Patents

Literature

43 results about "Merocyanine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Merocyanines pertain to the class of polymethine dyes which are clearly defined by a set structural properties. Merycyanines belong to the group of dyes referred to as functional dyes where their applications are not only determined by their colour but also their valuable chemical properties.

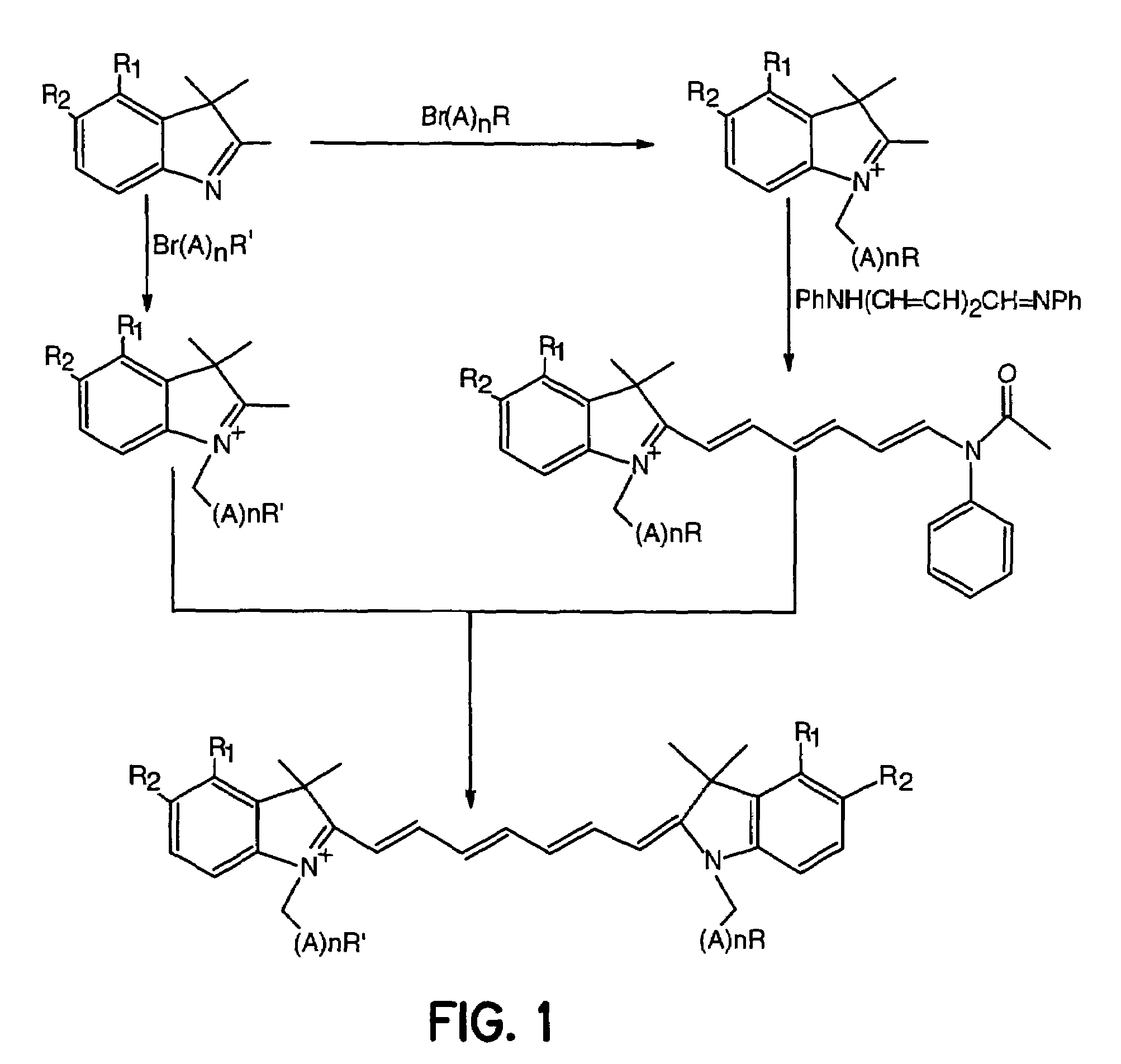

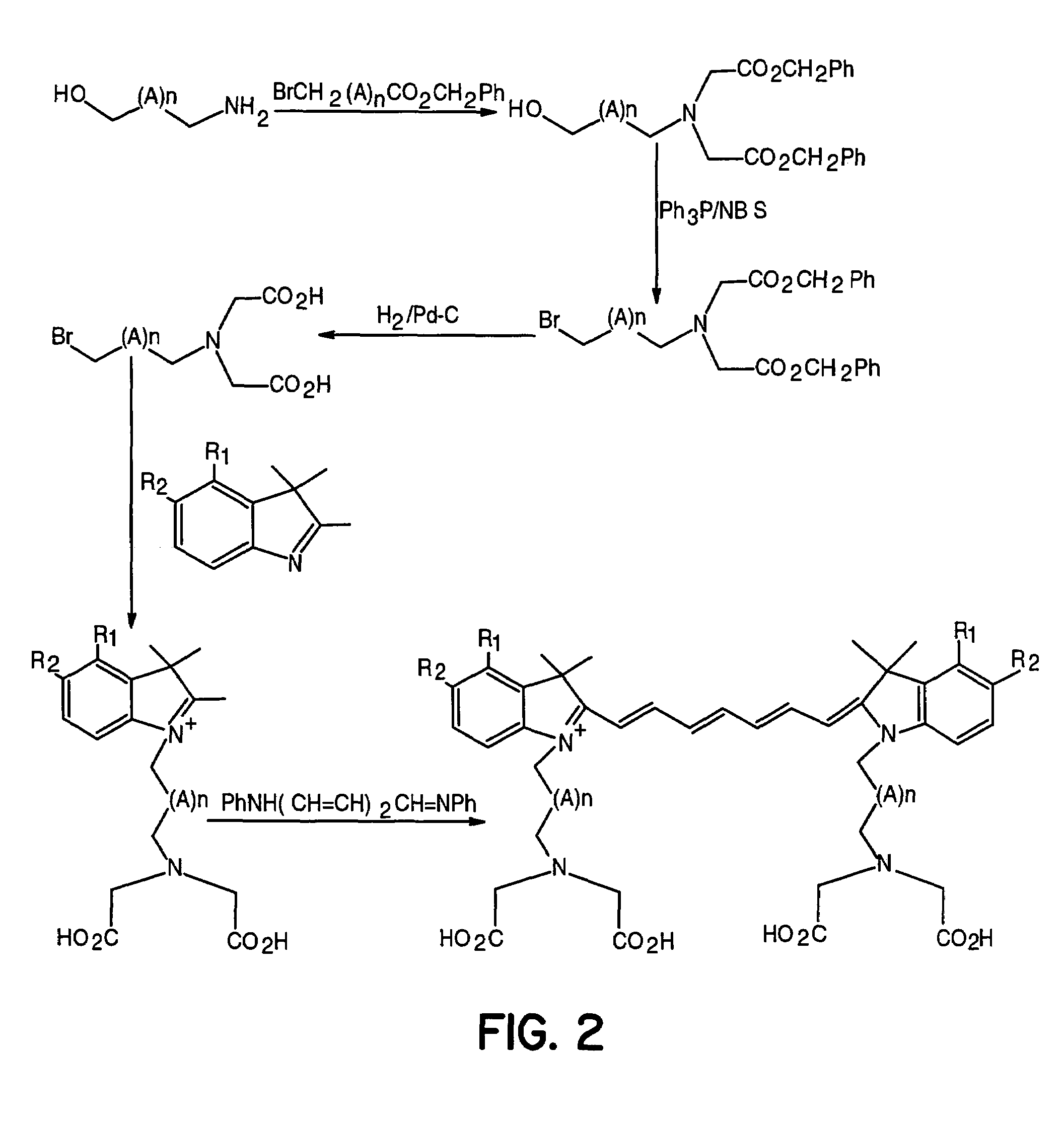

Cyanine dyes as labeling reagents for detection of biological and other materials by luminescence methods

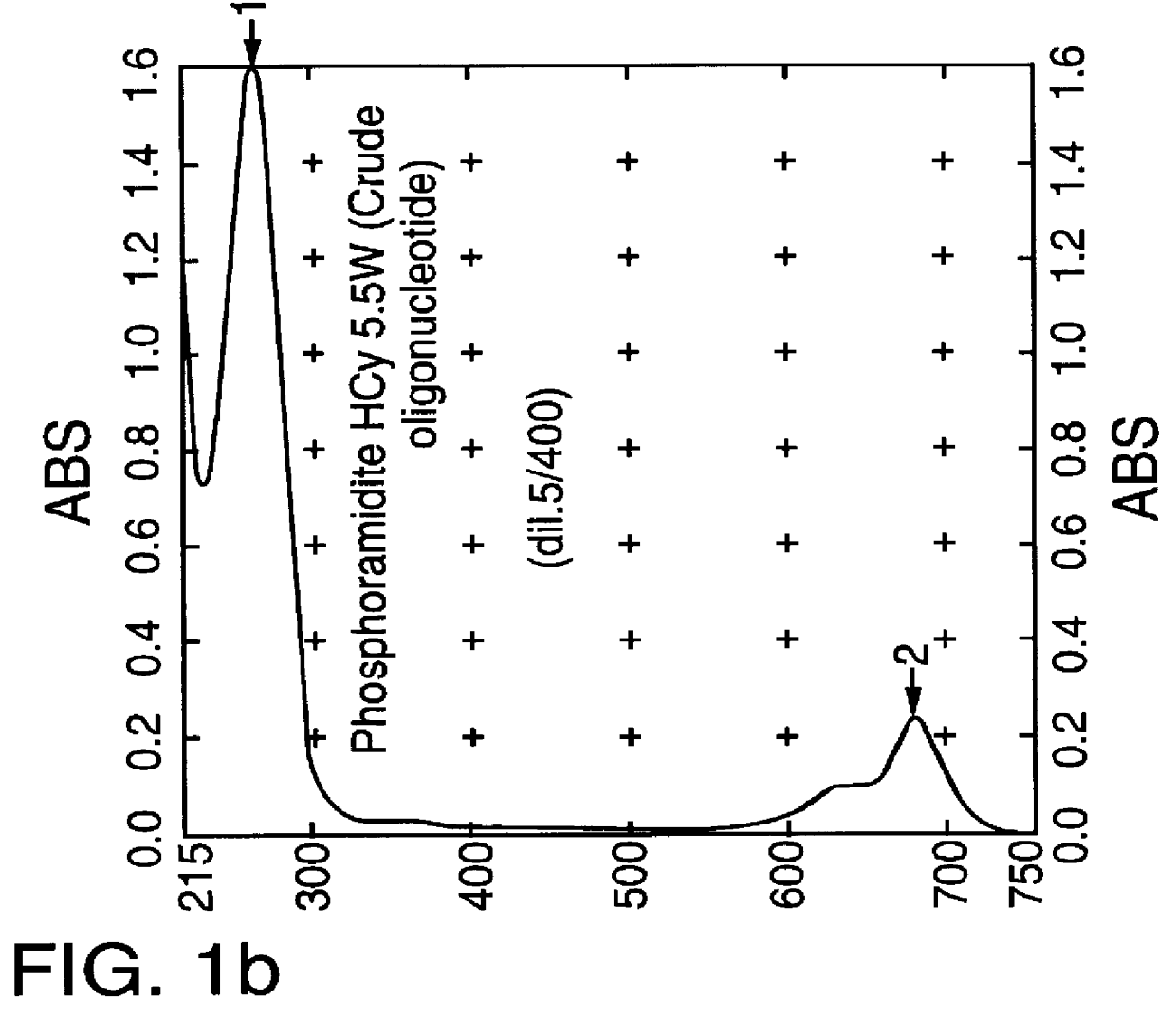

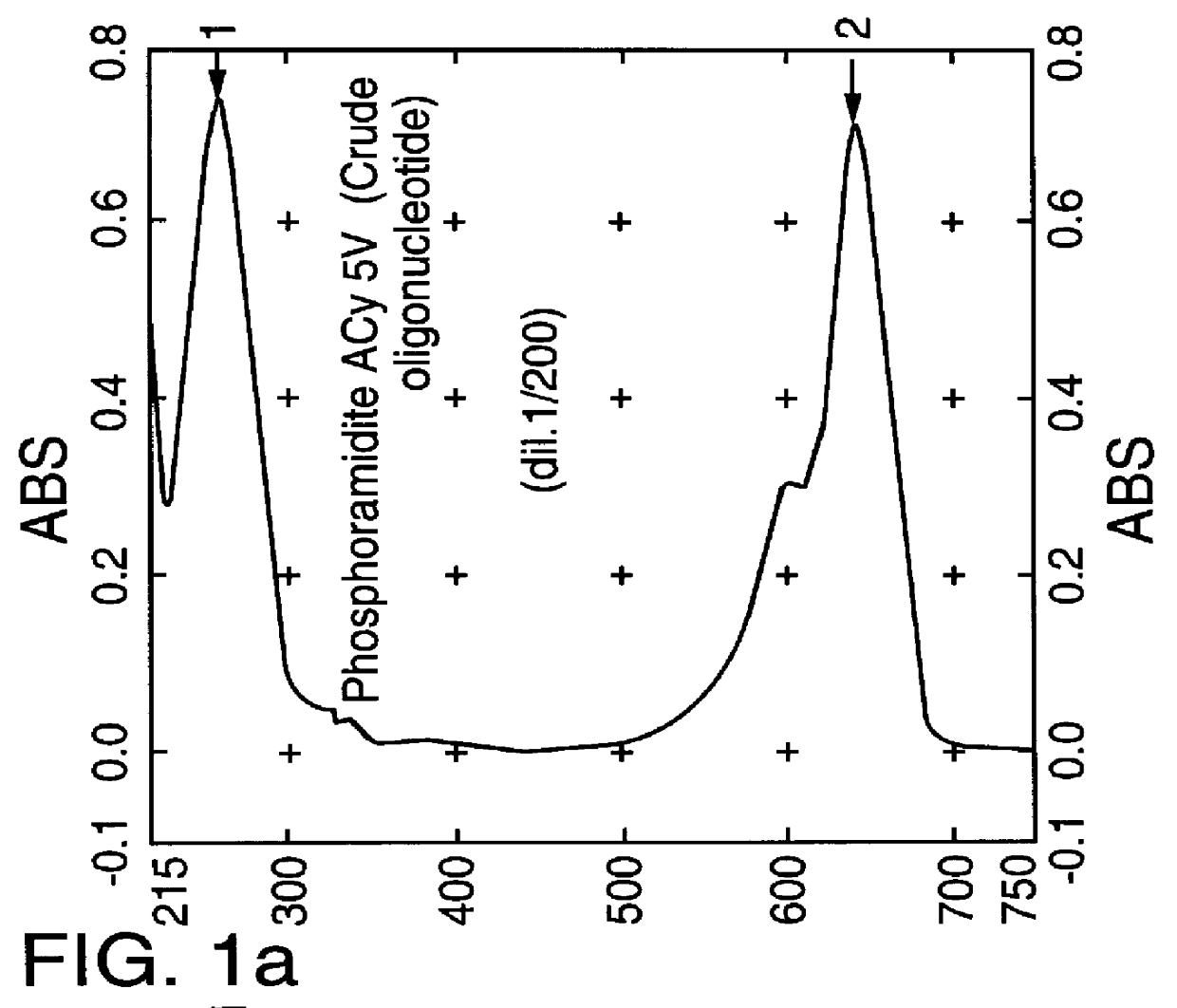

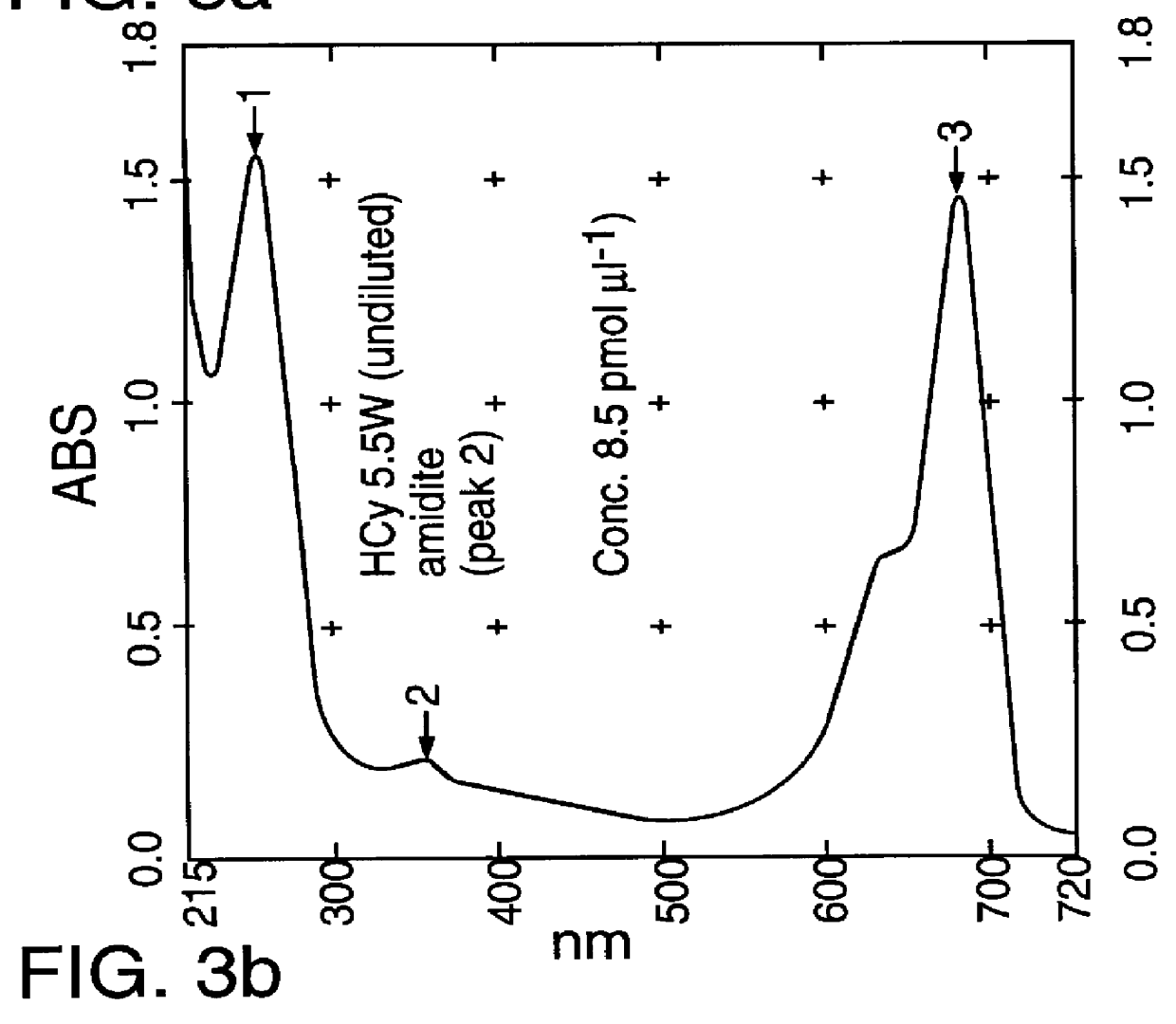

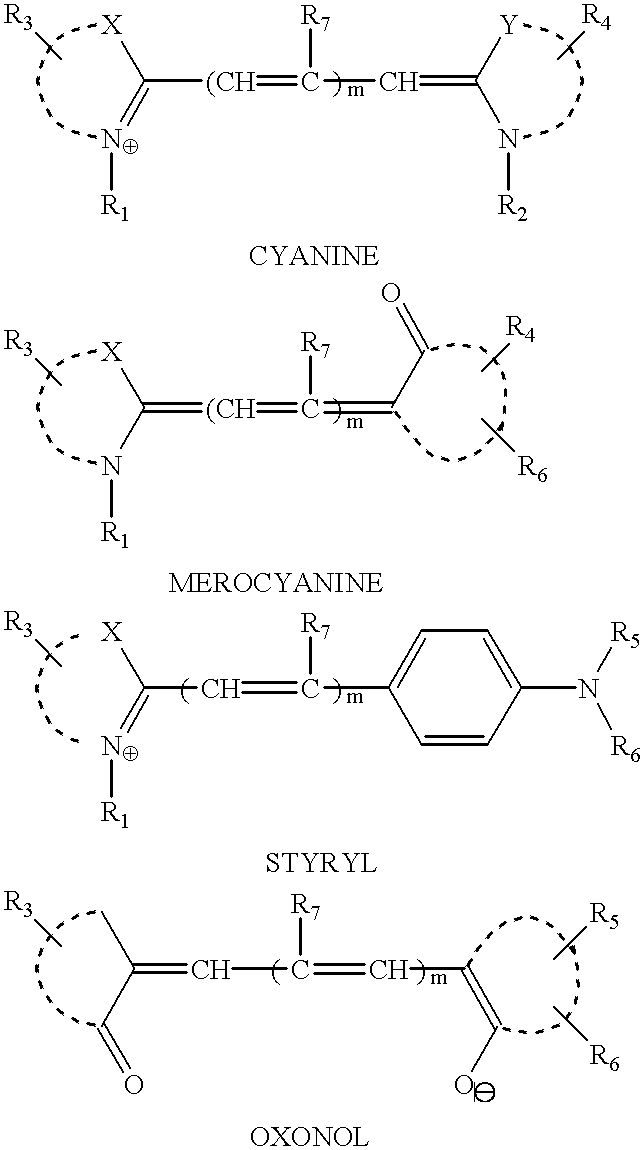

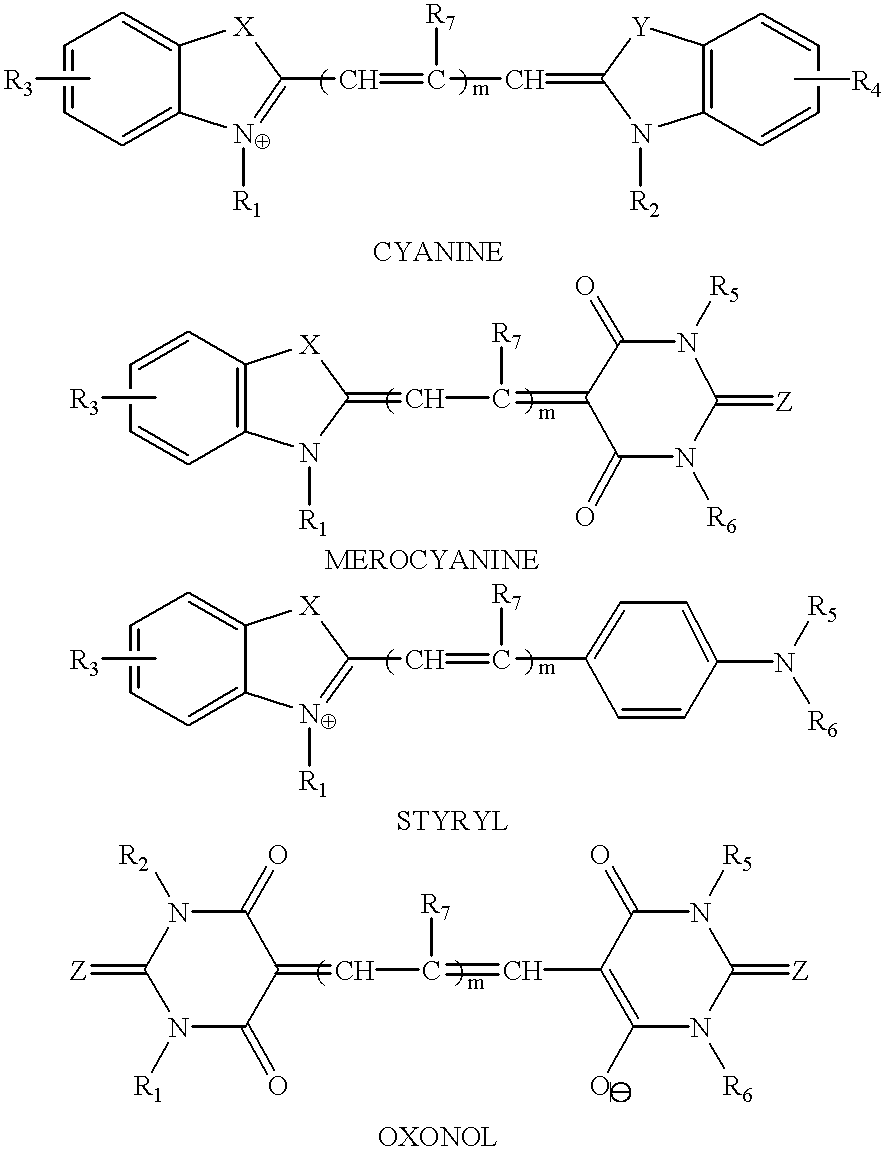

Cyanine and related dyes, such as merocyanine, styryl and oxonol dyes, are strongly light-absorbing and highly luminescent. Cyanine and related dyes having functional groups make them reactive with amine, hydroxy and sulfhydryl groups are covalently attached to proteins, nucleic acids, carbohydrates, sugars, cells and combinations thereof, and other biological and nonbiological materials, to make these materials fluorescent so that they can be detected. The labeled materials can then be used in assays employing excitation light sources and luminescence detectors. For example, fluorescent cyanine and related dyes can be attached to amine, hydroxy or sulfhydryl groups of avidin and to antibodies and to lectins. Thereupon, avidin labeled with cyanine type dyes can be used to quantify biotinylated materials and antibodies conjugated with cyanine-type dyes can be used to detect and measure antigens and haptens. In addition, cyanine-conjugated lectins can be used to detect specific carbohydrate groups. Also, cyanine-conjugated fragments of DNA or RNA can be used to identify the presence of complementary nucleotide sequences in DNA or RNA.

Owner:CARNEGIE MELLON UNIV

Cyanine dyes as labeling reagents for detection of biological and other materials by luminescence methods

Cyanine and related dyes, such as merocyanine, styryl and oxonol dyes, are strongly light-absorbing and highly luminescent. Cyanine and related dyes having functional groups make them reactive with amine, hydroxy and sulfhydryl groups are covalently attached to proteins, nucleic acids, carbohydrates, sugars, cells and combinations thereof, and other biological and nonbiological materials, to make these materials fluorescent so that they can be detected. The labeled materials can then be used in assays employing excitation light sources and luminescence detectors. For example, fluorescent cyanine and related dyes can be attached to amine, hydroxy or sulfhydryl groups of avidin and to antibodies and to lectins. Thereupon, avidin labeled with cyanine type dyes can be used to quantify biotinvlated materials and antibodies conjugated with cyanine-type dyes can be used to detect and measure antigens and haptens. In addition, cyanine-conjugated lectins can be used to detect specific carbohydrate groups. Also, cyanine-conjugated fragments of DNA or RNA can be used to identify the presence of complementary nucleotide sequences in DNA or RNA.

Owner:CARNEGIE MELLON UNIV

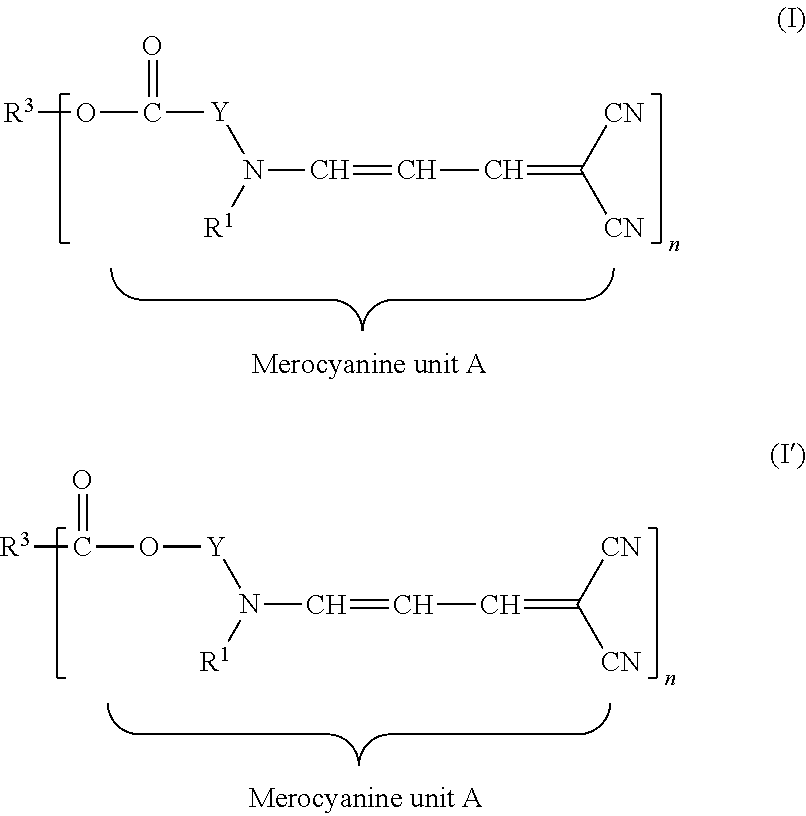

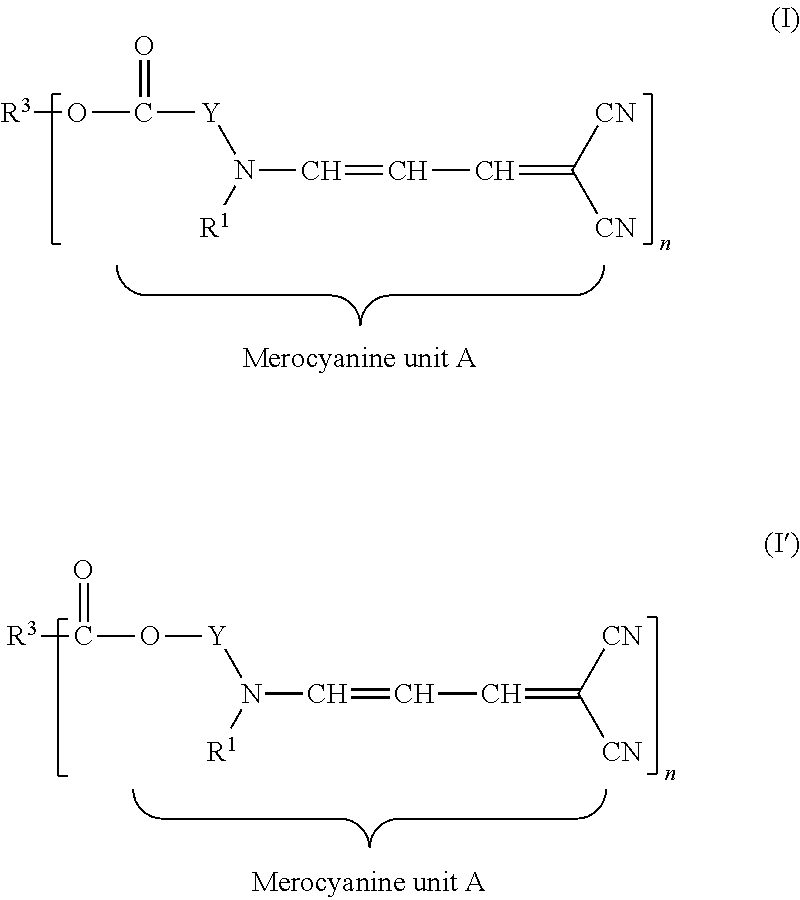

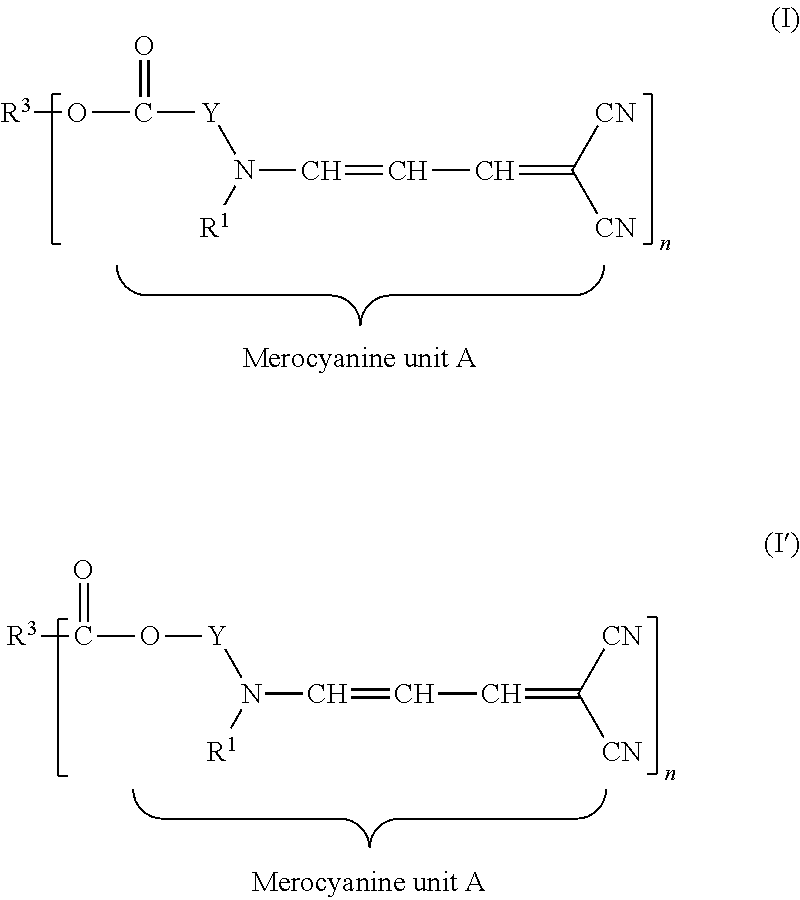

Polymer film, phase difference film, polarizing plate, liquid crystal display device, retardation inducing agent, and merocyanine-based compound

Owner:FUJIFILM CORP

Polymer film, phase difference film, polarizing plate, liquid crystal display device, retardation inducing agent, and merocyanine-based compound

ActiveUS20120329974A1Easy to produceHigh axial precisionLiquid crystal compositionsOrganic chemistryPolymer scienceLiquid-crystal display

Owner:FUJIFILM CORP

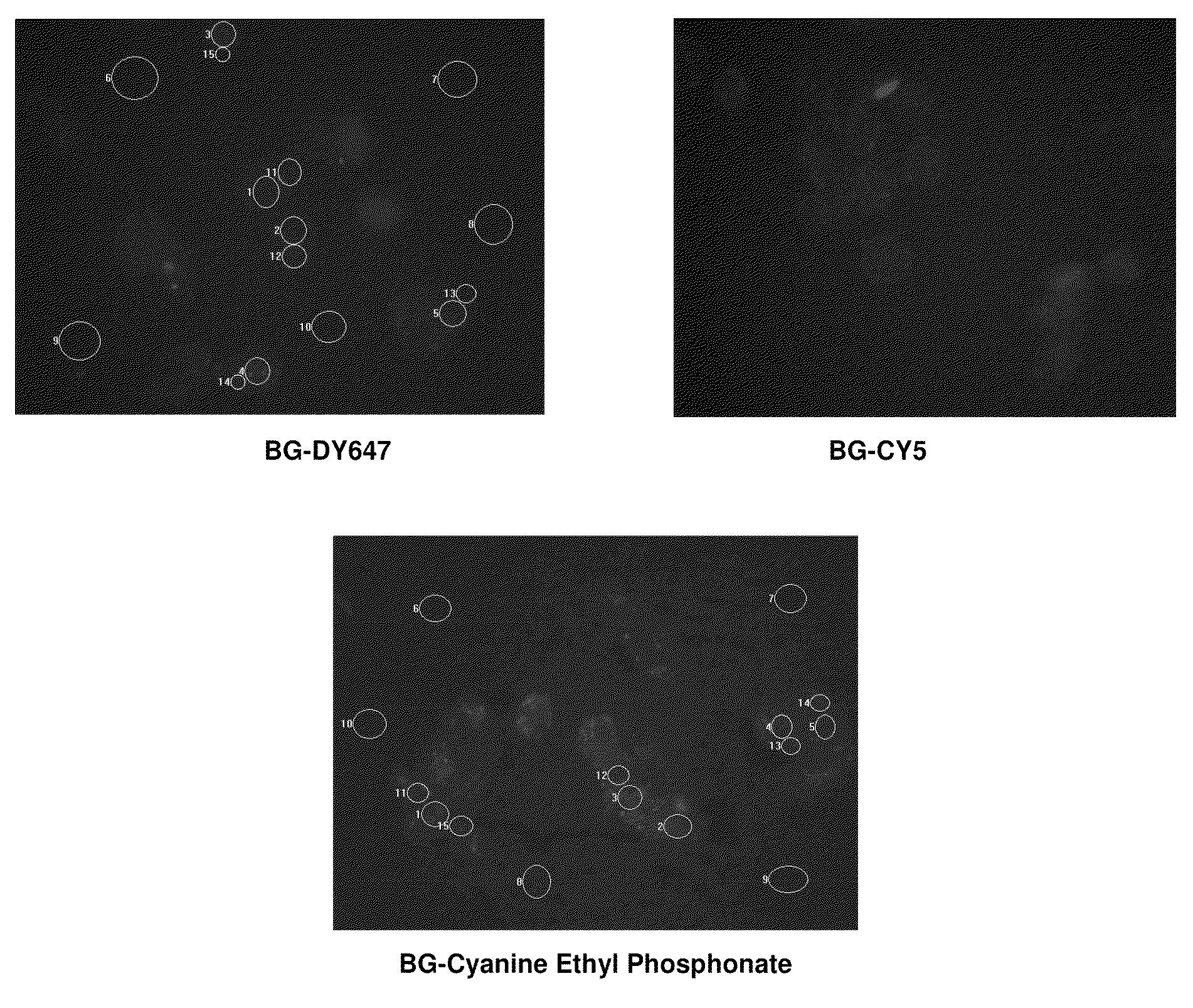

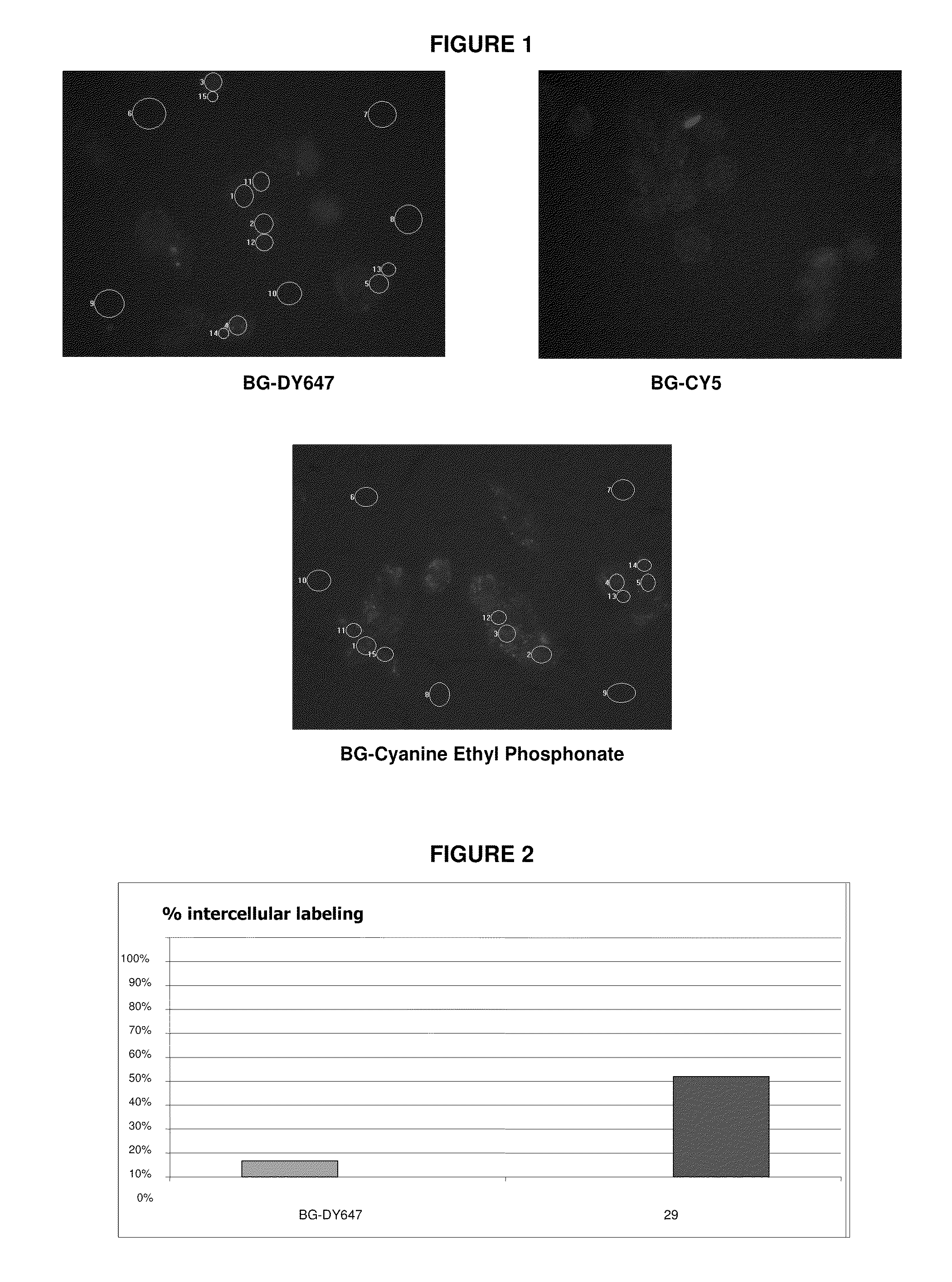

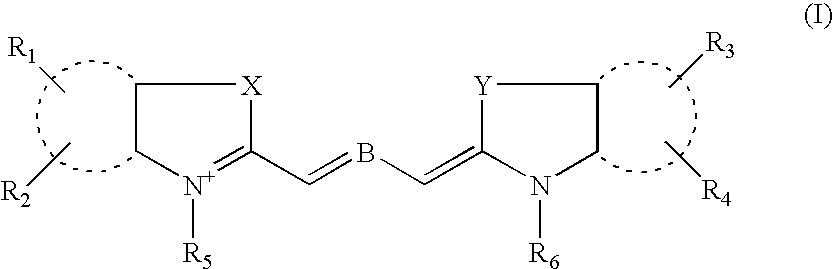

Cyanine derivatives, fluorescent conjugates containing same and use thereof

InactiveUS20100143960A1Microbiological testing/measurementPhosphorus organic compoundsCyanineSubject matter

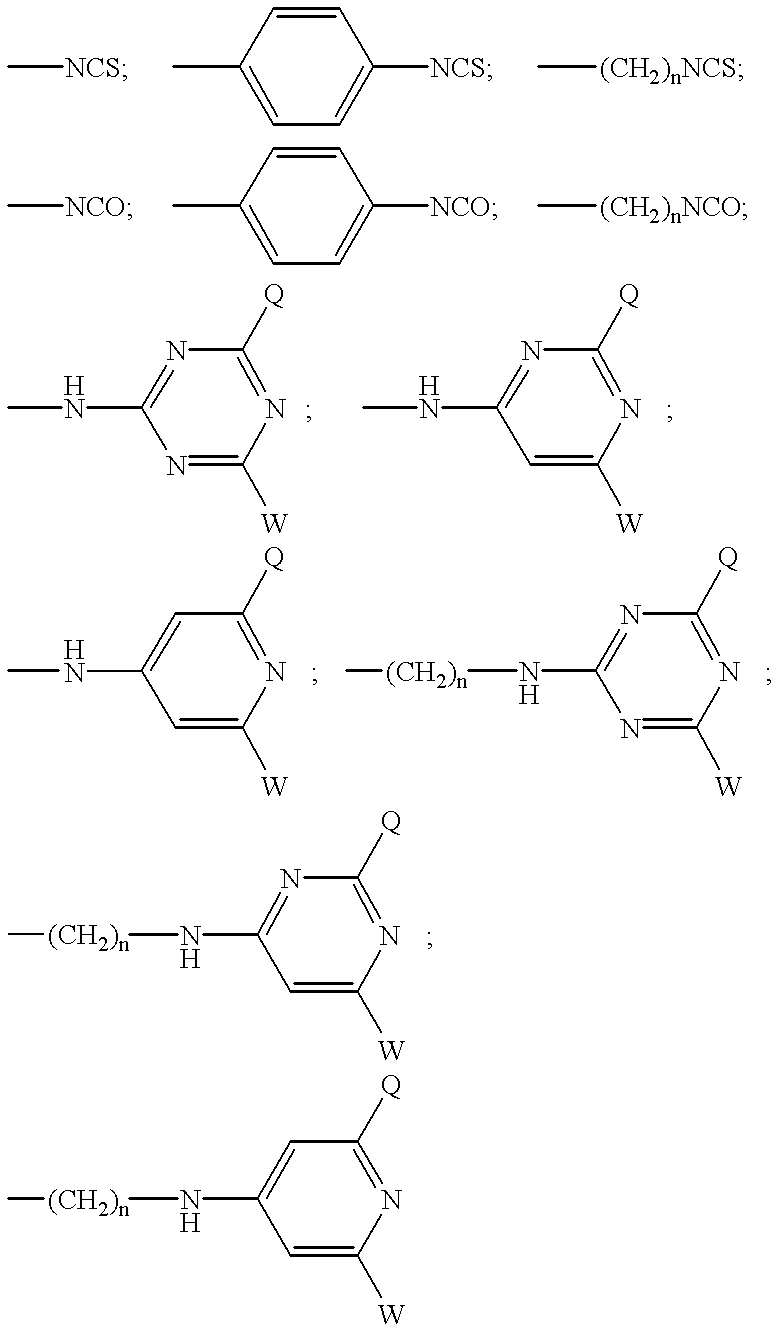

A subject matter of the invention is cyanine derivatives of formula:in which the dotted lines represent the atoms necessary for the formation of one or two fused aromatic rings, each ring comprising 5 or 6 carbon atoms;R1, R2, R3 and R4 represent, independently of one another: H; substituted or unsubstituted C1-C15 alkyl; C1-C6 alkoxy; (C2-C12)dialkylamino; C1-C6 alkoxycarbonyl; di(C2-C12)alkylamido; a substituted or unsubstituted aryl, arylalkyl or aryloxy group; a halogen atom; a nitro; an L1-W, L2-M, L2-A or L2-G group;R5 and R6 represent, independently of one another: substituted or unsubstituted C1-C15 alkyl; a substituted or unsubstituted aryl or arylalkyl group; an L1-W, L2-M, L2-A or L2-G group;X is chosen from: O, S or CR7R8; Y is chosen from: O, S or CR9R10;R7, R8, R9 and R10 independently represent: substituted or unsubstituted C1-C15 alkyl; substituted or unsubstituted aryl, arylalkyl or aryloxy; an L1-W, L2-M, L2-A or L2-G group;R7 and R8 and / or R9 and R10 can also together form a ring comprising 5 or 6 atoms or a heterocycle comprising 4 to 5 carbon atoms and an oxygen atom;B represents a polymethine bridge comprising 1 to 5 methine groups, said groups being in particular individually unsubstituted or substituted by a substituted or unsubstituted C1-C15 alkyl; a substituted or unsubstituted aryl, arylalkyl or aryloxy group; a nitro group; an L1-W, L2-M, L2-A or L2-G group;L1 and L2 are connecting arms; G is a reactive group; A is a coupling agent; M is a conjugated molecule, W is a phosphate or phosphonate ester (preferably diester), with the proviso that the cyanine derivative comprises at least one L1-W group and at least one L2-A, L2-G or L2-M group.

Owner:CIS BIO INT

Anthocyantin coloring agent and method for the production thereof from organic matter

InactiveUS6767999B2Wide spectrum of colorEasy to produceSugar derivativesWort preparationPhysical propertyPelargonidin

Owner:SMIRNOV +2

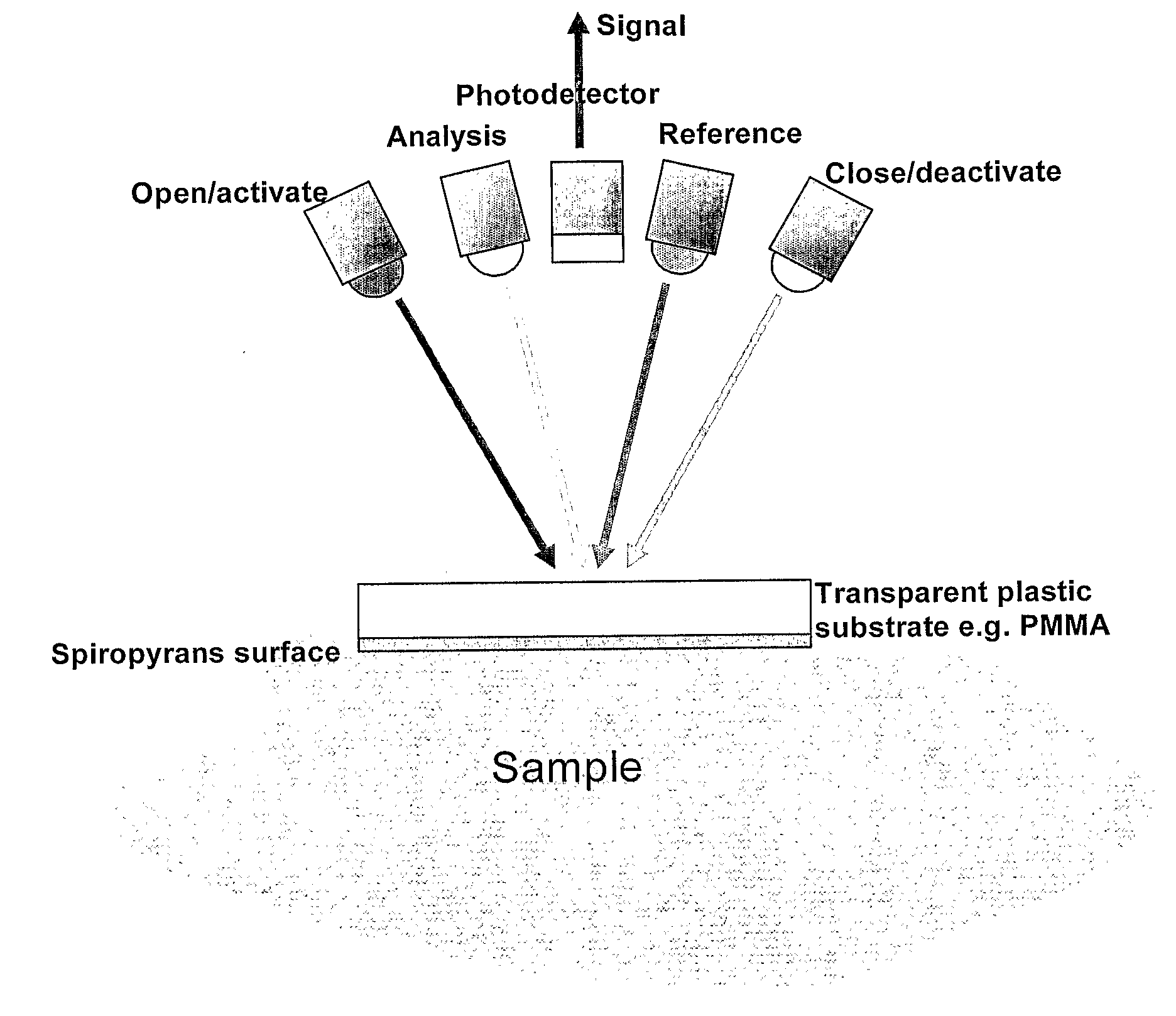

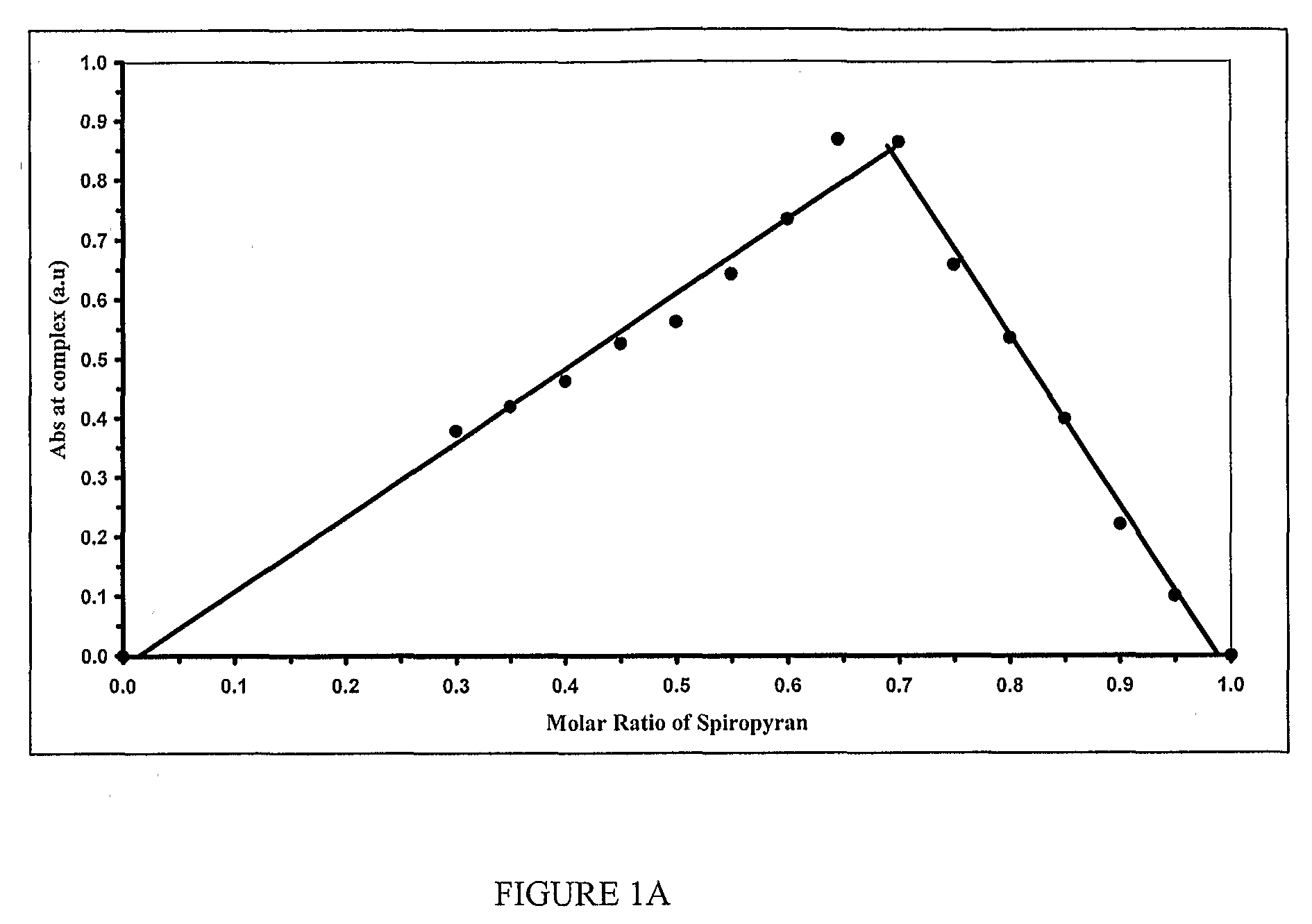

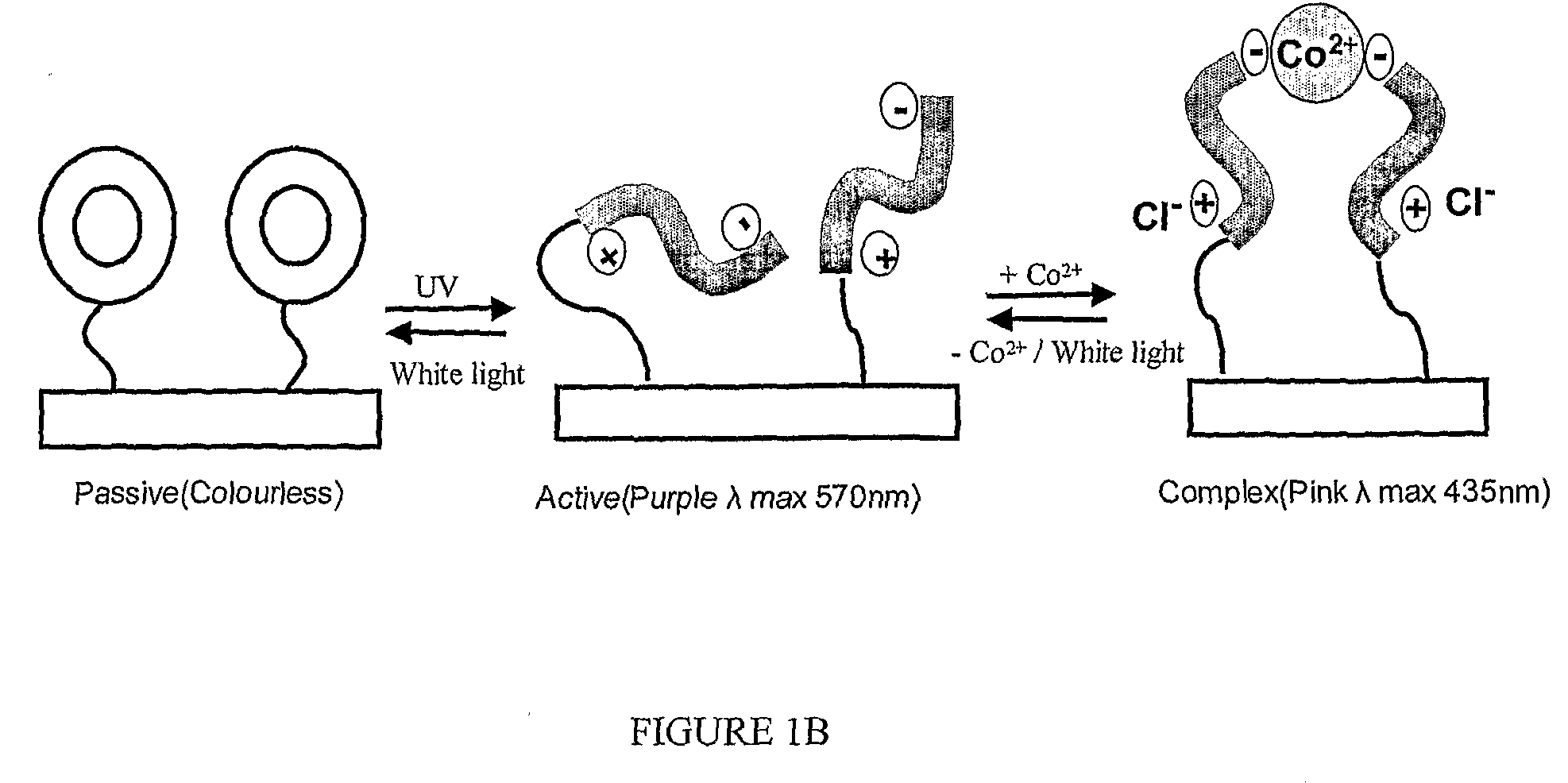

Photo-Swichable Surfaces with Controllable Physico-Chemical Properties

InactiveUS20080261323A1Reduce manufacturing costMaterial analysis by observing effect on chemical indicatorBiological testingMolecular switchGreen-light

Photochromic materials, such as spiropyran dyes, are disclosed that can be used for high-density optical storage and molecular switches. According to the disclosure these compounds can be used as transducers in optical sensors. When the spiropyran dye absorbs UV light it switches to the merocyanine form, and this structure has an active binding site for cations. When cations bind to the site, the resulting colored complex has a new absorption band in the visible spectrum. By shining white or green light on the colored complex, the dye is reverted to the closed spiropyran form, and the cation is released. The disclosure optimizes the immobilization of the spiropyran dye onto a polymer substrate via long chain alkyl groups. These long chain alkyl linkers enable the dye to reversibly form the preferred merocyanine (2):(1) cation sandwich complex.

Owner:DUBLIN CITY UNIVERSITY

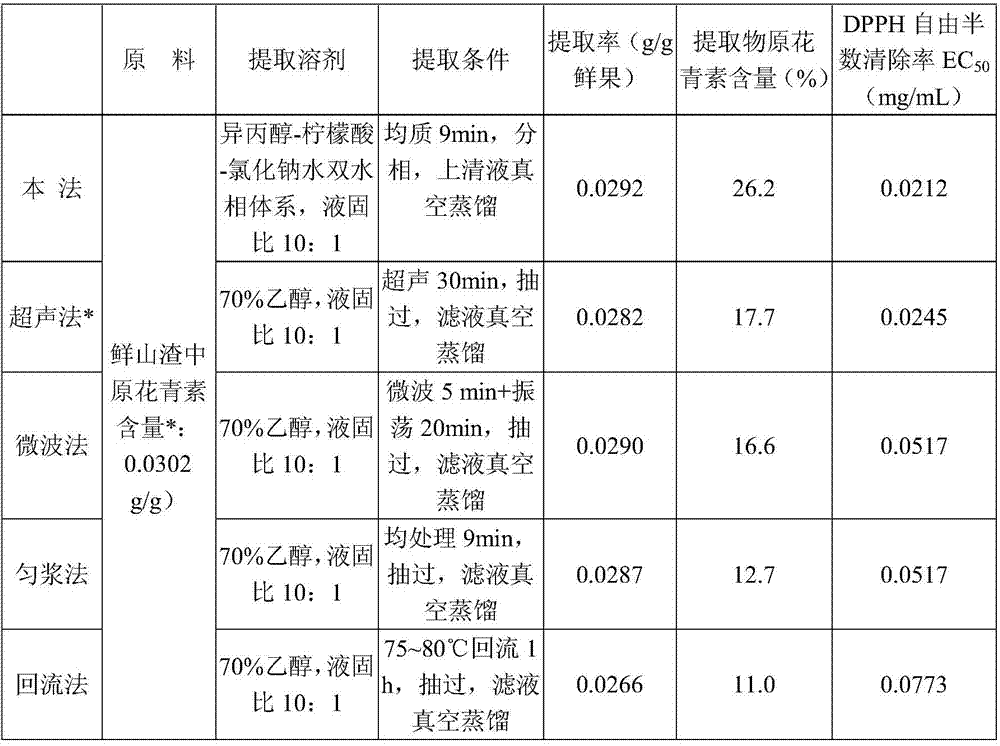

Method for preparing high content proanthocyanidin

This invention relates to a preparation method of high assay proto cyaniding. High assay proto cyaniding is got after solvent extraction, column chromatography separation and solvent precipitation process and original material is grape seed. Proto cyaniding content of solvent crude extract is about 50%, then it can be raised above 80% through macro pore polymeric adsorbent column chromatography refinery, and it can be raised above 90% through once solvent precipitation finally. proto cyaniding yield is above 75% of the whole process. The advantage is that technical process is simple, production cost is low, and it is convenient to industrialization.

Owner:ZHEJIANG UNIV

Procyanidine-modified carboxymethyl chitosan

The invention discloses procyanidine-modified carboxymethyl chitosan, a preparation method thereof, and application thereof in the fields of medical materials, health-care foods, cosmetics and the like. The procyanidine-modified carboxymethyl chitosan keeps the characteristics of carboxymethyl chitosan and has high oxidation resistance, antibacterial activity, barrier properties and the like, and is worthy of being applied.

Owner:SHIJIAZHUANG YISHENGTANG MEDICAL SUPPLIES

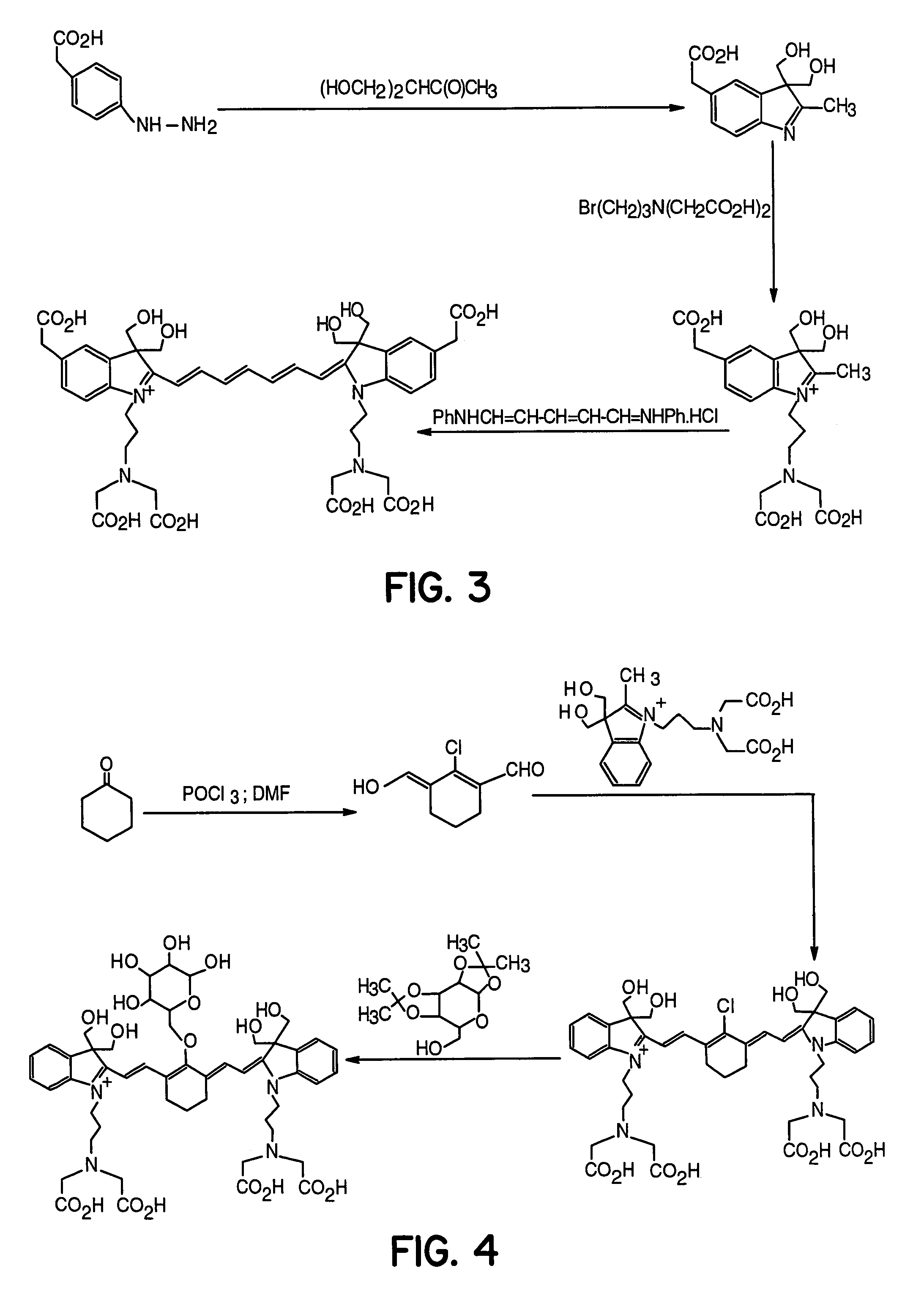

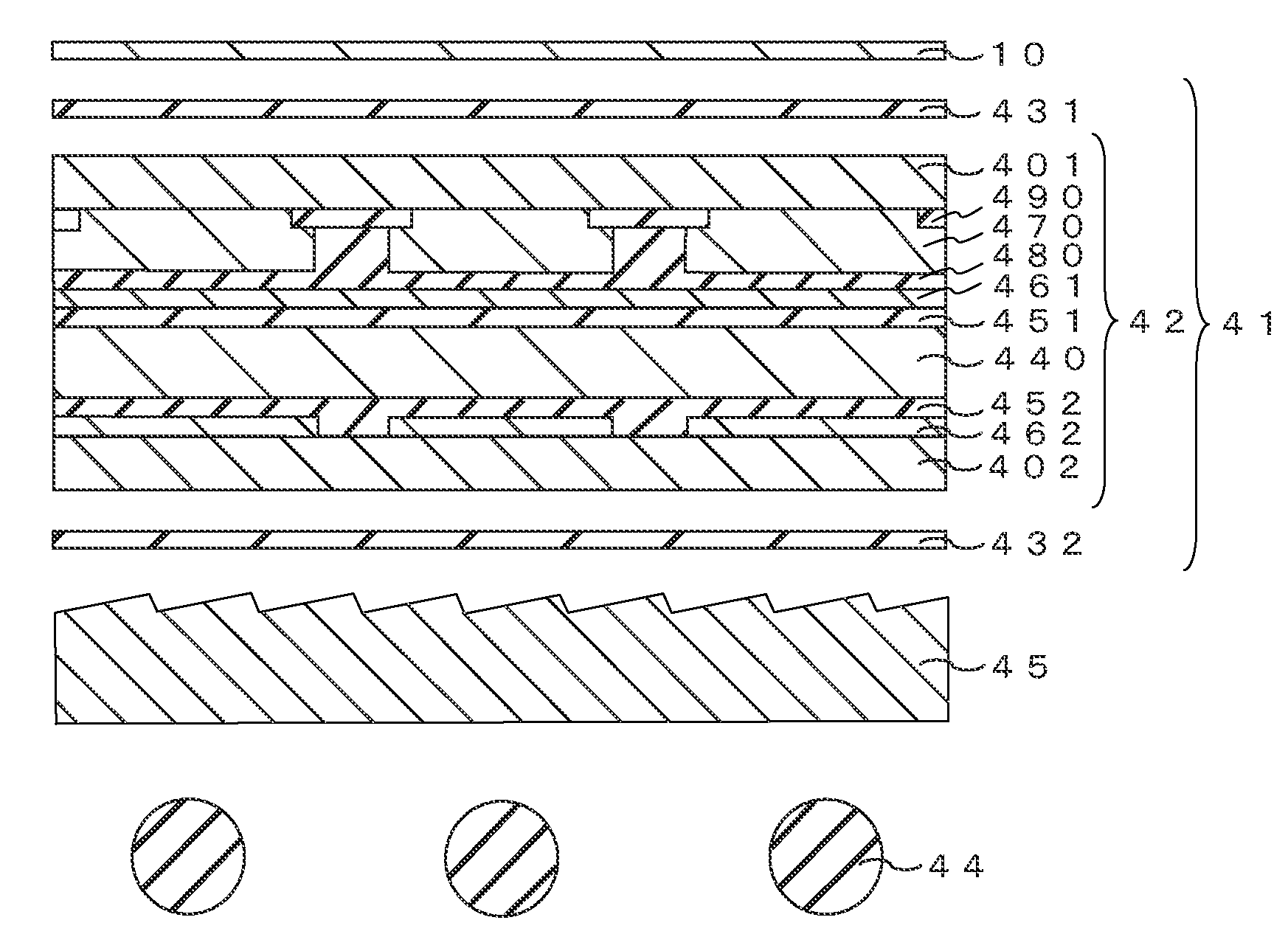

Receptor-avid exogenous optical contrast and therapeutic agents

InactiveUS7504087B2Ultrasonic/sonic/infrasonic diagnosticsMethine/polymethine dyesImaging agentCarboxylic acid

Cyanine and Indocyanine dye compounds and bioconjugates are disclosed. The present invention includes several cyanine and indocyanine dyes, including bioconjugates of the same, with a variety of bis- and tetrakis (carboxylic acid) homologues. The compounds of the invention may be conjugated to bioactive peptides, carbohydrates, hormones, drugs, or other bioactive agents. The small size of compounds of the invention allows favorable delivery to tumor cells as compared to larger molecular weight imaging agents. Further, use of a biocompatible organic solvent such as dimethylsulfoxide may be said to assist in maintaining the fluorescence of compounds of the invention. The compounds and bioconjugates herein disclosed are useful in a variety of medical applications including, but not limited to, diagnostic imaging and therapy, endoscopic applications for the detection of tumors and other abnormalities, localized therapy, photoacoustic tumor imaging, detection and therapy, and sonofluorescence tumor imaging, detection and therapy.

Owner:MEDIBEACON

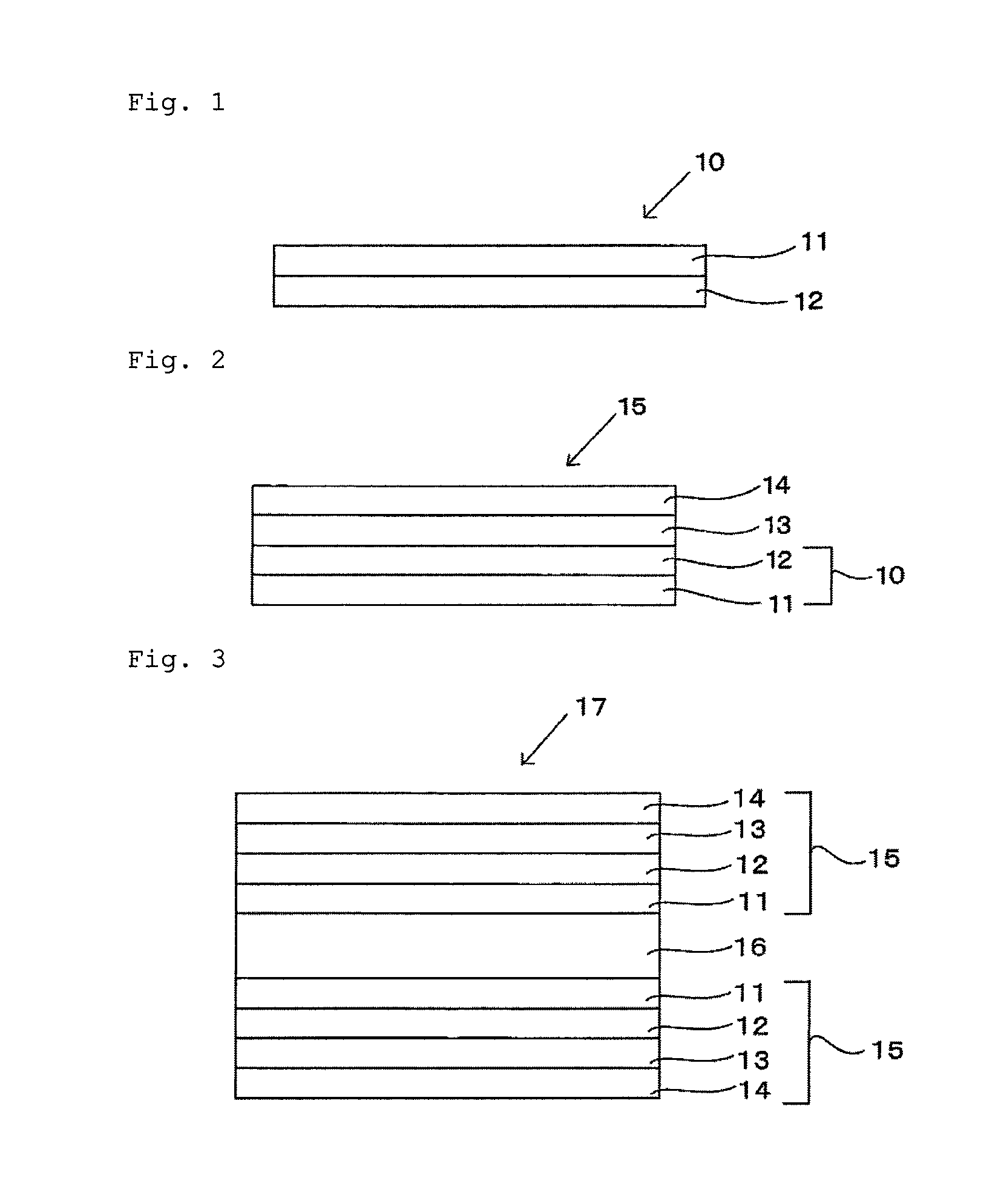

Crosslinked product, color correction filter, optical element, image display, and liquid crystal display

InactiveUS20100039591A1Increase brightnessImprove color tone representationOrganic chemistryNon-linear opticsLiquid-crystal displayCyanine

A crosslinked product with excellent durability is provided that can remove intermediate colors of light while preventing brightness from deteriorating and thereby can improve color tone representation. The crosslinked product of the present invention includes a J aggregate of a dye and is characterized in that the dye is at least one dye selected from the group consisting of cyanine, merocyanine, squarylium, and porphyrin, the J aggregate of the dye is formed in a matrix resin, and the matrix resin has been crosslinked.

Owner:NITTO DENKO CORP

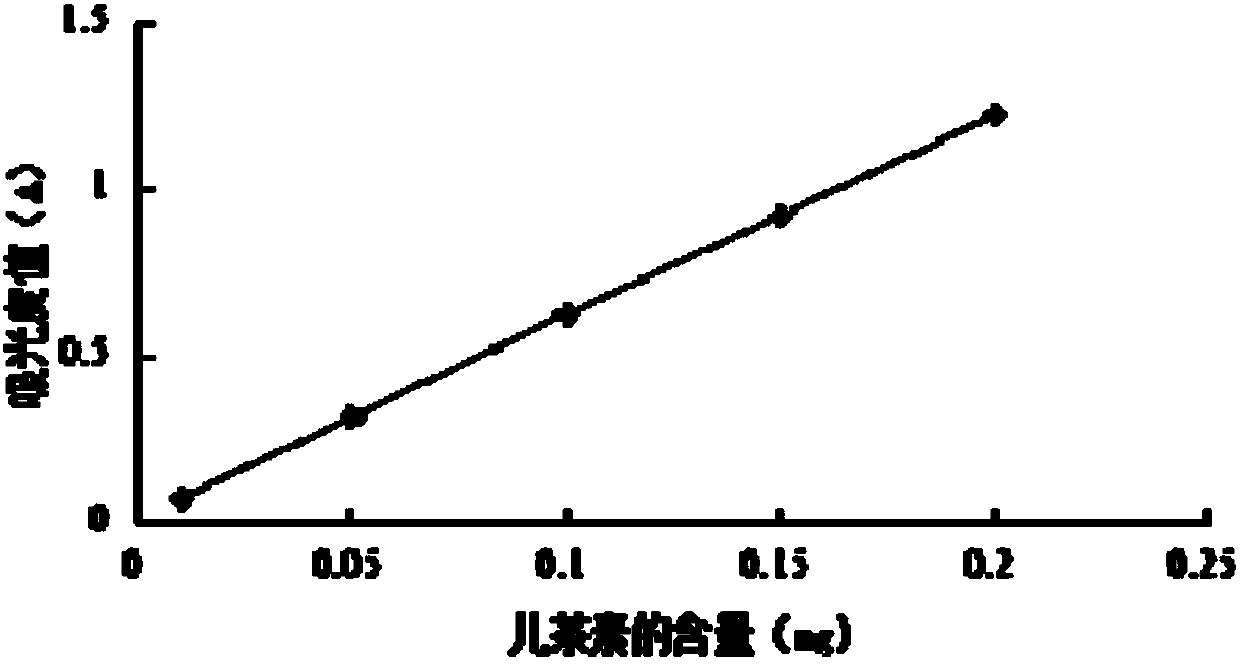

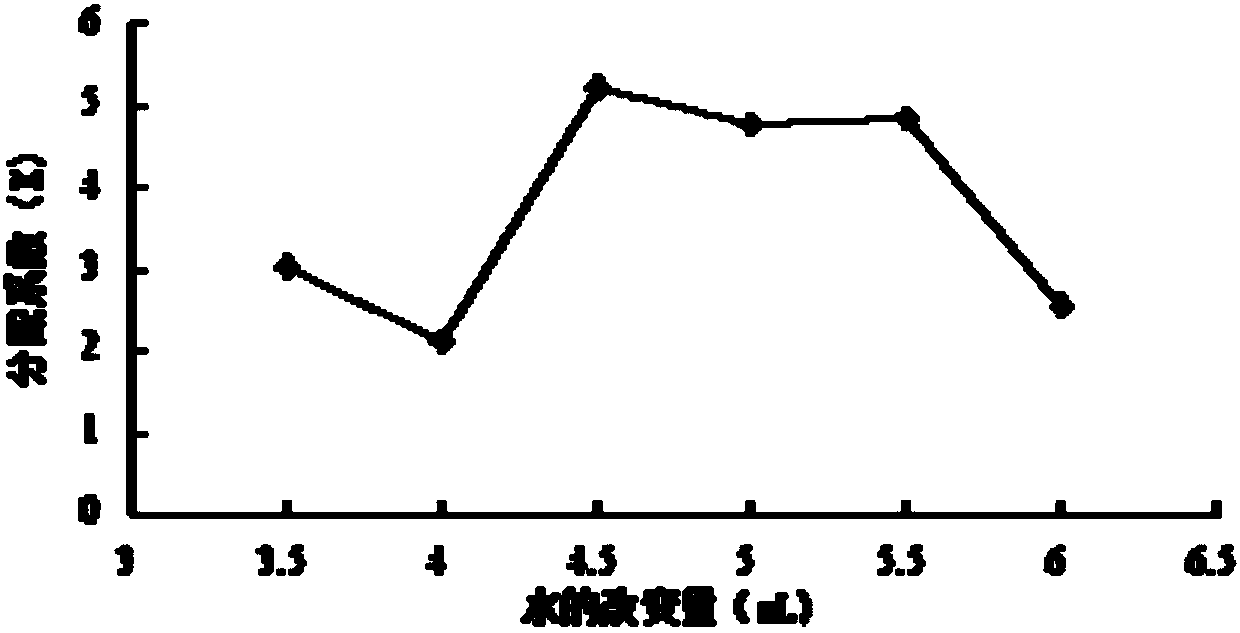

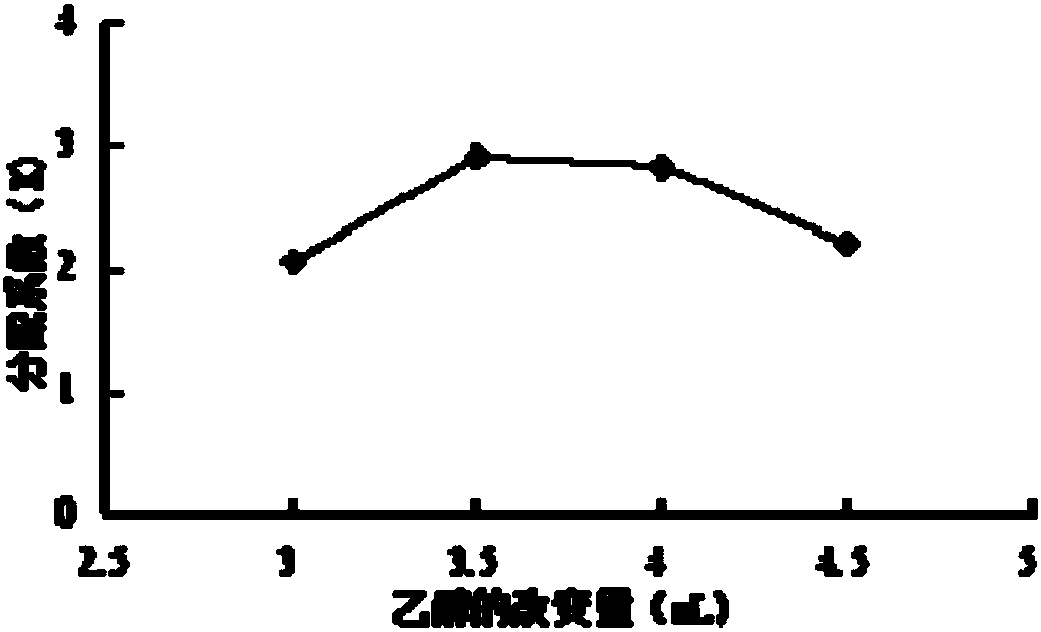

Method for extracting procyanidine by utilizing aqueous two-phase system

InactiveCN107739359AIncrease moisture contentInhibitory activityOrganic chemistryMoistureWater content

The invention discloses a method for extracting procyanidine from grape seeds by utilizing an aqueous two-phase system. The method comprises the following steps: 1) pretreating a material, namely drying grape seeds in a drying oven at the temperature of 50-80 DEG C for 18-36 hours, and grinding into powder; and 2) performing aqueous two-phase extraction, namely adding an aqueous two-phase extraction solution composed of ethanol, ammonium sulfate, distilled water and sodium chloride into a centrifugal device, adding the grape seed powder, fully mixing, centrifuging at a rotating speed of 3000-6000 revolutions per minute for 10-15 minutes, and standing for extracting, thereby obtaining procyanidine, wherein the aqueous two-phase extraction solution is composed of 30 wt%-35wt% of ethanol, 20wt%-25wt% of ammonium sulfate, 1.8 wt%-2.2wt% of sodium chloride and the balance of distilled water; and a mass ratio of the grape seed powder to the aqueous two-phase extraction solution is 1:(16-30). The method is rapid in phase separation and low in time consumption, the moisture content of the extraction system is high, an extract can be effectively prevented from being inactivated or denatured, the separation process is complete and economic and is simple in operation, and enlarged production and continuous operations are facilitated.

Owner:TIANJIN AGRICULTURE COLLEGE

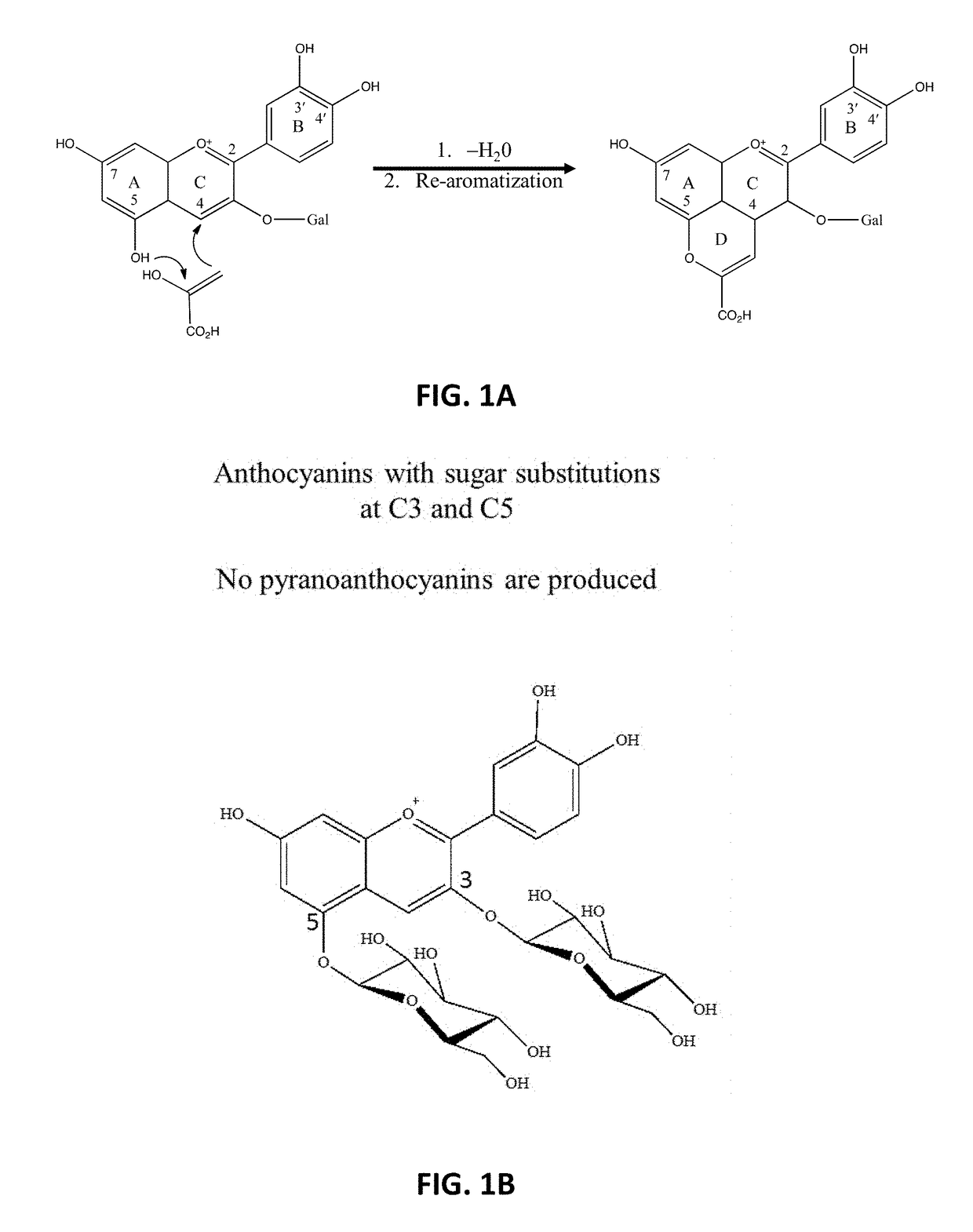

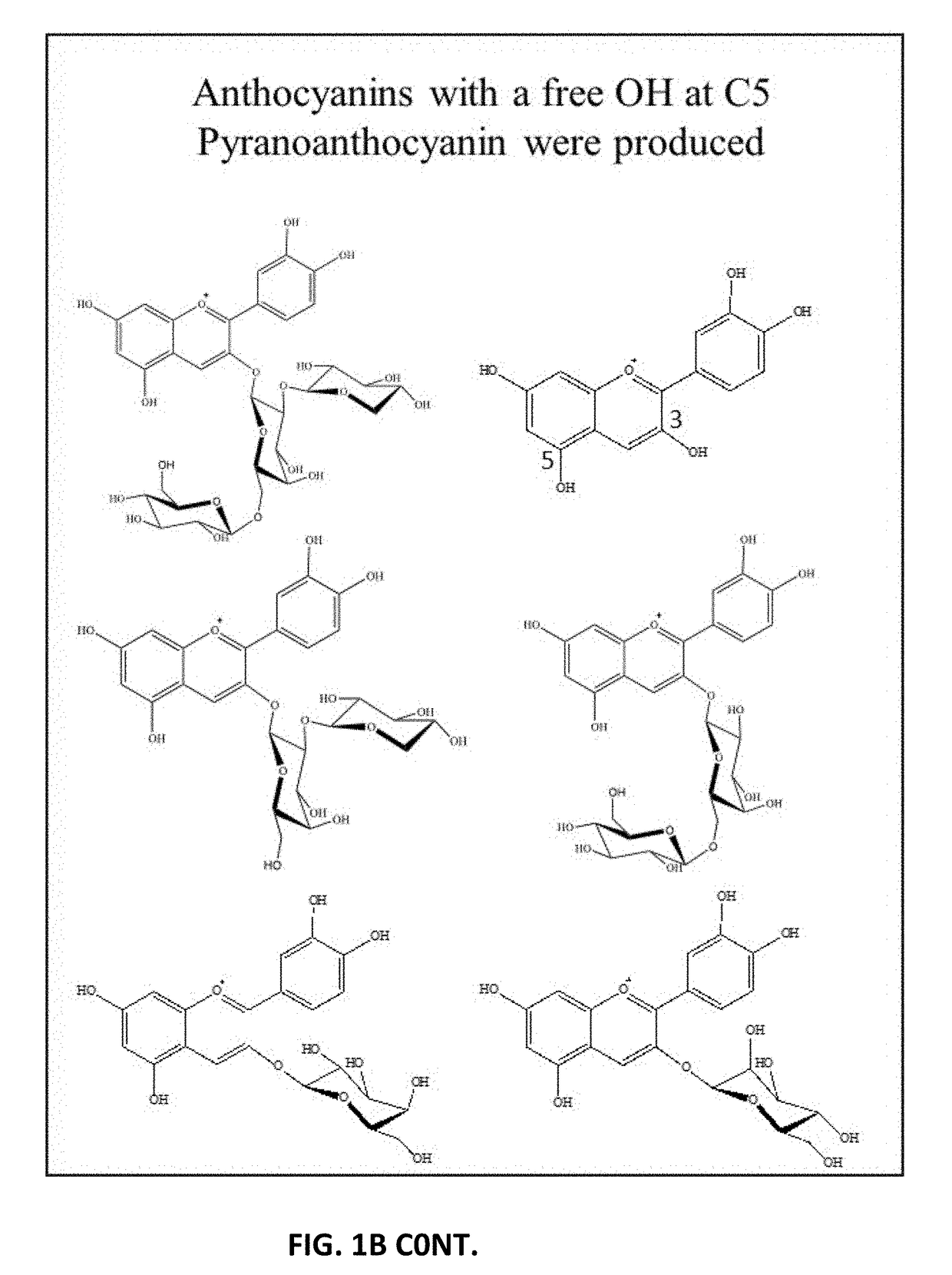

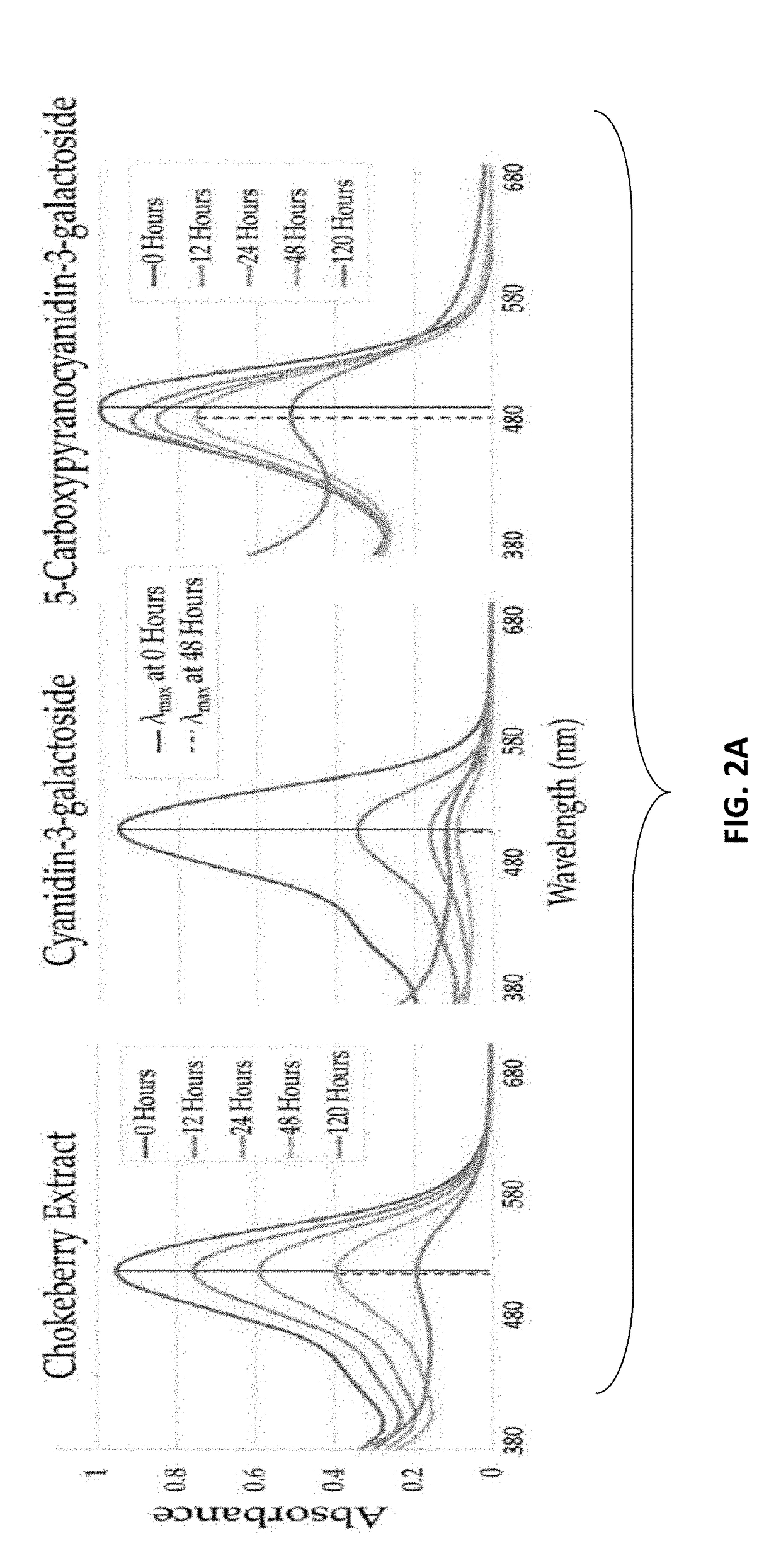

Formation of Stable Pyranoanthocyanins, and Uses Thereof as Sources of Natural Color

InactiveUS20180346731A1Reduce bleachingPreserved color expressionCoumarine dyesMetabolitePyranoanthocyanin

Described herein are chromophore compounds formed by interaction of ascorbic acid (AA) and a pyranoanthocyanin (PACN) compound. Also described herein are natural food colorant compositions that include chromophore compounds. The pyranoanthocyanins can be formed by the heterocyclic addition of the C4 and 5-OH of an anthocyanin, using a polar metabolite. Also described herein are pyranoanthocyanins, and methods of making and using the same.

Owner:OHIO STATE INNOVATION FOUND

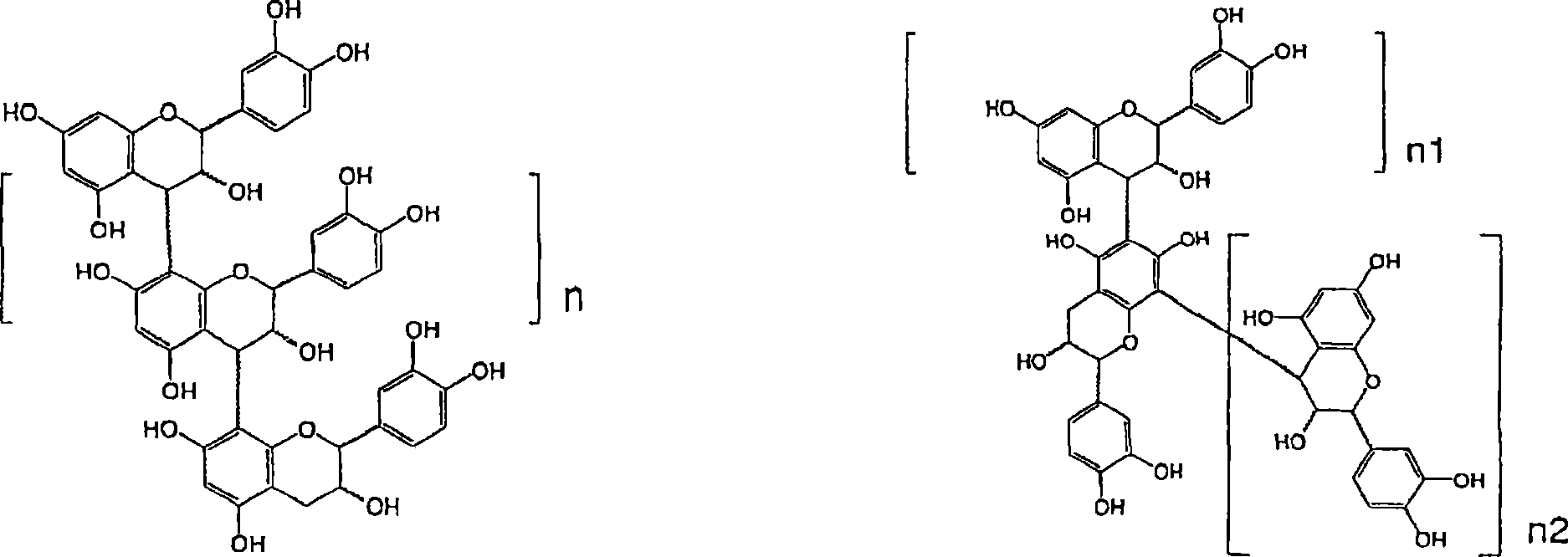

Synthesis of dimeric, trimeric, tetrameric pentameric, and higher oligomeric epicatechin-derived procyanidins having 4,8-interflavan linkages and their use to inhibit cancer cell growth through cell cycle arrest

Various processes are disclosed for preparing protected epicatechin oligomers having (4β,8)-interflavan linkages. In one process, a tetra-O-protected epicatechin monomer or oligomer is coupled with a protected, C-4 activated epicatechin monomer in the presence of an acidic clay such as a mortmorillonite clay. In another process, a 5,7,3′,4′-benzyl protected or a 3-acetyl-, 5,7,3′,4′-benzyl protected epicatechin or catechin monomer or oligomer is reacted with 3-O-acetyl-4-[(2-benzothiazolyl)thio]-5,7,3′,4′-tetra-O-benzylepicatechin in the presence of silver tetrafluoroborate. In another process, two 5,7,3′,4′-benzyl protected epicatechin monomers activated with 2-(benzothiazolyl)thio groups at the C-4 positions are cross-coupled in the presence of silver tetrofluoroborate. A process is also disclosed for reacting an unprotected epicatechin or catechin monomer with 4-(benzylthio)epicatechin or catechin. The use of naturally-derived and synthetically-prepared procyanidin (4β,8)4-pentamers to treat cancer is also disclosed.

Owner:MARS INC

Luminol-aniline copolymerization modified electrode and preparation method thereof

ActiveCN102706864ALow costSolve the problem of excessive dead volumeChemiluminescene/bioluminescencePlatinumElectricity

The invention discloses a preparation method of a luminol-aniline copolymerization modified electrode, which comprises the following steps as follows: (a) based on ITO (indium tin oxide) glass plate as a base electrode, paving an insulating material on the conducting surface of the base electrode, forming an electrode zone at one end of the ITO glass plate, forming a connection zone at the other end of the ITO glass plate, cleaning, and drying to obtain an ITO electrode; (b) dissolving NaOH solution containing luminol and aniline in H2SO4 under stirring condition to obtain a mixed solution; and (c) carrying out electrochemical copolymerization reaction by adopting cyclic voltammetry, and taking a saturated calomel electrode as a reference electrode, a platinum wire electrode as an auxiliary electrode and the ITO electrode as a working electrode under the stirring condition in the mixed solution obtained in the step (b), cleaning and airing to obtain the luminol-aniline copolymerization modified electrode. According to the invention, the immobilization of luminescent substances is realized; and experiments prove that compared with the traditional poly luminol modified electrode, the modified electrode has the advantages that the luminous intensity is improved by about 10 times, the detection limit on procyanidin is reduced by around 4 times, and unexpected technical effects are achieved.

Owner:SUZHOU UNIV

Preparation method and application of spiropyrane solid photostimulation-response compound

InactiveCN110117294APromote conversionPhoto-stimuli response achievedOrganic chemistryTenebresent compositionsPhotoswitchIsomerization

The invention provides a spiropyrane solid photostimulation-response compound. The molecular chemical formula of the compound is shown in a formula (I). The invention discloses a preparation method and application of the solid fluorescence stimulation-response compound containing spiropyrane and tetraphenyl ethylene. The spiropyrane is a common photostimulation-response molecule, reversible structural isomerization between the spiropyrane as a colorless closed ring body and merocyanine as a colored open ring body can be generated, and due to high molecule accumulation of the spiropyrane in a solid state, the above-mentioned isomerization cannot easily occur; the typical aggregation-induced emission phenomenon occurs on the tetraphenyl ethylene, and the tetraphenyl ethylene is large in volume and provides the free volume for the spiropyrane, so that the isomerization of the spiropyrane in the solid state is facilitated; spacers are introduced between the tetraphenyl ethylene and the spiropyrane, which is beneficial for improvement of the luminous efficiency of the spiropyrane. In this way, the solid photochromic fluorescent molecular switch material is provided and has wide application prospects in the fields of photoswitch molecular devices, anti-fake application, optical information storage and the like.

Owner:XIANGTAN UNIV

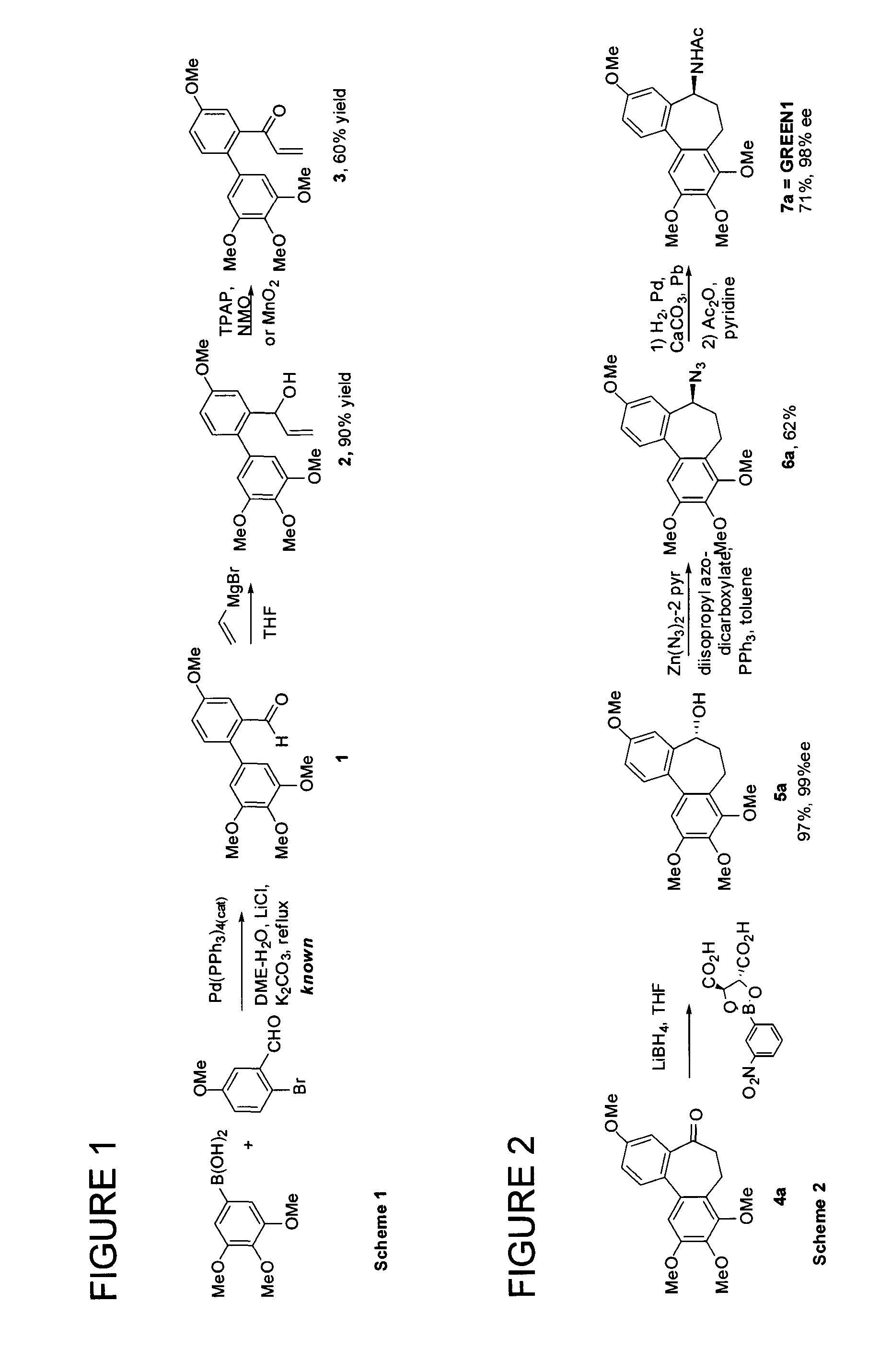

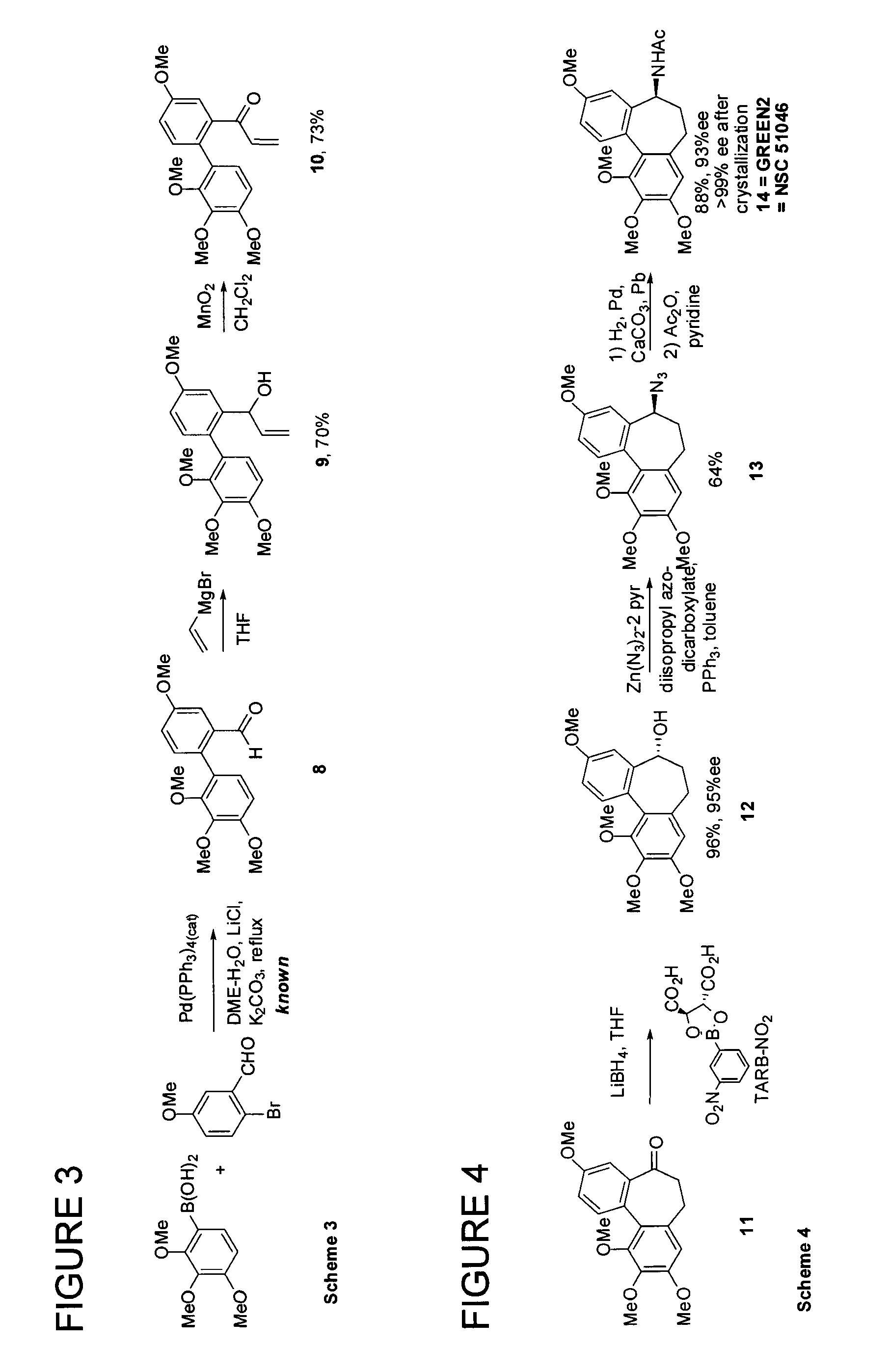

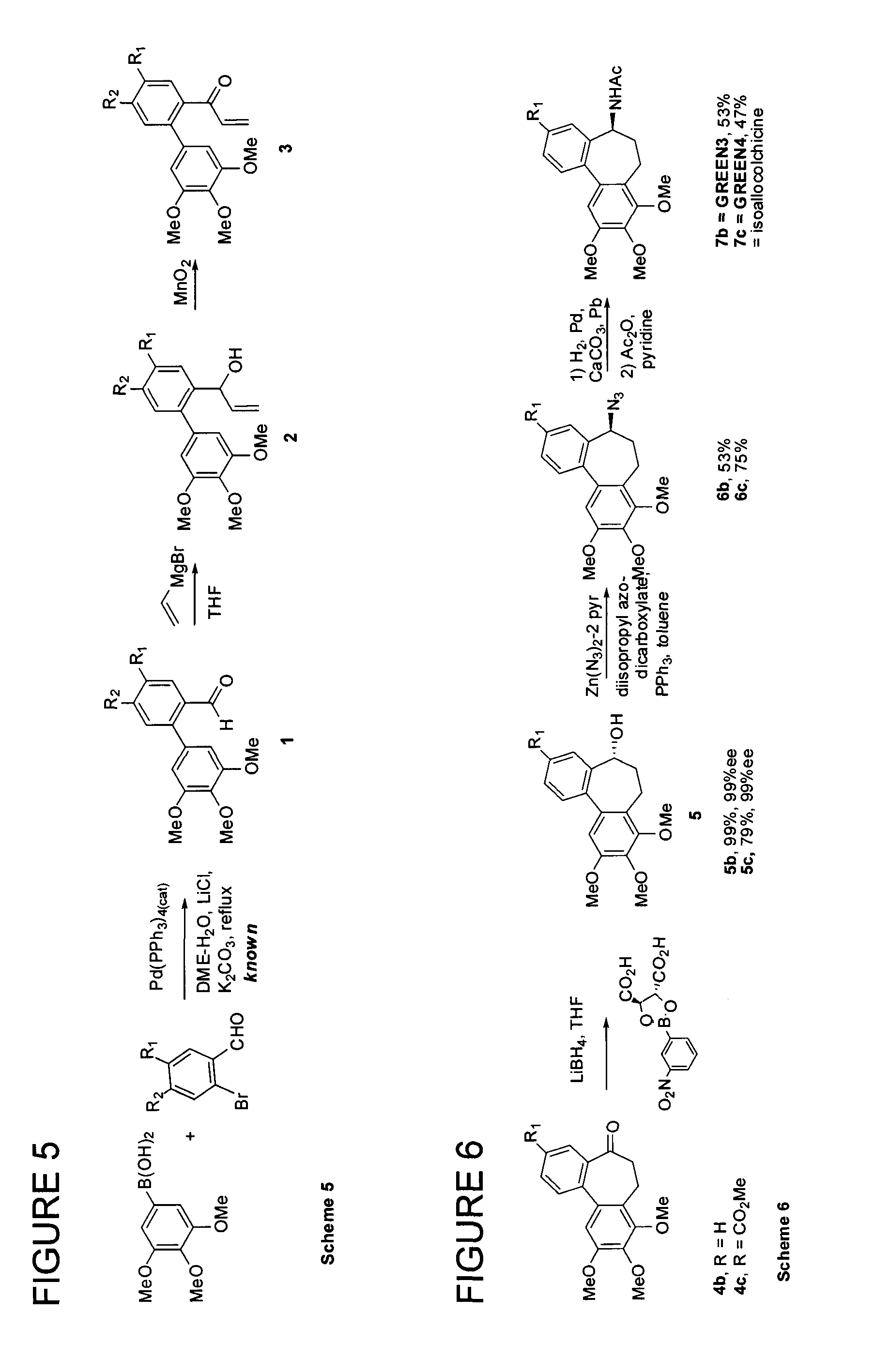

Catalytic Method for Dibenzocycloheptane Synthesis and Allocolchicinoid Synthesis

InactiveUS20150344411A1Efficient constructionBiocideOrganic compound preparationCatalytic methodMerocyanine

In a non-limiting embodiment, there is provided a compound of formula (I), which may permit for a method or use in treating or preventing a cancer, such as pancreatic cancer or leukemia. In one embodiment, there is also provide a method of preparing a compound of formula (Ia), the method including conducting a cyclization reaction of a compound of formula (III) to obtain a compound of formula (IV), wherein conducting the cyclization reaction comprises conducting a Michael reaction in the presence of a Lewis acid.

Owner:UNIVERSITY OF WINDSOR

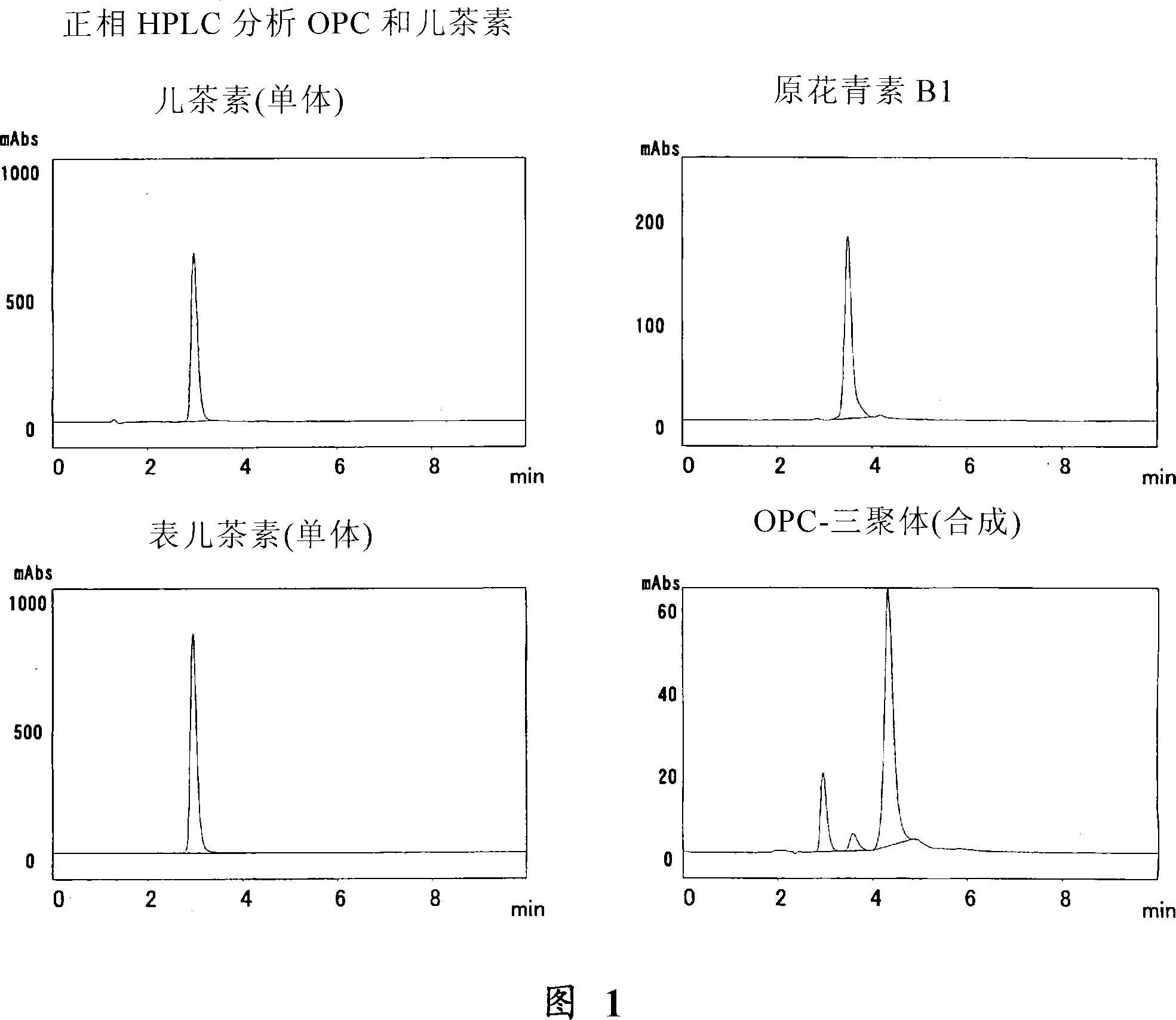

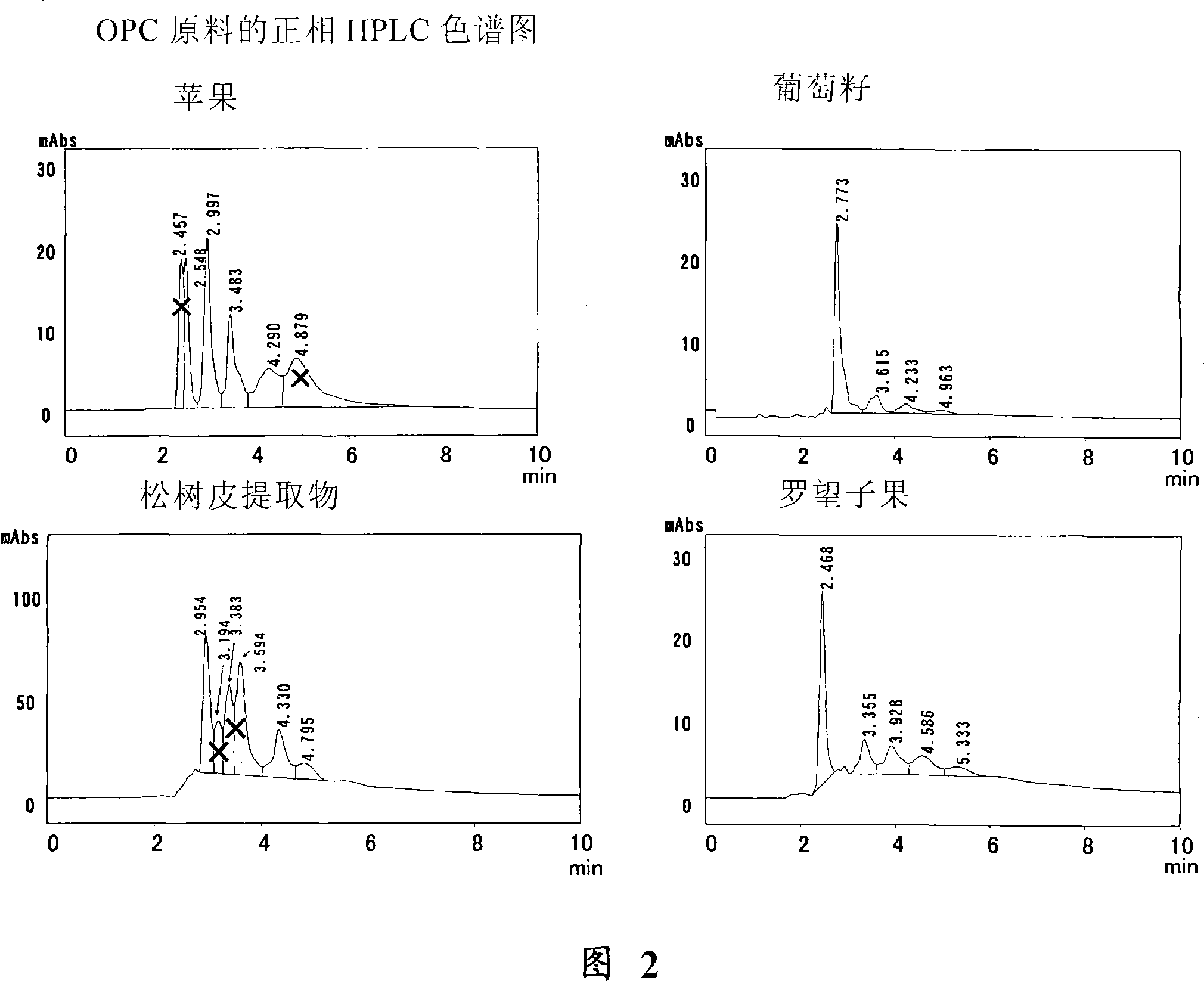

Method for analyzing oligomeric proanthocyanidin (opc)

The present invention provides a novel method for assaying OPC contained in natural substances, foods and beverages, pharmaceuticals and / or cosmetics. The present invention is a novel method for assay of OPC which assays anthocyanidin, obtained by hydrolysis of OPC, to determine the total amount of OPC, and elucidates the proportions of the polymerization degrees of OPC by high performance liquid chromatography (HPLC) to determine the contents of the respective polymers in OPC.

Owner:SUNTORY HLDG LTD

Anthocyantin coloring agent and method for the production thereof from organic matter

InactiveUS20030036640A1Raise the possibilityWide spectrum of colorSugar derivativesWort preparationPhysical propertyPelargonidin

Anthocyanic colorant made of vegetable primary material and process for its production relate to food, cosmetic, pharmaceutical and textile industry and may be used in production of alcoholic and soft drinks, confectionery, products made of sour milk, in coloring of tablet capsules, dying of children's underwear, toys, etc. According to the invention, pelargonidin glycoside was added to the composition of the natural colorant that contained cyanidin glycosides, peonidin glycosides, organic substance and mineral salts. The components percentage shall be as follows, %: cyanidin glycoside 0.1-8.6; peonidin glycoside 0.08-6.45 pelargonidin glycoside 0.005-4.3; organic substance and mineral salts-the rest. Due to the fact that the colorant solution contains pelergonidin glycoside further to cyanidin and peonidin glycosides, the proposed colorant obtained expanded color spectrum. Combination of these three anthocyans in the proposed colorant provides for the most rich spectrum of red colors. At the same time, the ratio of pelargonidin glycoside:peonidine glycoside:cyanidin glycoside must be 1:1.5:2, respectively, and it will provide for production of a colorant with a number of valuable physical properties. Namely, the colorant retains red color when pH of the environment is not more than 7, it is thermostable, photostable and maintains its properties during 2 (two) years, besides, its relative optical density is the highest when it is subjected to the light with wavelength of 505-515 nm. According to the invention, process of the colorant production implies that pre-dried vegetable maize-pulp containing anthocyan is grinded, extracted by a mix of aqueous solutions of hydrochloric and citric acids in the field of ultrasonic vibration. Then the extracted coloring matter is filtered and concentrated in vacuum. The primary material is additionally prepared for extraction by infusion of grinded material in extracting agent during 6-8 hours at the temperature of 35-40° C. Extraction may be performed in three steps. Processing for extraction of each lot shall be 30-40 minutes at the temperature of 35-40° C. The process makes the production technology easier and provides for additional source of primary materials. 2 independent claims, 8 dependent claims, 5 tables.

Owner:SMIRNOV +2

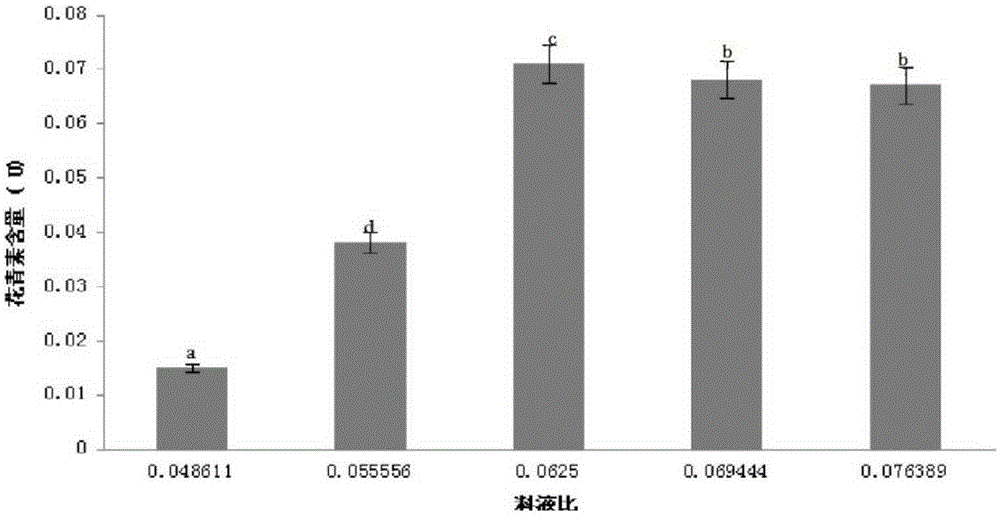

Extraction method of cyanidin

InactiveCN105199425AMeet safety requirementsNo pollution in the processOrganic chemistryNatural dyesFood additiveSolvent

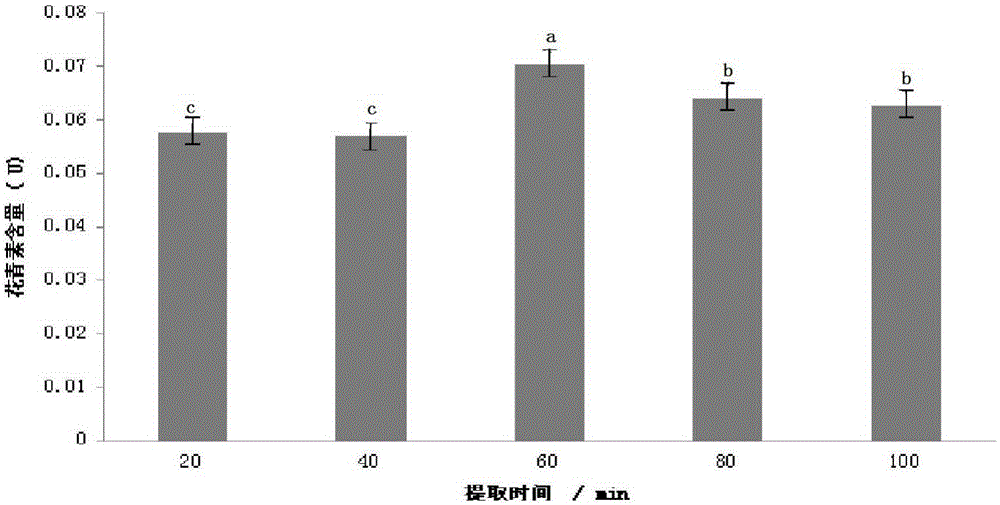

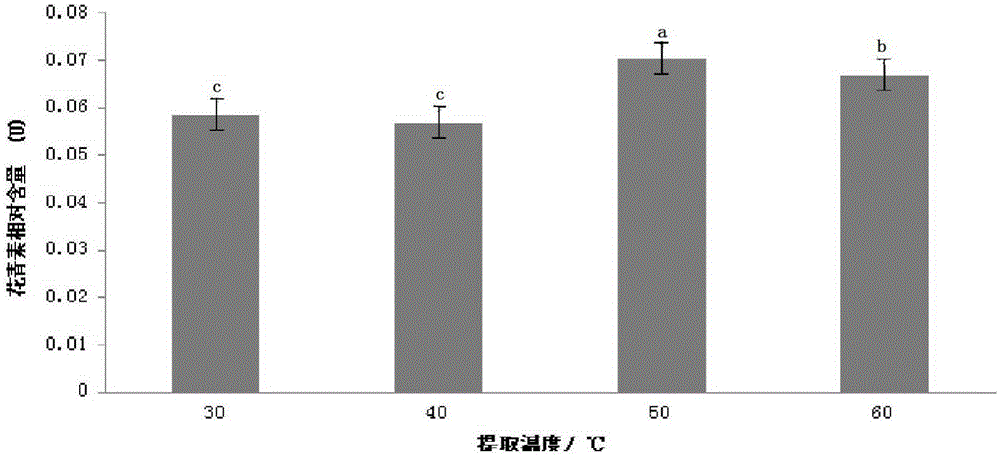

The invention belongs to the field of plant effective component extraction, and provides an extraction method of cyanidin. The method comprises the following steps: (1) sample preparation; (2) leaf grinding; and (3) cyanidin extraction. The orthogonal test by using a citric acid-sodium citrate buffer solution as an extraction solvent detects that the sequence of factors responding to the purple lettuce cyanidin extraction effect is as follows: material / liquid ratio>extraction temperature>extraction time; and therefore, the material / liquid ratio is preferentially determined in the cyanidin extraction process. The control on the material / liquid ratio, extraction time, extraction temperature and extracting solution pH value proves that the method enhances the extraction rate and cyanidin leaching rate on the premise of lowering the cost and simplifying the process. Since all the extraction solvents are nontoxic and are reagents widely used as food additives, the method can satisfy the requirements of modern people for safety, and thus, has wide applicability in the fields of food, health care, drugs and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

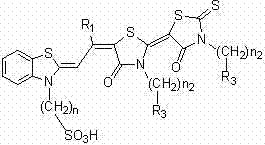

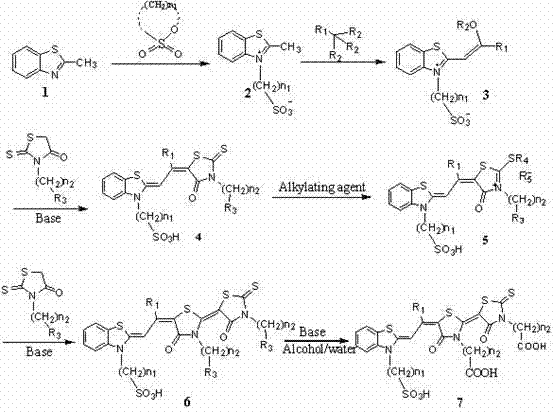

Preparation method for bis(rhodanine)merocyanine sensitizing dye with a benzothiazole skeloton

InactiveCN103588725AReduce pollutionLow costMethine/polymethine dyesOrganic chemistryThiazoleMethyl benzene

The invention belongs to bis(rhodanine)merocyanine sensitizing dyes, belongs to the field of organic synthetic dyes, and especially relates to a preparation method of a bis(rhodanine)merocyanine sensitizing material by taking 2-methylbenzothiazole and a rhodanine derivative as main initial raw materials. The target product is obtained by taking low-price 2-methylbenzothiazole and rhodanine carboxylate as the raw materials and performing five-step reaction. The beneficial effects comprise that: the method is simple and easy in reaction operation, small in environmental pollution, high in product purity and relatively low in cost, and is suitable for large-scale industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Nitrogen-doped carbon quantum dots and preparation method and application thereof

ActiveCN109135736AImprove performanceImprove bindingMaterial nanotechnologyNanoopticsNitrogen dopedHigh selectivity

The invention provides a preparation method of nitrogen-doped carbon quantum dots, and belongs to the technical field of preparation of functional materials. The preparation method comprises the following steps: mixing a crude extract containing procyanidine, an organic nitrogen doping agent and water, and carrying out hydrothermal carbonization to obtain the nitrogen-doped carbon quantum dots. The procyanidine extract is a carbon precursor, after the procyanidine extract is mixed with an organic nitrogen doping agent and then is subjected to hydrothermal reaction, the surface functional groups of the formed nitrogen-doped carbon quantum dots are abundant, and the nitrogen-doped carbon quantum dots have high fluorescence and excellent pH stability and high ion strength tolerance; and the nitrogen-doped carbon quantum dots have high selectivity on common perfluorooctane sulphonate in water. From embodiments, the detection linear range of the nitrogen-doped carbon quantum dots to the perfluorooctane sulphonate is 3-160* 10-10 mol / L, the detection limit is 0.3 nM, and the itrogen-doped carbon quantum dots can be used for rapidly detecting a trace amount of the perfluorooctane sulphonate in an environmental water sample.

Owner:NANCHANG HANGKONG UNIVERSITY

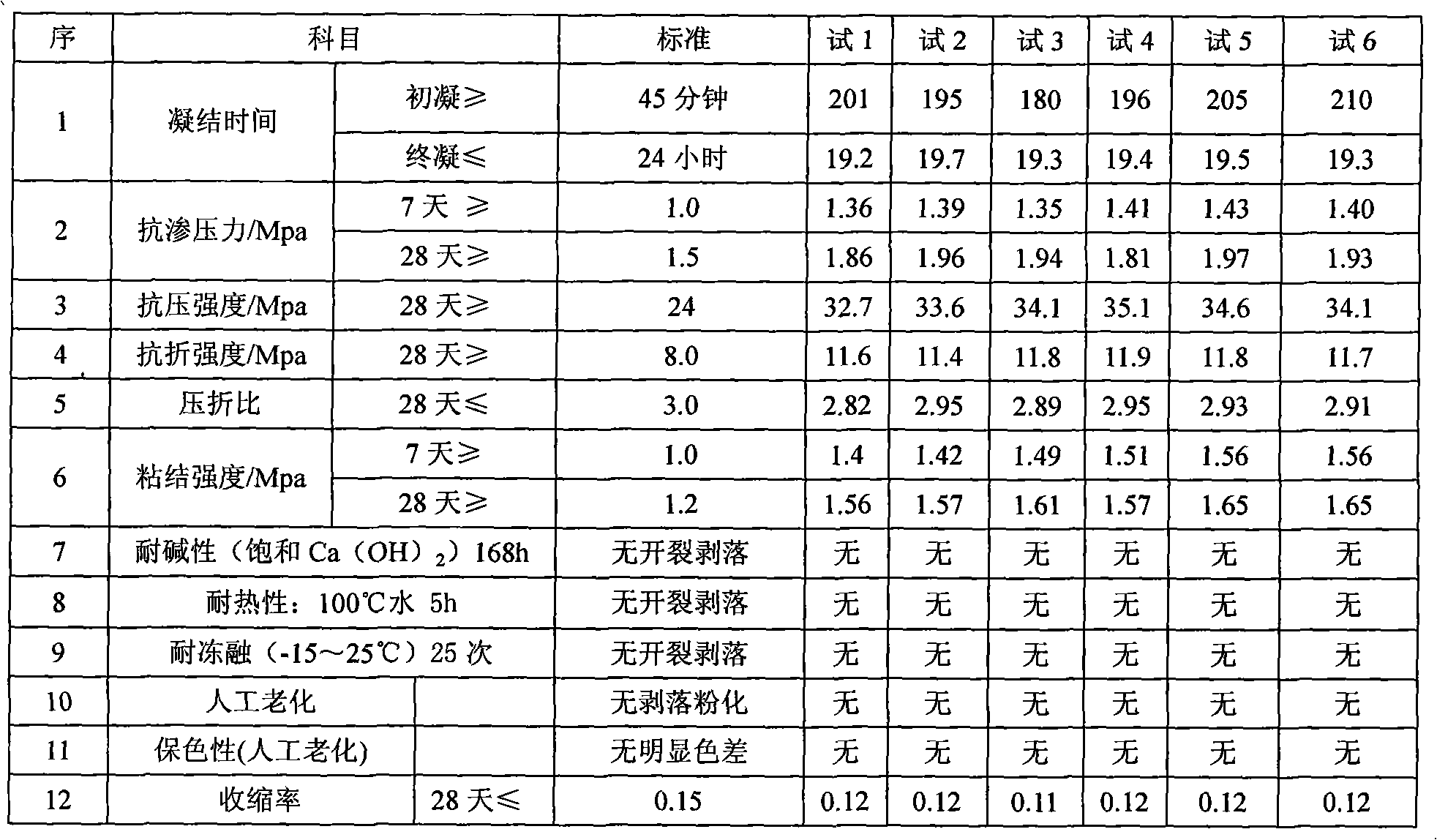

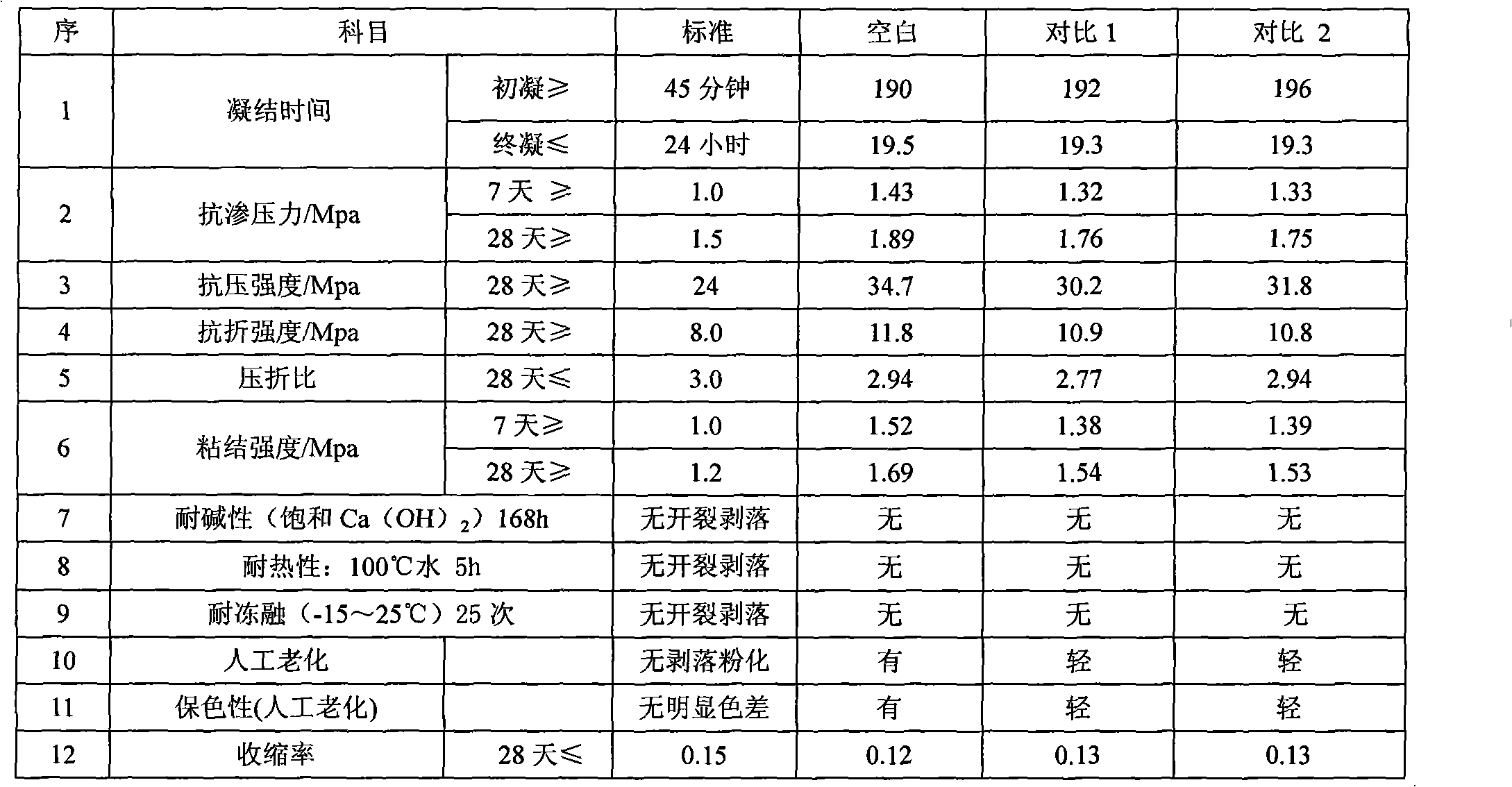

Cement-based waterproof mortar photosensitive ultraviolet resistance protectant

The invention discloses a cement-based waterproof mortar photosensitive ultraviolet resistance protectant and the protectant comprises the following components in parts by weight: 100 parts of gelatine water solution, 10-20 parts of copper sulfate, 1-2 parts of sodium hydroxide, 10-20 parts of thiourea, 20-30 parts of 3,3'-diethyloxacarbocyanine iodide merocyanine light-absorbing dye water solution and 10-20 parts of stannous chloride ethanol water. The invention protects the inner layer of mortar, protects the high polymer and pigment from the direct ultraviolet radiation and eliminates the surface chalking and skin peeling of mortar and the decolorization of the pigment.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

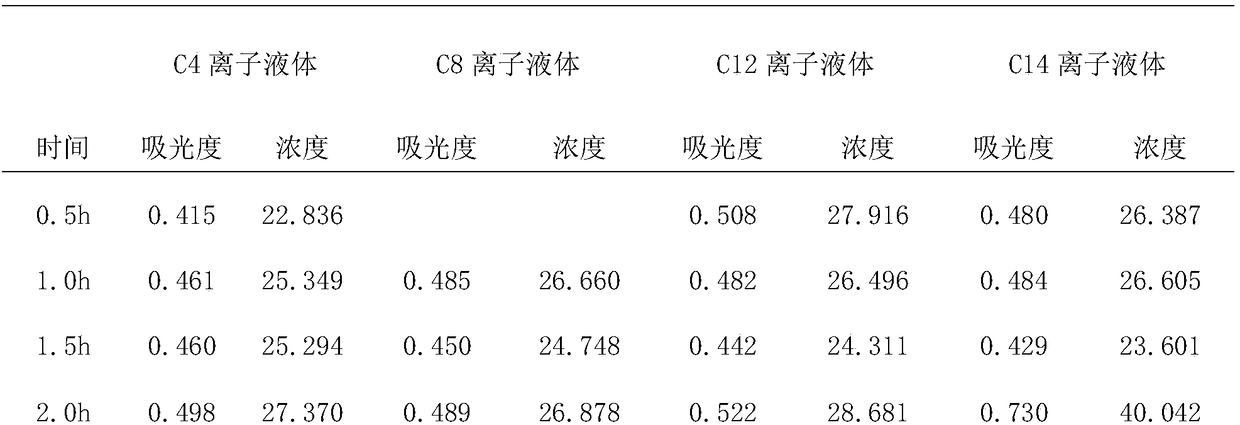

Method for degrading high-polymeric procyanidine

ActiveCN109096237AHigh catalytic activitySimple preparation processOrganic chemistryProanthocyanidinMerocyanine

The invention discloses a method for degrading high-polymeric procyanidine and belongs to the technical field of high-polymeric compound degradation. The method comprises the steps of utilizing quaternary ammonium salt type ionic liquid to conduct catalytic degradation on the high-polymeric procyanidine. When the quaternary ammonium salt type ionic liquid is utilized to conduct catalytic degradation on the high-polymeric procyanidine, the method has the advantages of being small in ionic liquid use amount, moderate in reaction conditions and high in catalytic activity. A low-polymeric procyanidine obtained through catalysis is high in content and complete in molecular structure, the quaternary ammonium salt type ionic liquid preparing process is simple, the cost is low, and the prepared quaternary ammonium salt type ionic liquid is long in storage time and is suitable for industrial large-scale production.

Owner:CHENGUANG BIOTECH GRP CO LTD +1

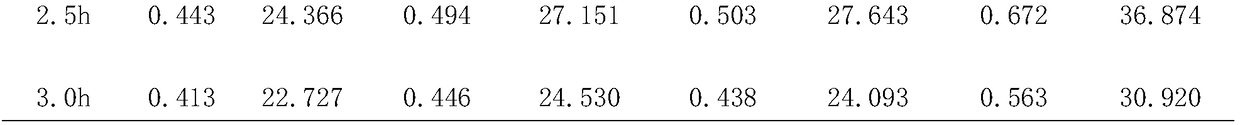

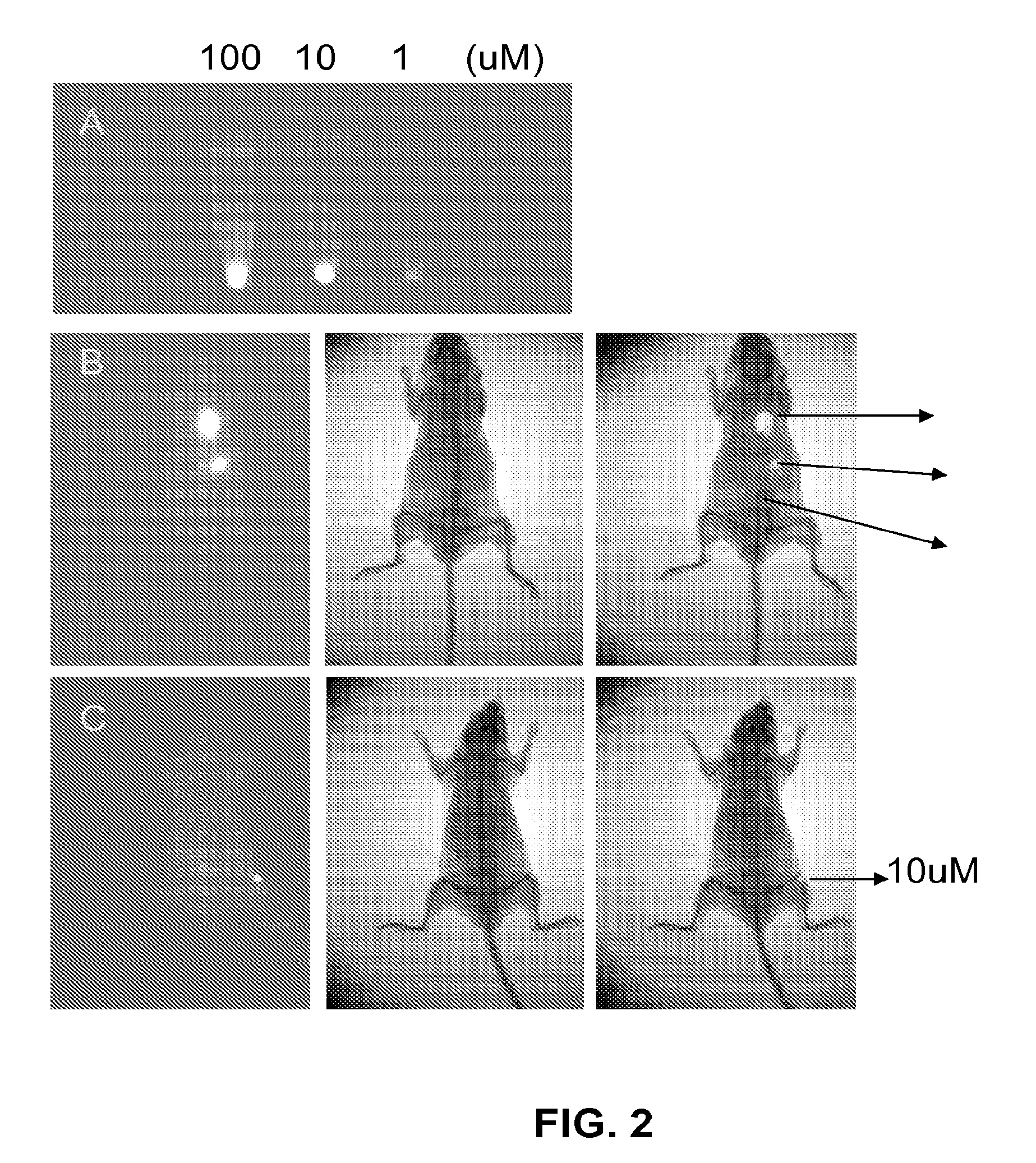

Cyanine-containing compounds for cancer imaging and treatment

This invention relates generally to cyanine-containing compounds; pharmaceutical compositions comprising cyanine-containing compounds; and methods of using cyanine-containing compounds for cancer cell imaging, cancer cell growth inhibition, and detecting cancer cells, for example. Compounds of the invention are preferentially taken up by cancer cells as compared to normal cells. This allows many uses in the cancer treatment, diagnosis, tracking and imaging fields.

Owner:EMORY UNIVERSITY +1

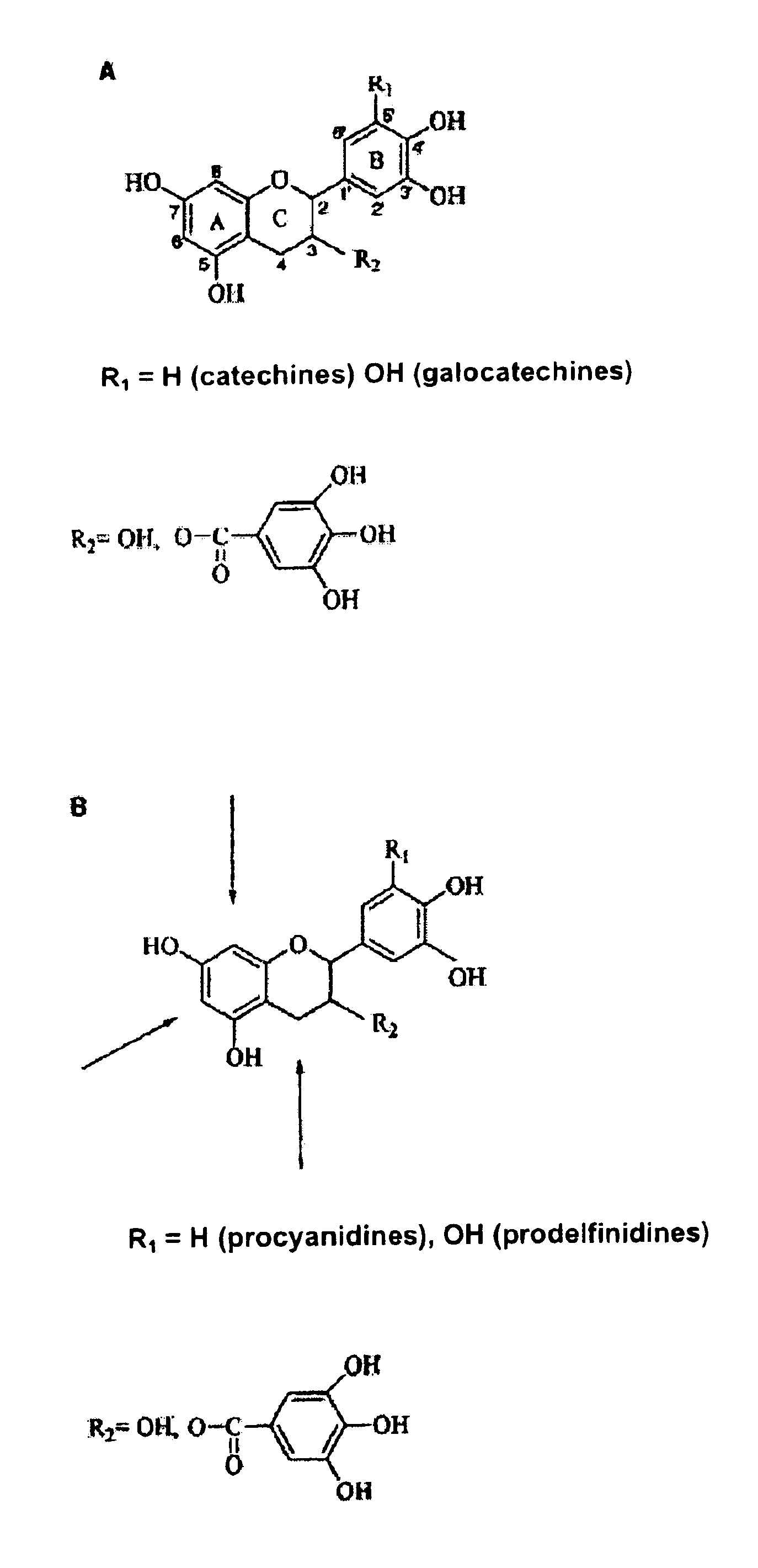

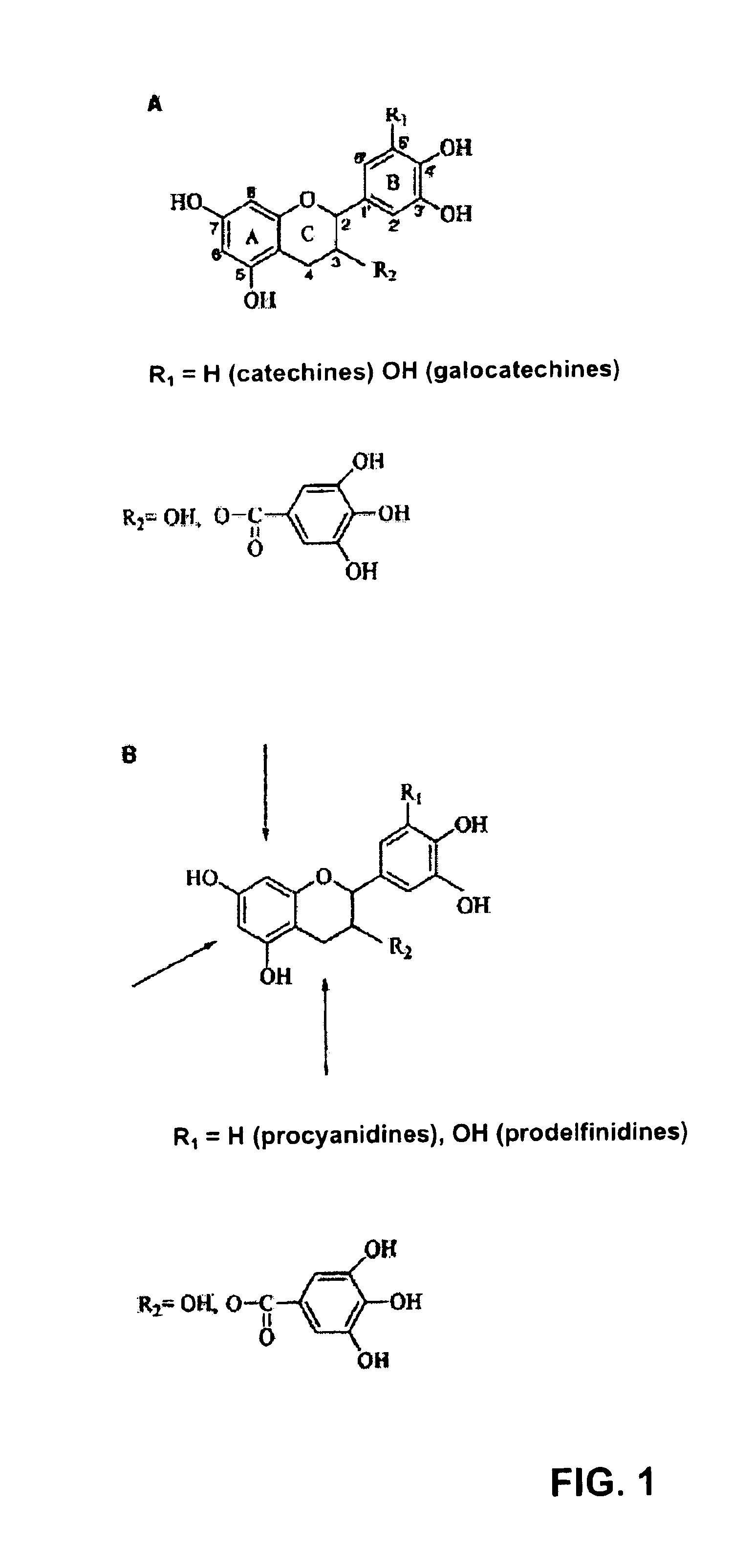

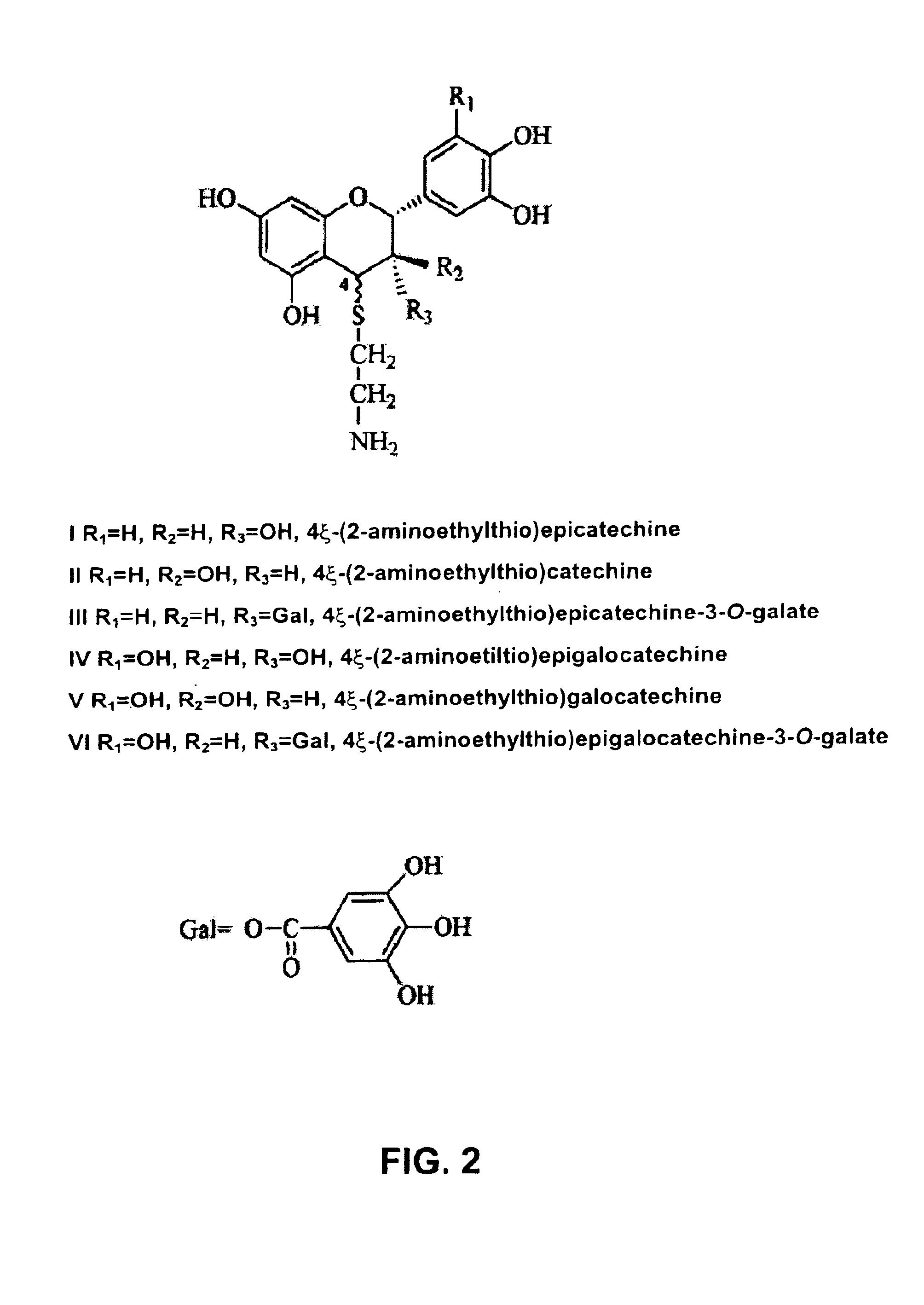

Flavanol and cysteamine conjugates

The present invention refers to new products generated by the conjugation of flavanols with molecules that contain the thiol group. New molecules are obtained from polyphenolic plant extracts rich in oligomeric and polymeric procyanidines and prodelfinidins. In this way, new products are generated with antioxidant properties for application as protective agents for the organism against disorders such as cancer, cardiovascular diseases and premature aging. The invention also refers to obtaining these new agents from waste material generated by the agroalimentary industry. Since these waste materials are highly complex mixtures a simple and effective method is described to isolate and purify these, based on the physico-chemical characteristics of the new molecules.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC)

Method for extracting high-quality proanthocyanidins from pine needle

The invention relates to a method for extracting high-quality proanthocyanidins from pine needle. The method comprises the following steps: extracting proanthocyanidins from pine needle raw material powder by using an alkaline aqueous solvent, concentrating the obtained extract liquid, extracting, adding an anti-solvent to the obtained new extract liquid for precipitating proanthocyanidins, and filtering to obtain a highly-pure proanthocyanidin product. The method has the advantages of simplicity, energy saving, environmental protection, and no need of large apparatus investment, and is very suitable for the industrialized production. The obtained highly-pure proanthocyanidin product can be used in food antioxidants, cosmetics, healthcare foods, medicines and the like.

Owner:张峻

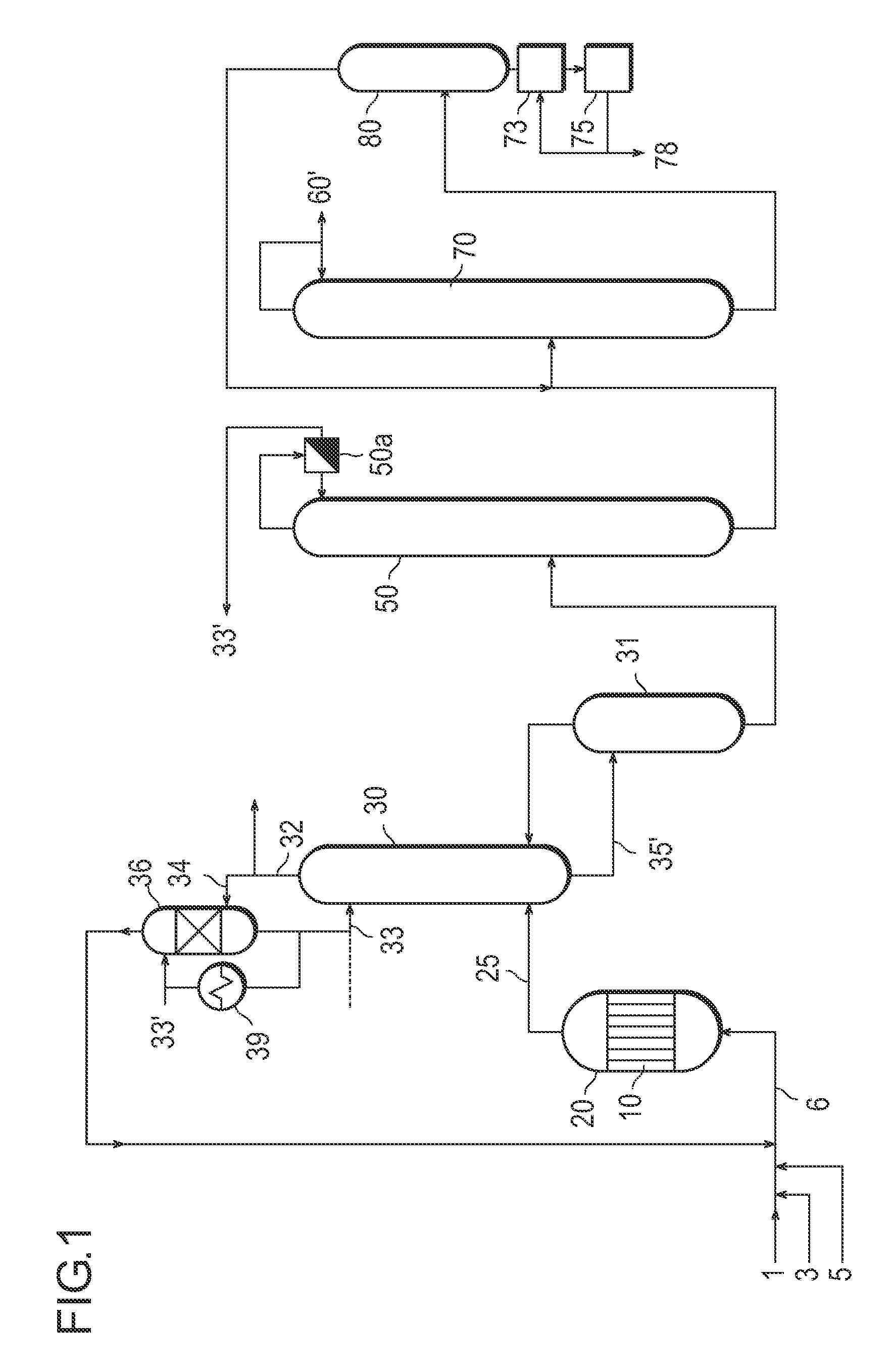

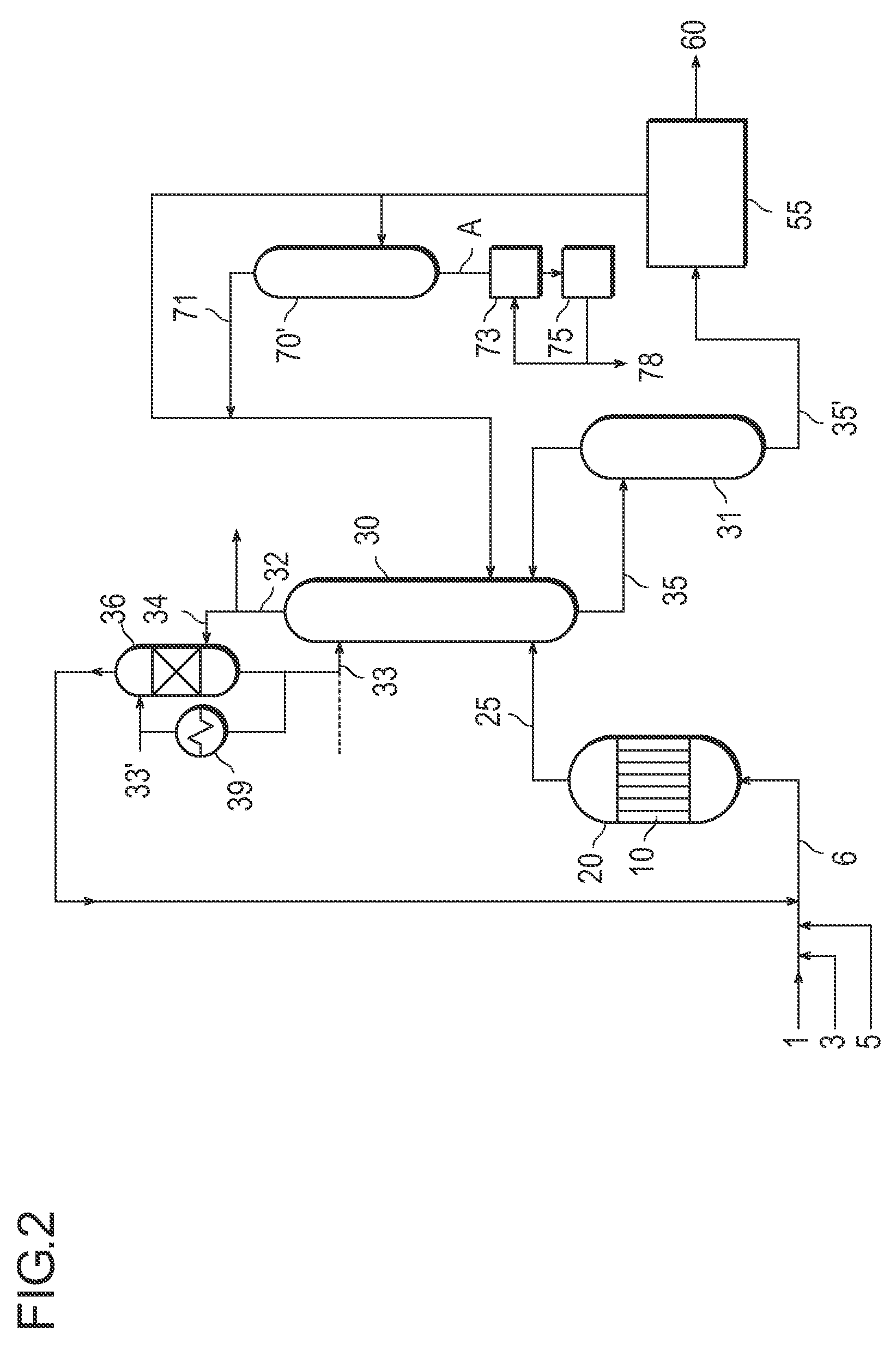

Method for producing acrylic acid, and method for producing hydrophilic resin and method for producing water-absorbing resin using production method thereof

ActiveUS8426640B2Simple methodIncrease productionOrganic compound preparationCarboxylic preparation by oxidationGas phaseFractionating column

[Problem]There is provided, in a process for producing acrylic acid having a catalytic gas-phase oxidation reaction step, a condensation step, a collection step, a distillation step, a crystallization step, an acrylic acid recovering step or the like, a production method for acrylic acid, in which contamination of acrylic acid with protoanemonin without providing any additional purification treatment to the resultant purified acrylic acid can be reduced.[Solution]The problems described above can be solved by providing the production method for acrylic acid comprising A) a step obtaining an acrylic acid-containing gas by a catalytic gas-phase oxidation reaction of gas containing a acrylic acid raw material; B) a step of obtaining the acrylic acid-containing solution by introducing the acrylic acid-containing gas to the collection column or the condensation column and performing collection or condensation; C) a step of obtaining the crude acrylic acid by introducing the acrylic acid-containing solution to the distillation column or the crystallizer and performing distillation or crystallization, wherein a step of heat treating the acrylic acid-containing solution or the crude acrylic acid containing 100 ppm by mass or more of protoanemonin, under the condition of 100° C. or more of temperature, 1 hour or more of time and a step of introducing the heat-treated acrylic acid-containing solution or the crude acrylic acid to the collection column, the condensation column, the distillation column or the crystallizer, are included.

Owner:NIPPON SHOKUBAI CO LTD

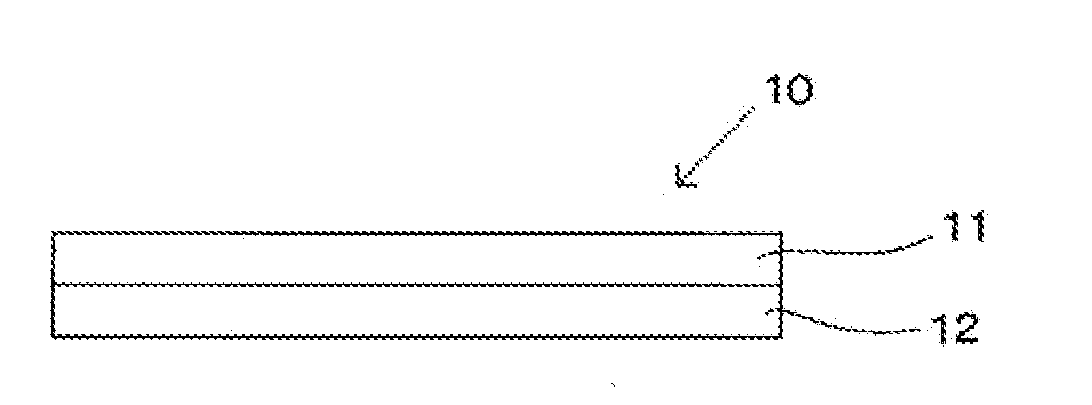

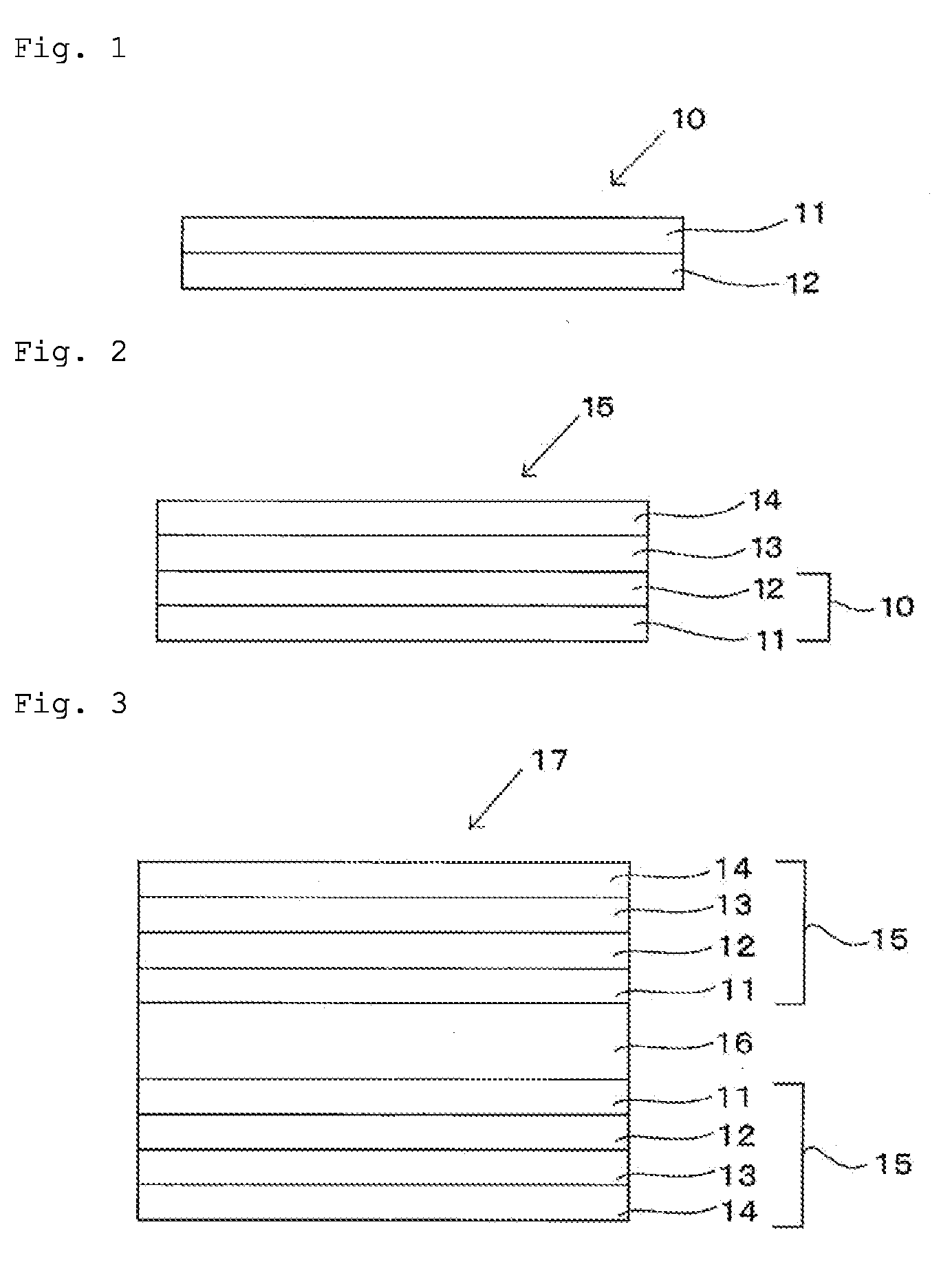

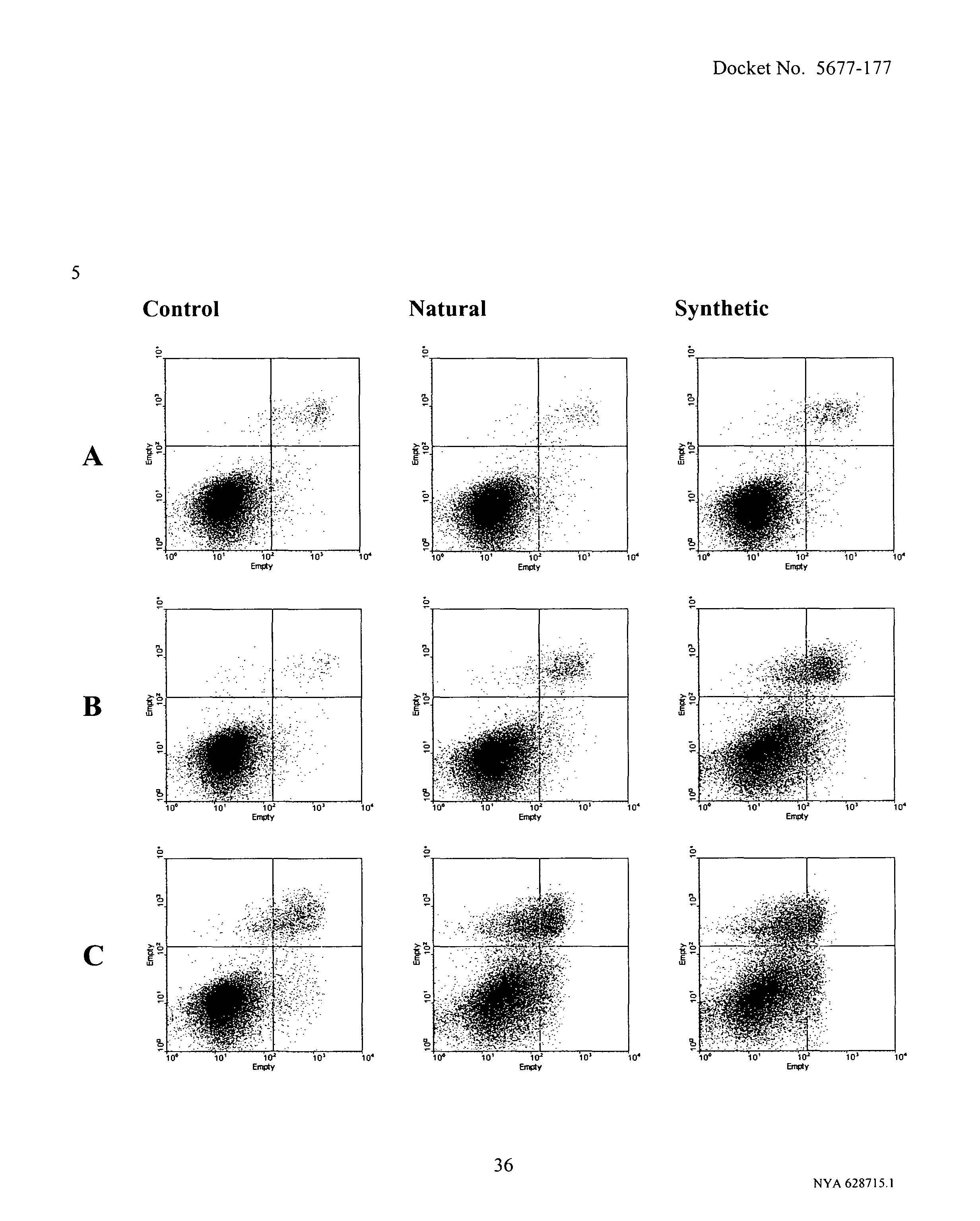

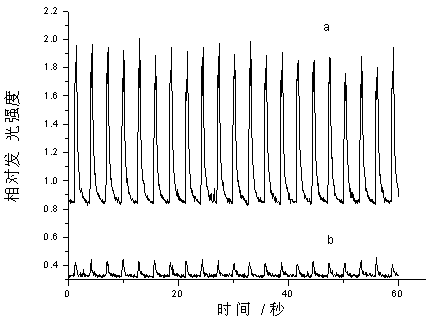

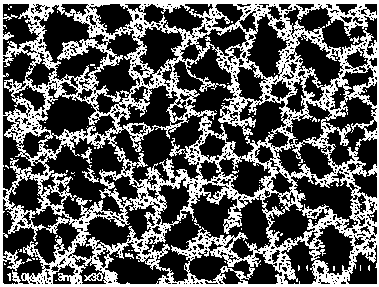

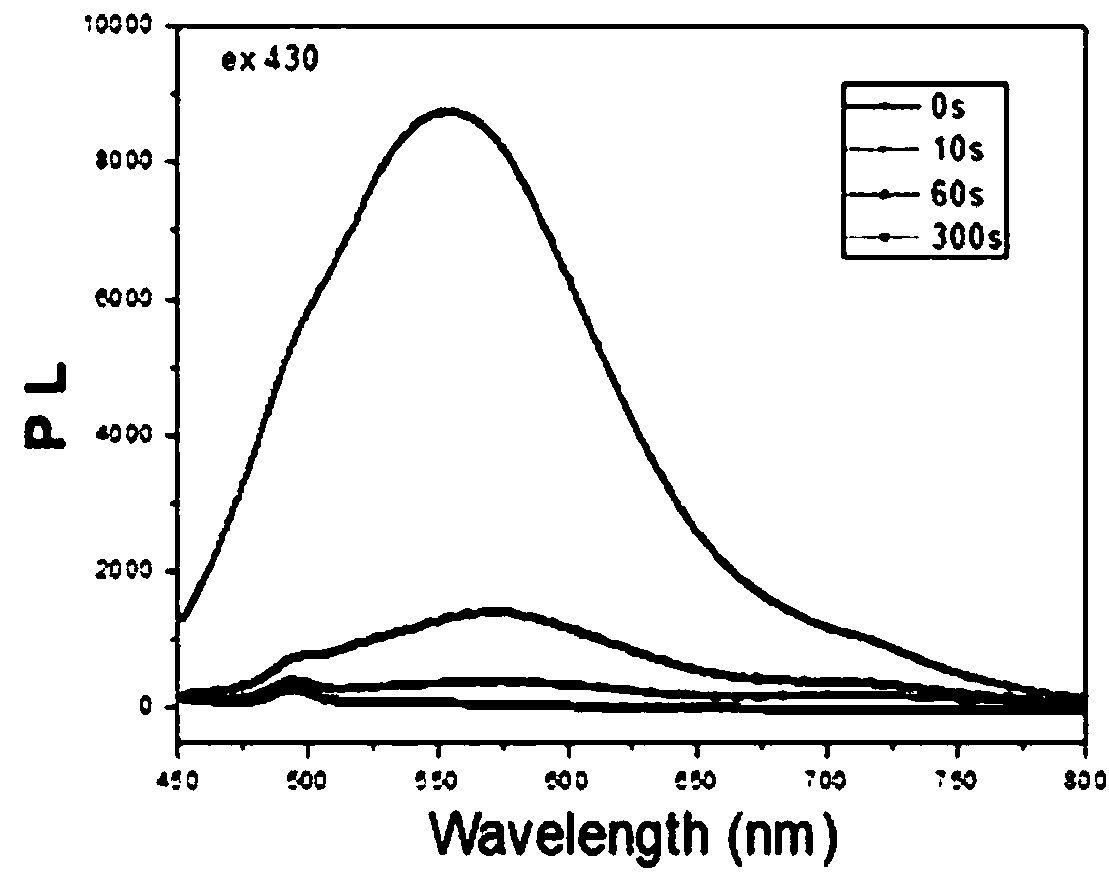

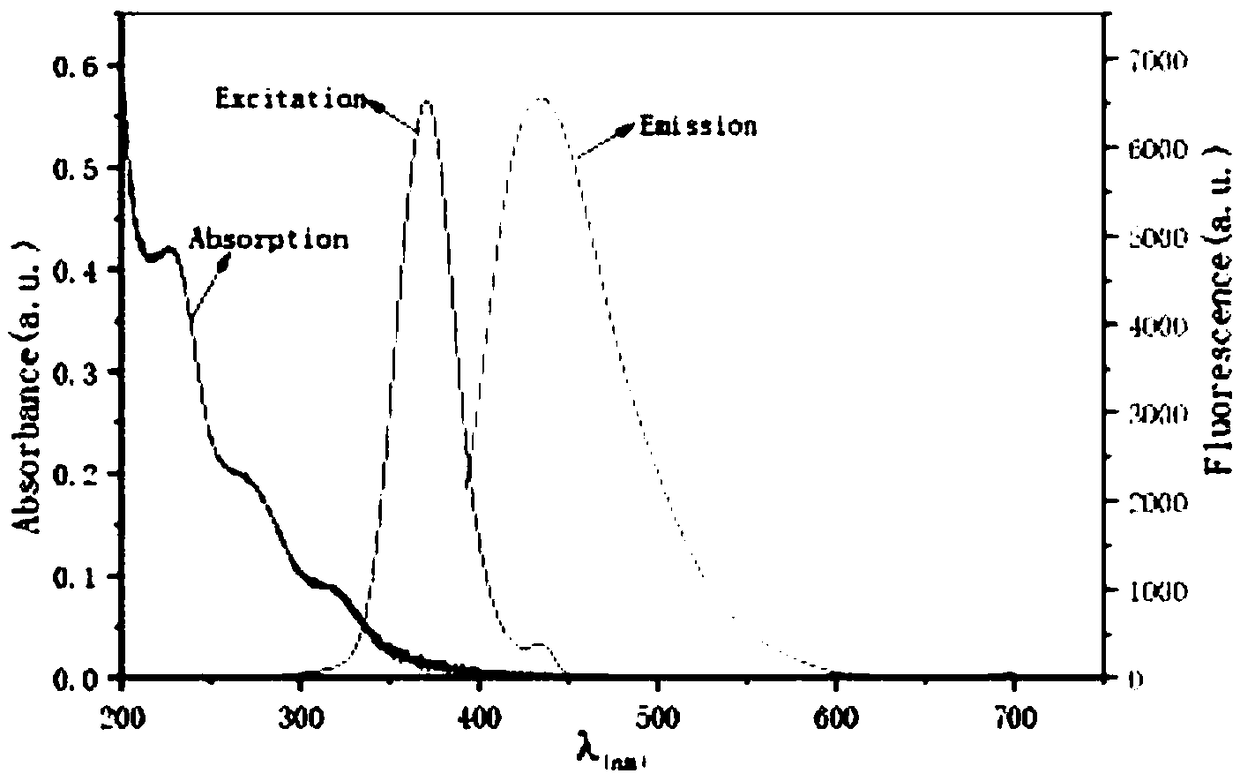

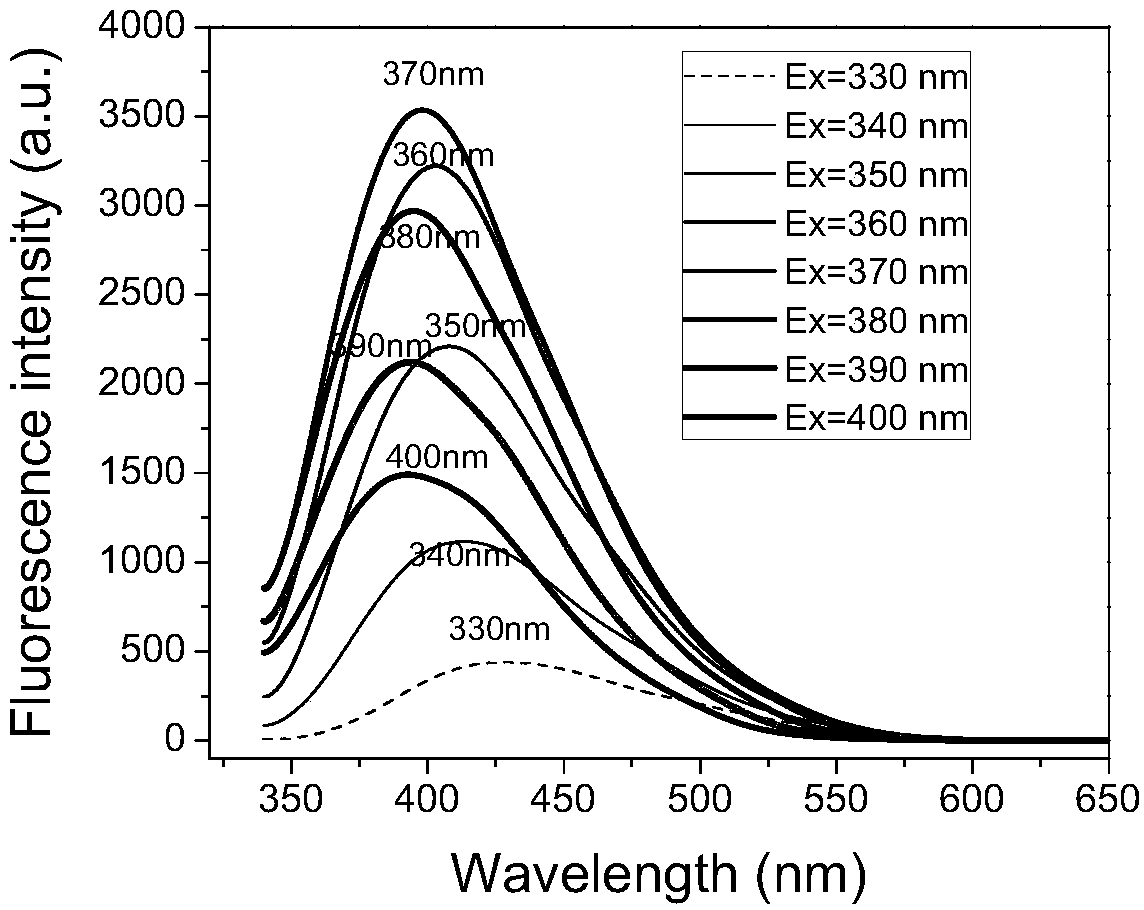

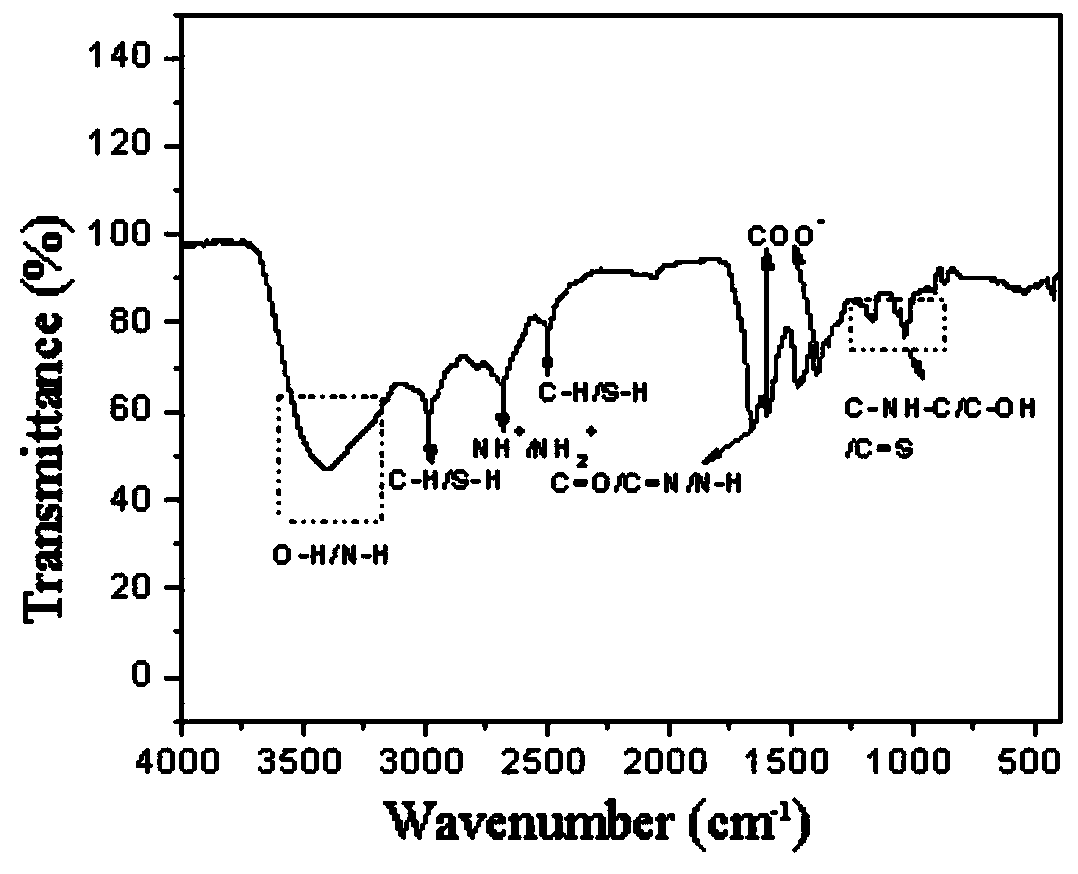

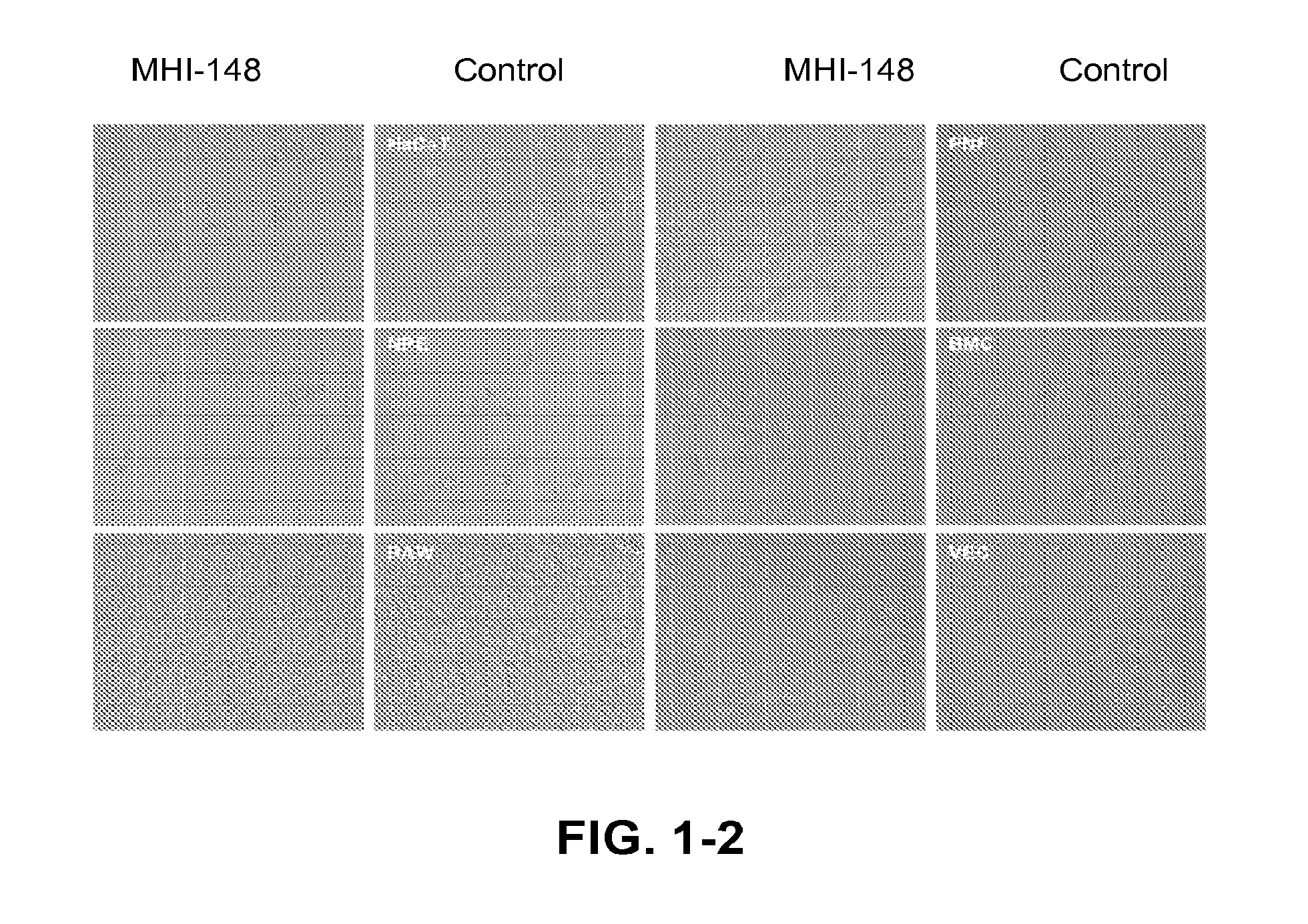

Benzo[c,d]indole rhodanine compound merocyanine and its synthesis method and application

InactiveCN106632307BHigh yieldExperiment operation is simpleOrganic chemistryPhotodynamic therapyPhotosensRhodanine

The invention discloses a benzo[c,d]indole rhodanine compound merocyanine and its synthesis method. It is used as a photosensitizer in photodynamic therapy for the first time, its dark toxicity and phototoxicity are studied, and the relationship between phototoxicity and concentration is discussed. The relationship between. The results showed that benzo[c,d]indole rhodanine complex merocyanine RC1, RC2 and RC4 had very low toxicity to SMMC‑7721 cells in the absence of light. However, RC1 and RC2 had obvious phototoxicity to SMMC‑7721 cells under light. The rhodanine complex merocyanine can be used as a potential photosensitizer in the field of PDT.

Owner:NORTHWEST UNIV

A method for extracting and separating proanthocyanidins from hawthorn meat by low-temperature two-phase cooling

InactiveCN104803960BLow semi-log clearanceRetain physiological activityOrganic chemistryNatural dyesRotary evaporatorEvaporation

The invention discloses a method for extracting and separating procyanidine of hawthorn fruit through low-temperature aqueous two-phase cooling. The method comprises steps as follows: after fresh hawthorn fruit is washed, 30-70 mL of citric acid solutions, 30-70 mL of sodium chloride solutions and 30-70 mL of isopropyl alcohol are added to every 10 g of hawthorn fruit, the mixture is cooled to subzero 18 DEG C in a freezer, taken out and subjected to homogenization treatment for three times by a homogenizer, homogenization treatment is performed for 1-3 min every time, a product is left to stand for 5-15 min, an isopropyl alcohol top phase is separated after complete phase separation, obtained isopropyl alcohol is collected, subjected to vacuum distillation through a rotary evaporator and removed through evaporation, 1-4 ml of ethanol is added, solids are precipitated, the obtained solids are subjected to vacuum drying at the temperature of 20-35 DEG C until the solids are dried, and a procyanidine extract of the hawthorn fruit is obtained. By means of the method, the variety of reagents is reduced, and non-toxic, degradable, green and environment-friendly properties are realized; a homogenizing technology is introduced to the extraction process, mass transfer is effectively improved, the extraction time is greatly shortened, and the purity of the obtained procyanidine of the hawthorn fruit is higher.

Owner:YUNNAN MINZU UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

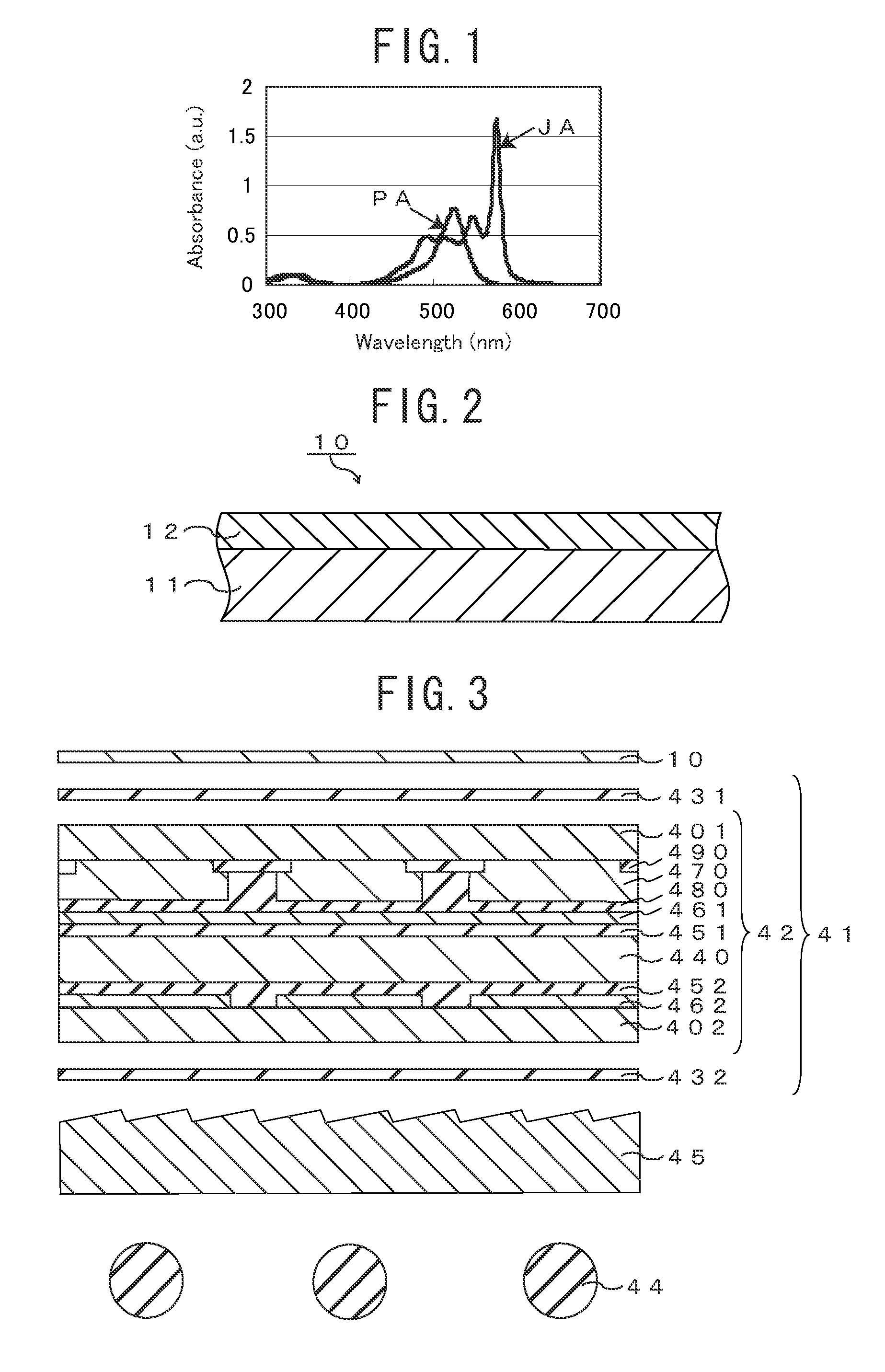

![Benzo[c,d]indole rhodanine compound merocyanine and its synthesis method and application Benzo[c,d]indole rhodanine compound merocyanine and its synthesis method and application](https://images-eureka.patsnap.com/patent_img/067e2904-292a-4bab-ac54-5a07cb749440/161130053235.png)

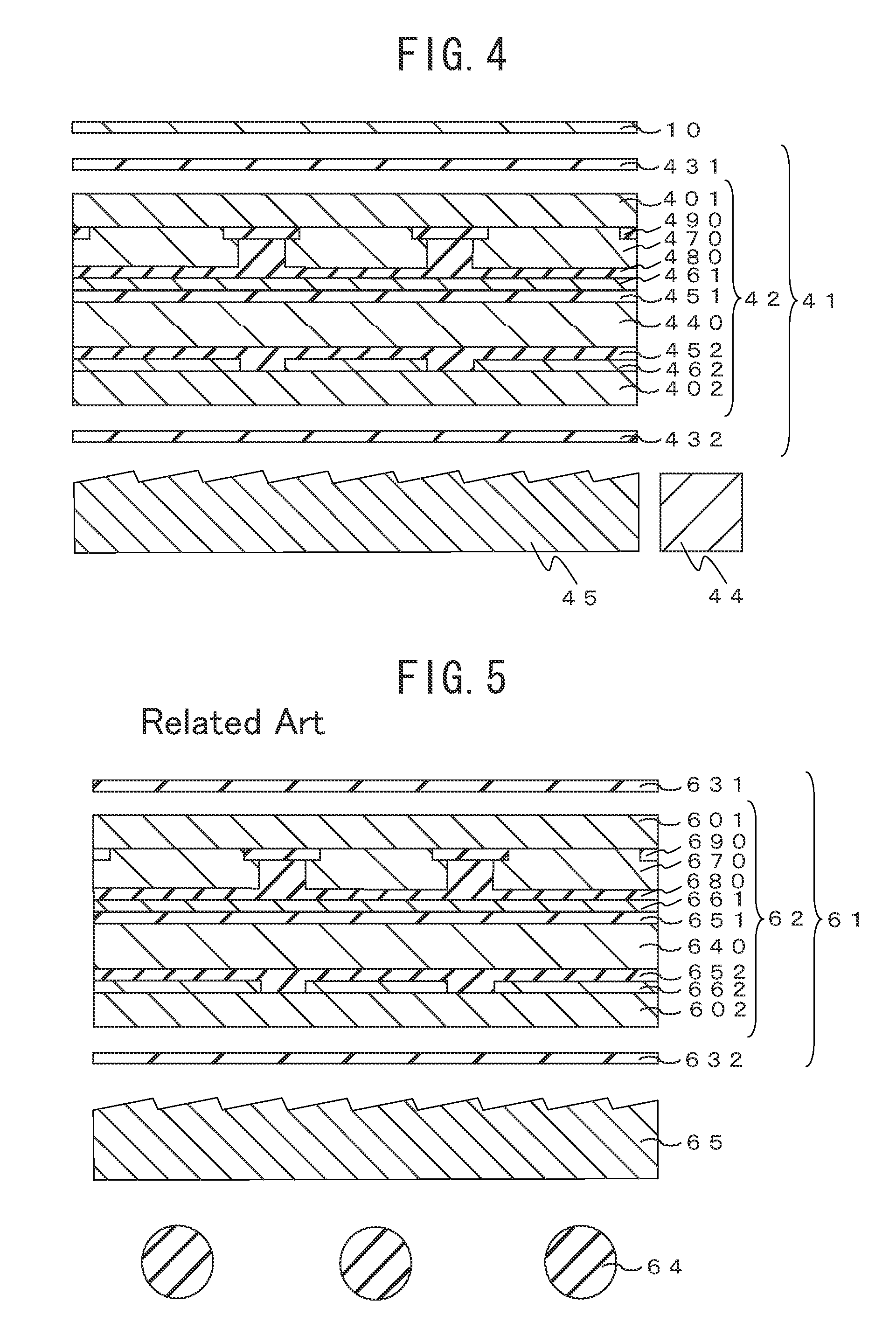

![Benzo[c,d]indole rhodanine compound merocyanine and its synthesis method and application Benzo[c,d]indole rhodanine compound merocyanine and its synthesis method and application](https://images-eureka.patsnap.com/patent_img/067e2904-292a-4bab-ac54-5a07cb749440/161130053238.png)

![Benzo[c,d]indole rhodanine compound merocyanine and its synthesis method and application Benzo[c,d]indole rhodanine compound merocyanine and its synthesis method and application](https://images-eureka.patsnap.com/patent_img/067e2904-292a-4bab-ac54-5a07cb749440/161130053241.png)