Extraction method of cyanidin

An extraction method and anthocyanin technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve problems such as consumer insecurity, and achieve the effects of simplifying extraction steps, reducing costs, and improving dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

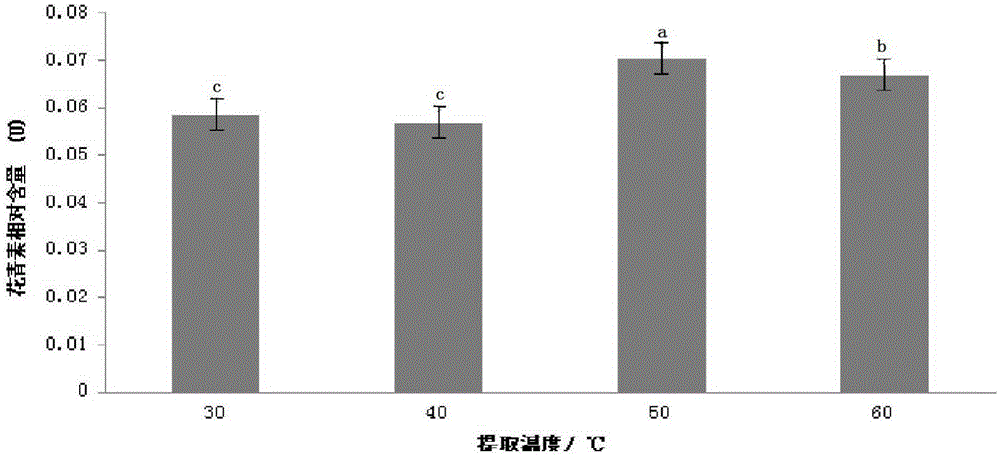

[0028] 1. The design ratio of solid to liquid is 1:20, 1:30, 1:40 (m / v, g / ml), the extraction temperature is 40, 50, 60°C, and the extraction time is 40, 60, 80min each time. Orthogonal experiment was designed, and the factor levels are shown in Table 1.

[0029] 2. Take fresh leaves, wash them, dry them, remove the main veins, cut the leaves into pieces, weigh 0.4g, and place them in a mortar. Add a small amount of pre-cooled citric acid-sodium citrate buffer solution with a pH of 3 to the mortar, grind and homogenize the slurry under ice bath conditions, and transfer it to a centrifuge tube.

[0030] Table 1 Orthogonal factor level table

[0031]

[0032] 3. According to the orthogonal test designed in the above step 1, add citric acid-sodium citrate buffer solution to the mortar several times to rinse the mortar, transfer the rinse solution to a centrifuge tube, and mix well so that the final material-to-liquid ratio is respectively 1:20, 1:30, 1:40 (m / v, g / ml), the ce...

Embodiment 2

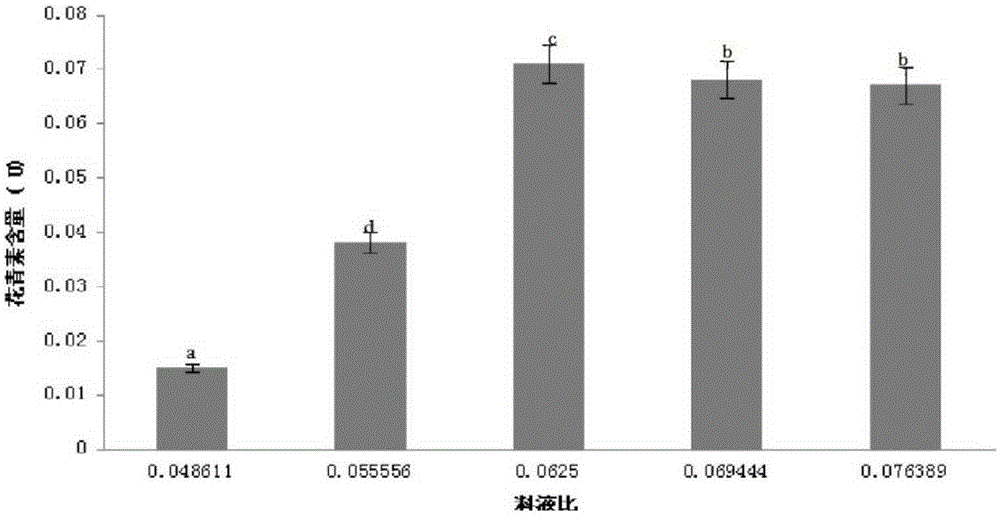

[0038] 1. Take a total of 15 parts of fresh leaves, wash them, dry them, remove the main veins, cut up the leaves and weigh them, each part is 0.4g, and put them in a mortar.

[0039] 2. Add a small amount of pre-cooled citric acid-sodium citrate buffer solution with a pH of 3 to the mortar, grind and homogenize in an ice bath, transfer the material liquid into a centrifuge tube and number it. Continue to add citric acid-sodium citrate buffer solution to the mortar, rinse the mortar several times, then transfer to the above-mentioned corresponding centrifuge tubes, mix well, and finally, the ratio of solid to liquid is 1:10, 1:20, 1:30, 1:40, 1:50 (m / v, g / ml), each material-liquid ratio was repeated 3 times, and the feed liquid in the centrifuge tube was extracted at 50°C for 60 minutes in the dark and shaken, and at 4°C, 4000rpm / min, centrifuge for 10min. The supernatant was filtered through filter paper and became the sample solution.

[0040] 3. Sample measurement: the sa...

Embodiment 3

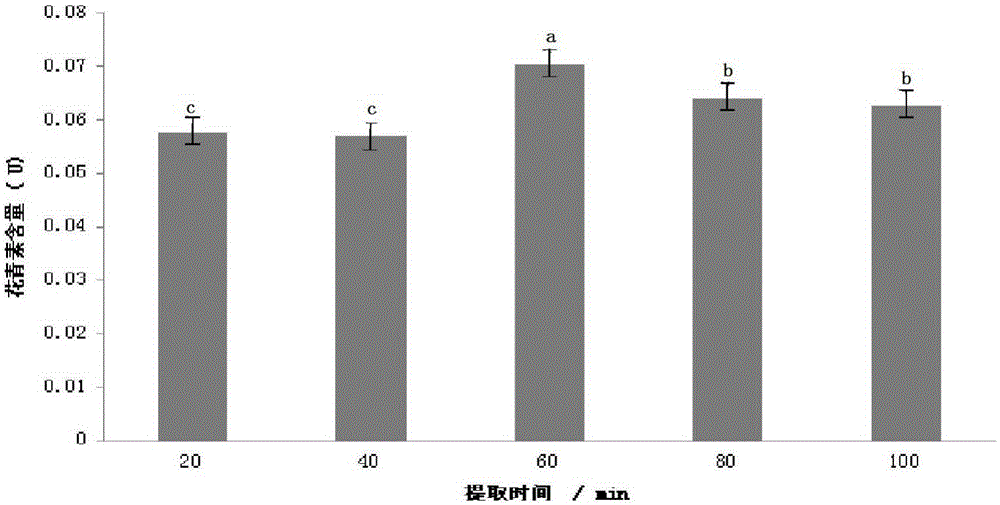

[0042] 1. Take a total of 15 parts of fresh leaves, wash them, dry them, remove the main veins, cut up the leaves and weigh them, 0.4g per part, and put them in a mortar.

[0043] 2. Add a small amount of pre-cooled citric acid-sodium citrate buffer solution with a pH of 3 to the mortar, grind and homogenize in an ice bath, then transfer the material liquid into a centrifuge tube and number it. Continue to add citric acid-sodium citrate buffer solution to the mortar respectively, rinse the mortar several times, then transfer to the above-mentioned centrifuge tubes respectively, mix well, and finally, the solid-liquid ratio is 1: 30 (m / v, g / ml), the feed liquid in the centrifuge tube was extracted at 50°C for 20, 40, 60, 80, and 100 min in the dark, respectively, and each extraction time was repeated 3 times. The centrifuge tube was centrifuged at 4°C, 4000 rpm / min for 10 min. The supernatant was filtered through filter paper and became the sample solution.

[0044]3. Sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com