Electron gun protection device for vacuum preheating electron beam welding device

An electron beam welding and protective device technology, applied in electron beam welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of thermal damage, affecting the service life of welding equipment, etc., and achieve the effect of improving service life and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] Referring to the accompanying drawings, the specific embodiments are as follows:

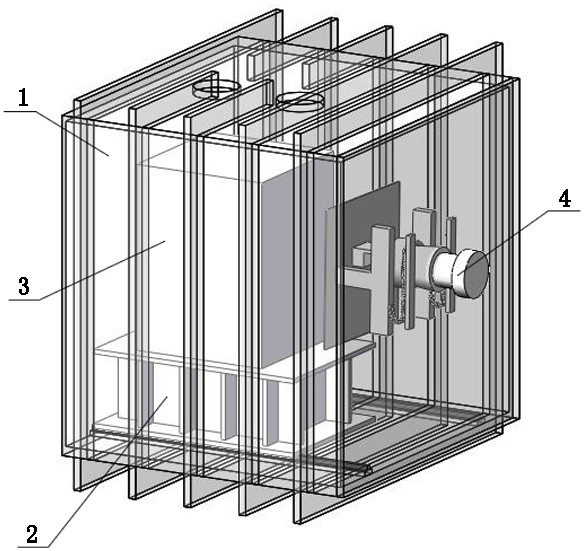

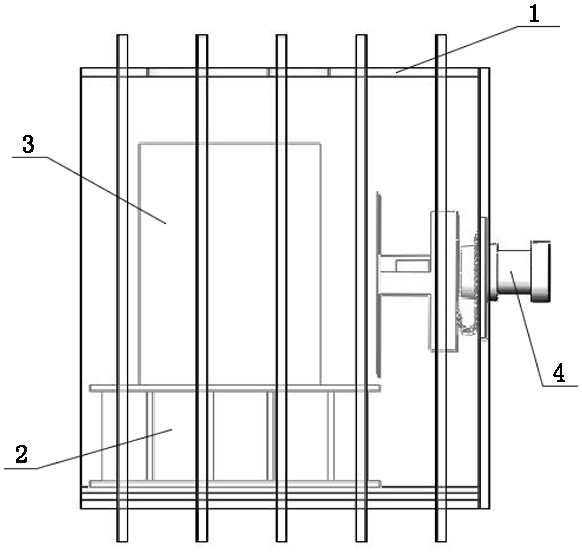

[0016] like figure 1 , 2 As shown, an electron gun protection device for a vacuum preheating electron beam welding device, the vacuum preheating electron beam welding device comprises a vacuum chamber 1, a moving platform 2 and a heating device 3 are arranged in the vacuum chamber 1, and the parts to be welded are placed On the mobile platform 2, the heating device 3 heats the workpiece to be welded by radiating heat radiation to realize pre-welding preheating of the workpiece to be welded. An electron gun 4 is installed on the side wall of the vacuum chamber 1, and one end of the electron gun 4 extends into the vacuum chamber 1. Internally, it is used for electron beam welding of parts to be welded.

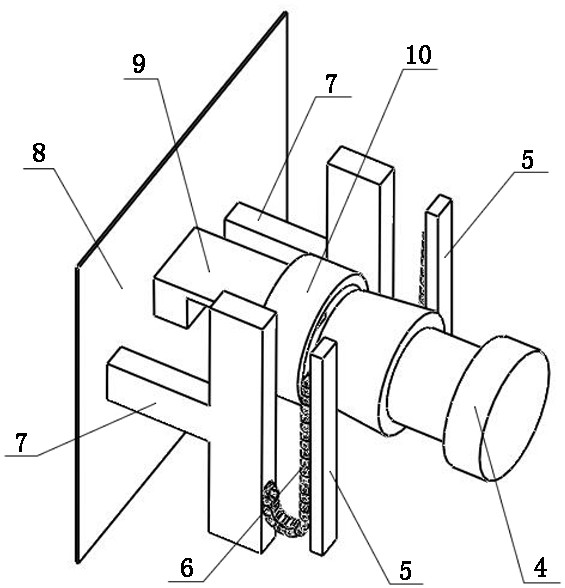

[0017] like image 3 As shown, the electron gun protection device includes two sections of electrically controlled slide rails 5 that are arranged on the inner wall of the vacuum chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com