Method for preparing carrageenan fibers with alkaline dissolution process

A technology of carrageenan and carrageenan base, which is applied in spinning solution preparation, fiber treatment, wet spinning and other directions, can solve problems such as excessive temperature requirements and energy waste, reduce heating and heat preservation requirements, solve energy waste, and solve The effect of spinneret plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

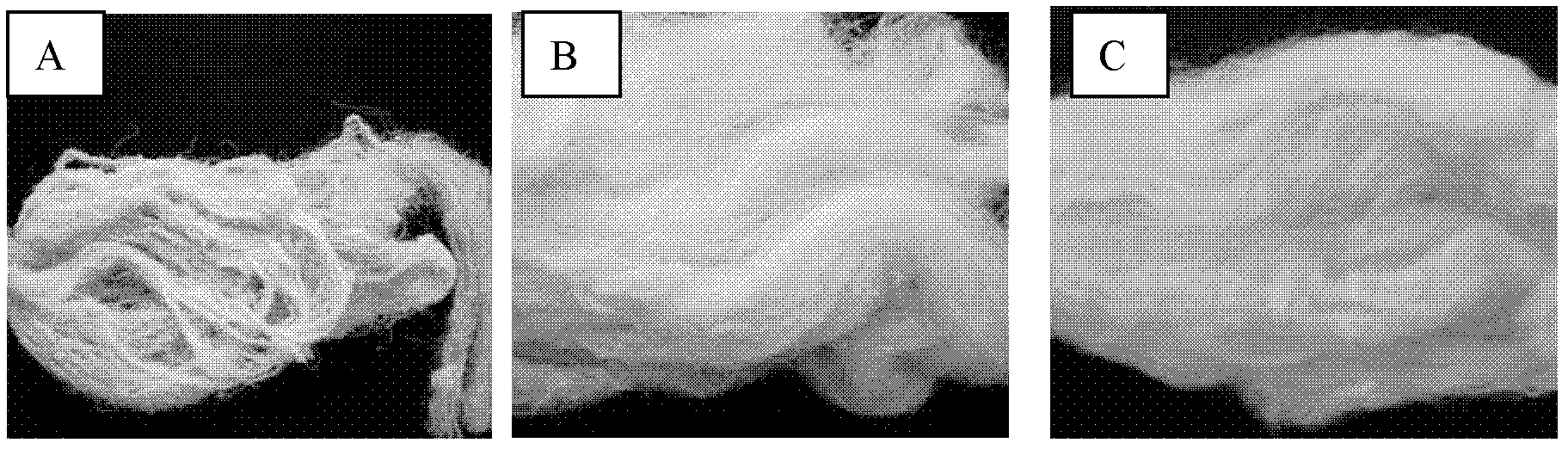

[0028] Add 80 grams of carrageenan to 920 grams of 2 mol / L NaOH solution, fully stir and dissolve at room temperature to obtain a carrageenan solution with a content of 8% (mass percentage), filter, defoam and stand for 8 hours to make spinning Spinning solution, the spinning solution passes through the wet spinning machine, and at room temperature (20°C), spins at a spinning speed of 25m / min and enters the coagulation bath for coagulation and drawing. The coagulation bath is 15% barium chloride solution, and the coagulation bath temperature room temperature (20°C), the drafting ratio of the fiber is 10%, the fiber is washed and dried to obtain the fiber material (see figure 1 C), the flexibility, strength and gloss of the fiber are better than those of aqueous solution spinning. The single filament tensile test index is shown in Table 2, and the mechanical strength is 9.09cN / tex, which is more than twice the strength of aqueous solution spinning fiber.

Embodiment 2

[0030] Add 70 grams of carrageenan to 630 grams of 2 mol / L KOH solution, fully stir and dissolve at room temperature to obtain a carrageenan solution with a content of 10% (mass percentage), filter, defoam and stand for 6 hours to make spinning At room temperature (20°C), the spinning solution is spun through a wet spinning machine at a spinning speed of 15m / min and enters a coagulation bath for coagulation and drawing. The coagulation bath is 5% barium chloride solution, and the temperature of the coagulation bath is room temperature. (20°C), the draft ratio of the fiber is 30%, the fiber is washed and dried to obtain the fiber material. The mechanical strength of the obtained fiber is 9.5 cN / tex, which is also more than 2 times higher than that of the aqueous solution spun fiber.

Embodiment 3

[0032] Add 60 grams of carrageenan to 690 grams of 4mol / L ammonia solution, stir and dissolve at room temperature to obtain a carrageenan solution with a content of 8%, filter, defoam and stand for 6 hours to make a spinning solution. ), the spinning solution is spun into the coagulation bath by the wet spinning machine at a spinning speed of 10m / min for coagulation and drawing. The elongation ratio is 50%, and the fiber is washed and dried to obtain a fiber material. The mechanical strength of the obtained fiber is 8.92 cN / tex, which is also more than 2 times higher than that of the aqueous solution spun fiber.

[0033] Table 2 Tensile test index of different carrageenan fibers monofilament

[0034] Fiber Preparation Method Maximum elongation (%) Maximum strength (cN) Strength (cN / tex) Linear Density (tex) Aqueous solution spinning (comparative example 2) 10.79 17.42 4.3 4.08 Alkali solution spinning (embodiment 1) 5.54 9.67 9.09 1.06

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com