Cement-based waterproof mortar photosensitive ultraviolet resistance protectant

A waterproof mortar, anti-ultraviolet technology, applied in the field of waterproof mortar photosensitive anti-ultraviolet protection agent, can solve the problems of pigment fading, easy fission, main influence of mortar performance, etc., and achieve the effect of eliminating skin peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

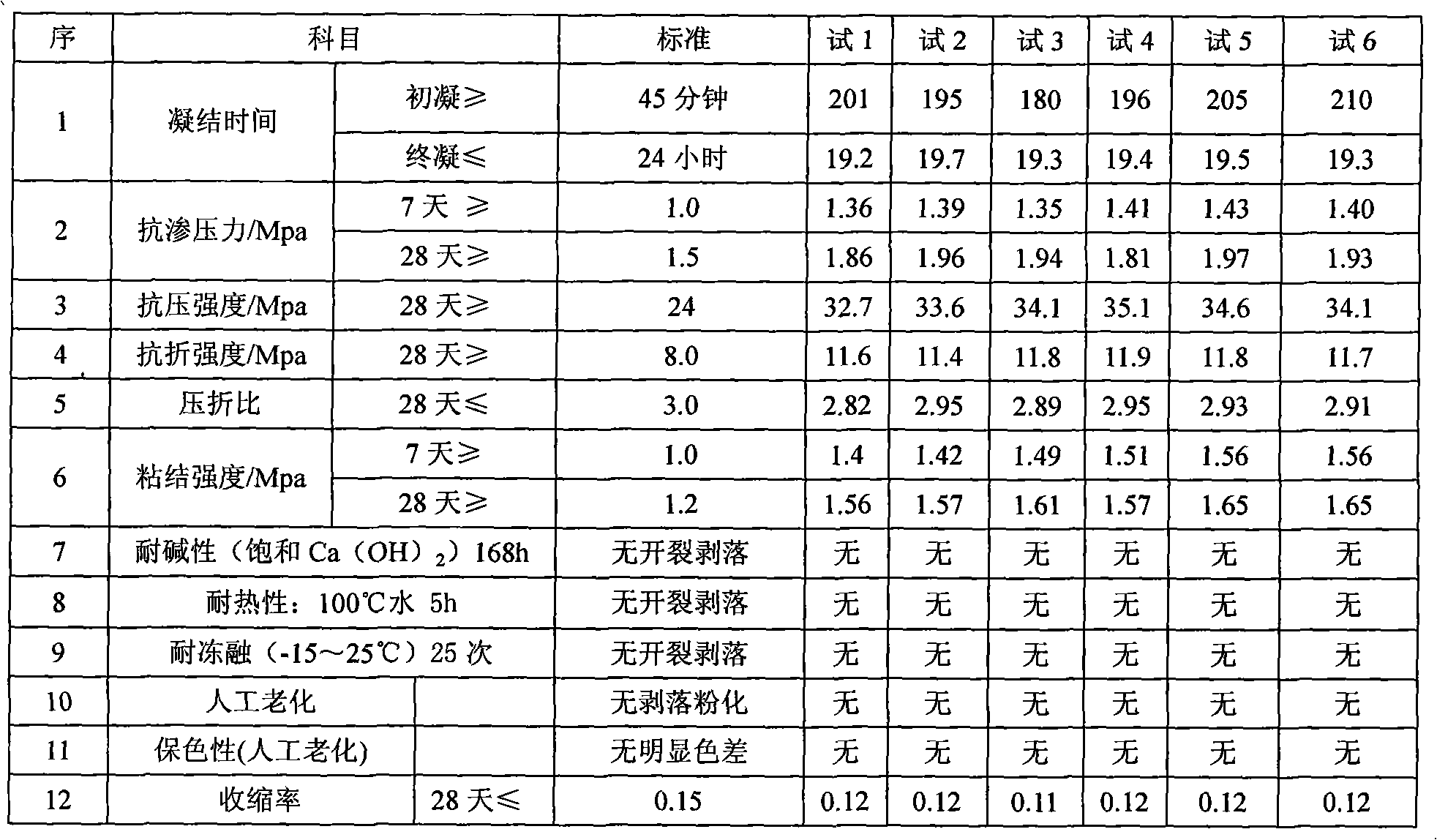

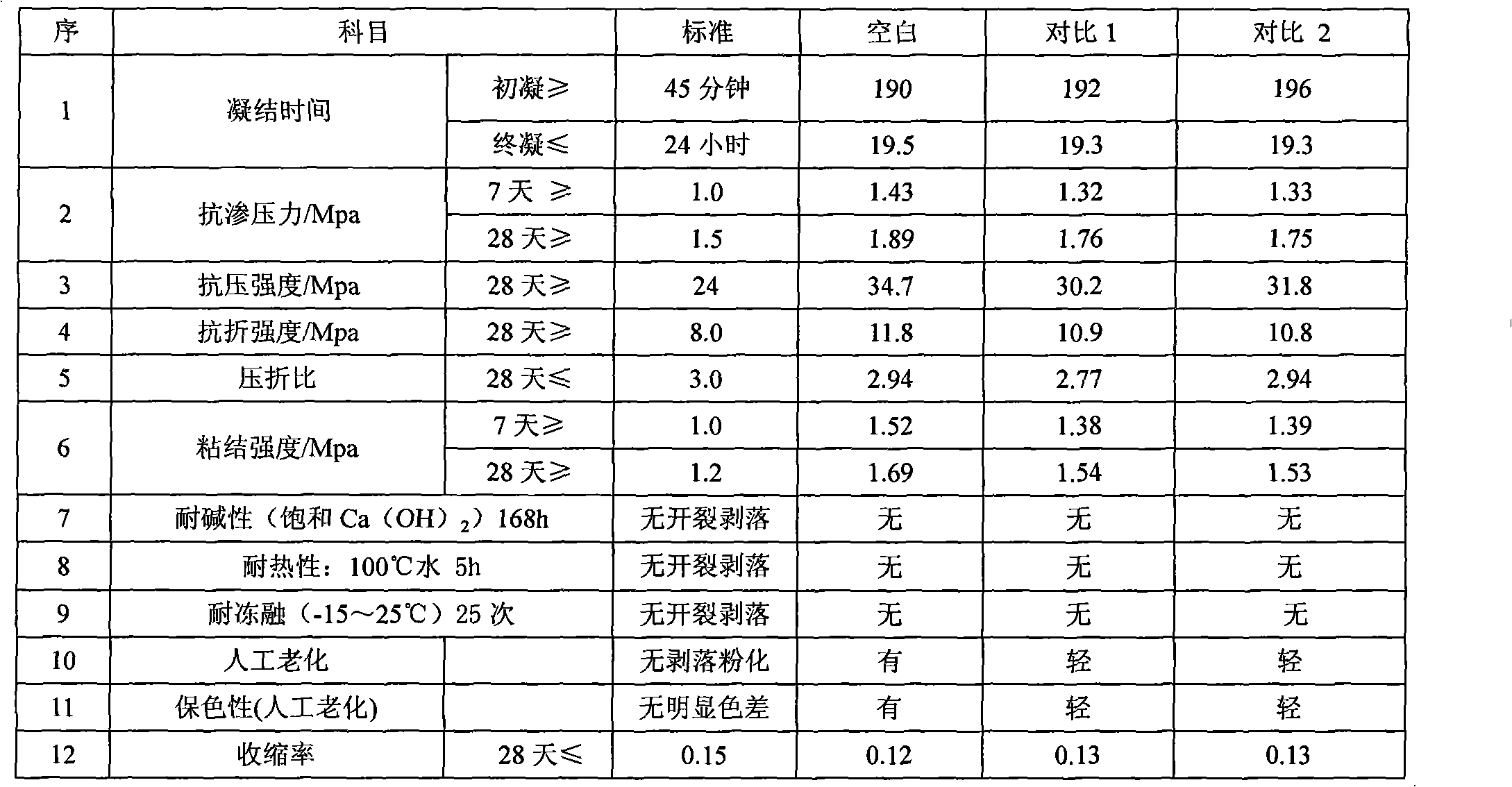

Examples

Embodiment 1

[0031] formula:

[0032] 100 parts of gelatin solution with a weight concentration of 1%, 10 parts of copper sulfate, 1 part of sodium hydroxide, 10 parts of thiourea, 20 parts of cyanine light-absorbing dye aqueous solution of 3.3'-diethyloxycarbocyanine iodide salt with a weight concentration of 1‰, by weight 10 parts of 10% stannous chloride ethanol solution;

[0033] Preparation:

[0034] Stir the gelatin solution in a mixer for 20 minutes, then raise the temperature to 65°C, and then add copper sulfate; 5 minutes later, add sodium hydroxide to make the glue turbid, and 5 minutes later, add thiourea to make the glue change. Become transparent, obtain glue solution;

[0035] Add 3.3'-diethyloxycarbocyanine iodide salt cyanine light-absorbing dye solution and tin protochloride ethanol solution to the glue solution. After 30 minutes, change the lighting to an incandescent lamp (without ultraviolet light), and then add Stannous chloride ethanol solution, after 10 minutes, a...

Embodiment 2

[0037] formula:

[0038] 100 parts of 1% gelatin solution by weight concentration, 15 parts of copper sulfate, 1.5 parts of sodium hydroxide, 15 parts of thiourea, 25 parts of cyanine light-absorbing dyes of 3.3'-diethyloxycarbocyanine iodide salt of weight concentration 1‰, weight concentration 15 parts of 10% stannous chloride ethanol solution.

[0039] The preparation method is the same as in Example 1.

Embodiment 3

[0041] formula:

[0042] 100 parts of weight concentration 1% gelatin solution, 20 parts of copper sulfate, 2 parts of sodium hydroxide, 20 parts of thiourea, weight

[0043] 30 parts of 3.3'-diethyloxycarbocyanine iodide salt cyanine light-absorbing dye solution with a concentration of 1‰, and 20 parts of 10% stannous chloride ethanol solution with a weight concentration of 1‰.

[0044] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com