A method for extracting and separating proanthocyanidins from hawthorn meat by low-temperature two-phase cooling

A technology of proanthocyanidins and two-phase water, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of reducing the activity of hawthorn proanthocyanidins, changing the sensory perception of hawthorn proanthocyanidins, and poor stability of hawthorn proanthocyanidins, so as to achieve easy follow-up processing , Shorten extraction time, inhibit enzymatic browning and non-enzymatic browning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

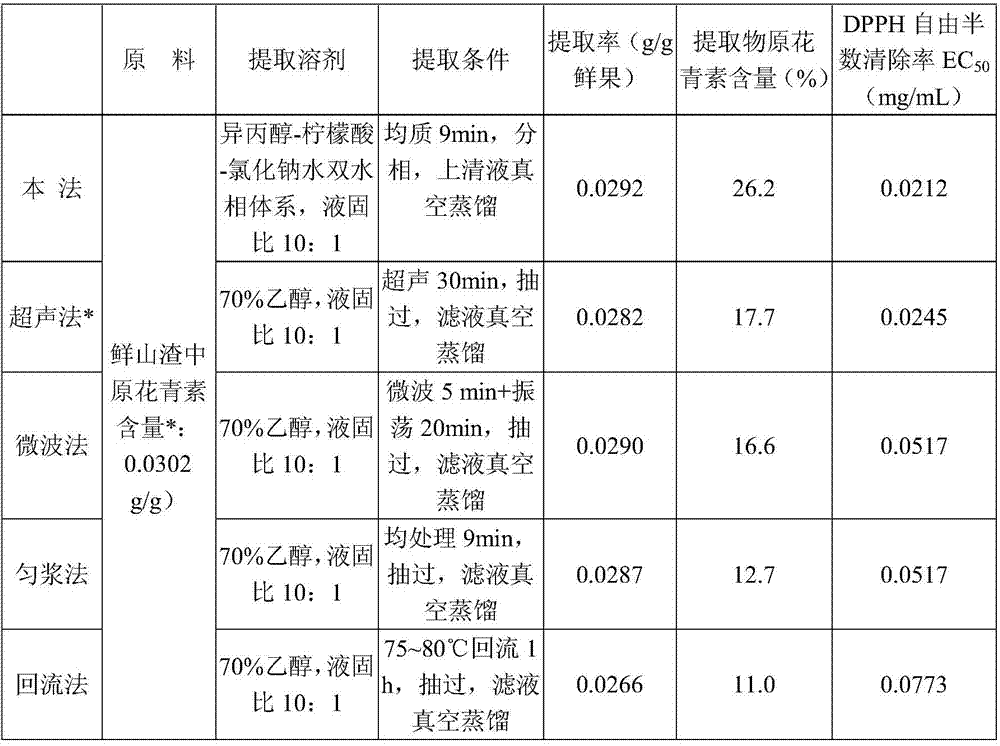

Method used

Image

Examples

Embodiment 1

[0022] The specific steps of the method for extracting and separating proanthocyanidins from hawthorn meat by low-temperature two-phase cooling of the present invention are as follows:

[0023] After cleaning the fresh mountain slag, add 30mL citric acid solution, 30mL sodium chloride solution, and 30mL isopropanol for every 10 grams of mountain slag, put it in a freezer and cool it to -18°C, take it out, and homogenize it with a homogenizer Treat three times, each time for 1 min, and let stand for 5 min. After the phase separation is complete, separate the upper phase of isopropanol, collect the obtained isopropanol and evaporate the isopropanol by vacuum distillation with a rotary evaporator, add 1ml of ethanol to wash the solid The resulting solid was vacuum-dried at 20° C. to dryness to obtain the hawthorn proanthocyanidin extract.

[0024] The concentration of the citric acid solution is 1 wt%, pH=3.

[0025] The solubility of the sodium chloride solution is 30wt%.

Embodiment 2

[0027] The specific steps of the method for extracting and separating proanthocyanidins from hawthorn meat by low-temperature two-phase cooling of the present invention are as follows:

[0028] After washing the fresh mountain slag, add 70mL citric acid solution, 70mL sodium chloride solution, and 70mL isopropanol for every 10 grams of mountain slag, put it in a freezer and cool it to -18°C, take it out, and homogenize it with a homogenizer Treat three times, each time for 3 minutes, and let stand for 15 minutes. After the phase separation is complete, separate the upper phase of isopropanol, collect the obtained isopropanol and evaporate the isopropanol by vacuum distillation with a rotary evaporator, add 4ml of ethanol to wash the solid The resulting solid was vacuum-dried at 35°C to dryness to obtain the hawthorn proanthocyanidin extract.

[0029] The concentration of the citric acid solution is 1 wt%, pH=3.

[0030] The solubility of the sodium chloride solution is 30wt%....

Embodiment 3

[0032] The specific steps of the method for extracting and separating proanthocyanidins from hawthorn meat by low-temperature two-phase cooling of the present invention are as follows:

[0033] After cleaning the fresh mountain slag, add 50mL citric acid solution, 50mL sodium chloride solution, and 50mL isopropanol for every 10 grams of mountain slag, put it in a freezer and cool it to -18°C, take it out, and homogenize it with a homogenizer Treat three times, each time for 2 minutes, and let stand for 10 minutes. After the phase separation is complete, separate the upper phase of isopropanol, collect the obtained isopropanol and evaporate the isopropanol by vacuum distillation with a rotary evaporator, add 2ml of ethanol to wash the solid. The resulting solid was vacuum-dried at 30°C to dryness to obtain the hawthorn proanthocyanidin extract.

[0034] The concentration of the citric acid solution is 1 wt%, pH=3.

[0035] The solubility of the sodium chloride solution is 30wt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com