Elevator buffer

A buffer and elevator technology, applied in the field of elevators, can solve the problem that friction brake buffers are rarely researched, and achieve the effects of reducing the number of use, reducing costs and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

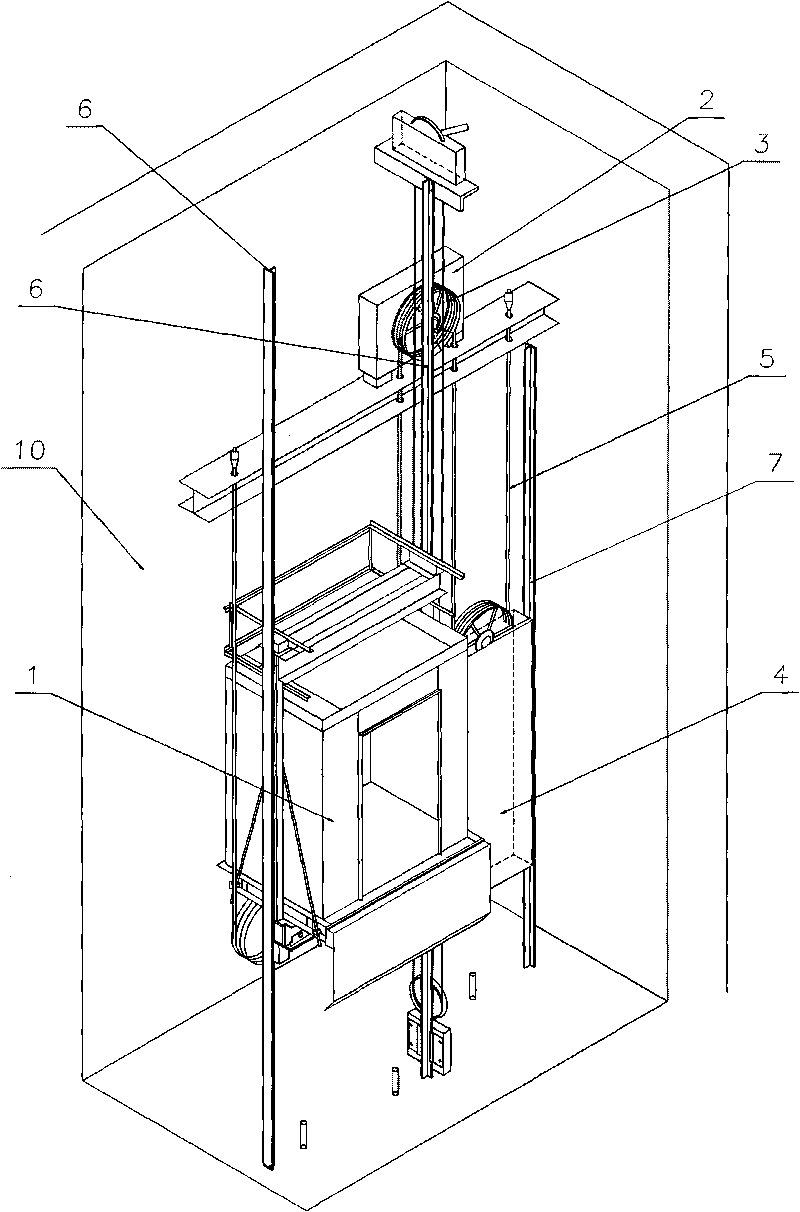

[0018] In order to more clearly illustrate the function and installation position of the present invention in the elevator, it is necessary to combine figure 1 Briefly describe the structure of the elevator.

[0019] exist figure 1 In the machine-room-less elevator shown, the car 101 runs up and down along the car guide rail 106, the counterweight 104 runs up and down along the counterweight guide rail 107, the suspension device 105 connects the car 101 and the counterweight 104, and the driving device 102 utilizes the driving wheel 103 drives the car 101 and the counterweight 104 to run in the hoistway 110, the elevator car descending safety gear 111 is installed at the lower end of the car 101, and the traditional buffer 112 is installed at the bottom of the hoistway 110.

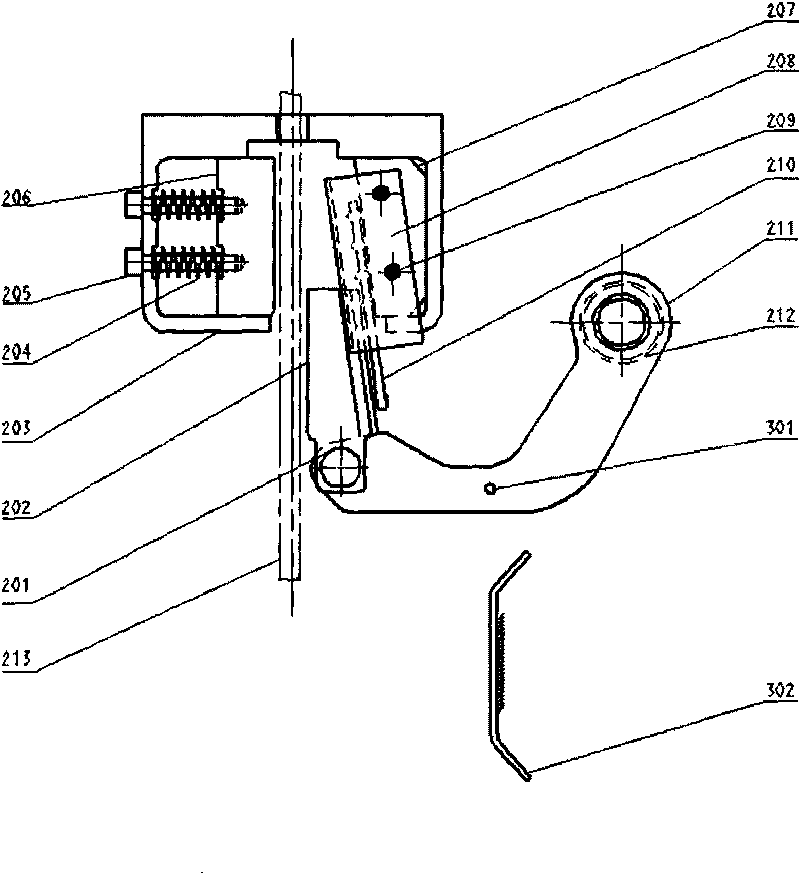

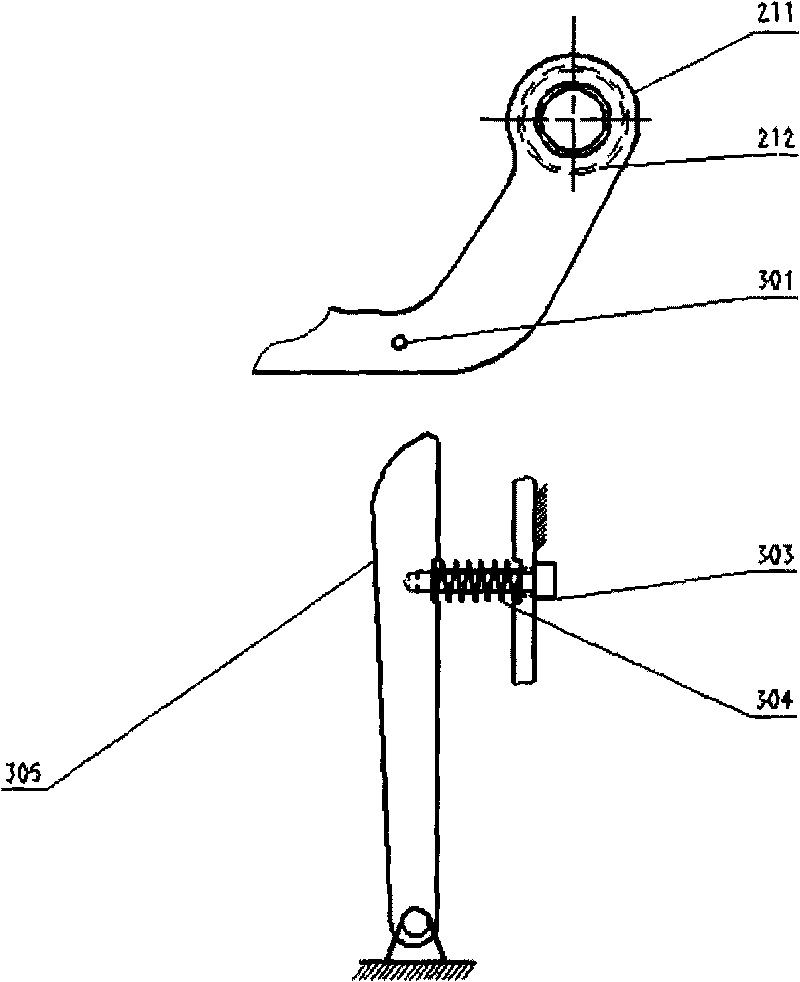

[0020] A preferred implementation of the present invention is a one-way mechanism similar to an elevator safety gear. When the elevator car or the counterweight goes down, the action of the brake device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com