Porous tantalum rod

A technology of porous tantalum and tantalum powder, used in medical science, internal bone synthesis, surgery, etc., can solve the problems of easy dislocation, inability to continuously decompress, inconvenient and accurate positioning, etc., and achieve a high success rate of implantation surgery and good support strength. , is conducive to the effect of fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

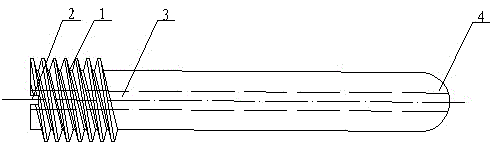

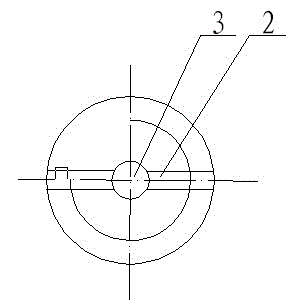

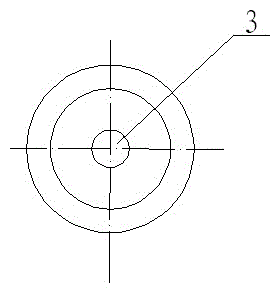

[0025] Example 1: see Figure 1 to Figure 3 , a porous tantalum rod, one end of which is provided with a fastening thread 1 structure connected with bone tissue, and the other end opposite to the threaded end is spherical 4; see further figure 2 , there is a notch 2 on the end face of the threaded end of the porous tantalum rod to facilitate the installation and use of surgical tools; combined image 3 , it can be seen that the center of the implant has a through hole 3, the cross section of the through hole in this example is circular, of course, it can also be square or any other shape, as long as it can be easily positioned and filled, and the relevant objects can be obtained. Can. The porous tantalum material used in the porous tantalum rod has a foam structure with three-dimensional interconnected distribution of pores, which is sintered by the foam impregnation method. On the foam skeleton formed by the accumulation of sintered pure tantalum powder, the tantalum powder...

Embodiment 2

[0028] Example 2: The structure of the porous tantalum rod is as described in Example 1. This example intends to further provide the material selection of the porous tantalum rod and the preparation method of porous tantalum.

[0029] It is made of 2-8% polyvinyl alcohol aqueous solution prepared by polyvinyl alcohol and water and tantalum powder with an average particle size of less than 50 μm and an oxygen content of less than 0.1%. , Density 0.015~0.065g / cm 3 , in polyurethane foam with a hardness greater than 40°, dipped until the pores of the organic foam are filled with tantalum powder slurry, then dried to remove the water in the organic foam poured with tantalum powder slurry, and degreased under an inert gas protective atmosphere to remove Polyvinyl alcohol and polyurethane foam, vacuum sintered to produce a porous sintered body, sintered pure tantalum powder piled up on the foam skeleton, tantalum powder particles have a sintered neck structure of 50% to 95% of each ...

Embodiment 3

[0030] Embodiment 3: The preparation method of the porous tantalum material for making the porous tantalum rod is further given.

[0031] Weigh 12.5 g of polyvinyl alcohol and put it into a container with 240 ml of distilled water; place it on an electric stove to heat and stir to make it an aqueous solution of polyvinyl alcohol. Use a 300g balance to weigh 60g of tantalum powder with an average particle size of less than 50 microns and an oxygen content of less than 0.1%, add 50ml of cooled polyvinyl alcohol aqueous solution, stir and mix evenly, and make it into a tantalum powder slurry. Use 10×10×30mm porous polyurethane foam (average pore diameter is 0.48mm, density 0.025g / cm 3 , hardness 50 0 ) into it and pour until the pores of the polyurethane foam are filled with the tantalum powder slurry, and the polyurethane foam absorbed with the tantalum powder slurry is taken out with a clip and put into the porcelain plate. Dry in a vacuum drying oven at a drying temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com