Manufacturing method of strengthened valve tappet

A technology of phosphating treatment and laser heat treatment, which is applied in the direction of coating and metal material coating process, can solve the problems of limited improvement and achieve the effects of eliminating pores, good wear resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention discloses a method for preparing a reinforced tappet, comprising the following steps:

[0033] Clean the working surface of the tappet, and carry out phosphating treatment on the working surface of the tappet after cleaning;

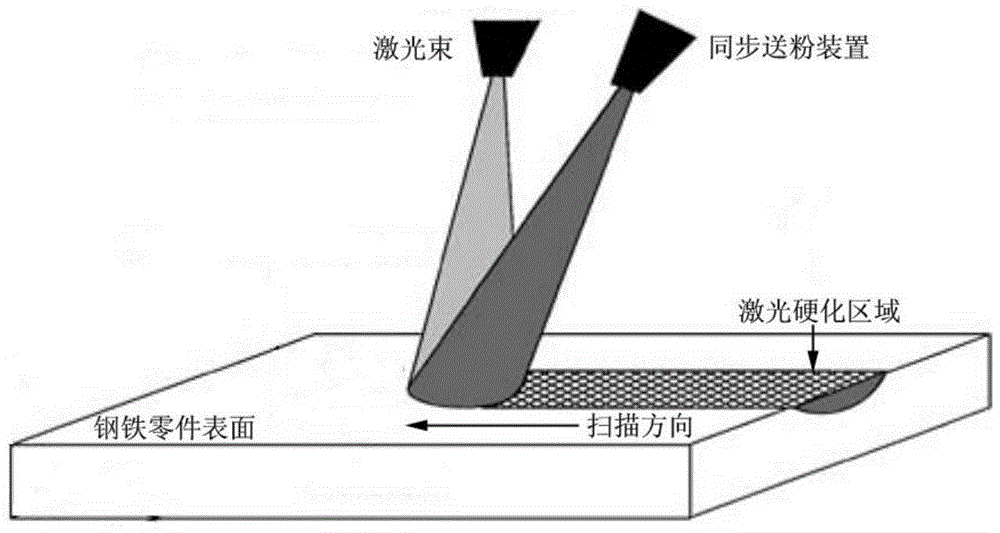

[0034] The working surface of the phosphating tappet is subjected to laser heat treatment to obtain a strengthened tappet;

[0035] The laser heat treatment is laser quenching treatment, laser remelting treatment or laser cladding treatment;

[0036] The laser power of the laser quenching treatment is 1000-3000W, the spot diameter is 1.0-5.0mm, the scanning speed is 500-1500mm / min, and the overlap rate is 20%-50%;

[0037] The laser power of the laser remelting treatment is 1500-3500W, the spot diameter is 1.0-5.0mm, the scanning speed is 100-1000mm / min, and the overlapping rate is 20%-50%;

[0038] The laser power of the laser cladding treatment is 1500-3500W, the spot diameter is 1.0-5.0mm, the scanning ...

Embodiment 1

[0065] The bottom surface of the 45 steel tappets to be treated is cleaned and pretreated with alcohol to remove surface oil; the pretreated bottom surface of the tappets is phosphated, and the bottom surface of the tappets is immersed in the phosphating solution for 5 to 10 minutes, and the residual liquid on the surface is washed with water , dry or wipe the surface with a dry cloth;

[0066] Laser quenching treatment is carried out on the bottom surface of the tappet after phosphating treatment, and the parameters of the laser quenching treatment are shown in Table 1;

[0067] The laser-strengthened tappet can be obtained by fine grinding the bottom surface of the tappet after laser quenching treatment.

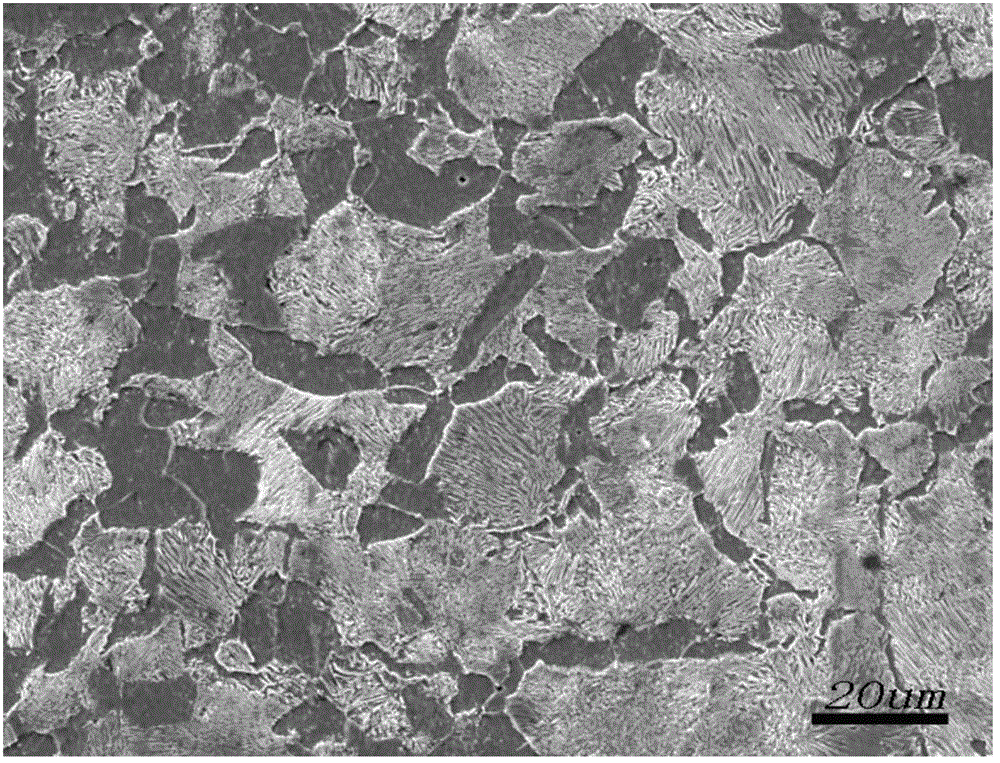

[0068] The performance of the tappet prepared in this example was tested, and the results are shown in Table 3. During the adhesive wear test on the surface of the tappet, the load was 200N and the duration was 1h, so as to measure the wear quality of the tappet. figure ...

Embodiment 2

[0070] The bottom surface of the 45 steel tappet to be treated is cleaned and pretreated with acetone to remove surface oil; the pretreated bottom surface of the tappet is phosphated, and the bottom surface of the tappet is immersed in the phosphating solution for 5 to 10 minutes, and the residual liquid on the surface is washed with water , dry or wipe the surface with a dry cloth;

[0071] Laser quenching treatment is carried out on the bottom surface of the tappet after phosphating treatment, and the parameters of the laser quenching treatment are shown in Table 1;

[0072] The laser-strengthened tappet can be obtained by fine grinding the bottom surface of the tappet after laser quenching treatment.

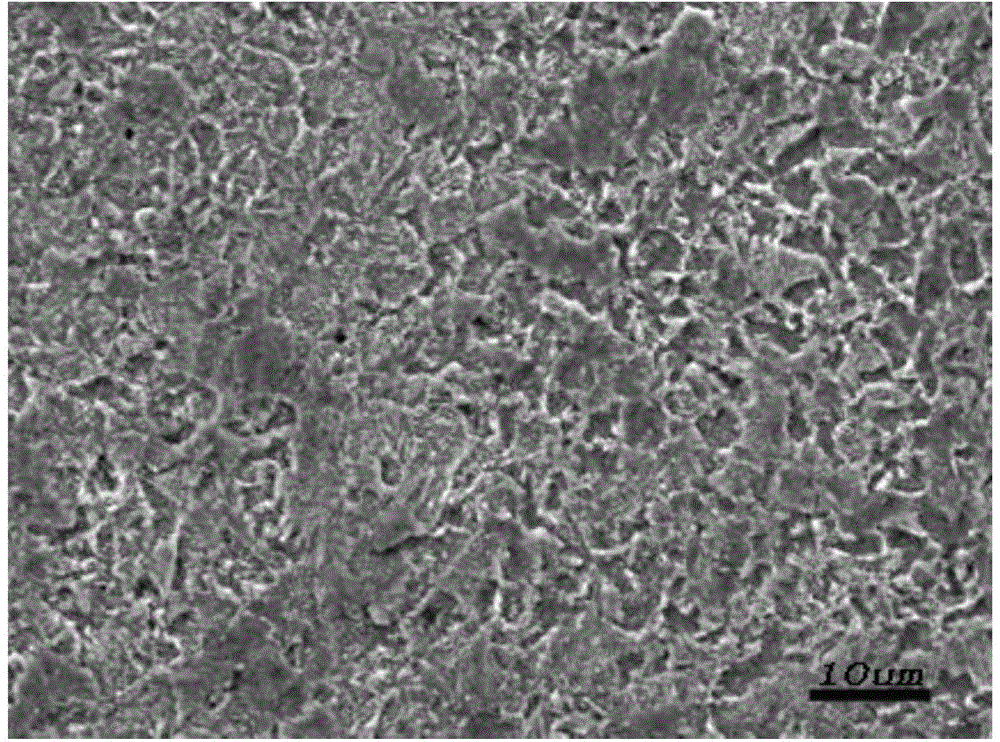

[0073] The performance of the tappet prepared in this embodiment was tested, and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com