Method for extracting procyanidine by utilizing aqueous two-phase system

A two-phase system, two-phase technology, applied in organic chemistry and other directions, can solve the problems of low comprehensive utilization rate of grape seeds, waste of materials, environmental pollution, etc. high water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for extracting proanthocyanidins utilizing a two-phase partitioning technique, comprising the following steps:

[0027] 1) Material pretreatment: Bake the purchased grape seeds in an oven for 24 hours, then take them out, grind them into powder and seal them in plastic bags for later use.

[0028] 2) Two-phase extraction operation: put 0.5 g of grape seed powder in a two-phase system consisting of 4.5 mL of water, 3.5 mL of ethanol, 2.5 g of ammonium sulfate, and 0.2 g of sodium chloride, and then extract the powder at 3600 r / min. Centrifuge at a rotating speed for 10 minutes, then stand still and separate the phases for 120 minutes, and separate the upper phase to obtain proanthocyanidins.

[0029] Absorbance measurement:

[0030] (1) Dilute the upper phase of the proanthocyanidins prepared in Example 1 three times, keep the lower phase unchanged, put it into a small test tube, and measure its absorbance value at 500 nm.

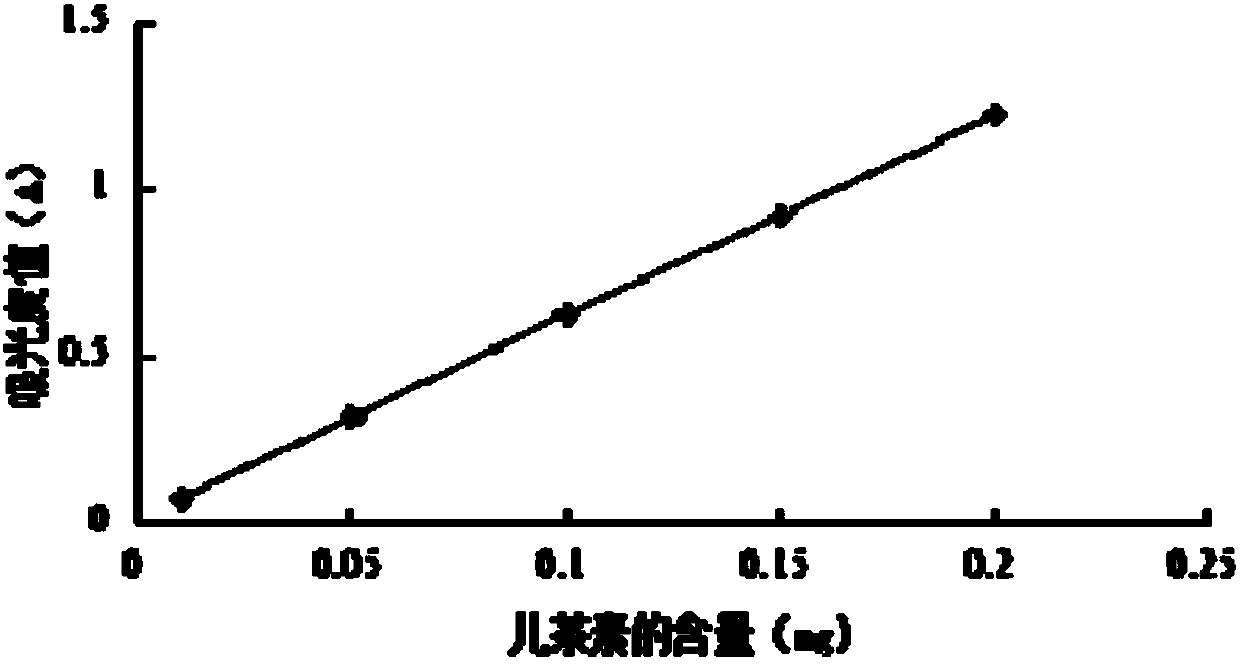

[0031] (2) Standard curve preparati...

Embodiment 2

[0034] A method for extracting proanthocyanidins utilizing a two-phase partitioning technique, comprising the following steps:

[0035] 1) Material pretreatment: Put the purchased grape seeds in an oven and dry them for 24 hours, then take them out and grind them into powder, and store them in sealed plastic bags for later use.

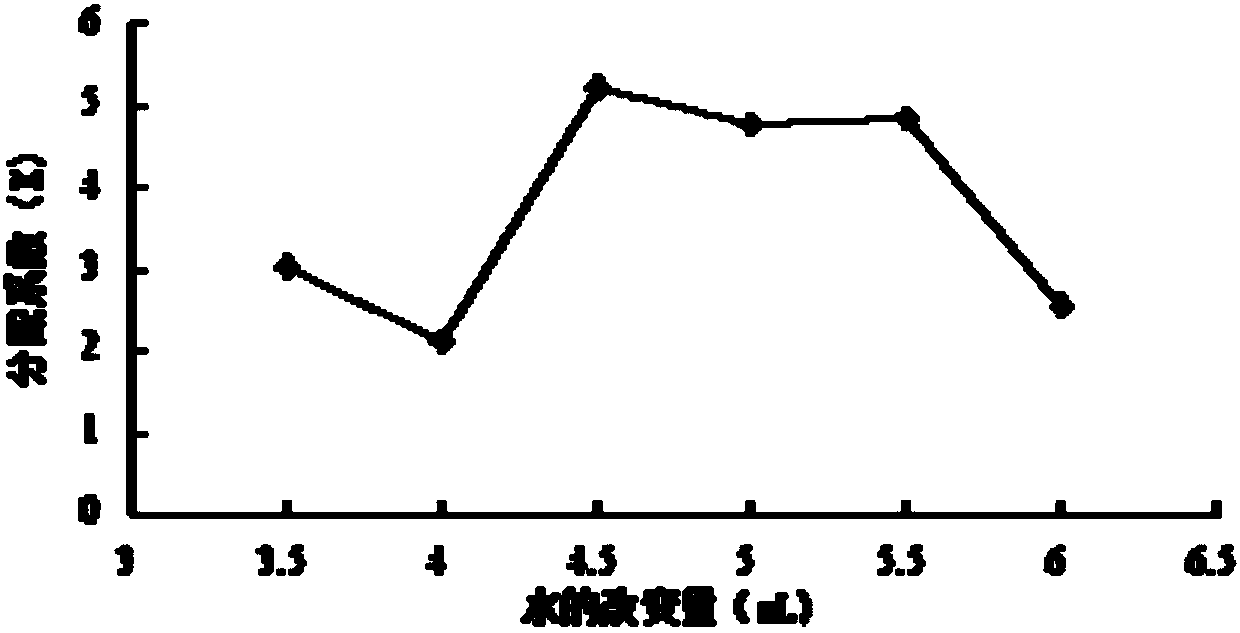

[0036] 2) Two-phase extraction operation: Take six 50mL centrifuge tubes, numbered 1-6. Add the same amount of ethanol (3mL) and ammonium sulfate (2g) to each centrifuge tube, and add different amounts of distilled water to each centrifuge tube, as shown in the table below. Then add 0.5g of grape seed powder, mix thoroughly, centrifuge at 3600r / min for 10min, place for 120min, collect the upper and lower phases, put the upper and lower phases containing proanthocyanidins into small test tubes, the numbers correspond to the centrifuge tubes, The upper phase was diluted 3 times, and the lower phase was kept unchanged, and then the absorbance values o...

Embodiment 3

[0046] A method for extracting proanthocyanidins utilizing a two-phase partitioning technique, comprising the following steps:

[0047] 1) Material pretreatment: Put the purchased grape seeds in an oven and dry them for 24 hours, then take them out and grind them into powder, and store them in sealed plastic bags for later use.

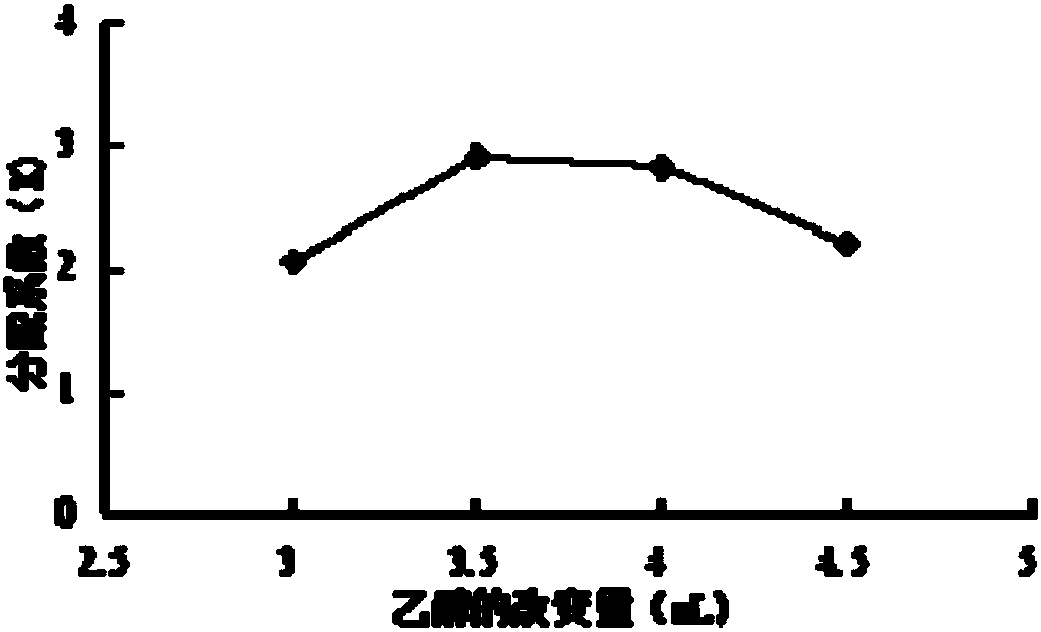

[0048] 2) Two-phase extraction operation: take four 50mL centrifuge tubes, numbered 1-4. Add the same amount of distilled water (6 mL) and ammonium sulfate (2 g) into each centrifuge tube, and add different amounts of ethanol into each centrifuge tube, as shown in Table 2 below. Then add 0.5g of grape seed powder, mix thoroughly, centrifuge at 3600r / min for 10min, collect the upper and lower phases, put the upper and lower phases containing proanthocyanidins into small test tubes, the numbers correspond to the centrifuge tubes, and separate the upper phase 3-fold dilution, keep the lower phase unchanged, then measure the absorbance value of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com