Polyurethane synthetic leather for silky suede sofa furniture and preparation method of polyurethane synthetic leather

A polyurethane and synthetic leather technology, applied in textiles and papermaking, etc., can solve the problems of non-compliance with national environmental protection requirements, scarcity of raw materials, high price, etc., and achieve stable physical and mechanical properties, good physical and mechanical properties, simple and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Choose the velvet release paper code-named H-969 produced by Wenzhou Honghe Technology Co., Ltd., and evenly coat the polyurethane surface layer slurry on the surface of the velvet release paper, dry it in an oven at 130°C for 4 minutes, and dry it. Finally, the surface layer is made; the scanning gram weight of the surface layer is 140g / ㎡.

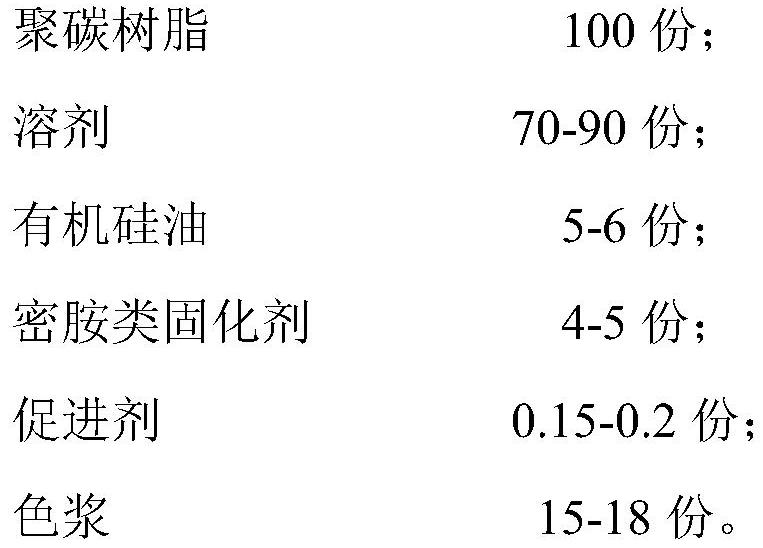

[0032] The polyurethane surface layer slurry is prepared from the following components in parts by weight:

[0033]

[0034] The preparation method of polyurethane slurry is: add polycarbon resin LT-8045 and solvent dimethylformamide (DMF) into the reaction kettle in proportion, and stir at a uniform speed to prepare the kettle material; then add organic silicone oil PMX- 200. Accelerator JF-320 and color paste are stirred at high speed to make them fully mixed to prepare the slurry to be reacted; finally, melamine curing agent JT-75 is added according to the proportion, and the above polyurethane surface layer slurry can be...

Embodiment 2

[0042] (1) Select the velvet release paper code-named Mei 498 produced by the SAPPI release paper company in the United States, and evenly coat the polyurethane surface layer slurry on the surface of the velvet release paper, dry it in an oven at 130 ° C for 4.5 minutes, and dry it. After drying, the surface layer is obtained; the scanning gram weight of the surface layer is 160g / ㎡.

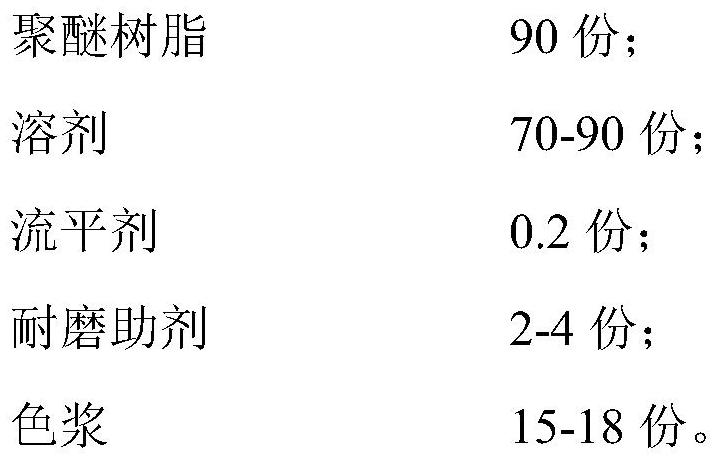

[0043] The polyurethane surface layer slurry is prepared from the following components in parts by weight:

[0044]

[0045] (2) Evenly coat the middle layer slurry on the surface layer obtained in step (1), and then put it into a 130°C oven to dry for 6 minutes, and use it as the middle layer after drying; the scanning weight of the middle layer is 180g / ㎡.

[0046] The middle layer slurry is prepared from the following components in parts by weight:

[0047]

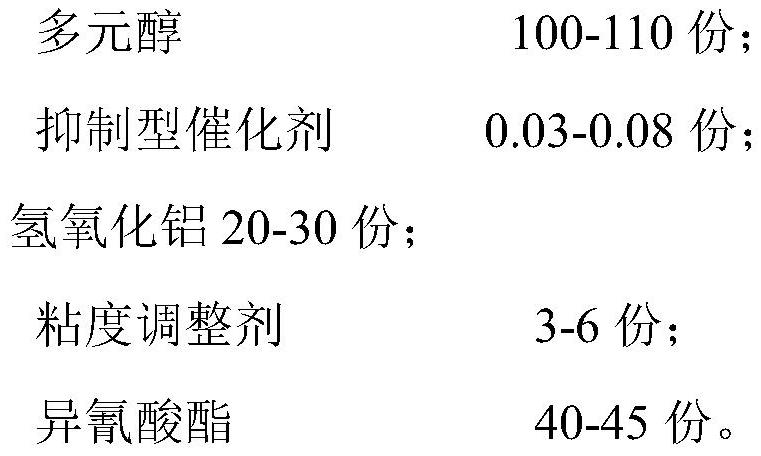

[0048](3) Uniformly coat the adhesive layer slurry on the surface of the intermediate layer obtained in step (2), put the coated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com