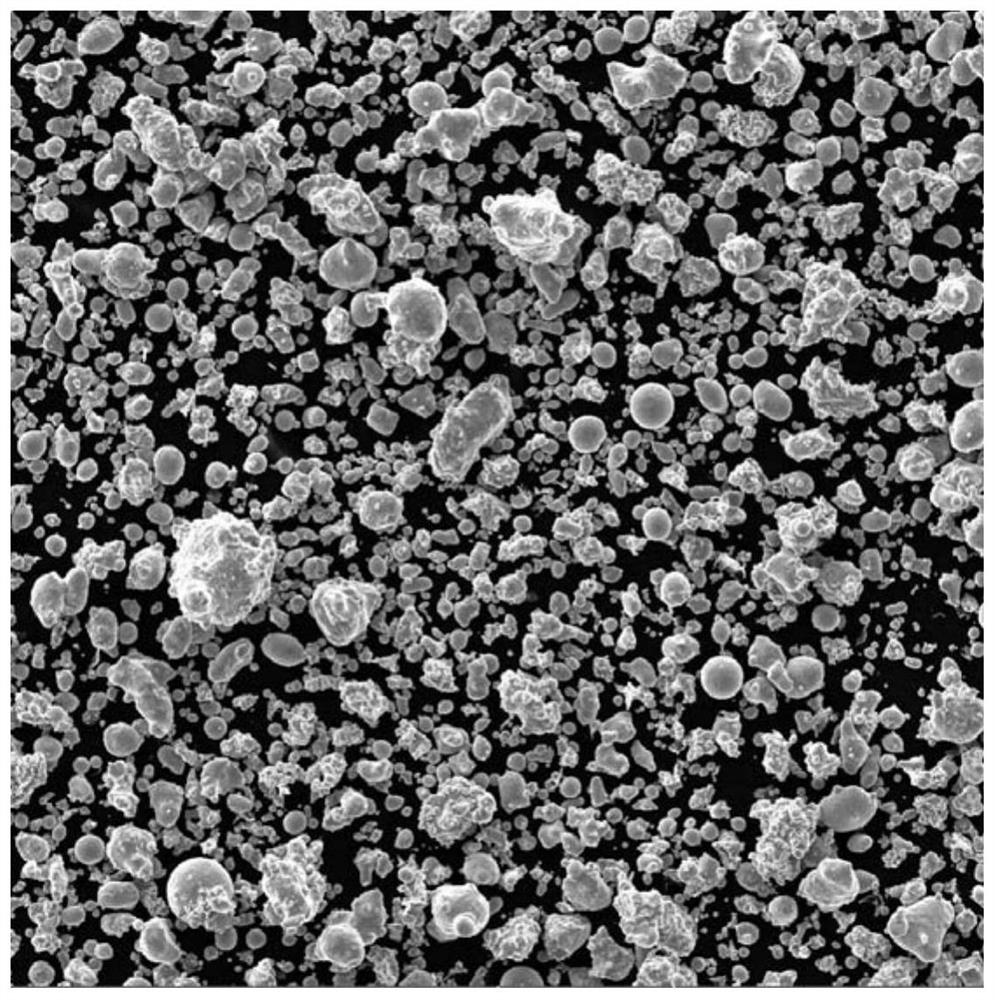

FeCuNiSn series alloy powder for diamond product and preparation method thereof

The invention discloses FeCuNiSn series alloy powder for a diamond product and a preparation method thereof, and belongs to the technical field of metal material powder metallurgy. The FeCuNiSn seriesalloy powder is prepared from the following components: Fe-Cu-Ni-Sn pre-alloy powder and Cr3C2 or / and Mo2C superfine additive powder. The preparation method comprises the following steps: preparing Fe-Cu-Ni-Sn four-component pre-alloy powder by adopting a high-temperature liquid smelting and high-pressure water atomization method, or uniformly mixing the Fe-Cu-Ni-Sn four-component pre-alloy powder and ultrafine additive powder to obtain FeCuNiSn series alloy powder. According to the invention, the wear resistance of a powder sintered body can be weakened, the sintering temperature is reduced,the density, the bending strength and the diamond holding force of a sintered matrix are improved, and the sharpness of a tool is improved; cr3C2 or / and Mo2C is / are added, so that the sharpness of the diamond product is obviously improved, and the development requirements of dry cutting / dry grinding and efficient machining of the diamond product are met.

Owner:HENAN HOLD DIAMOND TECH

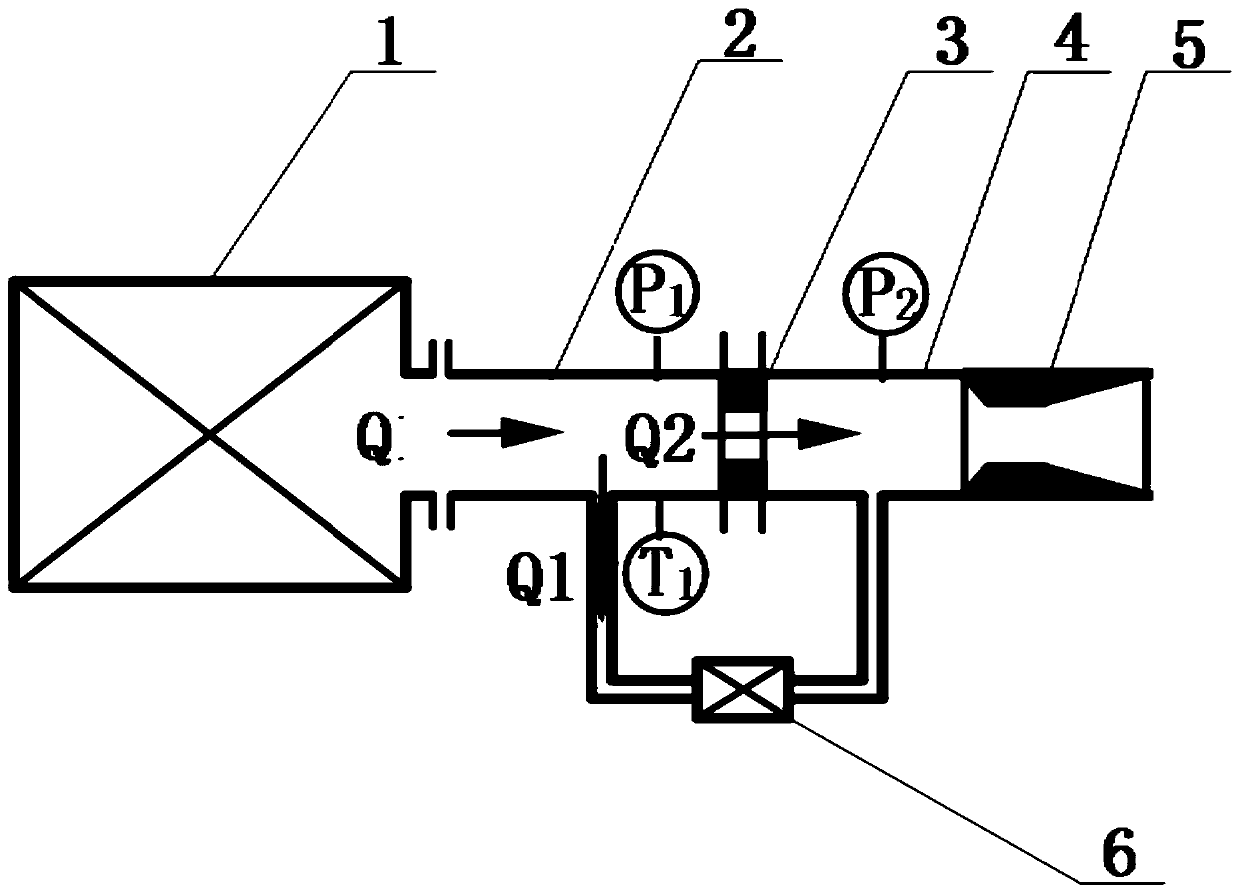

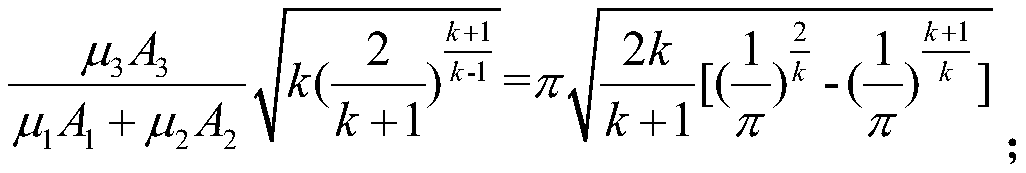

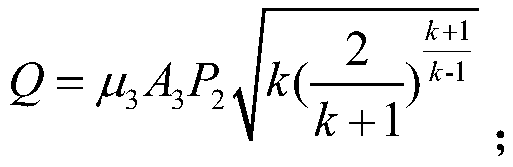

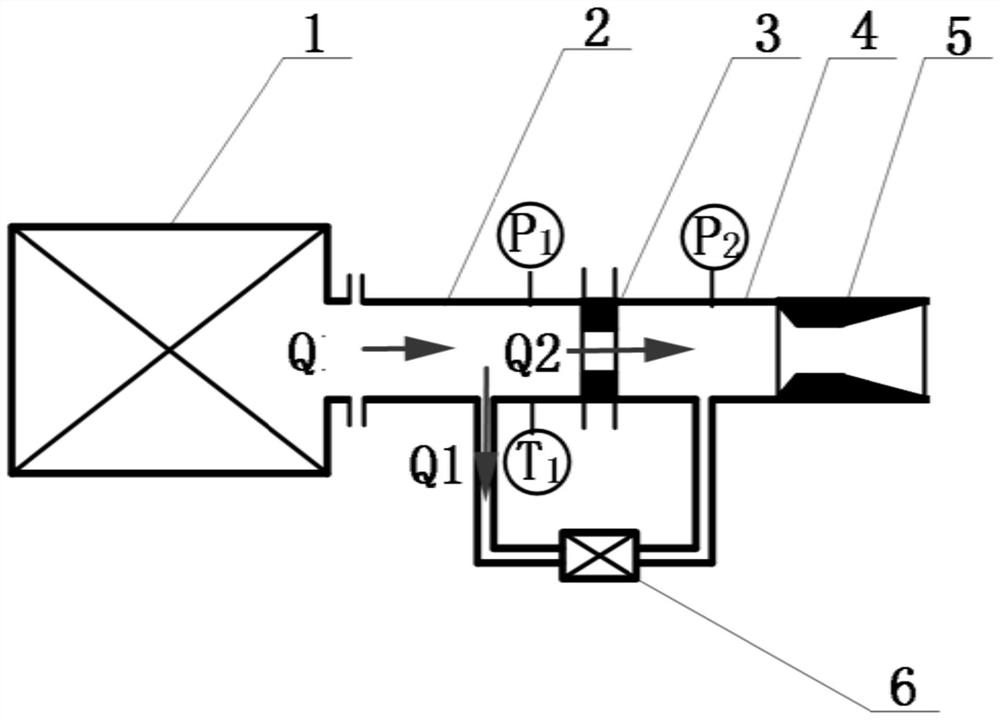

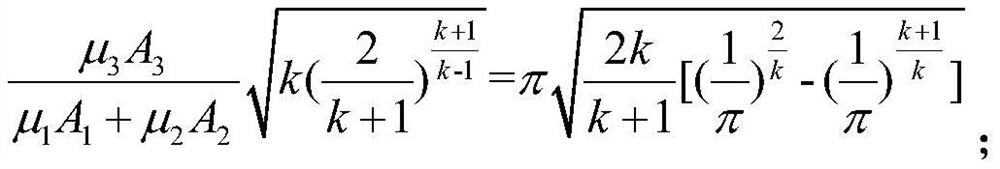

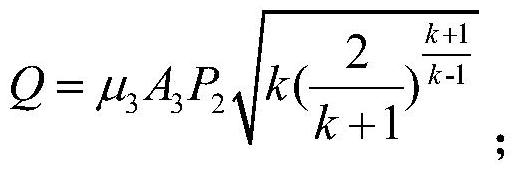

Continuous flow calibration system and method of high-temperature gas regulator

ActiveCN111076923ASimplified Flow Coefficient Calibration ProcedureSimple test methodMachine valve testingThermodynamicsContinuous flow

The invention discloses a continuous flow calibration system and method for a high-temperature gas regulator. The system is characterized in that a gas outlet of a gas generator is provided with a main pipeline, and the main pipeline is sequentially provided with a throttling ring and an outlet throat pipe in the gas flowing direction; an inlet of a branch pipeline is connected to the main pipeline between the gas generator and the throttling ring, and an outlet of the branch pipeline is connected to the main pipeline between the throttling ring and the outlet throat pipe; a to-be-calibrated gas regulator is mounted on the branch pipeline; e two pressure sensors are arranged on the inlet side and the outlet side of the throttling ring respectively. A temperature sensor is arranged on the inlet side of the throttling ring. The characteristic that the inlet and outlet pressure ratio of the gas regulator under the real working condition of the engine is equivalent to the inlet and outletpressure ratio of the gas regulator in a ground test system is utilized, the step of calibrating the flow coefficient of the gas generator is simplified, so that the ignition frequency and the numberof matched products required in the calibration process of the gas regulator are effectively reduced, and the cost is low.

Owner:XIAN AEROSPACE PROPULSION INST

A vacuum preheating electron beam welding device for large thickness workpieces

ActiveCN111761193BGuarantee welding qualityMeet the comprehensive mechanical propertiesElectron beam welding apparatusHeat-affected zoneTitanium alloy

The invention relates to a vacuum preheating electron beam welding device for large-thickness workpieces, comprising a vacuum chamber, a heating device, a mobile platform, an electron gun, a clamping tool and a workpiece to be welded. Two upper and lower heating components and three side wall heat insulation protection components are used to achieve high temperature preheating of workpieces in a vacuum environment, effectively reducing the cooling rate, avoiding the generation of hardened structures in welds and heat affected zones, using high temperature preheating and electron beams The welding method solves the problems of high-strength steel, high-strength titanium alloy and other products with a large tendency to crack in the weld and poor plastic toughness of the weld.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Application of coal ash synthetic channel jointing material on damping interface or in water construction

InactiveCN101349045BSolve sticking problemsMeet the requirements of engineering useOther chemical processesMarine site engineeringUltimate tensile strengthSystem construction

The invention discloses an application of a known impervious canal joint material synthesized by fly ash in the construction at a moist interface or in water. The proposer carries out an experiment tothe material at the moisture interface or in the water; experiments show that the bonding strength of the construction of the canal joint material synthesized by the fly ash at the moisture interfaceor in the water achieves more than 80 percent of that at a dry interface, so the impervious canal joint material synthesized by the fly ash can fully solve problems of moist and water-contained bonding which are encountered during the actual engineering, and satisfy the operating requirement of the engineering.

Owner:NORTHWEST A & F UNIV

A joint restoration method for chromium-contaminated soil

ActiveCN108160684BImprove repair effectImprove long-term stabilityOther chemical processesContaminated soil reclamationEngineeringCoal

A chromium pollution soil combined remediation method includes the steps that the concentration and the content of chromium and the optimum moisture content in chromium pollution soil are determined;a calcium polysulfide solution is selected, the chromium pollution soil and the calcium polysulfide solution are mixed and stirred according to a molar ratio of 2:1-3:1, and mixed material is added with water to maintain the optimum moisture content until the chromium of the chromium pollution soil is reduced from sexavalence to trivalence; coal ash is selected to compose zeolite, the amount of admixture is 10%-15%, the zeolite and the chromium pollution soil are mixed and stirred, mixed material is added with water to maintain the optimum moisture content until the steady absorption of the chromium of the chromium pollution soil is completed; and cement is selected, the amount of admixture is 5%-10% or 15%-20%, the cement is mixed and stirred with the chromium pollution soil, mixed material is added with water to maintain the optimum moisture content, and curing period is maintained for 7-28 days until the solidification of the chromium pollution soil is completed. The chromium pollution soil combined remediation method has the characteristics of good remediation effect, good long-term stability of the remediation effect, no secondary pollution, lower remediation cost and remediation mode reclamation.

Owner:LIAONING TECHNICAL UNIVERSITY

Application of coal ash synthetic channel jointing material on damping interface or in water construction

InactiveCN101684643BSolve sticking problemsMeet the requirements of engineering useOther chemical processesMarine site engineeringEngineeringSystem construction

The invention discloses application of a known coal ash synthetic channel jointing anti-seepage material on a damping interface or in water construction. The applicant carries out an experiment on the material on the damping interface or in water; and the experiment proves that the bonding strength of the coal ash synthetic channel jointing material on the damping interface or in water construction reaches more than 80 percent of that on a dry interface, which can fully solve the problems of dampness, water entrainment and adhesion encountered in practical engineering and meet the requirementof the engineering use.

Owner:NORTHWEST A & F UNIV

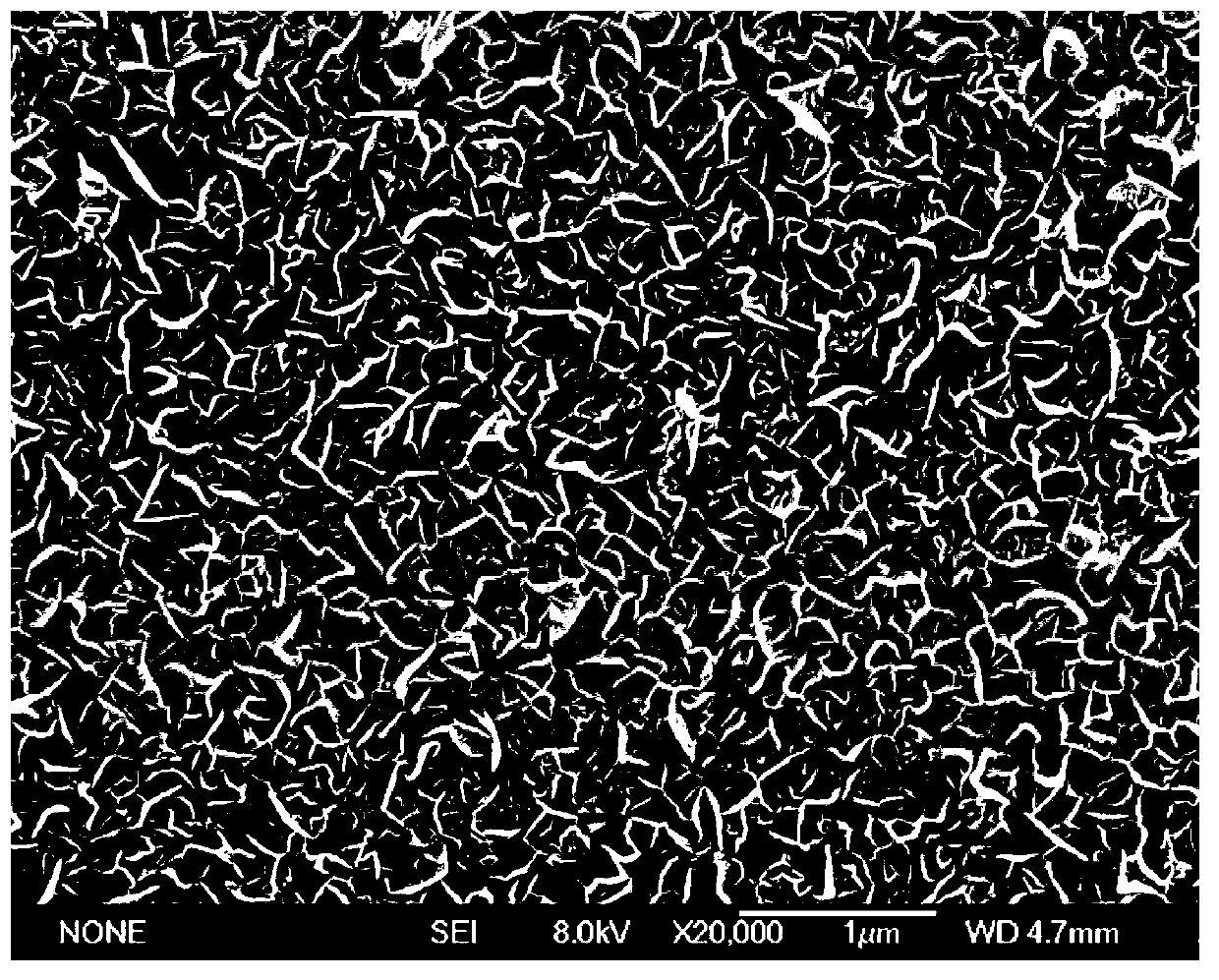

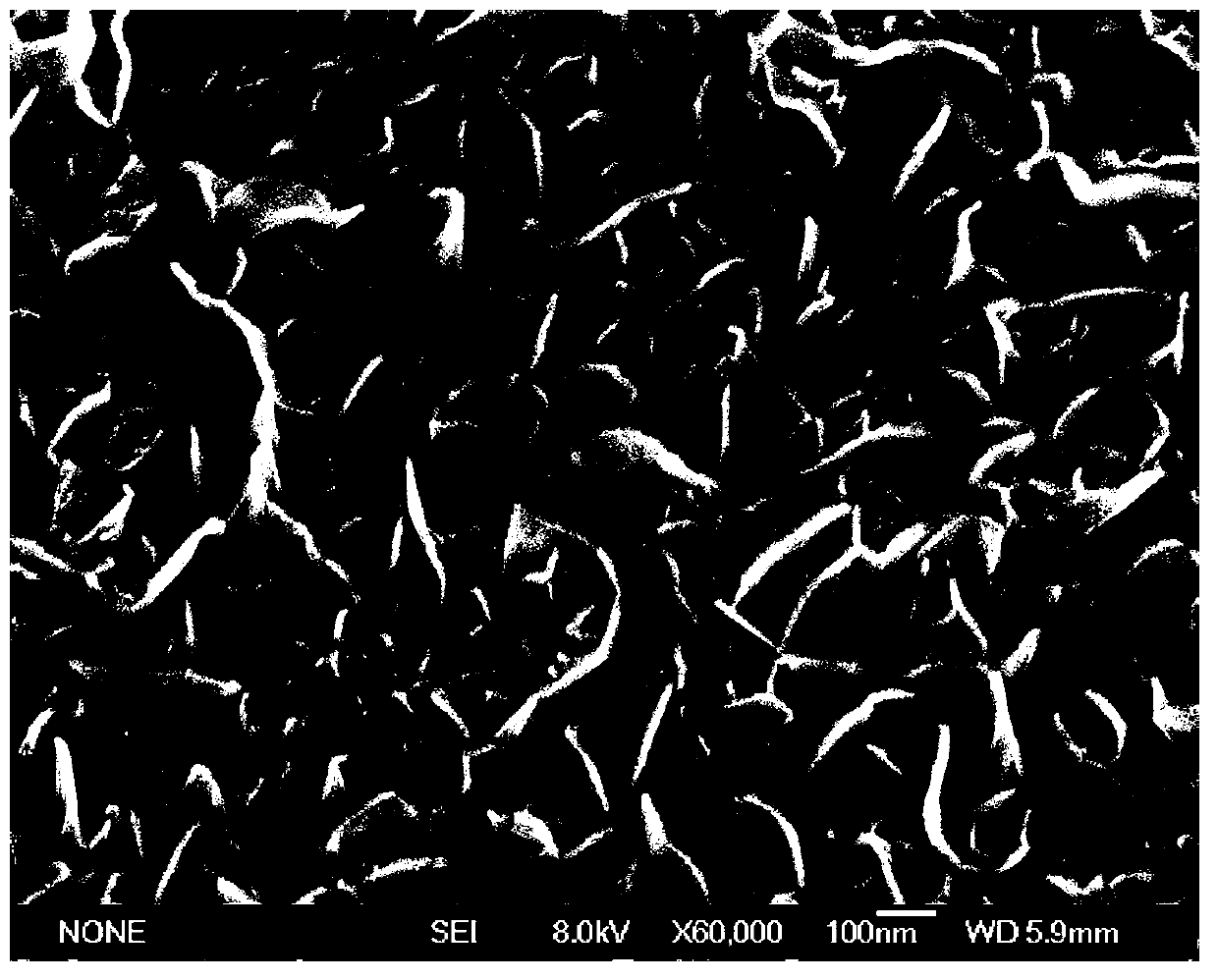

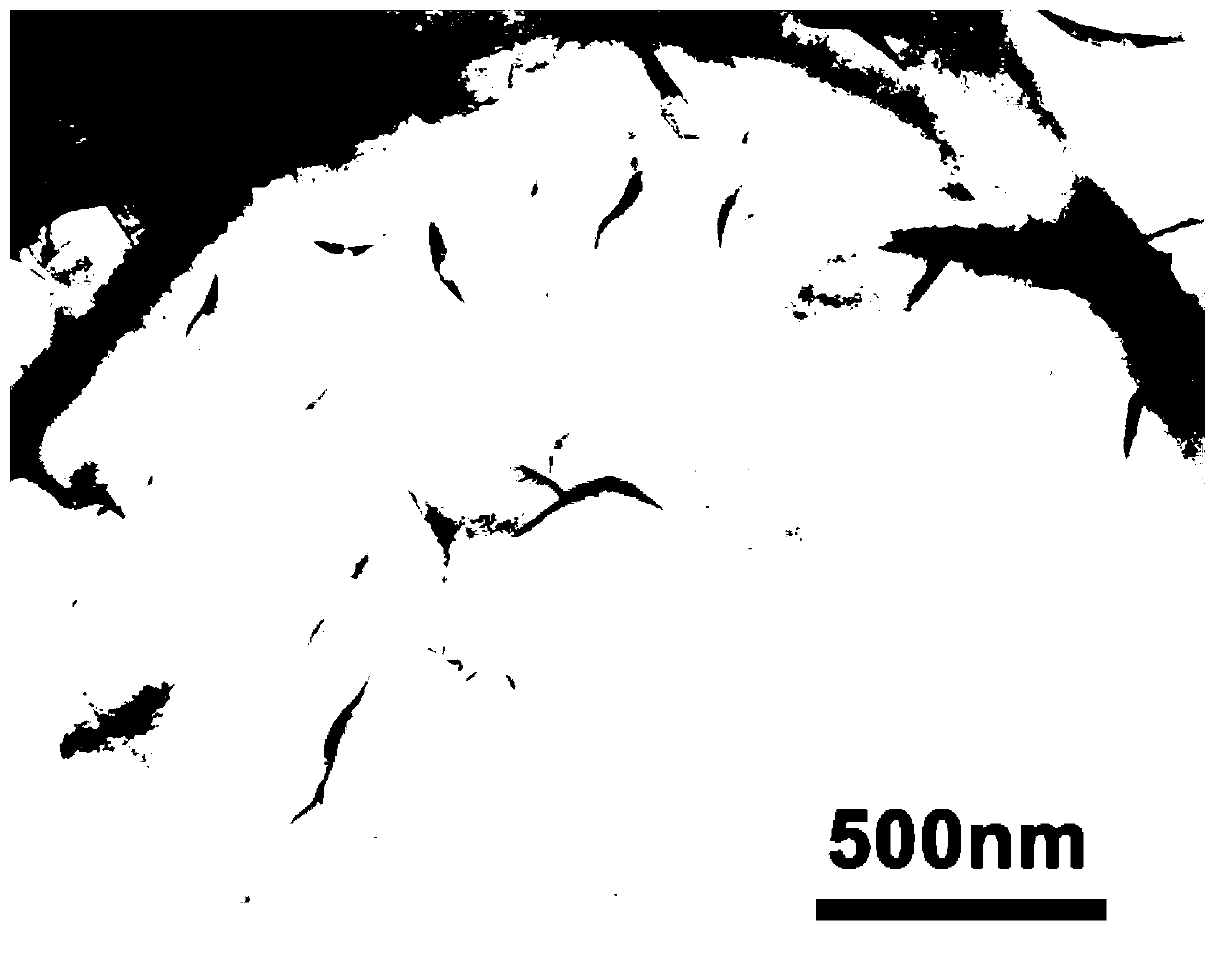

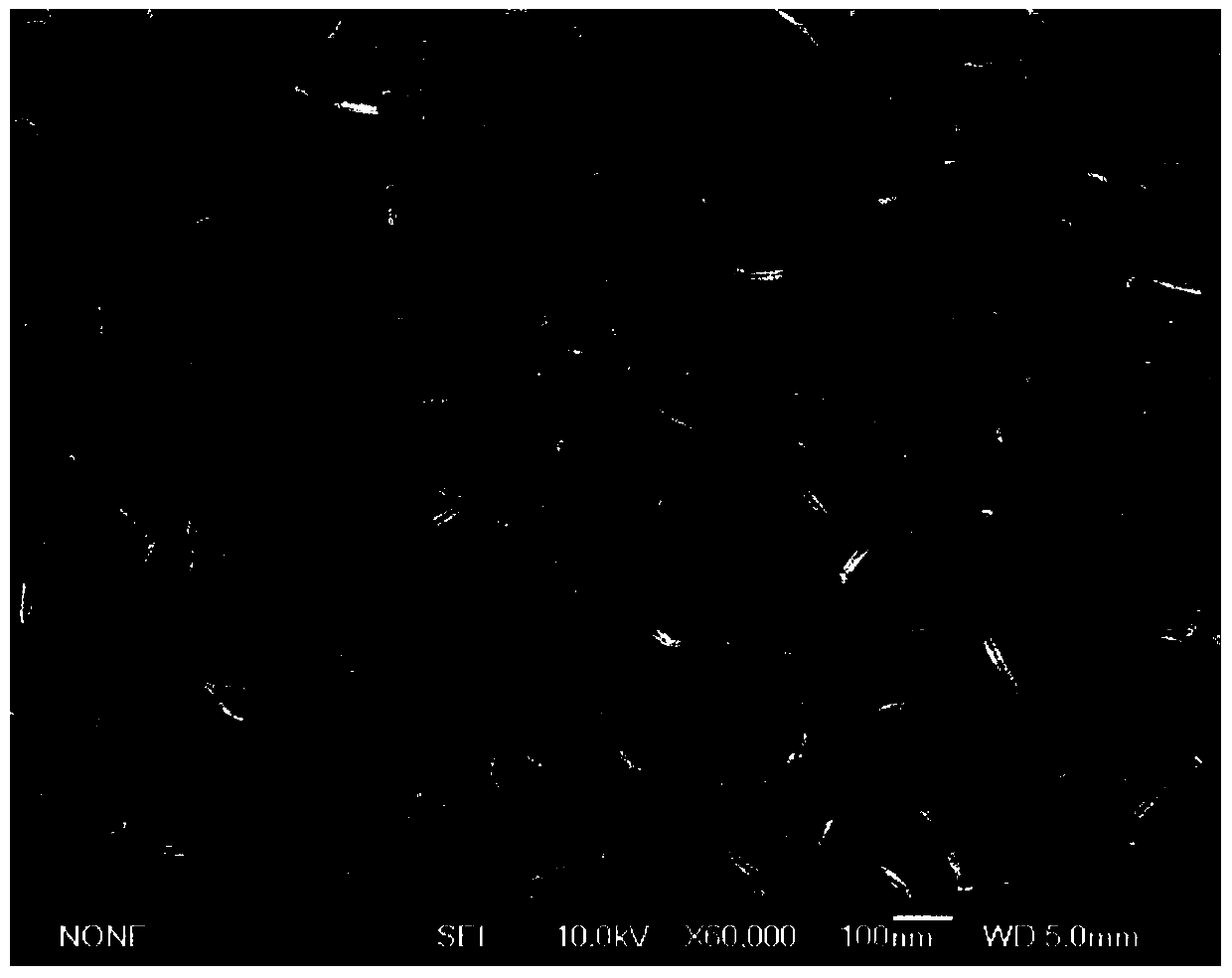

A preparation method of in-situ vertically grown graphene anti-corrosion layer on the surface of zirconium alloy

ActiveCN105220128BImprove water side corrosion resistanceImprove thermal conductivityChemical vapor deposition coatingGraphene coatingVertical growth

The invention discloses a method for preparing an in-situ vertically grown graphene anti-corrosion layer on the surface of a zirconium alloy, and the invention relates to a method for preparing an anti-corrosion layer on the surface of a zirconium alloy. The invention aims to solve the problems of poor water side corrosion resistance and short service life of the fuel cladding in the existing zirconium alloy cladding. Methods: 1. Pretreatment of zirconium alloy surface; 2. In situ growth of vertical graphene on the surface of zirconium alloy by PECVD method. The invention is used for the preparation of the in-situ vertically grown graphene anticorrosion layer on the surface of the zirconium alloy.

Owner:HARBIN INST OF TECH

A high-strength and high-toughness gas-shielded flux-cored welding wire for bridge steel

ActiveCN106334884BHigh tensile strengthHigh elongationArc welding apparatusWelding/cutting media/materialsAdditive ingredientManganese

The invention provides a high-strength and high-toughness gas shielded flux-core wire used for bridge steel. The high-strength and high-toughness gas shielded flux-core wire comprises a skin and a flux core wrapped by the skin. The flux core comprises, by weight, 30%-50% of rutile, 2%-8% of feldspar, 1%-6% of quartz, 0.5%-5% of zircon, 0.5%-5% of sodium fluoride, 0.1%-1.5% of lithium fluoride, 1%-8% of potassium-sodium arc stabilizers, 10%-25% of silicon-manganese alloys, 1%-8% of manganese metal, 1%-6% of magnesium powder, 5%-15% of nickel powder, 0.1%-1.5% of ferrotitanium, 0.05%-0.6% of ferroboron, and the balance iron powder, and the weight percents of the ingredients add up to 100%. According to the high-strength and high-toughness gas shielded flux-core wire used for the bridge steel, all the gradients and properties of the wire can meet the engineering using requirements of high-strength steel plates, and the wire is especially suitable for welding of Q500qE.

Owner:TIANJIN YONGCHANG WELDING WIRES +1

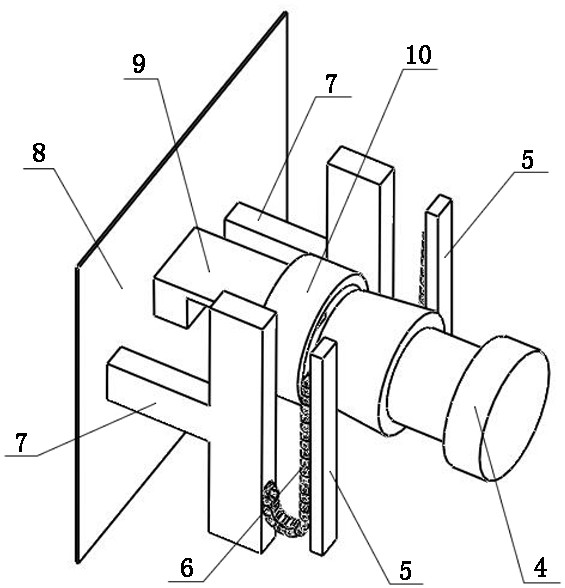

Electron gun protection device for vacuum preheating electron beam welding device

An electron gun protection device for a vacuum preheating electron beam welding device comprises an electric control sliding rail arranged on the inner wall of a vacuum chamber, the electric control sliding rail can drive a supporting block to move in the vertical direction through a drag chain, the end, away from the electric control sliding rail, of the supporting block is connected with a heat screen, and a connecting block is arranged on the side, facing an electron gun, of the heat screen. The connecting block is connected with one end of the heat insulation cylinder, the axial direction of the heat insulation cylinder is parallel to the axial direction of the electronic gun, the heat insulation cylinder can be driven by the electric control sliding rail to the position aligned with the electronic gun in the axial direction, and the electric control sliding rail, the supporting block and the electronic gun are all located in the projection of the heat insulation screen in the axial direction of the electronic gun. Double heat insulation of the heat insulation screen and the heat insulation cylinder can effectively protect the electron gun, the heat insulation screen can conduct heat insulation protection on the electric control sliding rail, the electron gun protection device can be matched with the welding process to move, heat insulation protection needed by the electron gun can be continuously provided at any time, it is guaranteed that the vacuum preheating electron beam welding process is smoothly and efficiently conducted, and the welding efficiency is improved. The service life of the welding device is prolonged.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A flow continuous calibration system and method for a high-temperature gas regulator

ActiveCN111076923BSimplified Flow Coefficient Calibration ProcedureSimple test methodMachine valve testingControl engineeringControl theory

The invention discloses a system and method for continuously calibrating the flow rate of a high-temperature gas regulator. In the system, the gas outlet of the gas generator is installed with a main pipeline, and the main pipeline is sequentially provided with a throttling ring and an outlet throat pipe along the gas flow direction; The inlet of the branch pipeline is connected to the main road between the gas generator and the throttle ring, and the outlet of the branch pipeline is connected to the main road between the throttle ring and the outlet throat pipe; the gas regulator to be calibrated is installed on the branch pipe On the road; there are two pressure sensors, located on the inlet side and outlet side of the throttle ring respectively; the temperature sensor is located on the inlet side of the throttle ring. The invention utilizes the characteristic that the inlet and outlet pressure ratios of the gas regulator under the real working conditions of the engine are equivalent to the inlet and outlet pressure ratios of the gas regulator in the ground test system, simplifies the calibration steps of the flow coefficient of the gas generator, and effectively reduces the The number of ignition times and the number of supporting products required for the calibration process of the gas regulator are low in cost.

Owner:XIAN AEROSPACE PROPULSION INST

A kind of processing method of red mud

ActiveCN107487997BExcellent mechanical propertiesEfficient curingSolid waste managementEnvironmental engineeringSporosarcina pasteurii

The invention discloses a red mud processing method. Red mud is mixed with a bacterial liquid containing Bacillus pasteurii to obtain a mixture 1. A consolidating solution is preferably added to the mixture 1, and the consolidating solution and the mixture 1 are mixed to obtain a mixture 2; and the mixture 2 is used in a civil engineering material, and the consolidating solution is sprinkled on the surface of the obtained civil engineering material after construction in order to complete the removal of the red mud from the civil engineering material. The Bacillus pasteurii is creatively compounded and contacted with the red mud to surprisingly obviously improve the strength and the rigidity of the red mud; the processed red can surprisingly meet requirements of roadbeds, base layers and sub-base layers of highways and port stockyards when used as a filling material; and heavy metals and other harmful components in the red mud also can be expectedly immobilized through the method. The method can realize the multi-channel and large-scale recycling of the red mud, and realize the purpose of changing red mud into valuables.

Owner:山东海逸生态环境保护有限公司

Material-distribution type cooling process of white cement clinker

ActiveCN103641345BIncrease productionReduce energy consumptionClinker productionForced-airEngineering

Owner:江西银杉白水泥股份有限公司

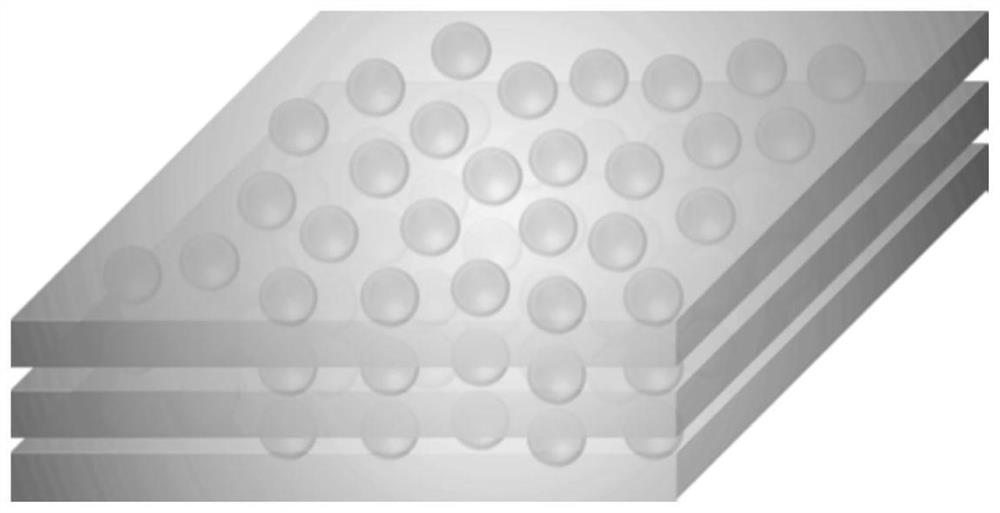

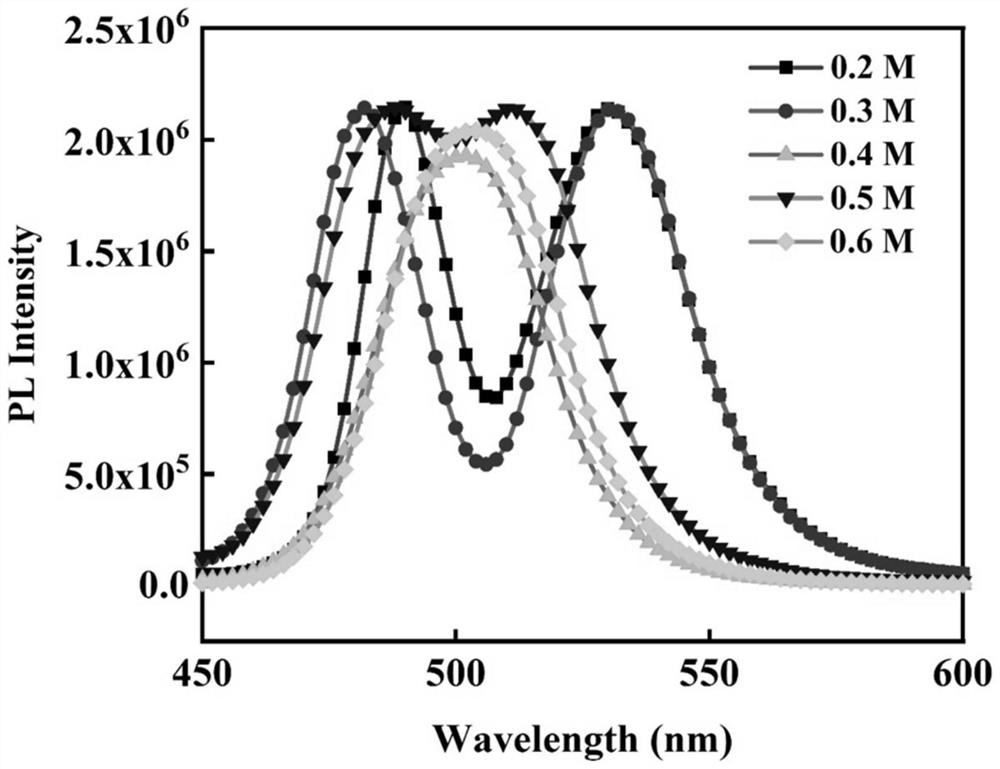

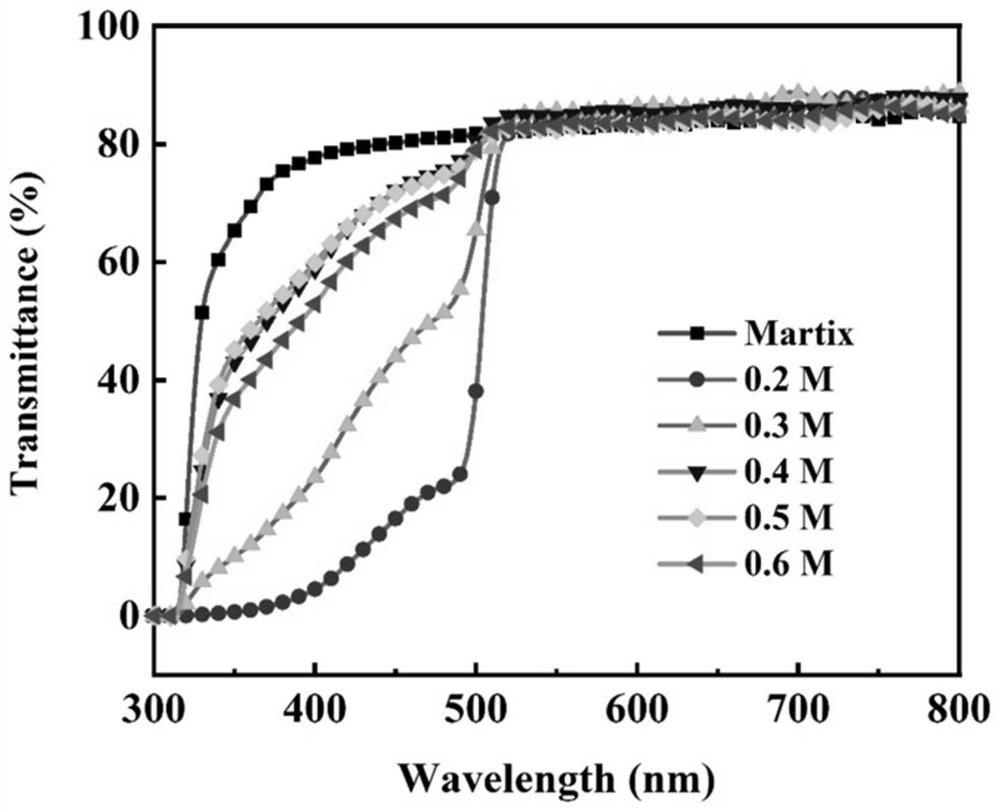

Preparation method of transparent perovskite/polymer scintillation screen applied to X-ray imaging

PendingCN113895137AHigh transparencyGood environmental stabilityX-ray/infra-red processesLamination ancillary operationsImage resolutionPolymer substrate

The invention discloses a preparation method of a transparent perovskite / polymer scintillation screen applied to X-ray imaging. The method comprises the following steps: immersing a transparent polymer substrate into a DMF solution of perovskite, and then putting into a reaction kettle; reacting the reaction kettle at 60-200 DEG C for 10-6000 minutes, soaking the transparent polymer substrates in isopropanol, drying, and finally stacking a plurality of transparent polymer substrates in a hot pressing or bonding manner to prepare the thick scintillation screen. According to the invention, the flexible large-area scintillation screen prepared by the invention has the advantages of high photon yield, high light transmittance, high imaging resolution and adjustable light emitting wavelength; and the developed dip dyeing process is high in repeatability and reliability, is suitable for preparing a large-area uniform perovskite scintillation screen, and is expected to be applied to curved surface X-ray imaging to reduce edge imaging distortion.

Owner:XI AN JIAOTONG UNIV

Microalloyed iron-based composite powder for diamond products and preparation method thereof

ActiveCN111036894BImprove sharpnessImprove mechanical propertiesTransportation and packagingMetal-working apparatusMetallic materialsAlloy

Owner:HENAN HOLD DIAMOND TECH

A Method of Obtaining Mechanical Properties of Metal Materials Based on Load-Depth Curve

ActiveCN102455263BRealize online detectionMeet the requirements of engineering useMaterial strength using tensile/compressive forcesInvestigating material hardnessTest materialTitanium alloy

The invention discloses a method for obtaining the mechanical property of a metal material based on a load-depth curve and belongs to the technical field of material property test. On the basis of determining to adopt a large pressed depth ratio (the depth h / the radius R of a pressing head), three kinds of engineering materials, namely alloy steel, aluminum alloy and titanium alloy, of which the elasticity modulus has remarkable difference are treated respectively by adopting two depth combinations (h1=0.1R and h2=0.4R) so as to obtain the respective material property coefficients; a ball factor S which reflects a hardening index effect is introduced so as to obtain a relational expression among a dimensionless function, W / (h3sigmarS ) and E* / (sigmarS); and the mechanical property of a tested material can be finally determined through constitutive relations, obtained by simulation by adopting finite element values, between the coefficients and the materials. By the method, the obtained result is more accurate; and the method is easy and quick and applicable to engineering structural materials in accordance with the power law.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

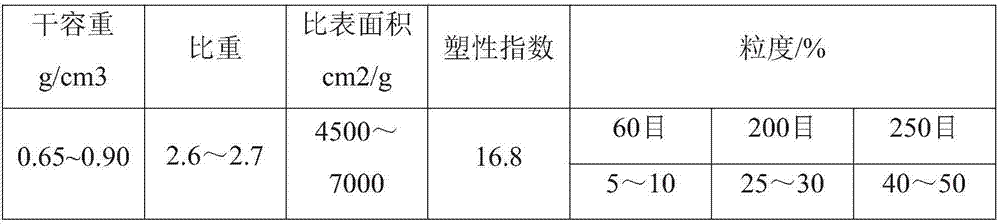

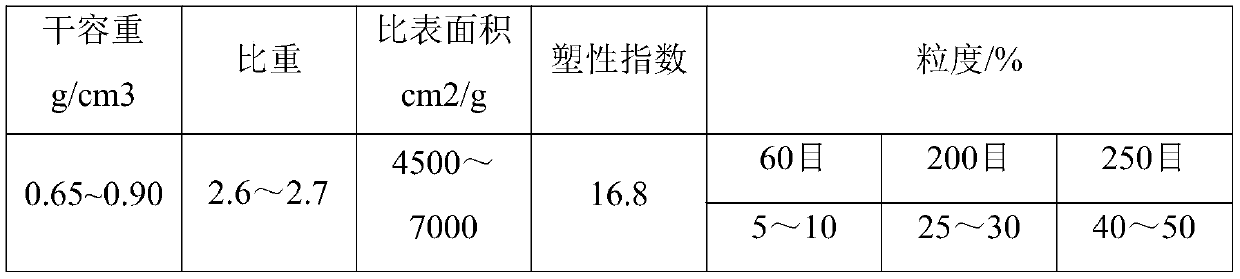

Superfine clay-based foam light soil and preparation method thereof

PendingCN114213151AEnhanced anti-leakage performanceEasy to prepareCeramicwareMetakaolinApparent viscosity

The invention discloses superfine clay-based foam light soil and a preparation method thereof. The superfine clay-based foam light soil is prepared from the following components in parts by weight: 230-330 parts of cement, 205-300 parts of hollow glass beads, 35-55 parts of metakaolin, 80-195 parts of superfine clay, 190-220 parts of water and 20-38 parts of a foaming agent. The compressive strength index of the prepared foam light soil meets the engineering requirements, meanwhile, the anti-seepage performance of the foam light soil is improved, and the preparation method is simple; due to the particle morphology, microstructure and charge characteristics of the clay mineral, the clay mineral has very strong adsorption capacity on additives and water and has great influence on the rheological property of the cement-based material, and most of the clay mineral is layered silicate with negative charges and is formed by interlayer electrostatic interaction; the superfine clay is added into the foam light soil slurry, so that the yield stress, the plastic viscosity and the apparent viscosity of the foam light soil slurry can be remarkably improved, the impermeability of the foam light soil slurry is improved, and the engineering use requirements are met.

Owner:上海市地江建筑科技有限公司 +1

Fecunisn series alloy powder for diamond products and preparation method thereof

Owner:HENAN HOLD DIAMOND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com