A kind of processing method of red mud

A treatment method and technology of red mud, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of ineffective industrial application, high cost, large investment, etc., and achieve residue-free biocompatibility , low energy consumption, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

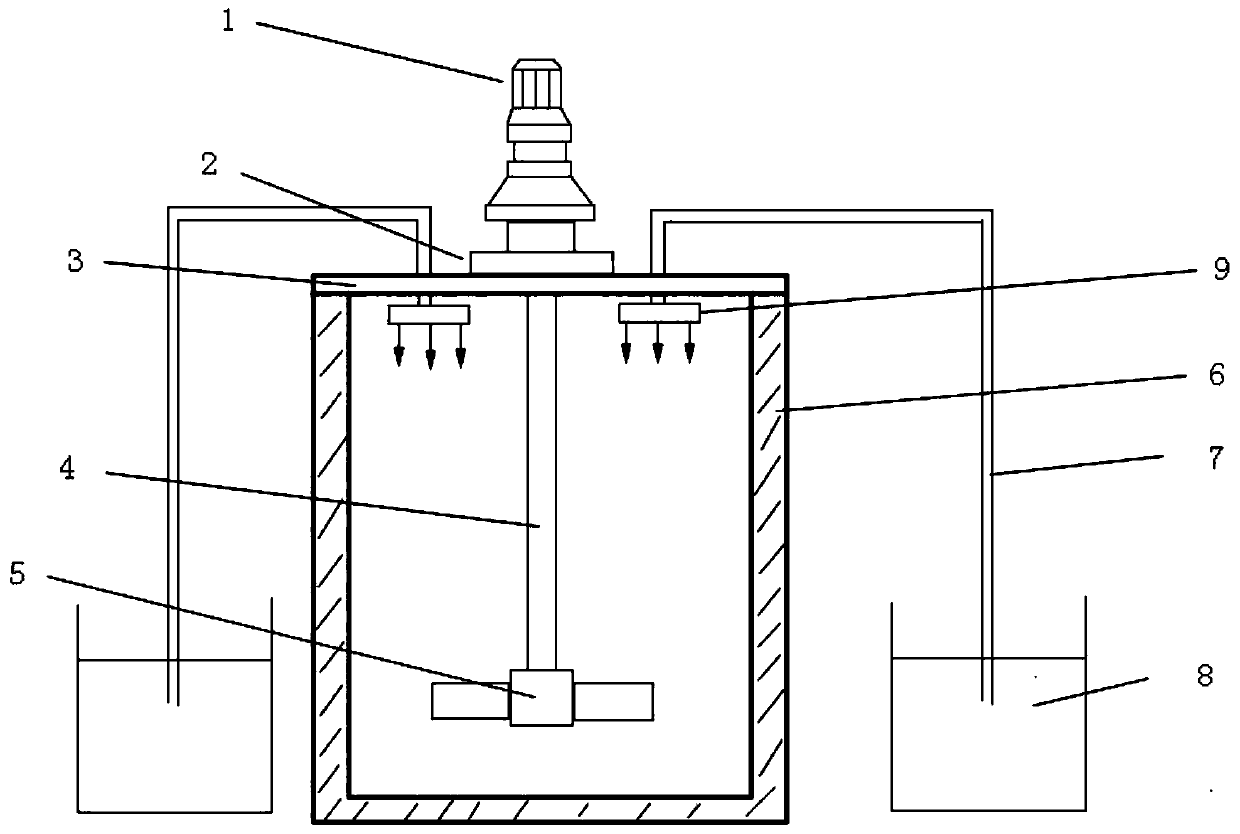

[0076] In this example, a method for microbial agitation and solidification of red mud, the method includes the following steps:

[0077] a. Red mud is loaded into container 6;

[0078] b. Through the infusion pipeline 7, through the sprinkler 9, first spray the red mud in the container 6 to the red mud in the container 8. The concentration of 1.5 times of the pore volume of the red mud to be solidified in the container 8 is the Bacillus pasteurian liquid of OD600=1.2, while spraying Drive the paddle 5 of the main shaft 4 through the reducer 1 to stir the red mud, and let it stand for 3 to 12 hours;

[0079] c. Utilize infusion pipeline 7, sprinkler 9 again to the cementing liquid in container 8 of red mud spraying in container 6 (Bacillus pasteurian bacteria liquid: cementing liquid=1: 1, contain urea and calcium chloride in the cementing liquid, The concentration is 1mol / 1), and while spraying, the paddle 5 of the main shaft 4 is driven by the reducer 1 to stir the red mud;...

Embodiment 2

[0084] Pour 200-300g of red mud into the beaker, make it evenly cover the bottom of the beaker, then pour 400ml of Bacillus pasteurian bacteria liquid (OD600=1.2), stir well, then let stand for 12 hours. Then add 400mL of cementing solution (Bacillus pasteurian bacteria solution: cementing solution = 1:1, the cementing solution contains urea and calcium chloride, the concentration is 1mol / 1), fully stir, and at room temperature 20 ~ 30 ℃ Stand at constant temperature under the environment, then pour out the liquid in the beaker every 12 hours, and add 100ml of cementing solution. Finally, solidified red mud is obtained after 6 rounds.

[0085] [Application and Effect] The unconfined compressive strength after treatment is 1.5MPa; the compressibility coefficient is 0.92MPa -1 ; Rebound modulus 435MPa.

Embodiment 3

[0087] Pour 200-300g of red mud into the beaker, make it evenly cover the bottom of the beaker, then pour 400ml of Bacillus pasteurian bacteria liquid (OD600=1.2), stir well, and then let it stand for 12 hours. Then add 400mL of cementing solution (Bacillus pasteurian bacteria solution: cementing solution = 1:1, the cementing solution contains urea and calcium chloride, the concentration is 1mol / l), fully stir, and at room temperature 10 ~ 20 ℃ Stand at a constant temperature under a certain environment, then pour out the liquid in the beaker every 6 hours, and add 100ml of cementing solution. Finally, solidified red mud is obtained after 6 rounds.

[0088] [Application and Effect] The unconfined compressive strength after treatment is 1.2MPa; the compressibility coefficient is 0.105MPa -1 ; Modulus of resilience 390MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com