A kind of adhesive EPDM waterproof membrane

A technology of EPDM rubber and waterproof membrane, applied in the field of waterproofing, can solve problems such as hindering the development of EPDM membrane waterproofing system, not paying attention to the development and application of supporting materials for the system, and water leakage problems occurring from time to time. , to achieve the effect of uniform appearance quality, good high and low temperature resistance, and stable physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

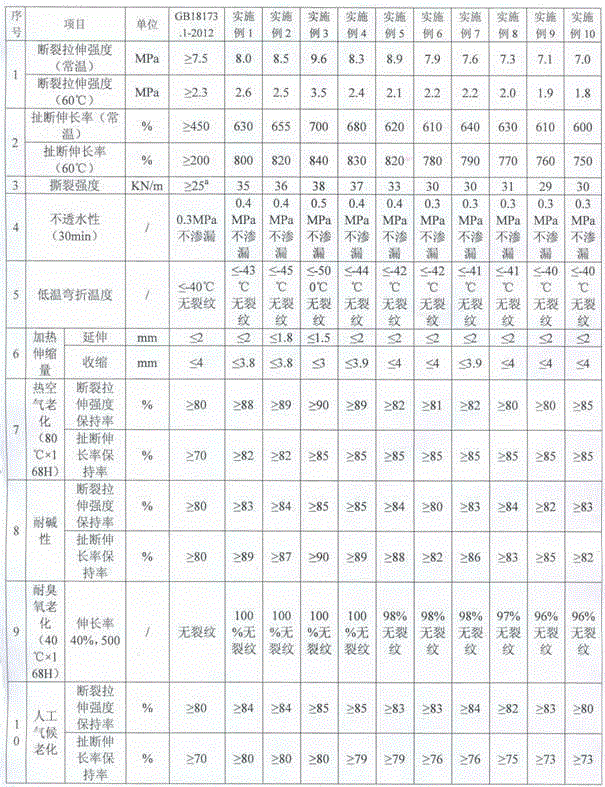

Examples

Embodiment 1

[0019] Embodiment 1: An adhesive EPDM waterproof membrane, mainly made of the following components, the components are calculated in parts by weight, wherein EPDM rubber 38 parts, carbon black 15 parts, powder filler light 19 parts of calcium, 11 parts of liquid filler naphthenic oil, 7 parts of anti-aging agent stearic acid, 1.2 parts of catalyst zinc oxide, 4 parts of accelerator DM, 2.1 parts of vulcanizing agent sulfur and 0.7 parts of nano-modifier.

Embodiment 2

[0020] Embodiment 2: A kind of glued EPDM waterproof roll material is mainly made of the following components, and the components are calculated in parts by weight, wherein EPDM rubber is 43 parts, carbon black is 15 parts, and powder filler is light 19 parts of calcium, 11 parts of liquid filler naphthenic oil, 7 parts of anti-aging agent stearic acid, 1.2 parts of catalyst zinc oxide, 4 parts of accelerator DM, 2.1 parts of vulcanizing agent sulfur and 0.7 parts of nano-modifier.

Embodiment 3

[0021] Embodiment 3: A kind of glued EPDM waterproof membrane is mainly made of the following components, the components are calculated in parts by weight, wherein EPDM rubber is 41 parts, carbon black is 15 parts, and powder filler is light 19 parts of calcium, 11 parts of liquid filler naphthenic oil, 7 parts of anti-aging agent stearic acid, 1.2 parts of catalyst zinc oxide, 4 parts of accelerator DM, 2.1 parts of vulcanizing agent sulfur and 0.7 parts of nano-modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com