Microalloyed iron-based composite powder for diamond products and preparation method thereof

A technology of composite powder and pre-alloyed powder, which is applied in metal processing equipment, transportation and packaging, etc., and can solve problems such as environmental pollution, sharpness reduction, and complicated preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

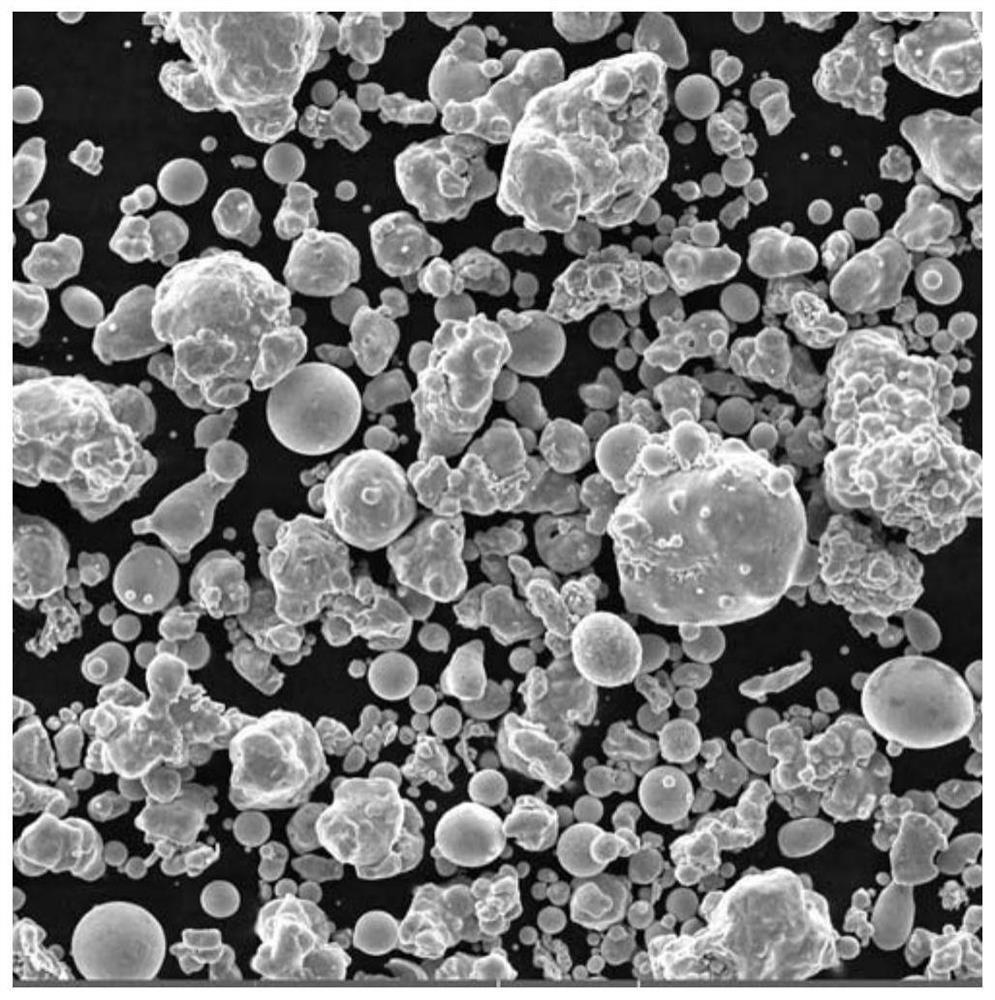

[0027] The preparation of embodiment 1 Fe-based pre-alloyed powder (1)

[0028] A medium frequency induction smelting furnace with a capacity of 250kg is used, and the composition ratio is 98.8% Fe, 0.3% Si, 0.6% Mn, 0.3% rare earth, and a furnace charge with a total weight of 200kg is prepared. The weight of raw materials is as shown in Table 1:

[0029] Table 1 Embodiment 1 Raw materials and feeding weight ratio

[0030] raw material Fe block Si block Mn block rare earth block gross weight Weight (kg) 197.6 0.6 1.2 0.6 200

[0031] Add Fe, Si, Mn, and rare earth to the medium-frequency induction furnace in turn, energize to melt and refine, add 0.2% carbon powder of the total weight of the smelt to deoxidize, adjust the superheat of the melt to 150-200°C, and pour it into the tundish , After the melt passes through the leakage hole at the bottom of the bag, it is crushed by high-pressure water, and atomized into powder in the atomizing barr...

Embodiment 2

[0034] The preparation of embodiment 2Fe base pre-alloyed powder (2)

[0035] A medium-frequency induction smelting furnace with a capacity of 250kg is used, and the composition ratio is 99.75% Fe, 0.1% Si, 0.1% Mn, and 0.05% rare earth. The total amount of feed is 200kg, and the ratio of raw materials and weight is shown in Table 3 below:

[0036] Table 3 Embodiment 2 raw materials and weight proportion

[0037] raw material Fe block Si block Mn block rare earth block gross weight Weight (kg) 199.5 0.2 0.2 0.1 200

[0038] Add Fe, Si, Mn, and rare earth to the medium-frequency induction furnace in turn, energize to melt and refine, add 0.2% carbon powder of the total weight of the smelt to deoxidize, adjust the superheat of the melt to 150-200°C, and pour it into the tundish , After the melt passes through the leakage hole at the bottom of the bag, it is crushed by high-pressure water, and atomized into powder in the atomizing barrel filled...

Embodiment 3

[0041] The preparation of embodiment 3 Fe-based pre-alloyed powder (3)

[0042] Use a 250kg intermediate frequency induction smelting furnace, the composition ratio is 99.4% Fe, 0.2% Si, 0.3% Mn, 0.1% rare earth, and the total weight of the feed is 200 kg. The raw materials and feed weight are shown in Table 5:

[0043] Table 5 Embodiment 3 raw materials and weight ratio

[0044] raw material Fe block Si block Mn block rare earth block gross weight Weight (kg) 198.8 0.4 0.6 0.2 200

[0045] Add Fe, Si, Mn, and rare earth to the medium-frequency induction furnace in turn, energize to melt and refine, add 0.2% carbon powder of the total weight of the smelt to deoxidize, adjust the superheat of the melt to 150-200°C, and pour it into the tundish , After the melt passes through the leakage hole at the bottom of the bag, it is crushed by high-pressure water, and atomized into powder in the atomizing barrel filled with nitrogen protection. The pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com