Spiral seam submerged-arc welded pipe butt joint process

A technology of submerged arc welded pipe and spiral seam, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of substandard steel pipe length, reduced yield and reduced yield, etc., to improve performance and reduce welding lines. Effects of energy, reduced tissue and performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

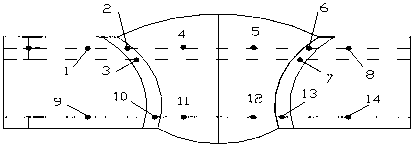

[0018] In this embodiment, the outer diameter of the steel pipe is F1016 mm, the wall thickness is 14.3 mm, and the manufacturing process steps of the butt joint of the material X70 steel grade spiral seam submerged arc welded pipe are as follows (see Table 1 for specific process parameters):

[0019] 1. Pipe end rounding and chamfering: transfer two short pipes that meet the standard length, round the end of the steel pipe, and then pour out the blunt edge size of 7mm through the chamfering equipment, the bevel angle is 25°, and the pipe sections are butted Finally, a 50° Y-shaped groove is formed.

[0020] 2. Steel pipe butt joint: Find the joint position of the two pipe sections on the frequency conversion driven rotating idler to ensure that the circumferential interval of the spiral weld at the pipe end meets the standard requirements (API Spec 5L requires that the minimum circumferential interval should be 50mm, West Gas East Input requirements 160mm ~ 800mm).

[0021] ...

Embodiment 2

[0040] In this embodiment, the outer diameter of the steel pipe is F1219mm, the wall thickness is 18.4mm, and the material is X80 steel grade spiral seam submerged arc welded pipe butt joint manufacturing. The manufacturing process steps of the submerged arc welded pipe are the same as in Example 1, and its specific implementation parameters are shown in Table 6 shown.

[0041] Table 6 Process parameters

[0042]

[0043] Table 7 Tensile test

[0044]

[0045] Table 8 Guided bending test

[0046]

[0047] Table 9 Impact toughness test

[0048]

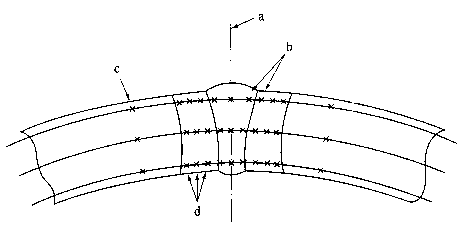

[0049] Hardness measurement detection location map, as attached figure 2 shown;

[0050] Table 10 Hardness measurement results (ASTM E92-03)

[0051]

[0052] Provided in Table 7-10 are the main performance test results and main performance requirements of the actual object of the butt girth weld in this embodiment. It can be seen from the table that the butt girth weld of the spiral submerged arc welded pipe manufac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com