Preparation method of transparent perovskite/polymer scintillation screen applied to X-ray imaging

A transparent polymer, perovskite technology, applied in X-ray/infrared processes, chemical instruments and methods, conversion screens, etc., can solve the problem of difficulty in realizing large-area flexible scintillation screens, poor long-term stability of scintillation screens, and difficulty in realizing flexible screens. and other problems, to achieve high environmental and work stability, improve photon yield, and have the effects of process amplification and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing a transparent perovskite / polymer scintillation screen applied to X-ray imaging, comprising the following steps:

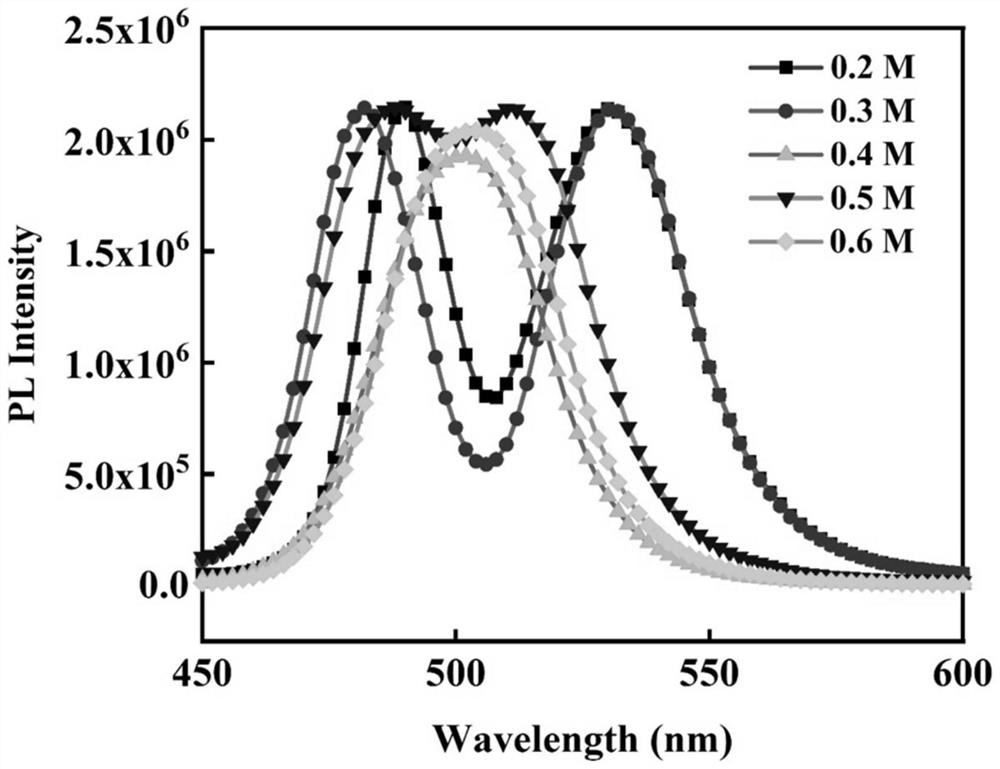

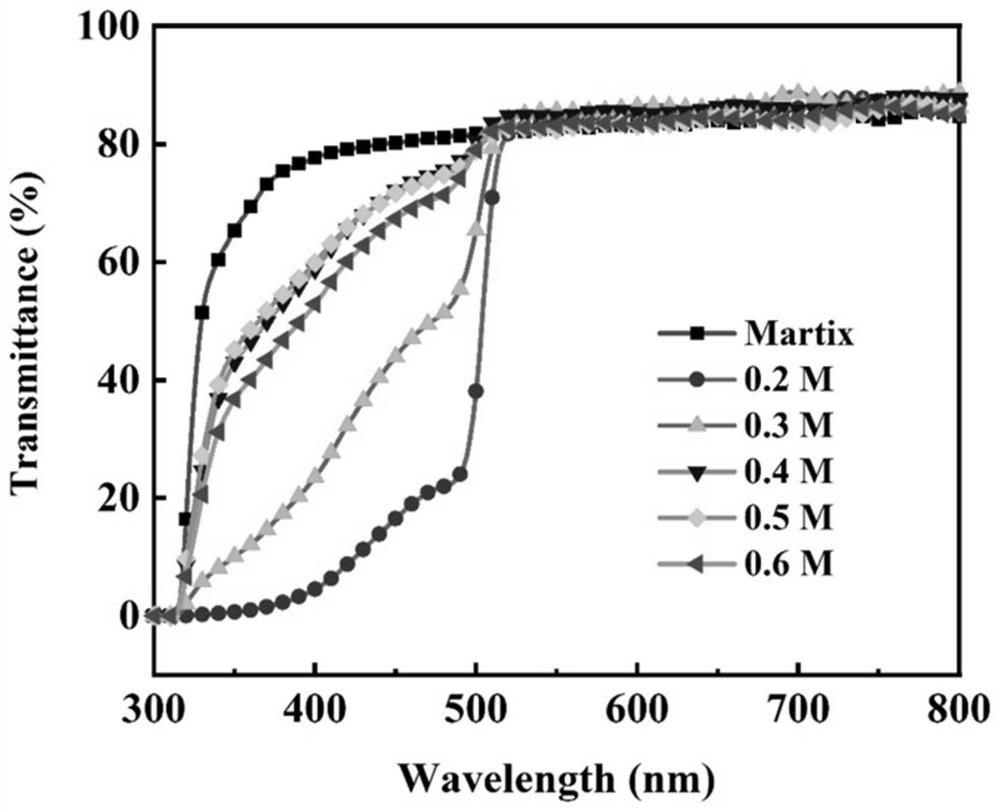

[0023] 1) Immerse the transparent polymer substrate in 0.01-1mol / L perovskite DMF solution, and put it into the reaction kettle;

[0024] Wherein, the transparent polymer substrate is polyethylene terephthalate (PET), polyimide (PI) or polystyrene (PS), polycarbonate (PC). The thickness of the transparent polymer substrate is 0.001~10mm, and the area of the polymer substrate is 1~400cm 2 .

[0025] 2) Transfer the reaction kettle to a constant temperature box and react at 60-200°C for 10-6000min;

[0026] 3) Take out the transparent polymer substrate and soak it in isopropanol at 80°C for 1-60 minutes;

[0027] 4) Take out the transparent polymer substrate and dry it in an incubator at 80°C for 30-300 minutes;

[0028] 5) A thick scintillation screen is made by stacking multiple transparent polymer substrates by hot pressing or b...

Embodiment 1

[0031] 1) Make a thickness of 0.1mm and an area of 4cm 2 The transparent PET substrate is immersed in 0.3mol / L MAPbBr 3 DMF solution, packed in 50ML reactor;

[0032] 2) Transfer the reactor to a thermostat at 180°C for 120 minutes;

[0033] 3) Take out the transparent polymer substrate and soak it in isopropanol at 80°C for 15 minutes;

[0034] 4) Take out the transparent polymer substrate and dry it in an incubator at 80° C. for 120 minutes.

[0035] 5) Bond two PET substrates to form a transparent perovskite / polymer scintillation screen with a thickness of 0.2mm.

Embodiment 2

[0037] 1) Make a thickness of 0.1mm and an area of 100cm 2 The transparent PET substrate is immersed in 0.3mol / L (PEA) 2 PB 4 DMF solution, put into 200ML reactor;

[0038] 2) Transfer the reactor to a thermostat at 180°C for 240 minutes;

[0039] 3) Take out the transparent polymer substrate and soak it in isopropanol at 80°C for 15 minutes;

[0040] 4) Take out the transparent polymer substrate and dry it in an incubator at 80° C. for 120 minutes.

[0041] 5) Bond three PET substrates to form a transparent perovskite / polymer scintillation screen with a thickness of 0.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com