A kind of gradient material method brazing method for stainless steel and hard alloy

A technology of cemented carbide and gradient materials, applied in the direction of welding medium, welding/cutting medium/material, welding equipment, etc., can solve the problems of large residual stress in welded joints, etc., to ensure welding quality, improve mechanical properties, and eliminate welding defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

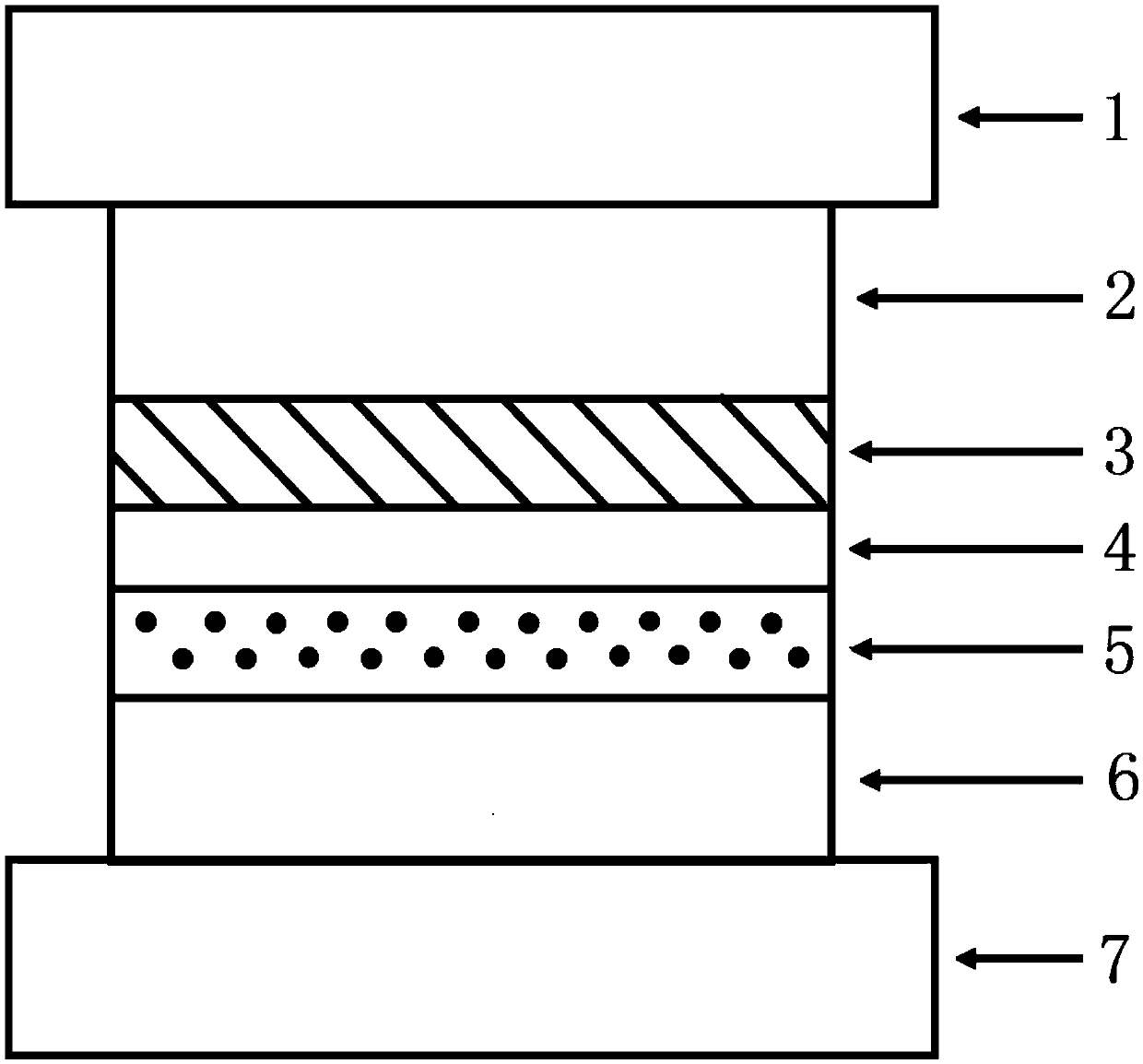

[0026]Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is a method for brazing stainless steel and cemented carbide by gradient material method. The method is specifically carried out according to the following steps:

[0027] 1. Add 10-30wt% reinforcement particles to the solder powder to obtain composite solder powder with high reinforcement content, and add 1-10 wt% reinforcement particles to the solder powder to obtain composite solder powder with low reinforcement content powder;

[0028] 2. Put the composite solder powder with high reinforcement content and the composite solder powder with low reinforcement content into the stainless steel mixing tank respectively, and stir for 1 to 3 hours at a speed of 250 to 300 rpm;

[0029] 3. Put the composite solder powder with high reinforcement content and the composite solder powder with low reinforcement content obtained in step 2 respectively into a mortar, and add 1 to 10 wt% liqu...

specific Embodiment approach 2

[0039] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the solder powder in step 1 is Ni-Cr-B-Si alloy powder, Ni-Cr-B-Si-Mo alloy powder or Ni-Cr - B-Si-Mo-Cu alloy powder. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the reinforcement particles in Step 1 are SiC particles, WC particles or Cr particles. 3 C 2 particles. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com