Graphene auxiliary brazing method for ceramic matrix composite material and metal material

A technology of composite materials and metal materials, applied in the field of graphene-assisted brazing of ceramic matrix composite materials and metal materials, can solve the problems of poor mechanical properties of welded joints, achieve high-quality connections, relieve residual stress, and improve mechanical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

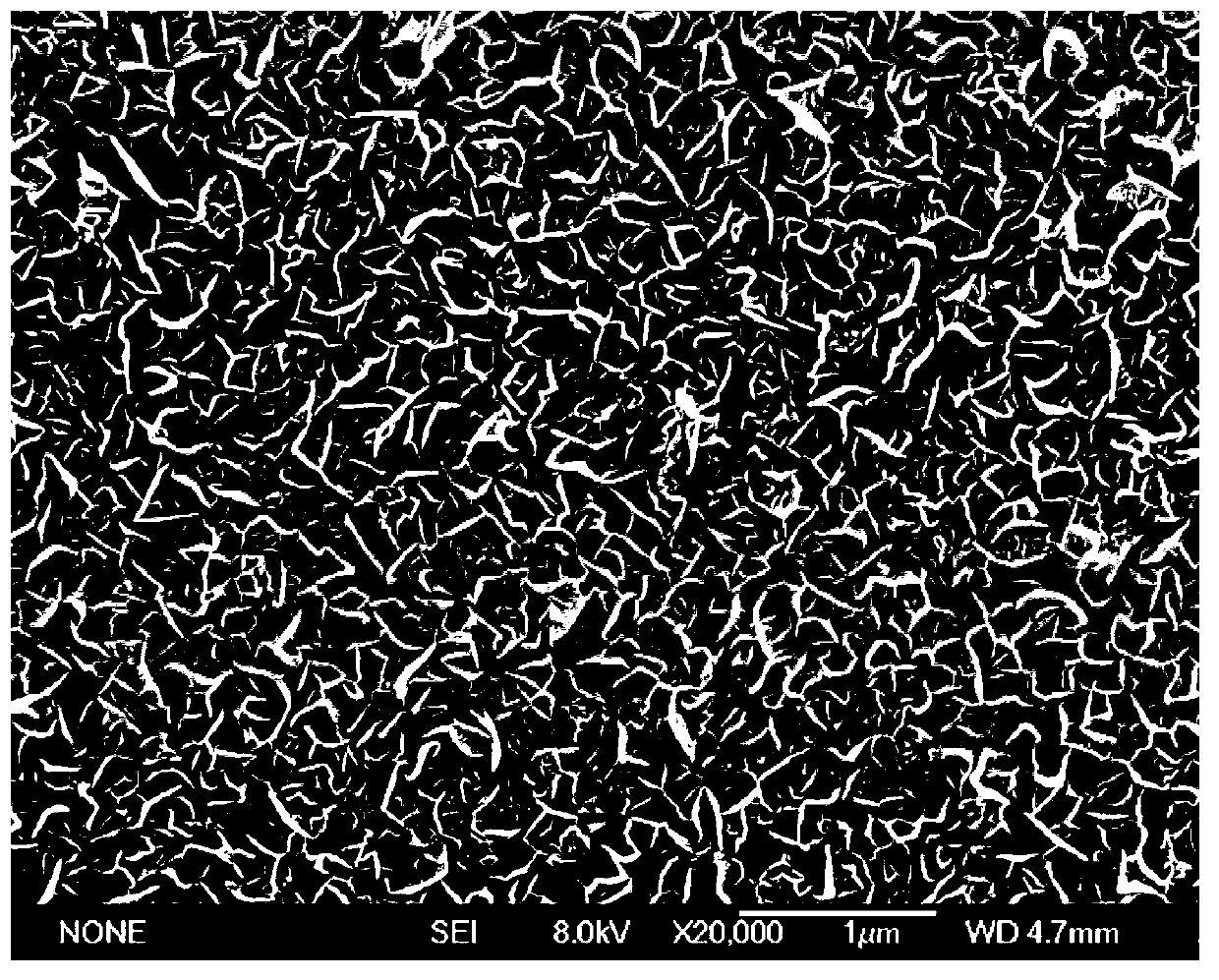

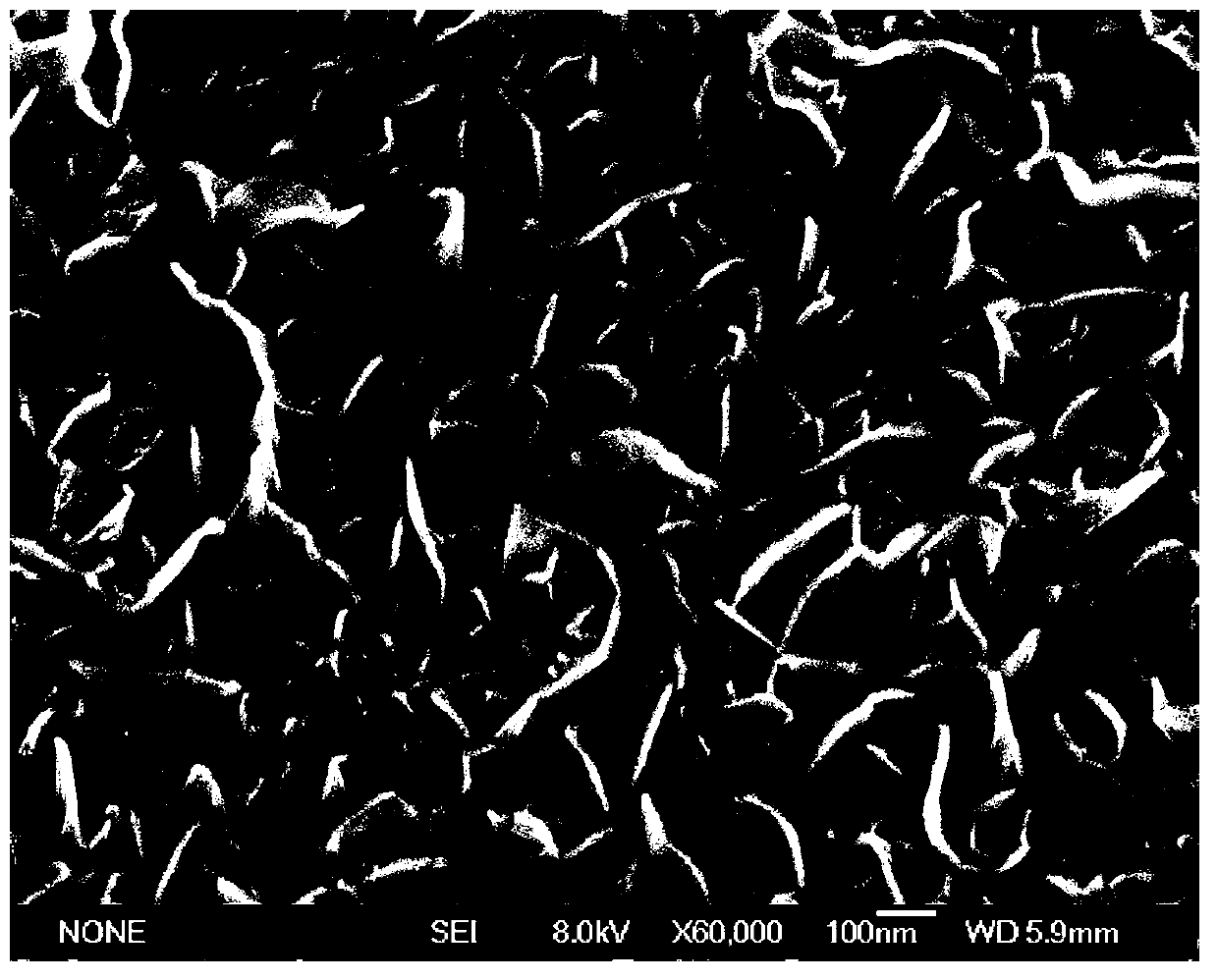

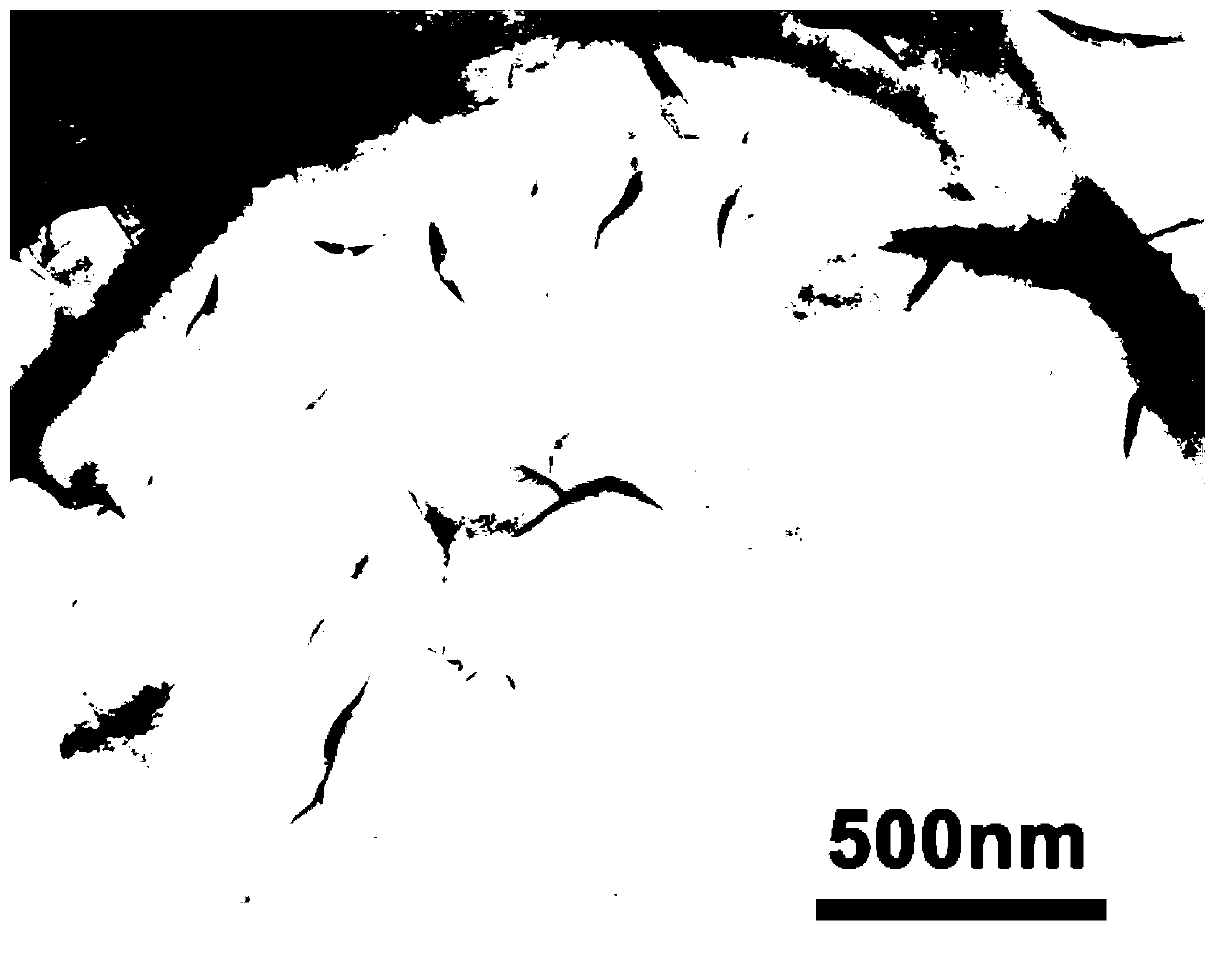

Image

Examples

specific Embodiment approach 1

[0019] Specific implementation mode one: the graphene-assisted brazing method of ceramic matrix composite material and metal material in this implementation mode is realized according to the following steps:

[0020] 1. Put the ceramic matrix composite material into the plasma-enhanced chemical vapor deposition equipment, evacuate to below 5Pa, and pass in the protective gas H 2 and Ar gas, adjust the H 2 The flow rate is 10-50sccm, the Ar flow rate is 10-50sccm, the protective gas pressure is 100-500Pa, and then the working temperature is raised to 500-1000°C. After reaching the working temperature, turn on the RF power supply, adjust the RF power to 200W, and process for 10-30min Perform plasma surface treatment;

[0021] 2. After the surface treatment is finished, turn off the RF power supply and switch on CH 4 Gas, Regulated CH 4 The flow rate is 10-50sccm, the Ar flow rate is 50-100sccm, adjust and maintain the working pressure at 100-500Pa, turn on the RF power supply...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the ceramic matrix composite material is SiO 2 ceramic matrix composites, Si 3 N 4 Ceramic matrix composites, SiC ceramic matrix composites, quartz fiber woven ceramic matrix composites or SiC fiber reinforced ceramic matrix composites. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the metal material is metal niobium, titanium alloy or Invar alloy. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com