Procyanidine-modified carboxymethyl chitosan

A technology of carboxymethyl chitosan and proanthocyanidin, which is applied in the field of preparation of carboxymethyl chitosan to achieve the effects of short production cycle, increased molecular weight and prolonged degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

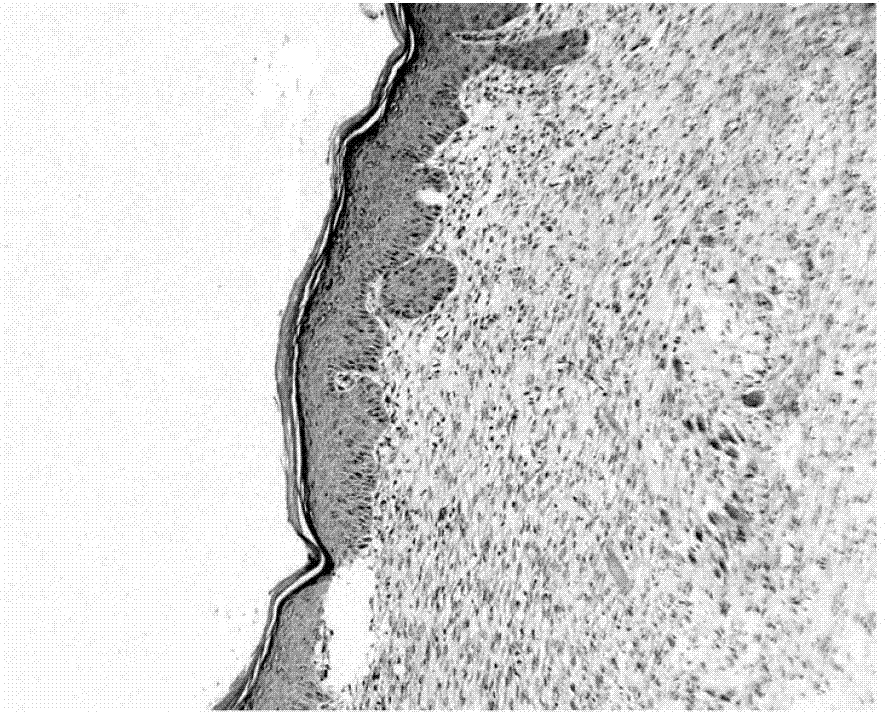

Image

Examples

Embodiment 1

[0039] Take 0.5g of proanthocyanidin (polymerization degree is 3) and dissolve in 100g of purified water, filter; take 20g of carboxymethyl chitosan (weight average molecular weight is 150,000), add into 1000g of purified water to dissolve, filter; stir the proanthocyanidin solution Slowly add carboxymethyl chitosan solution, stir well, and react at 40°C for 2.5 hours. Then, 3000 mL of absolute ethanol was added under stirring to generate a precipitate. Filter, wash the precipitate 3 times with 75% ethanol, then wash 3 times with absolute ethanol, and dry in vacuum at 40°C for 24 hours to obtain 17.7 g of proanthocyanidin-modified carboxymethyl chitosan with a yield of about 86%. According to the second method of the second appendix of the Chinese Pharmacopoeia 2010 edition, the dynamic viscosity of the 1% mass concentration aqueous solution is 1,885mPa.s as measured by a rotor-type rotational viscometer.

Embodiment 2

[0041] Take 1g of proanthocyanidin (polymerization degree is 3) and dissolve in 100g of purified water, filter; take 20g of carboxymethyl chitosan (weight average molecular weight is 150,000), add into 1000g of purified water to dissolve, filter; Add it into the carboxymethyl chitosan solution, stir well, and react at 50°C for 2.5 hours. Then, 3300 mL of 95% ethanol was added under stirring to generate a precipitate. After filtering, the precipitate was washed three times with 75% ethanol, then three times with absolute ethanol, and dried in vacuum at 40°C for 24 hours to obtain 18.2 g of proanthocyanidin-modified carboxymethyl chitosan with a yield of about 87%. According to the second method of the second appendix of the Chinese Pharmacopoeia 2010 edition, the kinetic viscosity of the 1% mass concentration aqueous solution is 3,260mPa.s, measured with a rotor-type rotational viscometer.

Embodiment 3

[0043] Take 1g of proanthocyanidin (polymerization degree is 3) and dissolve in 100g of purified water to make an aqueous solution with a mass concentration of 1%, and filter; take 20g of carboxymethyl chitosan (weight average molecular weight is 150,000), add 1000g of purified water to dissolve, Filtration; slowly add the proanthocyanidin solution into the carboxymethyl chitosan solution under stirring state, fully stir evenly, and react at 50° C. for 1 hour. Then, 3300 mL of 95% ethanol was added under stirring to generate a precipitate. After filtration, the precipitate was washed three times with 75% ethanol, then three times with absolute ethanol, and dried in vacuum at 40°C for 24 hours to obtain 17.8 g of proanthocyanidin-modified carboxymethyl chitosan with a yield of about 85%. According to the second method of the second appendix of the Chinese Pharmacopoeia 2010 edition, the dynamic viscosity of the 1% mass concentration aqueous solution is 2,590mPa.s.

[0044] Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com