Calcium carbonate, rubber and polyvinyl chloride composition and preparation method thereof

A polyvinyl chloride and calcium carbonate technology, applied in the field of polymer processing, can solve the problems of difficult removal of additives, poor physical and mechanical properties of filled powder rubber products, and affect the application performance of the composition, so as to achieve less impurities and simple drying process Ease of operation and stable physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Calcium carbonate raw material preparation:

[0051] According to the method described in the third page to the fourth page step (1) to (3) of the patent document CN 1631789A instruction manual, the solid content is 6wt% calcium carbonate suspension, and the average particle diameter of the calcium carbonate particles tested by the specific surface area method is 30nm .

[0052] Composition preparation:

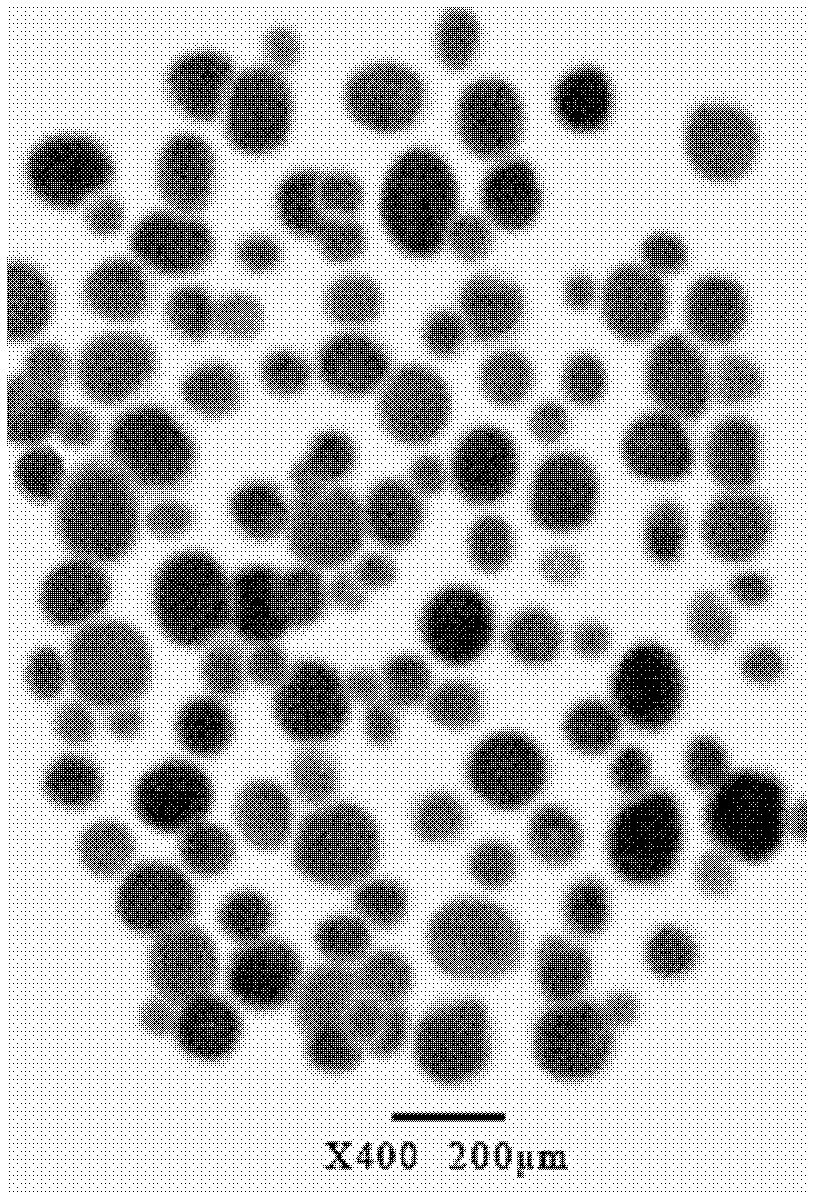

[0053] Take 900g of calcium carbonate suspension and put it into a 2L reaction kettle, stir at 800r / min and heat up to 50°C, then add 275g of SBR-1502 styrene-butadiene latex with a solid content of 24wt%, stir and mix, keep warm for 10min, filter and dehydrate, The particle distribution of the obtained filter cake is shown in Table 1. The entire filter cake was blended with 60 g of XS-5 polyvinyl chloride dry powder, and dried in an oven at 120° C. for 2 hours to obtain the composition of the present invention.

[0054] Wherein: calcium carbonate 45.0wt% in initial...

Embodiment 2

[0062] Calcium carbonate raw material preparation:

[0063] According to the same method of embodiment 1, the difference is that the average particle diameter of calcium carbonate is 55nm, and the solid content of calcium carbonate suspension is 11.6wt%.

[0064] Composition preparation:

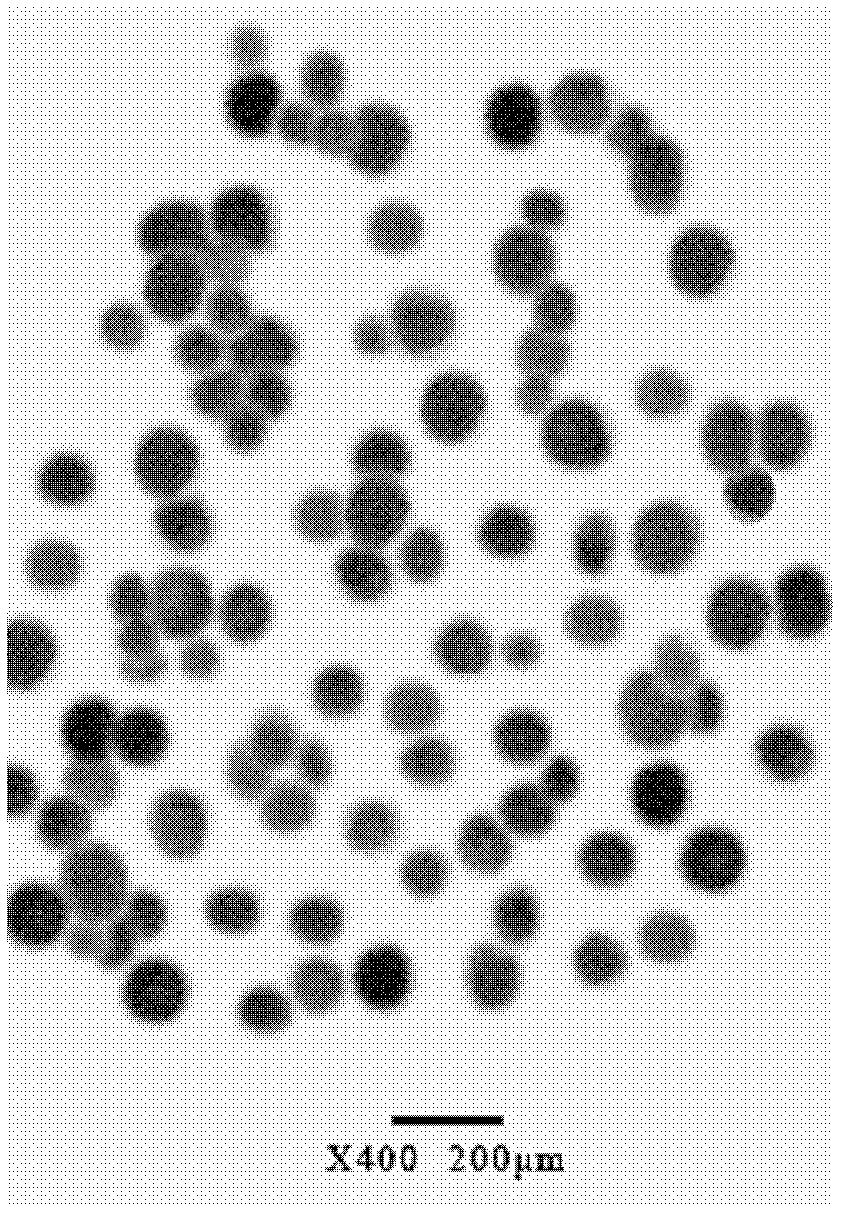

[0065] Take 800g of calcium carbonate suspension and put it into a 2L reactor, stir at 500r / min and heat up to 75°C, then add 620g of NBR-1704 nitrile latex with a solid content of 10wt%, stir and mix, keep warm for 20min, filter and dehydrate, The particle distribution of the obtained filter cake is shown in Table 1. All the filter cake was added to 247.7 g of GB1150 polyvinyl chloride suspension with a solid content of 50 wt % to disperse, and spray dried (the temperature of the tail gas was 89° C.) to obtain the composition of the present invention.

[0066] Wherein: calcium carbonate 59.9wt% in the initial composition, polymer elastomer 40.1wt%;

[0067] 100 parts of weight of calcium...

Embodiment 3

[0071] Calcium carbonate raw material preparation:

[0072] According to the same method of embodiment 1, the difference is that the average particle diameter of calcium carbonate is 87nm, and the solid content of calcium carbonate suspension is 10.4wt%.

[0073] Composition preparation:

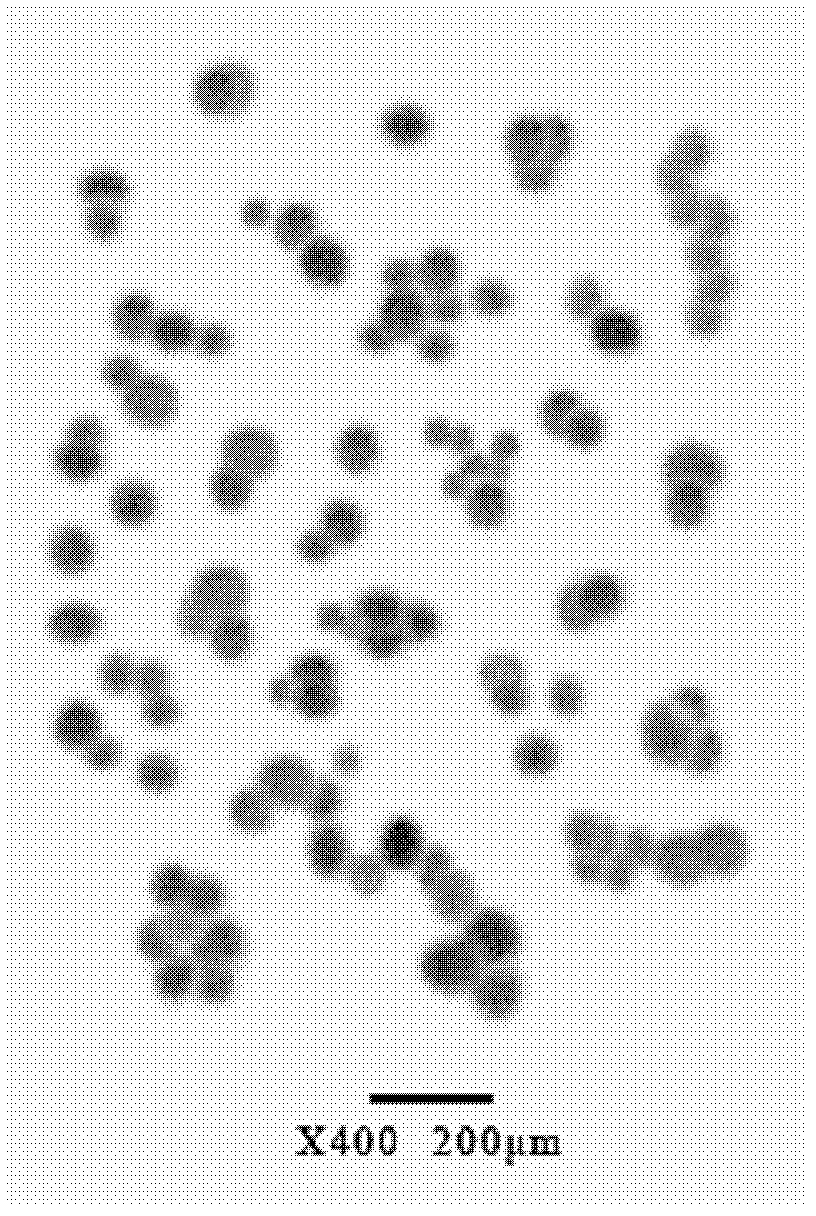

[0074] Take 700g of calcium carbonate suspension and put it into a 2L reactor, stir at 400r / min and heat up to 95°C, then add 624g of CRL40-Gx neoprene latex with a solid content of 5wt%, stir and mix, keep warm for 30min, filter and dehydrate, The particle distribution of the obtained filter cake is shown in Table 1. The entire filter cake was blended with 104g of XJ-2 dry polyvinyl chloride powder, and dried in an oven at 80°C for 2 hours to obtain the composition of the present invention.

[0075] Calcium carbonate 70.0wt% in the initial composition, polymer elastomer 30.0wt%;

[0076] 100 parts by weight of calcium carbonate and rubber initial composition in the invention composition,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com