Microbiological consolidation method and application method of bayer process red mud roadbed

A technology of Bayer process red mud and solidification method, applied in the field of road engineering, can solve the problems of small cumulative speed effect, high investment, low production efficiency, etc., and achieve the effect of good biocompatibility and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this example, the Bayer red mud roadbed microbial solidification method and application method are used to treat the red mud roadbed, and the method includes the following steps:

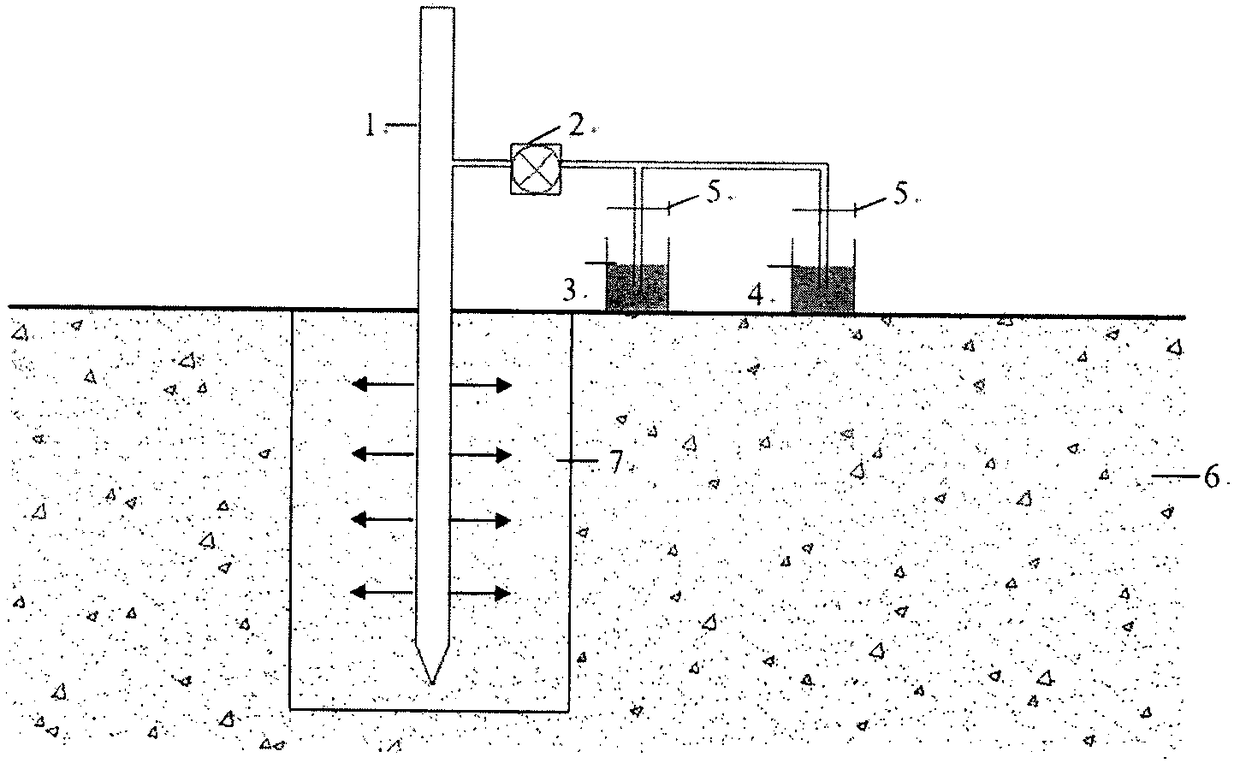

[0045]Use red mud 6 as roadbed filling material (such as roadbed, base and subbase filling materials) for construction, and lay a red mud layer with a thickness of about 30cm; after laying, perform mechanical plowing on the red mud layer to be treated; Tilling while spraying OD 600 =1.2 Bacillus pasteurian bacteria liquid; so repeated many times, until the thickness of the red mud foundation 6 reaches 1.5m;

[0046] a. Vertically drive the grouting flower tube 1 into the red mud foundation 6;

[0047] b. Through the grouting flower tube 1, first inject the nutrient solution 3① of 1.5 times the pore volume of the soil to be solidified into the red mud to be solidified 7, and then inject urea with a concentration of 1.0 mol / L and 1.0 mol / L equal to the volume of the nutrient solution 3①. m...

Embodiment 2

[0051] In this example, the Bayer red mud roadbed microbial solidification method and application method are used to treat the red mud roadbed, and the method includes the following steps:

[0052] Use red mud 6 as roadbed filling material (such as roadbed, base and subbase filling materials) for construction, and lay a red mud layer with a thickness of about 50cm; after laying, perform mechanical plowing on the red mud layer to be treated; Tilling while spraying OD 600 =1.2 Bacillus pasteurian bacteria liquid; so repeated many times, until the thickness of the red mud foundation 6 reaches 3m;

[0053] a. Vertically drive the grouting flower tube 1 into the red mud foundation 6;

[0054] b. Through the grouting flower tube 1, first inject an OD of 1.5 times the pore volume of the soil to be consolidated into the red mud to be consolidated 7 600 =1.2 of the Bacillus pasteurian bacteria liquid 3②, and then inject the same volume as the bacteria liquid 3② of urethra with a conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com