Method for suppressing stray crystal forming and growing at seed crystal starting end, and casting case construction thereof

A technology of starting end and seed crystal, applied in the field of preparation of single crystal superalloy, can solve the problems of large gap, loss of single crystal nucleation core of seed crystal, flow down along the gap, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

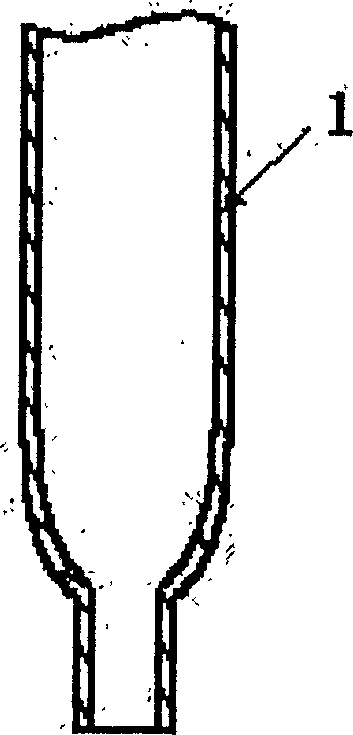

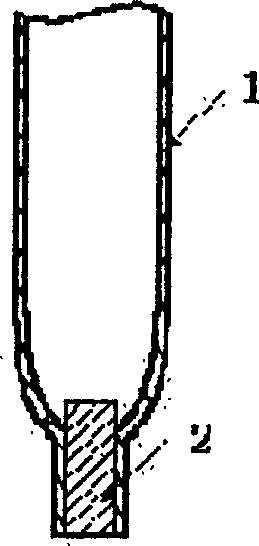

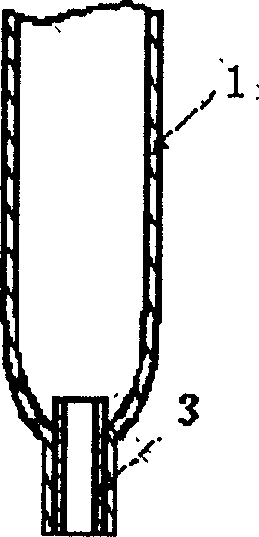

[0018] The method for suppressing the formation and growth of miscellaneous crystals at the initial end of the seed crystal growth of the present invention is based on the seed crystal method, a necking structure is set at the initial end, and the seed crystal is inserted into the seed crystal by the method of presetting the seed crystal, so as to suppress The formation and growth of miscellaneous crystals at the beginning of crystal growth make the alloy melt grow into a single crystal by means of epitaxial growth on the unmelted interface of the seed crystal.

[0019] Such as image 3 As shown, the mold shell structure used in the method for suppressing the formation and growth of miscellaneous crystals at the starting end of the seed crystal growth is a mold shell 1 structure in which the seed crystal 2 is preset, and a mold shell 1 is set above the seed crystal growth starting position at the bottom of the mold shell 1. A constricted structure ensures the close contact bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com