Application of coal ash synthetic channel jointing material on damping interface or in water construction

A fly ash and channel technology, applied in water conservancy projects, marine engineering, other chemical processes, etc., can solve the problems that polyurethane sealing materials cannot be constructed, materials cannot be cured, and bonding surfaces cannot be bonded into a whole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

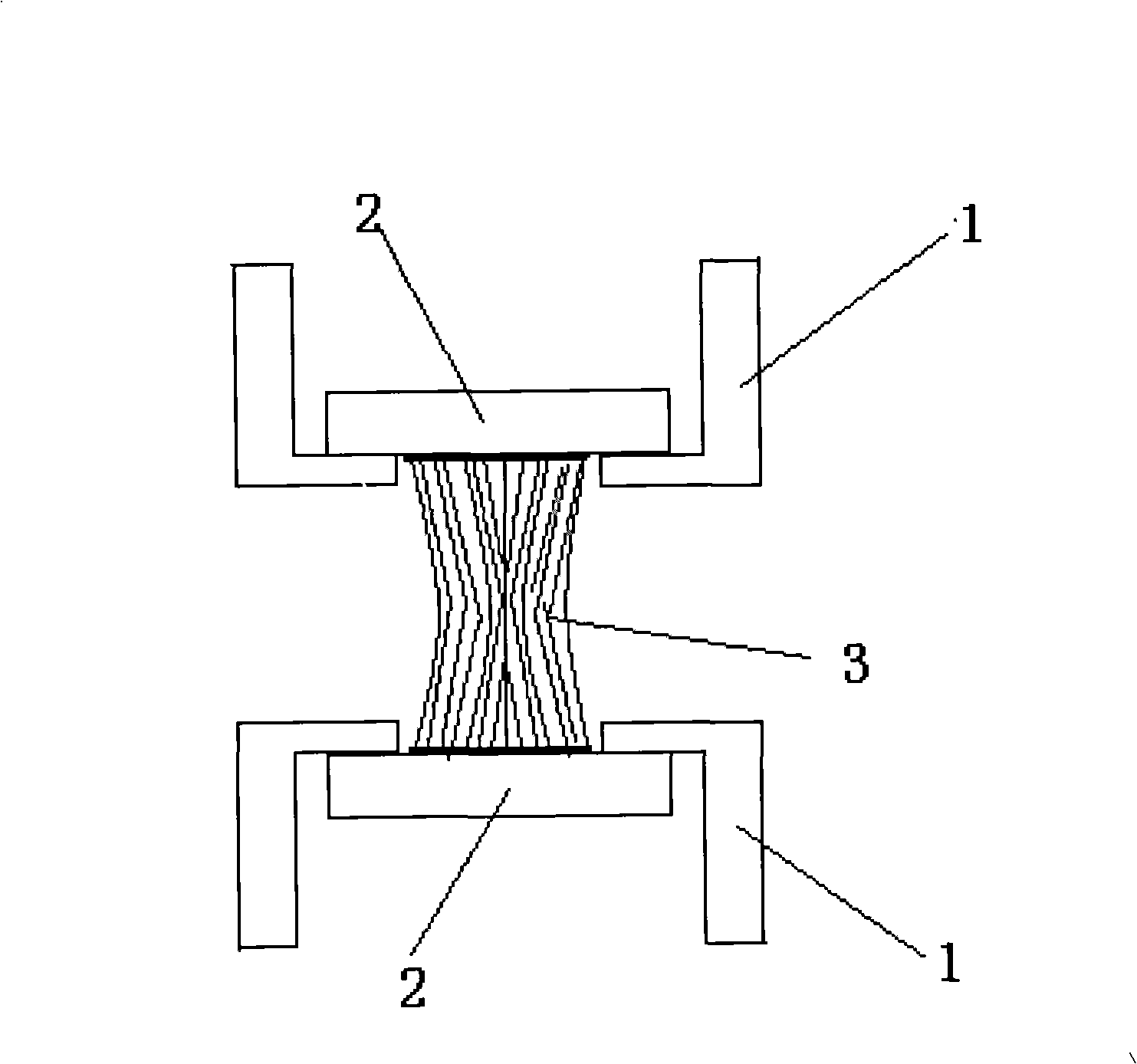

Image

Examples

experiment example 1

[0049] Experimental example 1, the bond strength measured on the dry surface is 1.02MPa, the bond strength measured on the wet interface is 0.91MPa, and the bond strength in water is 0.83MPa.

experiment example 2

[0050]In Experimental Example 2, the bond strength measured on the dry surface is 1.10 MPa, the bond strength measured on the wet interface is 0.93 MPa, and the bond strength in water is 0.84 MPa.

experiment example 3

[0051] In Experimental Example 3, the bond strength measured on the dry surface is 0.92 MPa, the bond strength measured on the wet interface is 0.81 MPa, and the bond strength in water is 0.73 MPa.

[0052] The above bonding strength values are all greater than the 0.2MPa bonding strength value stipulated in the national standard JC / T482 and JC / T483, which can far meet the requirements of practical engineering applications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com