Method for extracting moringa oleifera saponins from moringa oleifera leaf

A technology of Moringa oleifera leaves and Moringa oleifera, applied in the field of separation and purification of natural products, can solve problems such as not involving extraction, and achieve the effects of reducing the amount of impurities introduced, saving resources, and having a high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

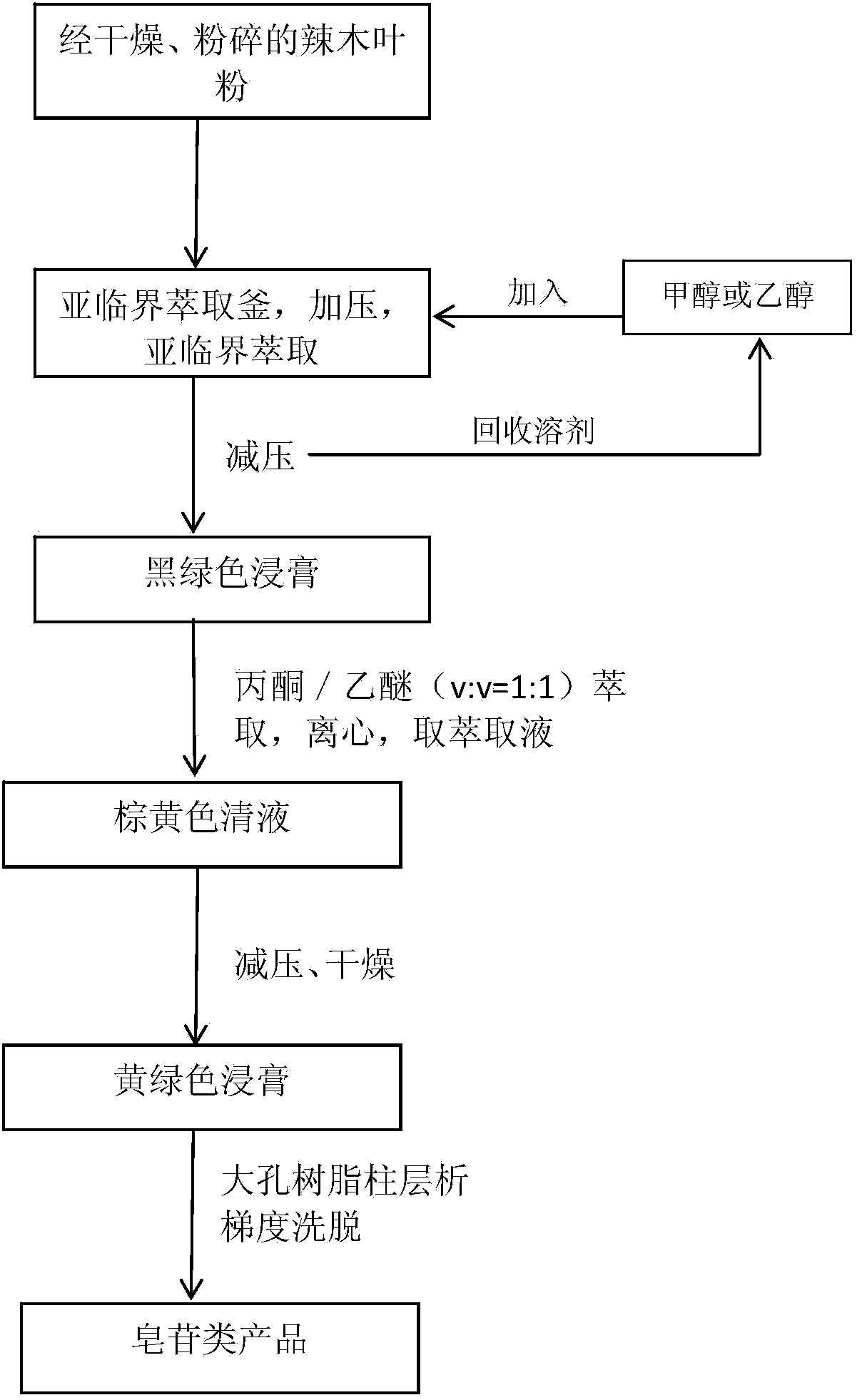

Method used

Image

Examples

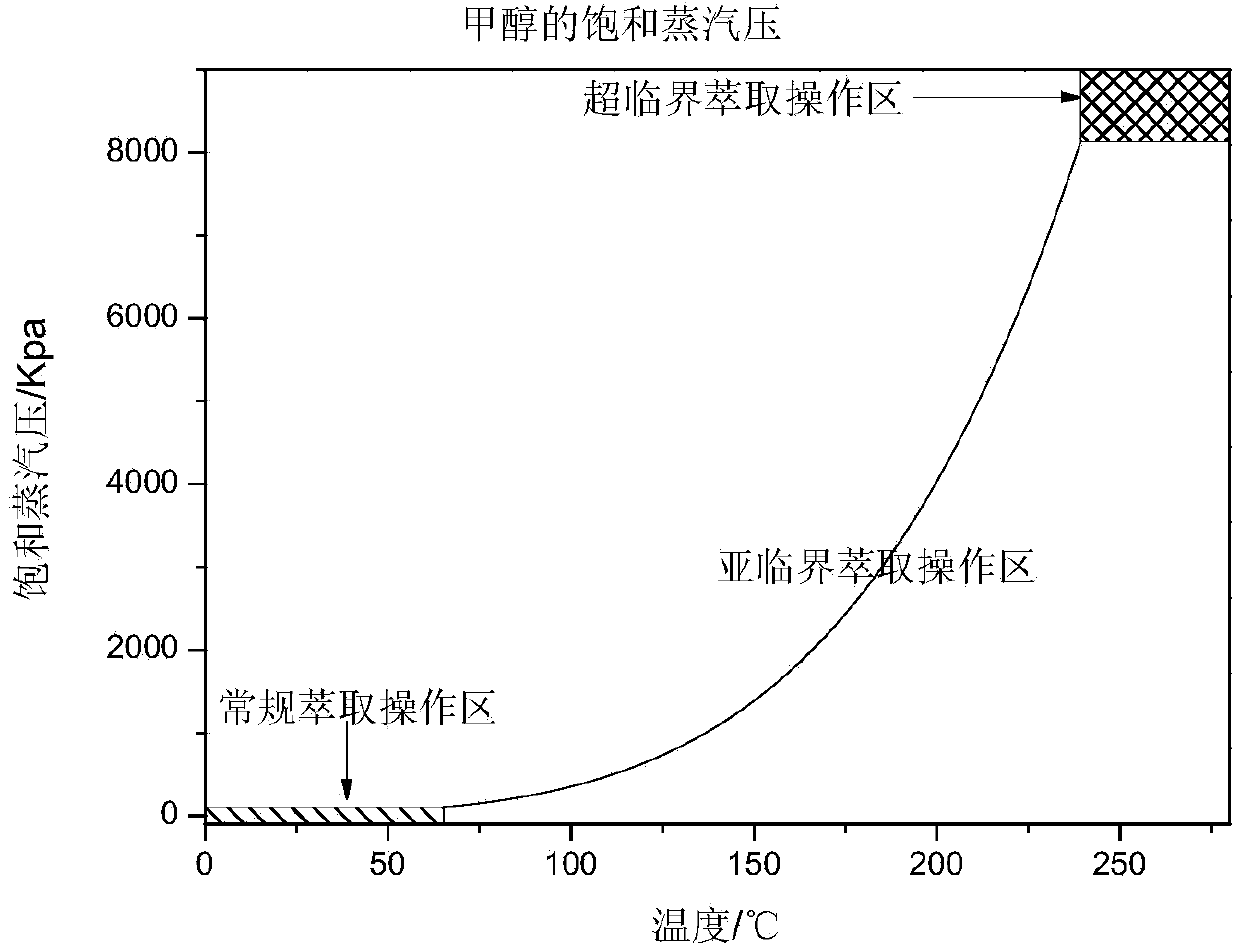

Embodiment 1

[0036] Take 1 kg of Moringa leaves, crush them through a 700-mesh sieve, put them into a filter frame, put them into a CBE-5L type subcritical extraction kettle, seal the extraction kettle, adjust the vacuum in the extraction kettle to 0.1Mpa, add methanol extractant, and adjust the solid-liquid The ratio is 1:20 (g:ml), the extraction temperature is adjusted to 200°C, the extraction pressure is 4.048MPa, and the extraction is carried out 3 times, each extraction is 4h, the extract is put into a solvent recovery kettle, the pressure is reduced to a vacuum of 0.1Mpa to recover the solvent, and vacuum drying , to obtain black-green extract. Add 5 times the amount (by mass) of acetone / ether (v:v=1:1) to the extract for extraction, centrifuge in a centrifuge, take the extract, depressurize to a vacuum of 0.01-0.1Mpa, concentrate, and dry Obtain a yellow extract; take the extract and put it on a D101 macroporous resin column, and use a methanol-water eluent with a volume ratio of 5...

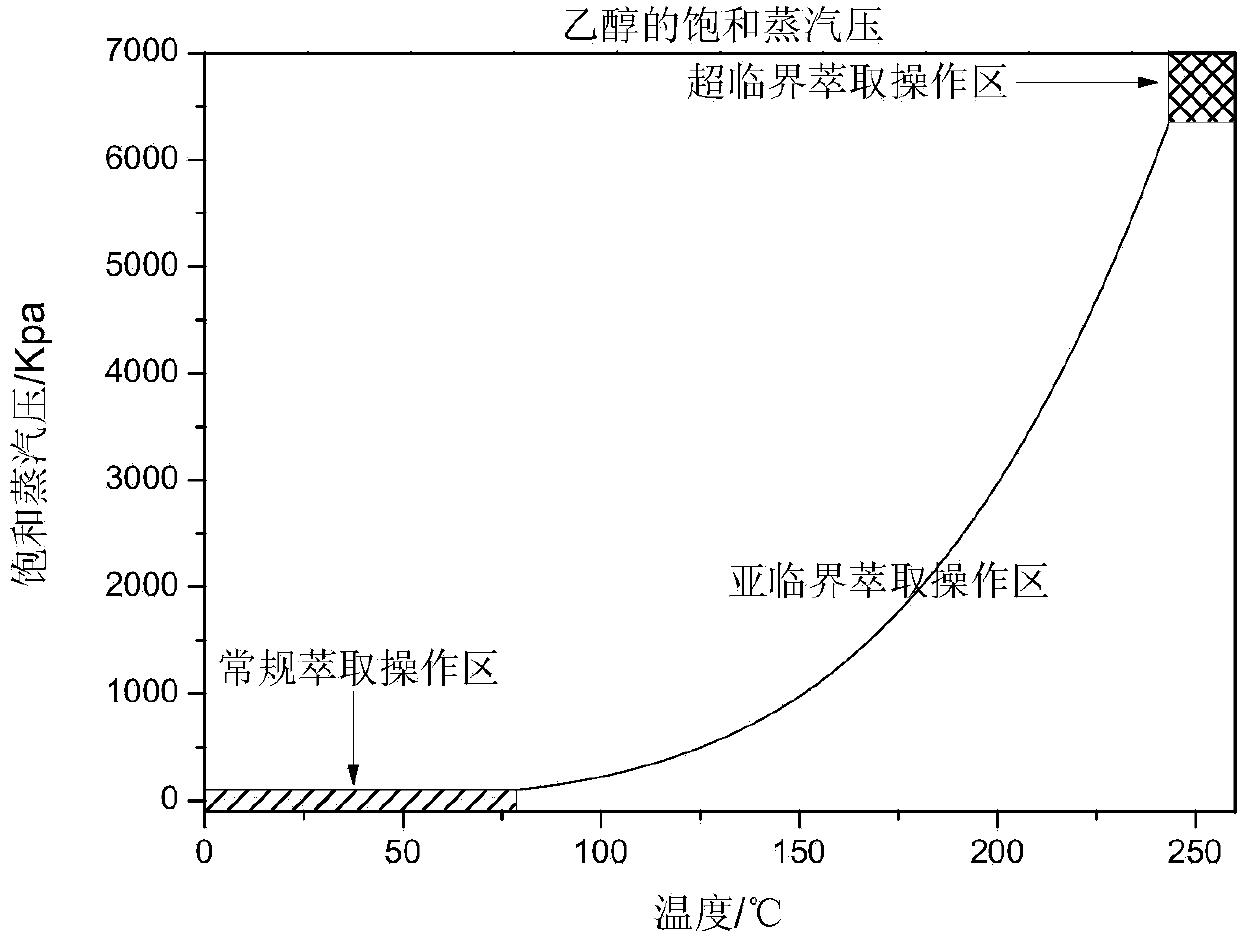

Embodiment 2

[0038]Get Moringa leaf 0.9kg, pulverize through 100 mesh sieves, put into filter frame, drop into subcritical extraction kettle, airtight extraction kettle, adjust the vacuum in the extraction kettle to 0.06Mpa, add ethanol extractant, adjust solid-liquid ratio to be 1 :5 (g:ml), adjust the extraction temperature to 80°C, the extraction pressure to 0.108MPa, extract 2 times, extract 0.5h each time, put the extract into the solvent recovery kettle, reduce the pressure to a vacuum of 0.01Mpa to recover the solvent, and dry it in vacuum to obtain Black-green extract. Add 5 times the amount (by mass) of acetone / ether (v:v=1:1) to the extract for extraction, centrifuge in a centrifuge, take the extract, depressurize to a vacuum of 0.01-0.1Mpa, concentrate, and dry Obtain a yellow extract; take the extract and put it on an X-5 macroporous resin column, and use methanol-water and anhydrous methanol eluent with a volume ratio of 50:50 to 99.9:0.1 to elute according to the gradient fro...

Embodiment 3

[0040] Get Moringa leaf 1.3kg, crush through a 500-mesh sieve, put into a filter frame, put into a subcritical extraction kettle, seal the extraction kettle, adjust the vacuum in the extraction kettle to 0.08Mpa, add ethanol extractant, and adjust the solid-liquid ratio to 1 :10 (g:ml), adjust the extraction temperature to 100°C, the extraction pressure to 0.223MPa, extract 3 times, extract 2h each time, put the extract into the solvent recovery kettle, reduce the pressure to a vacuum of 0.1Mpa, recover the solvent, and dry in vacuum to obtain Black-green extract. Add 5 times the amount (by mass) of acetone / ether (v:v=1:1) to the extract for extraction, centrifuge in a centrifuge, take the extract, depressurize to a vacuum of 0.01-0.1Mpa, concentrate, and dry Obtain a yellow extract; put the extract on an AB-8 macroporous resin column, and elute with ethanol-water and absolute ethanol eluent with a volume ratio of 50:50 to 99.9:0.1 according to the gradient from small to large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com