A Method of Obtaining Mechanical Properties of Metal Materials Based on Load-Depth Curve

A metal material and curve technology, applied in the field of material mechanical performance testing, can solve the problem of not being able to separate two different materials correctly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

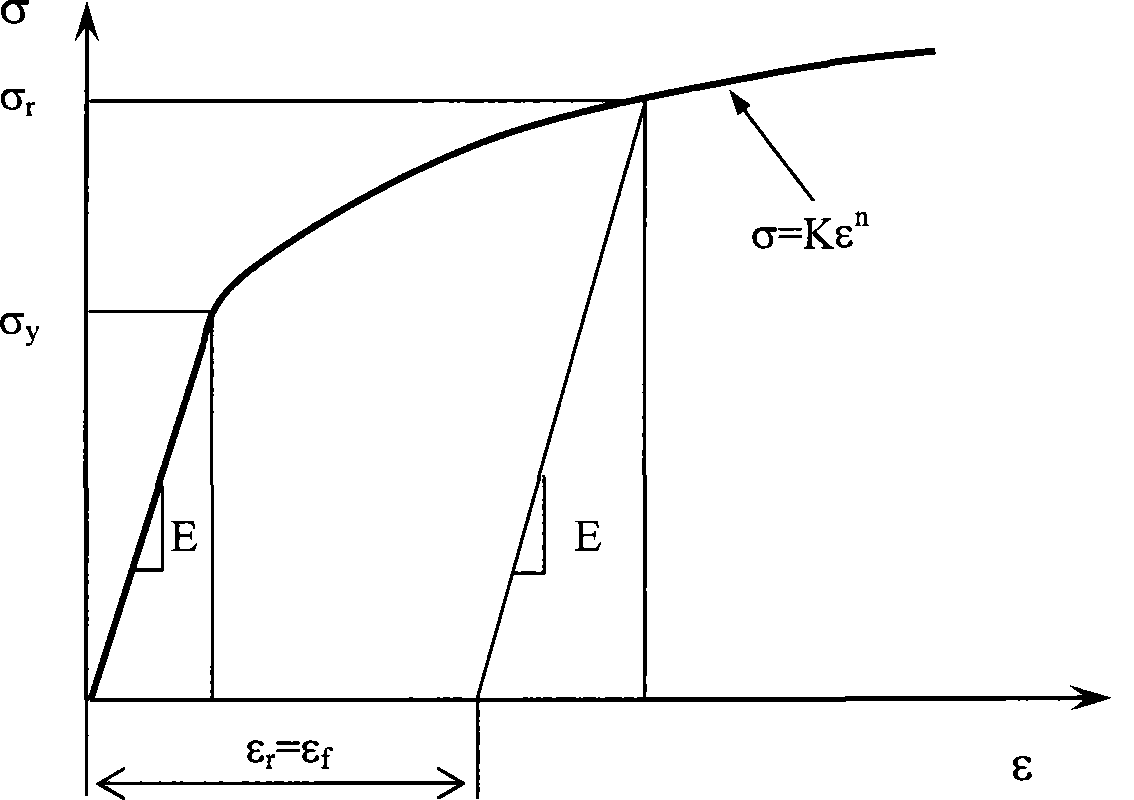

Method used

Image

Examples

Embodiment 1

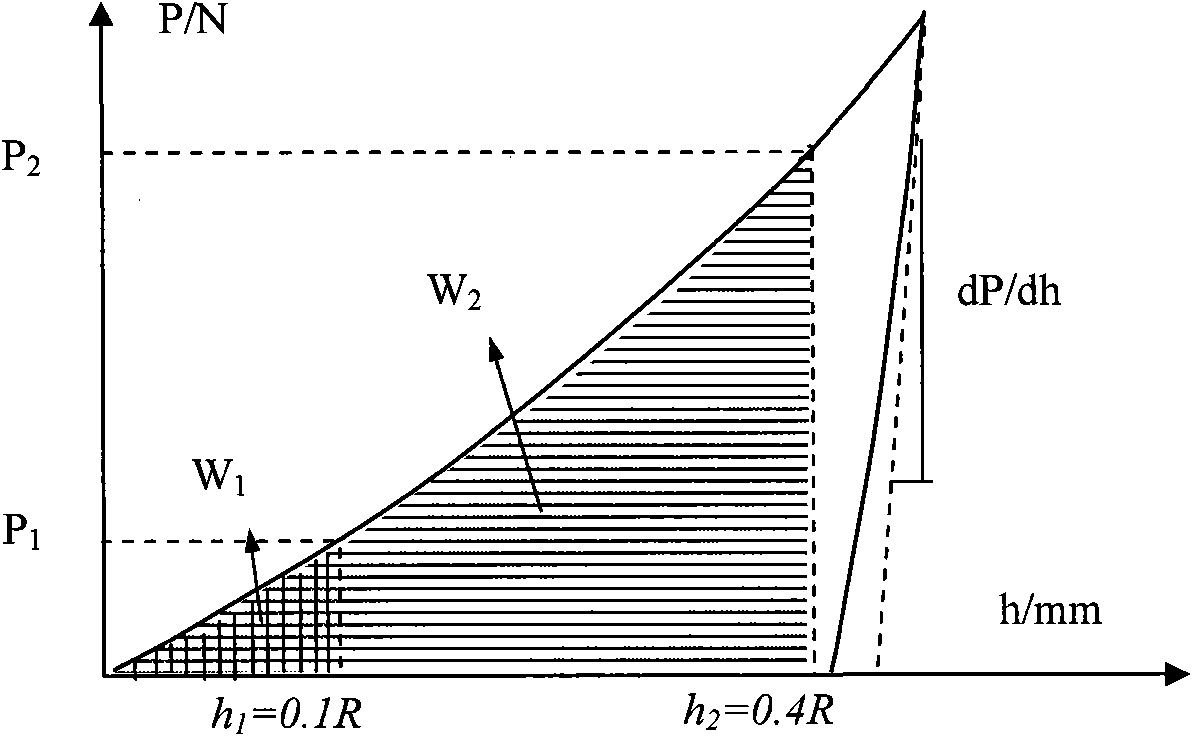

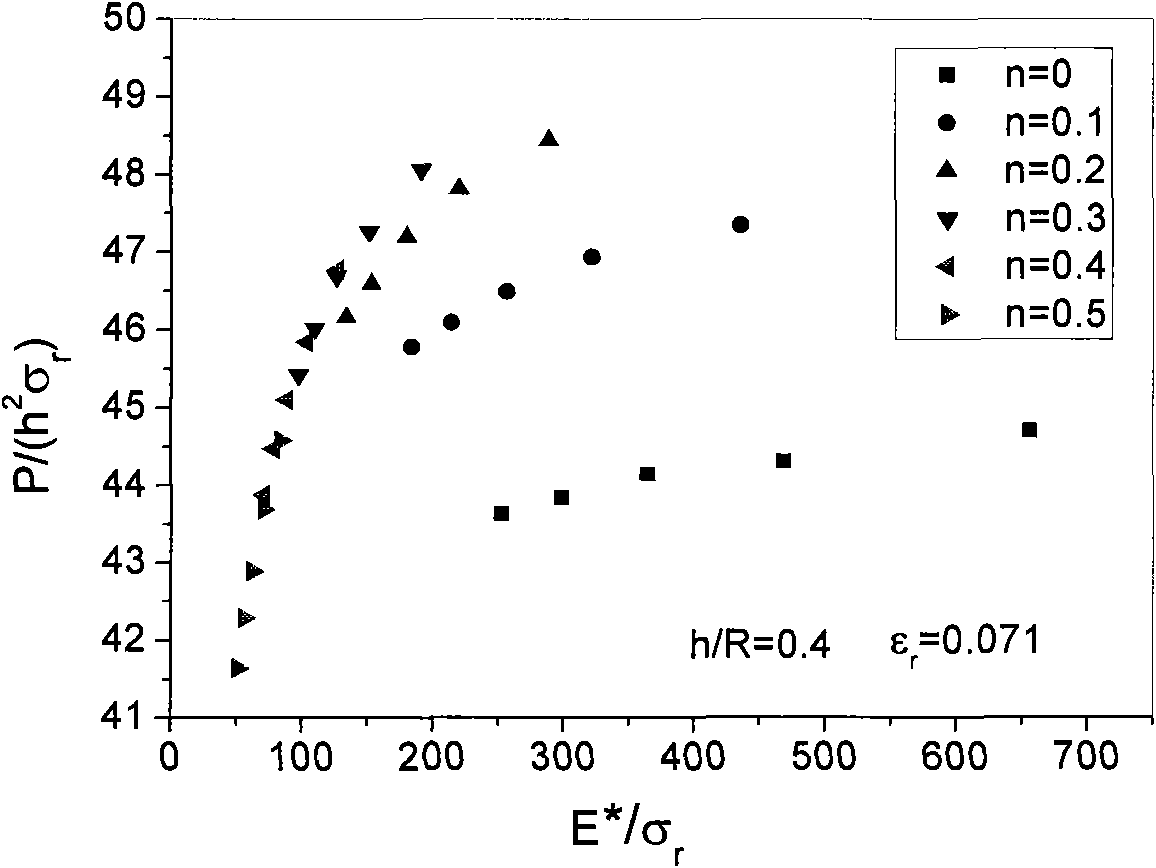

[0057] Embodiment 1: Firstly, finite element numerical simulation is used to carry out simulation calculations for three materials, alloy steel, aluminum alloy and titanium alloy, whose constitutive relationship conforms to the power law. The radius R of the steel ball used in this example is 0.25mm, and the model diagram is as follows Figure 7 As shown, the respective P-h curves of the obtained alloy steel, aluminum alloy and titanium alloy, such as Figure 8 Some of the results are shown.

[0058] In this case by Figure 8 The curves in get two depths down (h 1 = 0.1R, h 2 =0.4R) integral area, select respective corresponding formula coefficients according to different materials, then by known elastic modulus E, obtain the method for material performance according to the present invention, as flow process Figure 6 As shown, the plastic property parameters of three different materials are obtained: including yield strength, strain hardening exponent and tensile strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com