Liquid mixing and temperature adjusting method of cooling process of heat transformation

A cooling process and heat technology, applied in the field of heat exchange, can solve complex and difficult problems, and achieve the effect of meeting the requirements of engineering use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

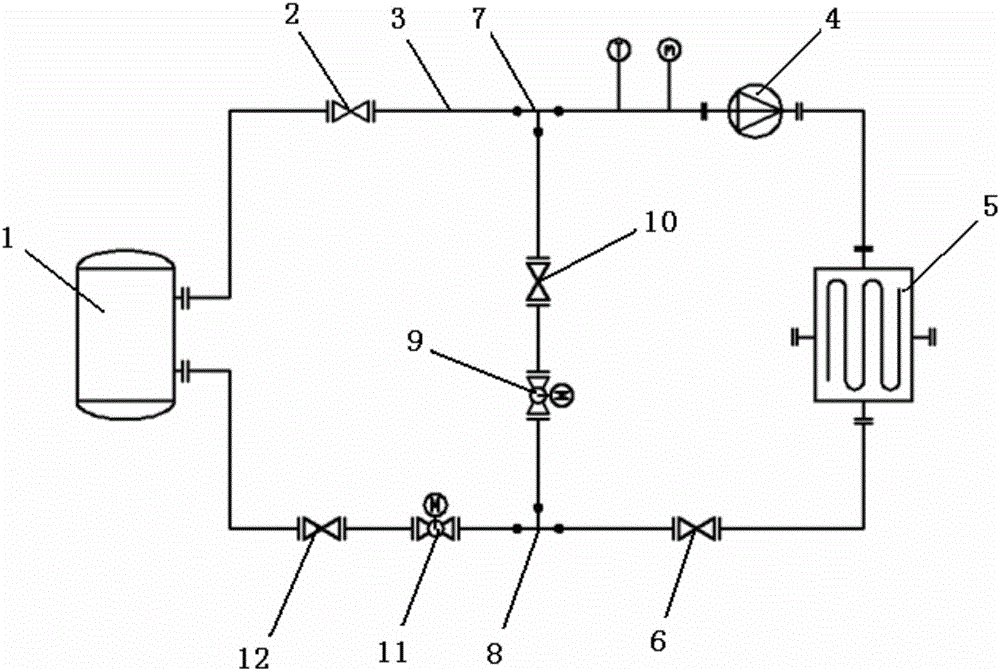

[0012] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

[0013] See attached figure 1 As shown, the mixed liquid temperature adjustment method of the heat-changing cooling process, the heat-changing cooling cycle process is as follows: the cold fluid flows through the pipeline 3 from the constant-low temperature storage tank 1, the shut-off valve I2, and the circulation pump 4 to the heat exchanger 5. After the heat exchanger 5 completes the heat conversion, it flows back to the constant-low temperature storage tank 1 through the shut-off valve II6. In this circuit, a temperature measuring point and a flow measuring point are set at the inlet of the circulating pump 4. It is characterized in that : On the pipeline 3 between the cut-off valve I2 and the circulation pump 4, a three-way I7 is set to form a liquid return branch road, and the other end of the liquid return branch road i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com