A kind of carboxymethyl chitosan drug-loaded microspheres and preparation method thereof

A technology of carboxymethyl chitosan and microspheres, which is applied in the field of drug carriers and its preparation, can solve the problems of destroying drug efficacy and complicated operation, and achieve the effects of good sustained release performance, simple preparation process, and high coating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

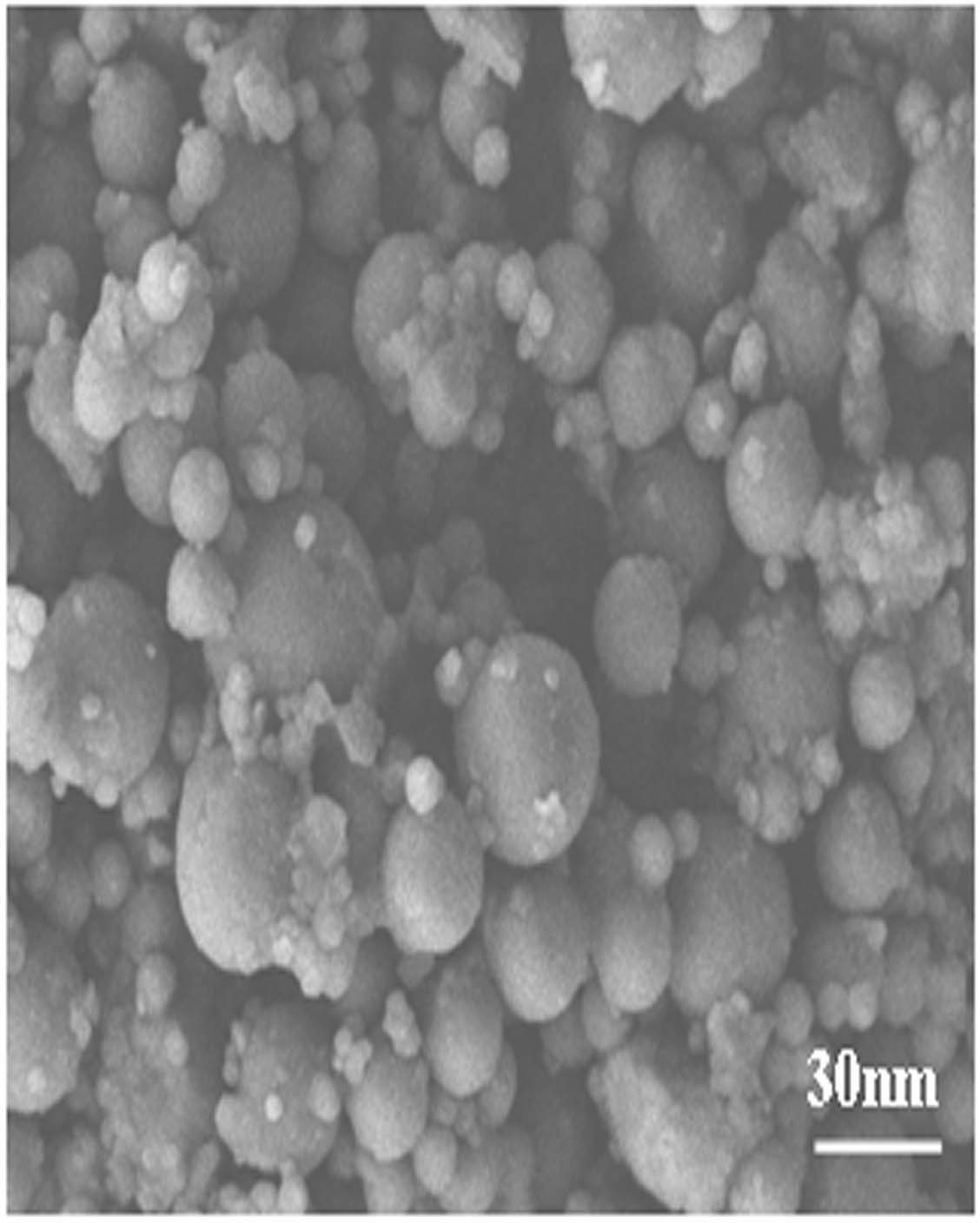

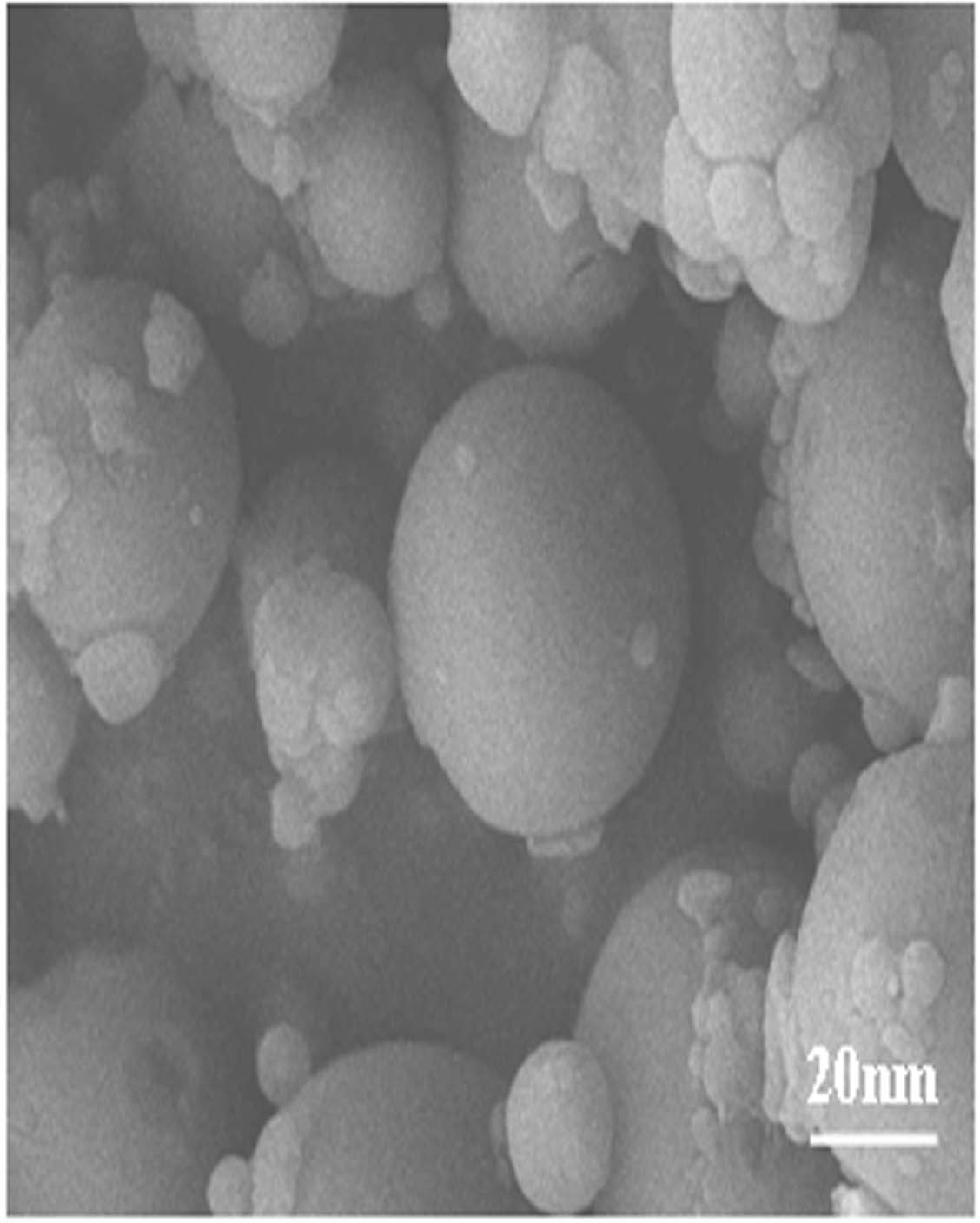

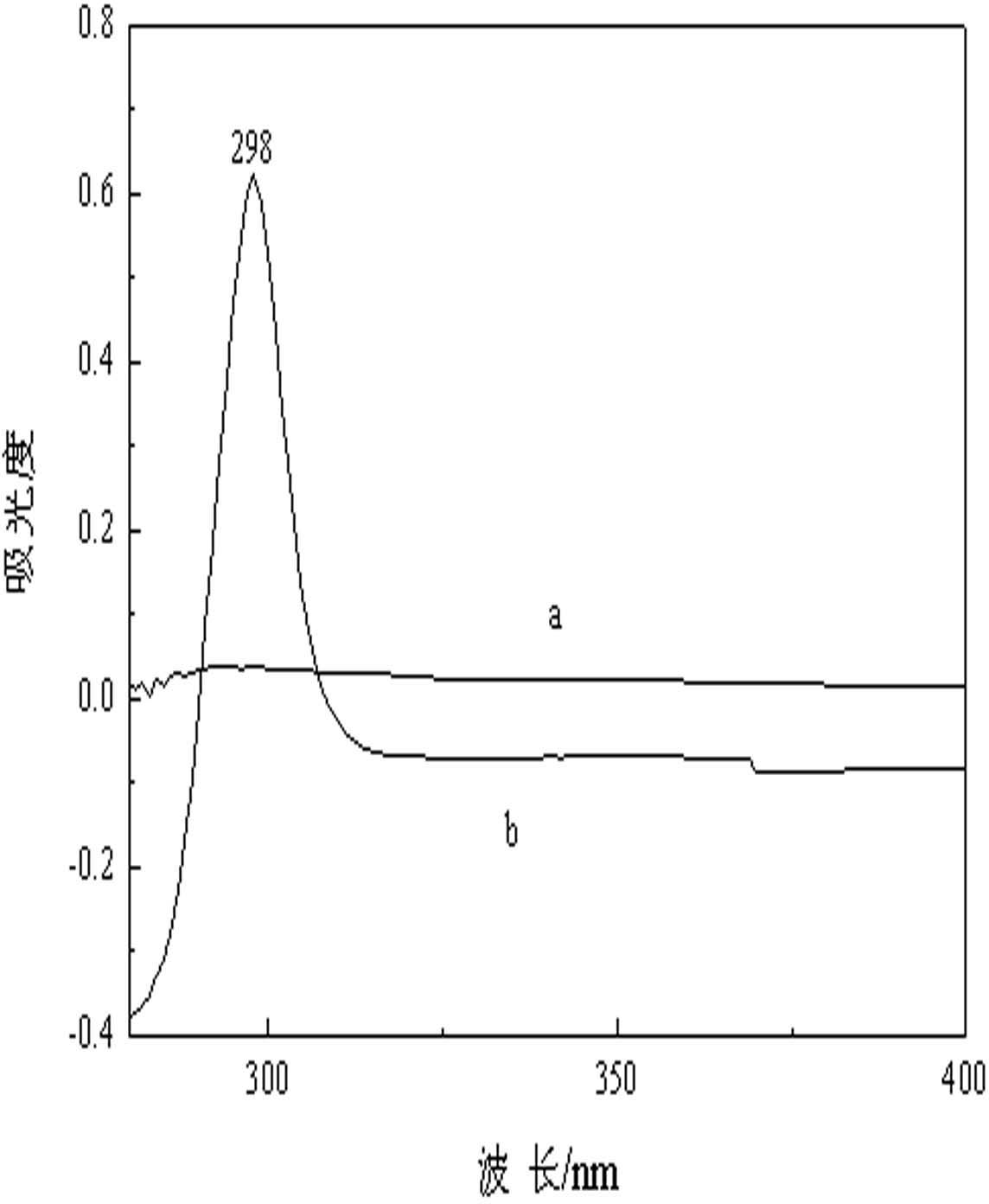

[0033] First, take the composition of carboxymethyl chitosan drug-loaded nano microspheres and the parts by weight of the content thereof are 50 parts of carboxymethyl chitosan; 20 parts of L-tryptophan; 2 parts of calcium chloride; 15 parts of glutaraldehyde share. The method of ion cross-linking in the solution and chemical cross-linking in the compound microemulsion is used to coat the drug. The drug can be soluble in water or insoluble. This method is not limited to soluble drugs.

[0034] Next, 5 g of carboxymethyl chitosan was added into 100 ml of water, and stirred at a speed of 2000 rpm to form a 5 wt % carboxymethyl chitosan solution. Add 2 g of L-tryptophan and stir at 3000 rpm for 10 minutes. Add 20 mL of 1% calcium chloride solution with constant stirring. Add 5mL of Span-80 to 600mL of liquid paraffin, shear and stir at 10,000 rpm with a shearing instrument, take the reaction solution after calcium chloride cross-linking reaction and add it to 600mL of Span-80 a...

Embodiment 2

[0041] 1g of carboxymethyl chitosan was added to 100mL of water, and stirred at a speed of 1000 rpm to prepare a 1wt% carboxymethyl chitosan solution. Add 0.2 g of quercetin, and stir at 2000 rpm for 10 minutes. Add 5 mL of 1% calcium chloride solution with constant stirring. Add 2mL of Span-85 to 200mL of liquid paraffin, shear and stir at 8000 rpm with a shearing instrument, take 10mL of the reaction solution after the calcium chloride crosslinking reaction, and add it to 200mL with a volume ratio of 1:20. In the liquid paraffin of Span-85, shear and stir to form a water-in-oil mixture. Add 5 mL of 10% glutaraldehyde solution to carry out the second curing cross-linking reaction. After reacting for 10 minutes, the stirring was stopped, and the reaction solution was centrifuged at 10000 rpm. The precipitate in the lower layer was removed, washed with petroleum ether, and centrifuged, and this was repeated 3 times. The precipitate was washed twice with deionized water. A ...

Embodiment 3

[0044] 10g of carboxymethyl chitosan was added into 100mL of water, and stirred at a speed of 3000 rpm to form a 10wt% carboxymethyl chitosan solution. Add 3g apigenin, stir for 15 minutes at 5000 rpm. Add 20 mL of 1% calcium chloride solution with constant stirring. Take 5mL of Twen-80 and add it to 800mL of peanut oil, and use a shearing instrument to perform shearing and stirring at 20,000 rpm. Take 10 mL of the reaction solution after the calcium chloride cross-linking reaction and add it to 800 mL of the added twen at a ratio of 1:80 by volume. -80 peanut oil, shear and stir to form a water-in-oil mixture. Add 20mL of 20% glutaraldehyde solution to carry out the second curing crosslinking reaction. After reacting for 30 minutes, the stirring was stopped, and the reaction liquid was centrifuged at 20000 rpm. The precipitate in the lower layer was removed, washed with petroleum ether, and centrifuged, and this was repeated 3 times. The precipitate was washed twice with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com