A high-strength and high-toughness gas-shielded flux-cored welding wire for bridge steel

A flux-cored welding wire and bridge technology, applied in welding equipment, welding medium, welding equipment, etc., can solve the problems that the welding wire cannot meet the requirements of engineering use, and achieve excellent performance, good crack resistance, and low diffusible hydrogen content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

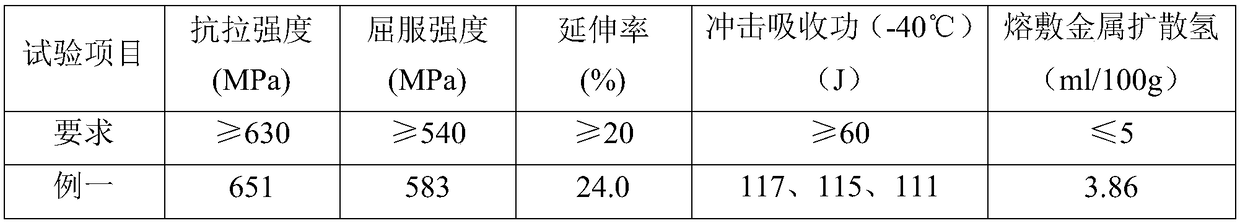

Embodiment 1

[0018] A high-strength and high-toughness gas-shielded flux-cored welding wire for bridge steel, the flux core includes the following components in weight fractions: 42% rutile, 4% feldspar, 2.5% quartz, 1.5% zirconium quartz, 1.5% sodium fluoride, and fluorine Lithium 0.4%, potassium sodium arc stabilizer 3%, silicon-manganese alloy 16%, metal manganese 3%, magnesium powder 3%, nickel powder 9%, titanium iron 0.4%, boron iron 0.2%, and the balance is iron powder, The weight fractions of the above ingredients add up to 100%.

[0019] The mass fraction of titanium dioxide contained in the rutile is 95%.

[0020] The outer skin is an SPCC-SD cold-rolled low-carbon steel strip.

[0021] The ratio of the flux core to the total weight of the welding wire is 17%.

[0022] Welding wire deposited metal composition detection, its weight percentage is carbon 0.042%, sulfur 0.006%, manganese 1.49%, silicon 0.38%, phosphorus 0.013%, chromium 0.019%, nickel 1.32%, molybdenum 0.007%, vana...

Embodiment 2

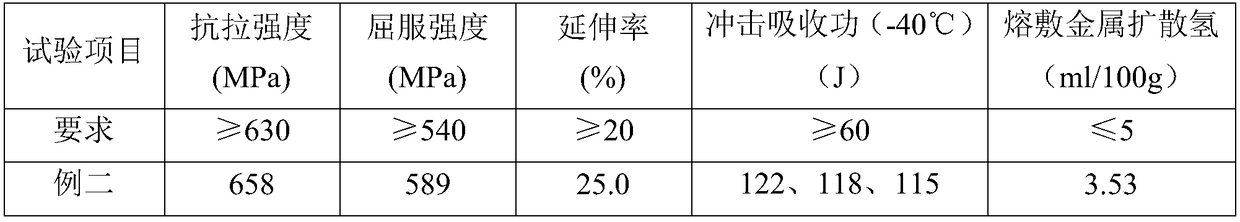

[0026] A high-strength and high-toughness gas-shielded flux-cored welding wire for bridge steel, the flux core includes the following components by weight: 40% rutile, 5% feldspar, 3% quartz, 2% zirconium quartz, 2% sodium fluoride, and fluorine Lithium 0.6%, potassium sodium arc stabilizer 4%, silicon manganese alloy 18%, metal manganese 4%, magnesium powder 4%, nickel powder 10%, titanium iron 0.6%, boron iron 0.3%, the balance is iron powder, The weight fractions of the above ingredients add up to 100%.

[0027] The mass fraction of titanium dioxide contained in the rutile is 95%.

[0028] The outer skin is an SPCC-SD cold-rolled low-carbon steel strip.

[0029] The ratio of the flux core to the total weight of the welding wire is 15%.

[0030] Welding wire deposited metal composition detection, its weight percentage is carbon 0.043%, sulfur 0.007%, manganese 1.52%, silicon 0.40%, phosphorus 0.012%, chromium 0.018%, nickel 1.35%, molybdenum 0.008%, vanadium 0.013%, and th...

Embodiment 3

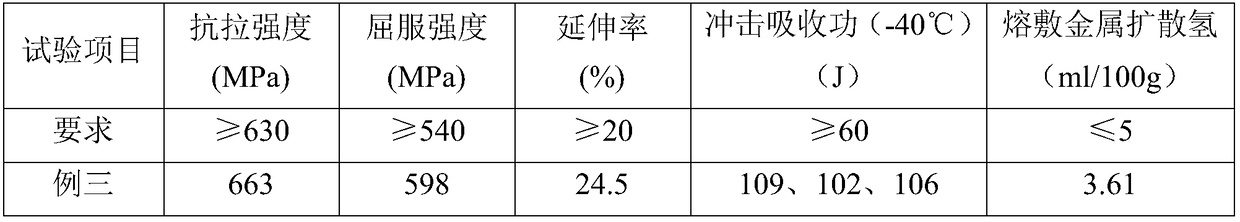

[0034] A high-strength and high-toughness gas-shielded flux-cored welding wire for bridge steel, the flux core includes the following components in weight fractions: 37% rutile, 5% feldspar, 3.5% quartz, 2.5% zirconium quartz, 2.5% sodium fluoride, and fluorine Lithium 0.8%, potassium sodium arc stabilizer 4%, silicon manganese alloy 19%, metal manganese 5%, magnesium powder 5%, nickel powder 11%, titanium iron 0.8%, boron iron 0.5%, the balance is iron powder, The weight fractions of the above ingredients add up to 100%.

[0035] The mass fraction of titanium dioxide contained in the rutile is 95%.

[0036] The outer skin is an SPCC-SD cold-rolled low-carbon steel strip.

[0037] The ratio of the flux core to the total weight of the welding wire is 13%.

[0038] Welding wire deposited metal composition detection, its weight percentage is carbon 0.048%, sulfur 0.007%, manganese 1.57%, silicon 0.43%, phosphorus 0.013%, chromium 0.021%, nickel 1.34%, molybdenum 0.009%, vanadiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com