High-efficiency flexible dye-sensitized solar cell and preparation method thereof

A technology of solar cells and dye sensitization, which is applied to the structure and preparation of high-efficiency flexible dye-sensitized solar cells. temporary effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Example 1, polymer / plastic substrate flexible dye-sensitized solar cell

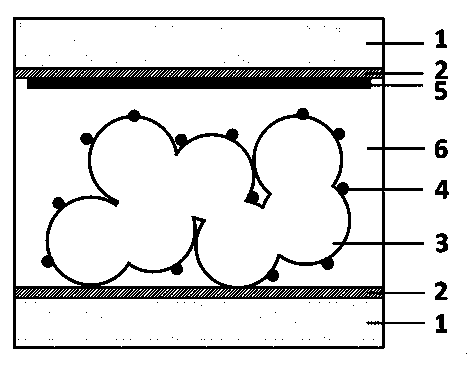

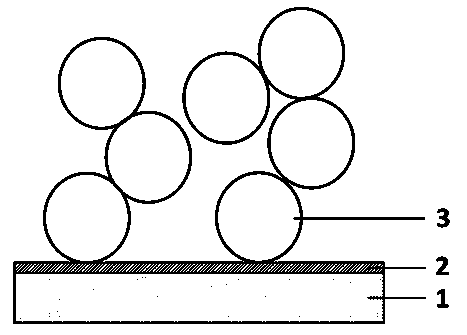

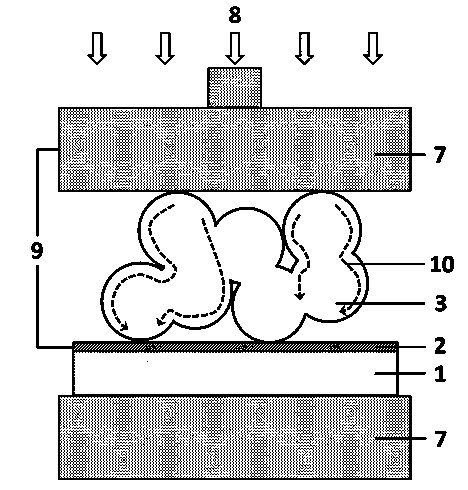

[0032] figure 1 Shown is a schematic diagram of the cross-sectional structure of the flexible polymer / plastic substrate. This flexible dye-sensitized solar cell (DSC) consists of a photoanode, a counter electrode, and an electrolyte 6 between the two electrodes. Wherein, the photoanode includes a plastic substrate 1, a transparent conductive film 2 plated on the surface of the plastic substrate 1, a porous metal oxide film 3 deposited on the surface of the transparent conductive film 2, and a porous metal oxide film adsorbed on the surface of the porous metal oxide film 3. Layer Dye Molecules 4. The counter electrode includes a plastic substrate 1 , a transparent conductive film 2 plated on the surface of the plastic substrate 1 , and a catalyst film 5 attached to the transparent conductive film 2 .

[0033] In this embodiment, the conductive substrate is a plastic substrate 1 coated with a tran...

Embodiment 2

[0050] Example 2, metal substrate flexible dye-sensitized solar cell

[0051] Such as Figure 5 Shown is a schematic cross-sectional structure of a flexible dye-sensitized solar cell on a metal substrate. In this embodiment, the metal substrate 11 is used as the conductive substrate of the photoanode, and the metal substrate 11 is a titanium sheet. The metal substrate 11 can also be a stainless steel sheet or other metal sheets. Other content is the same as embodiment 1.

[0052] The preparation process of the metal substrate flexible dye-sensitized solar cell in this example is as follows:

[0053] 1) Preparation of photoanode

[0054] To prepare metal oxide slurry, such as silicon oxide slurry, mix metal oxide nanopowder with volatile organic solvents such as ethanol, isopropanol or acetone in a ratio of 1:100~50:100, and stir magnetically for more than 2 hours. Such as Figure 5 As shown, the metal substrate 11 is used as the conductive substrate of the photoanode, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com