Method for producing marsh gas by using entermorpha prolifera as raw material

A biogas and prolifera technology, applied in the energy field, can solve problems such as insufficient use, and achieve the effects of preventing marine red tides, simplifying the process and reducing marine red tides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

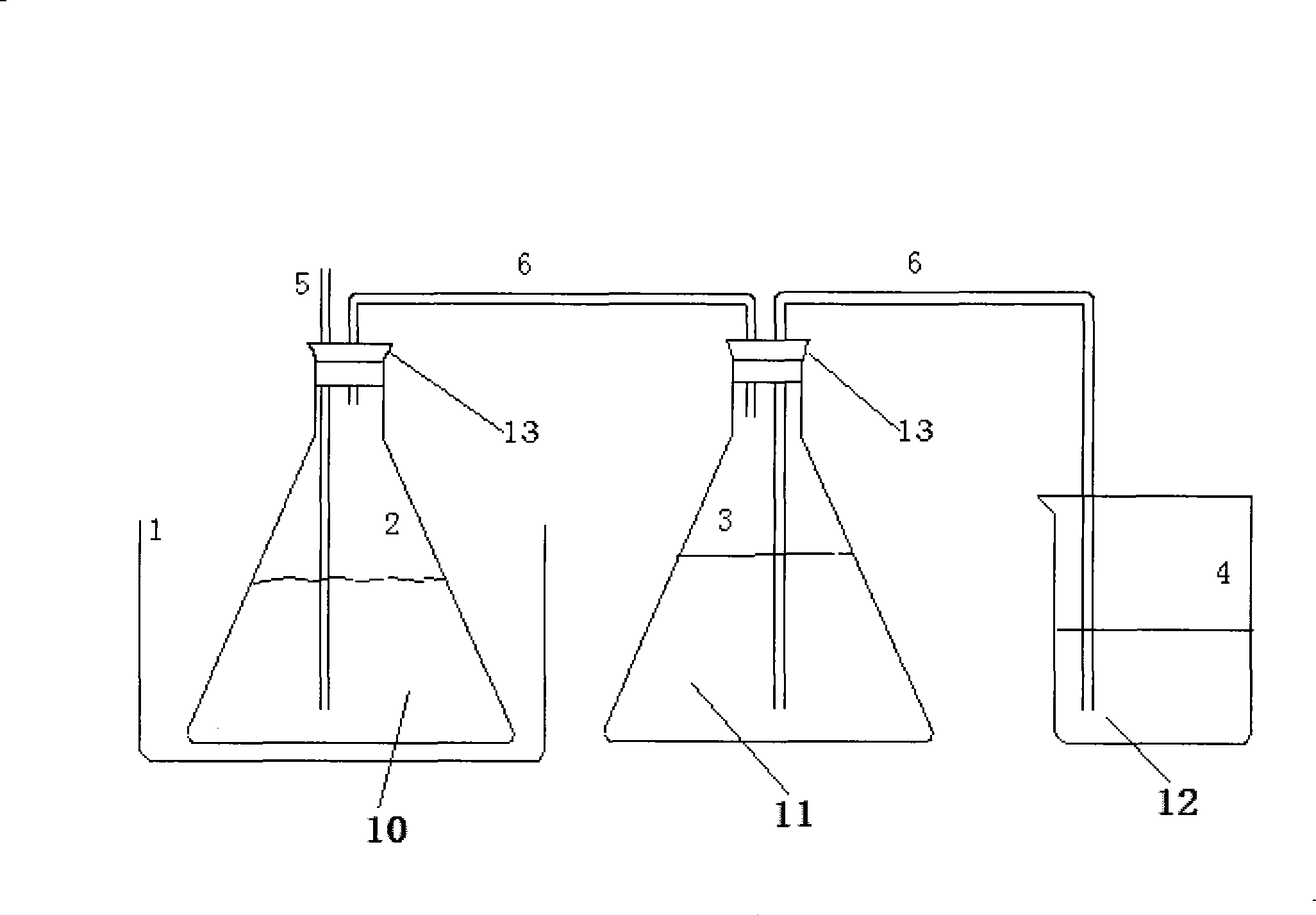

Method used

Image

Examples

Embodiment 1

[0024] (1) Rinse Enteromorpha with tap water to remove impurities such as salt and silt;

[0025] (2) Add a certain amount of water to the Enteromorpha obtained in step (1), and process it with a high-speed tissue grinder for 3 minutes to make the Enteromorpha particle size reach 0.5-2 mm.

[0026] (3) 100 grams (9.76 grams of dry weight) of Enteromorpha (dry weight 9.76 grams) that step (2) gained is dropped into in the fermenter, add inoculum cow dung 61.3 grams (9.76 grams of dry weight), at this moment, inoculum TS (total solid content ) and the weight ratio of Enteromorpha TS (total solid content) is 1:1;

[0027] (4) add fresh water in the fermentation device, and adjust the total solids content in the fermentation device to be 2.58%;

[0028] (5) Add a small amount of saturated lime water in the reaction device, make the initial pH value of the fermentation broth at 6.5;

[0029] (6) Seal the fermentation device, place it in a constant temperature water bath, control ...

Embodiment 2

[0033] (1) Rinse Enteromorpha with tap water to remove impurities such as salt and silt;

[0034] (2) Add a certain amount of water to the Enteromorpha obtained in step (1), and process it with a high-speed tissue grinder for 5 minutes to make the Enteromorpha particle size reach 0.5-2mm.

[0035] (3) 300 grams of Enteromorpha (dry weight 29.28 grams) of step (2) gained is dropped in the fermenter, add the inoculum pig manure of dry weight 9.76 grams, at this moment, inoculum TS (total solid content) and Enteromorpha The weight ratio of moss TS (total solid content) is 1:3;

[0036] (4) Add fresh water in the fermentation device, and adjust the total solids content in the fermentation device to be 5.16%;

[0037] (5) Add a small amount of plant ash in the reaction device to make the initial pH value of the fermentation broth at 7.5;

[0038] (6) Seal the fermentation device, place it in a constant temperature water bath, control the fermentation temperature at 35±3°C, and st...

Embodiment 3

[0042] (1) Rinse Enteromorpha with tap water to remove impurities such as salt and silt;

[0043] (2) Add a certain amount of water to the Enteromorpha obtained in step (1), and process it with a high-speed tissue grinder for 5 minutes to make the Enteromorpha particle size reach 0.5-2mm.

[0044] (3) 400 grams of Enteromorpha (dry weight 39.04 grams) that step (2) gained is dropped into in the fermenter, add the inoculum human excrement of dry weight 9.76 grams, at this moment, inoculum TS (total solid content) and Enteromorpha The weight ratio of moss TS (total solid content) is 1:5;

[0045] (4) Add fresh water in the fermentation device, and adjust the total solids content in the fermentation device to be 9.98%;

[0046] (5) Adding a small amount of ammoniacal liquor to the reaction device to make the initial pH value of the fermentation broth at 7.0;

[0047] (6) Seal the fermentation device, place it in a constant temperature water bath, control the fermentation temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com