Metal oxide dispersion, metal oxide electrode film, and dye sensitized solar cell

A technology for solar cells and dye sensitization, which is applied in the field of metal oxide dispersions and can solve problems such as high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

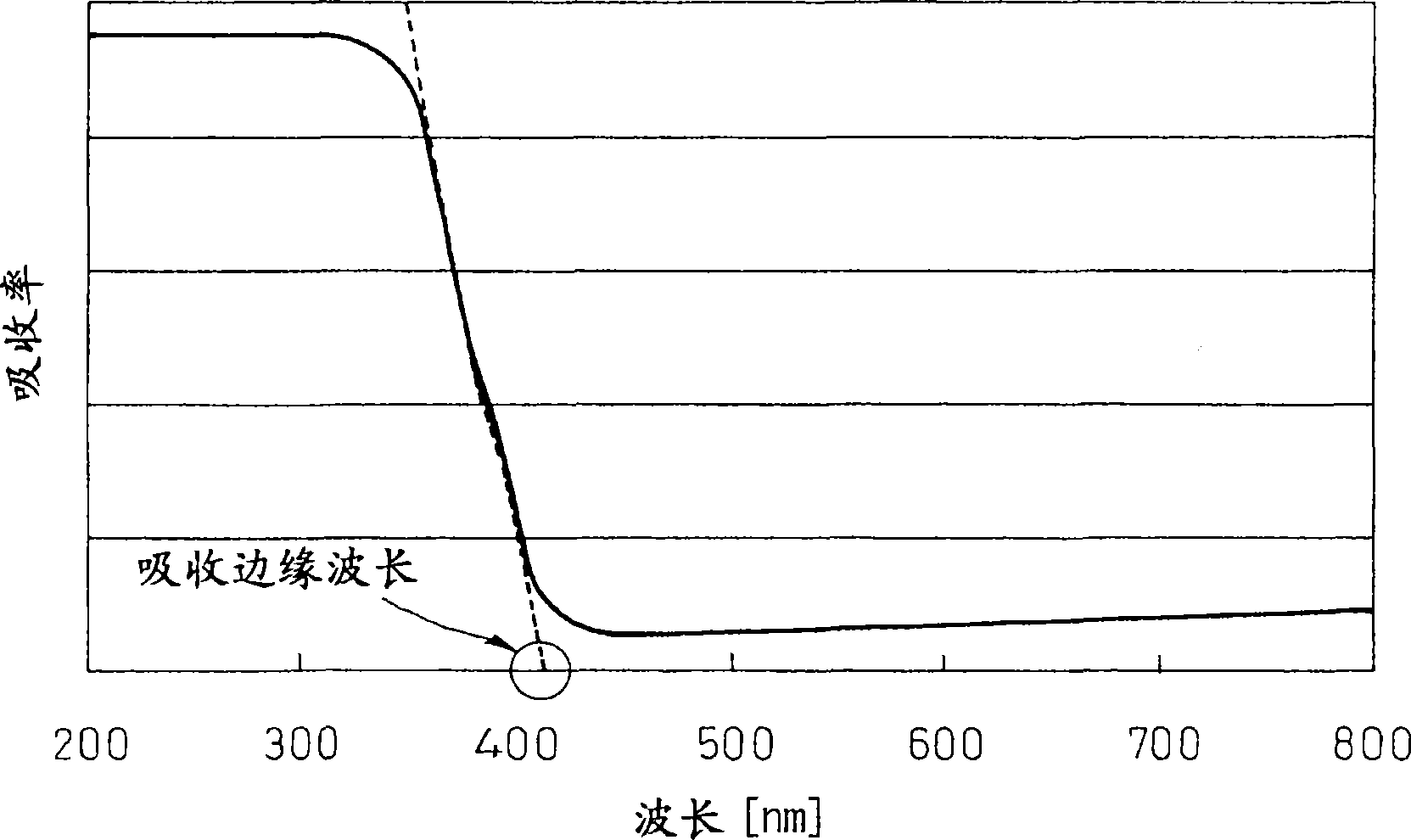

[0259] As the sensitizing dye supported on the surface of the metal oxide, dyes used in dye-sensitized solar cells can be widely used. Specific examples thereof include: ruthenium-biphenylazobisaminopyridine (bipyridium) complex, xanthene dyes, merocyanine dyes, porphyrin derivatives, and phthalocyanine derivatives. The sensitizing dye is loaded onto the photosensitive electrode by a generally used method of dissolving the sensitizing dye in alcohol and immersing the photosensitive electrode in the resulting solution. For the counter electrode used here, a material having a resistance of 2000Ω / □ or less and having catalytic activity can be used, and there is no limitation on whether it is transparent or not. Catalytic activity here refers to the electrolyte acting to reduce oxidation at the photosensitive electrode when a small overvoltage is applied across the counter electrode. In particular, platinum, ruthenium, graphite and carbon black have this function. Therefore, the...

example 1

[0311] Example 1: Dispersion including ethanol

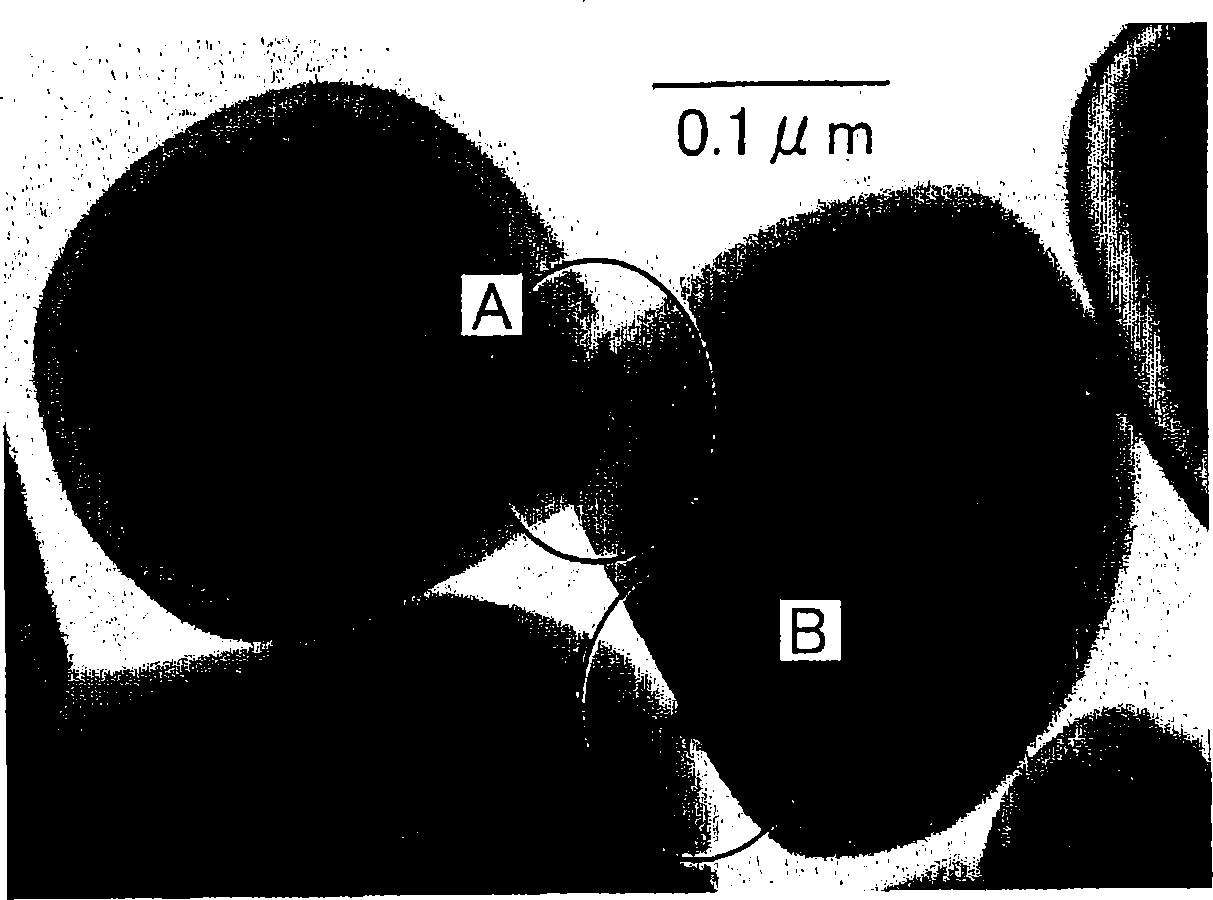

[0312] 800cm in ball mill (AV, manufactured by Asahi Rika Seisakusho) 3 Add in the polyethylene container (ф96 * 133mm) of volume: 3g liquid-phase process titanium dioxide (Supertitania (registered trademark) G-2, manufactured by Showa Denko K.K.), its average primary particle diameter is 500nm; 9g titanium dioxide (Supertitania (registered trademark) ) F-4, manufactured by the same company), its average primary particle diameter is 30nm; 30g liquid phase process titanium dioxide sol; 2g water-soluble 1% N-vinylacetamide-sodium acrylate copolymer (VIAC GE-195, by Showa Denko K.K.) solution, 6 g of water, 50 g of ethanol (pure chemical reagent), and 500 g of 3ф zirconia balls were mixed at a rotation speed of 80 rpm for 12 hours to obtain a titanium dioxide liquid dispersion.

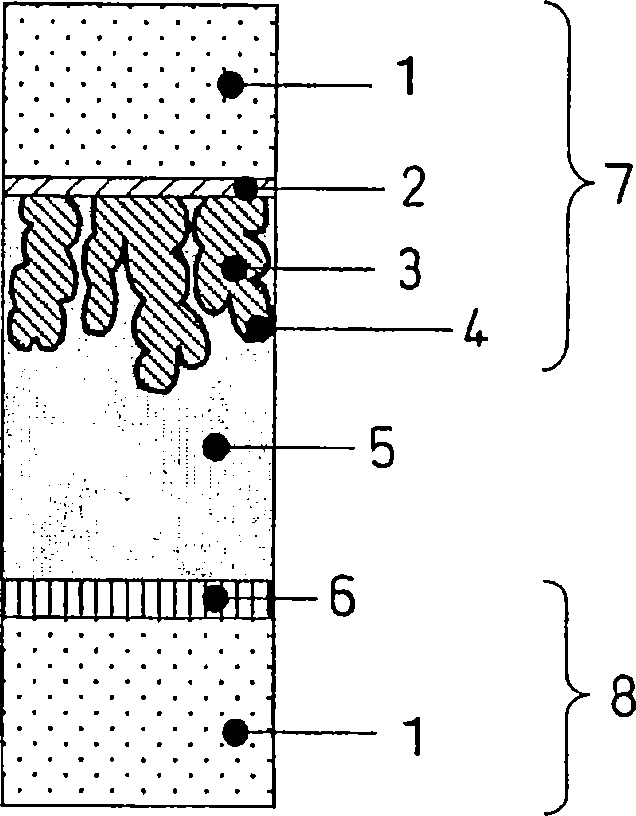

[0313] Two sheets of transparent conductive resin substrates (OTEC-110, manufactured by Tobi Co., Ltd., thickness: 125 μm) were prepared, and a contact a...

example 2

[0316] Example 2: Dispersion including butanol

[0317] Contact angles were evaluated, and solar cells were manufactured and evaluated in the same manner as in Example 1, except that 40 g of 2-methyl-2-propanol and 10 g of ethanol were used instead of 50 g of ethanol. However, the dispersions obtained are highly viscous and can be applied by rolling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com