Material-distribution type cooling process of white cement clinker

A cooling process, white cement technology, applied in clinker production, cement production, etc., can solve the problems of high energy consumption and low output, and achieve the effects of increased clinker output, low consumption, and reduced heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

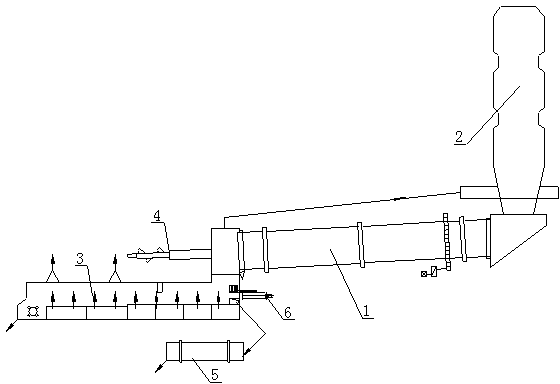

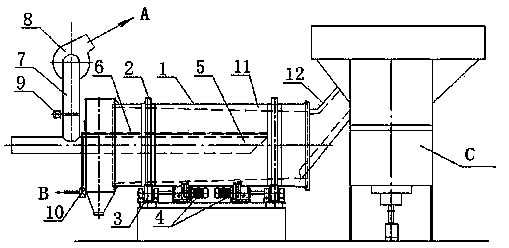

[0020] combined with figure 1 described as follows:

[0021] During the process of the high-temperature clinker coming out of the rotary kiln (1) falling into the grate cooler (3), the distributor (6) installed at the front end of the grate cooler removes about 50% of the clinker The material is introduced obliquely into the discharge port on the side of the grate cooler and enters the rotary bleaching machine (5). The material entering the rotary bleaching machine is cooled to 100~300°C by spraying water, and then sent to the clinker storage by the chain bucket conveyor . The steam-containing gas discharged from the rotary bleaching machine enters the electric precipitator at the kiln head for dust removal and then is discharged into the atmosphere.

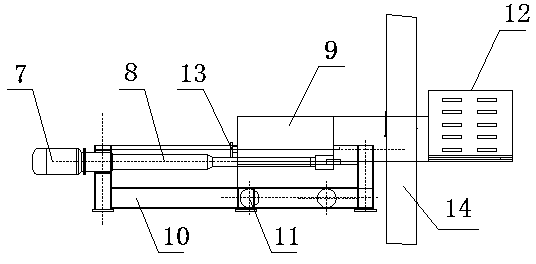

[0022] The outlet of the rotary bleaching machine is equipped with an infrared thermometer to monitor the temperature of the clinker and adjust the amount of water sprayed by adjusting the opening of the water spray electri...

Embodiment 2

[0029] In Example 1, the proportion of material distribution is adjusted to be 4:6 between the clinker of the rotary bleaching machine and the clinker of the grate cooler, and the other processes are the same as in Example 1. The heat consumption is about 5% lower than in Example 1, but the clinker whiteness is about 1% lower.

Embodiment 3

[0031] In Example 1, the ratio of the material distribution is adjusted so that the ratio of the clinker into the rotary bleaching machine and the clinker in the grate cooler is 3:7, and the other processes are the same as in Example 1. The heat consumption is about 10% lower than in Example 1, but the clinker whiteness is about 2% lower. This scheme can introduce medium-temperature air into the AQC boiler at the kiln head for waste heat power generation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com