Spindle system for realizing friction surfacing with shaft shoulder

A technology of friction stacking and belt shaft, which is applied in the direction of welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of reduced connection strength, waste of surfacing materials, and low utilization rate of round bar consumables, etc., to increase the axial pressure , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

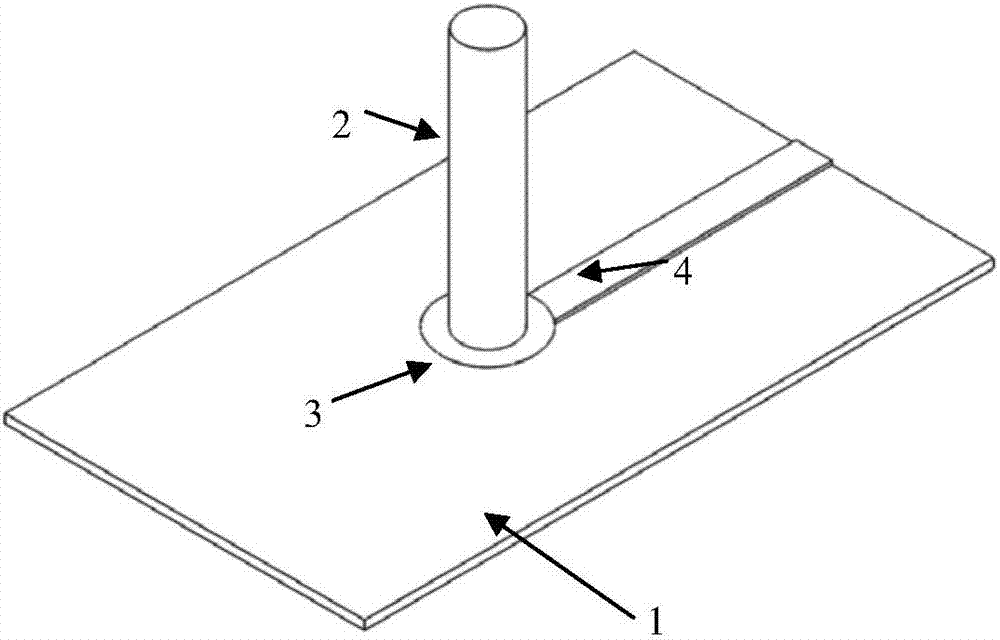

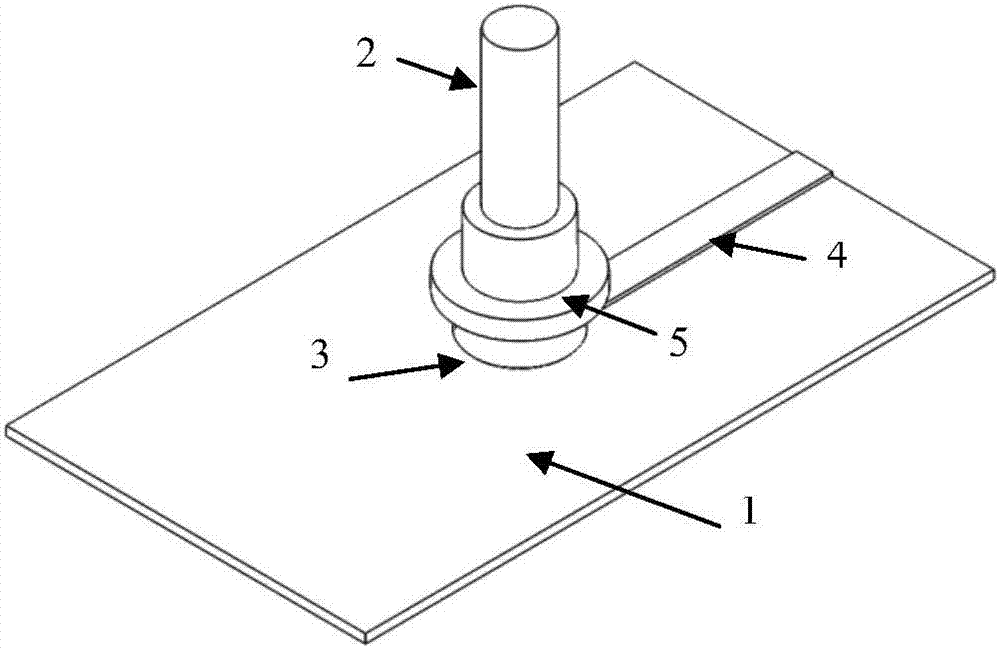

[0041] figure 1 Shown is the traditional friction surfacing process. During the surfacing process, the round bar consumable 2 is rotating at a high speed, applying axial pressure, upsetting and pressing the substrate surface 1, and moving laterally along the substrate surface 1. Due to the rotation friction heating and The upsetting pressure acts on the friction interface to form consumable material flash 3 , and at the same time, the consumable material gradually transitions to the substrate surface 1 to form a surfacing layer 4 . In this process, the friction surface of the consumables is completely free and has no restrictions. The consumables are not only subjected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com