Continuous machining device for necking and flaring connecting parts of automotive air conditioner metal fittings

A technology for automotive air conditioners and metal fittings, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of inability to form in one step, low work efficiency, and inability to achieve, improve product quality and processing efficiency, and shorten processing. Process and effect of continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

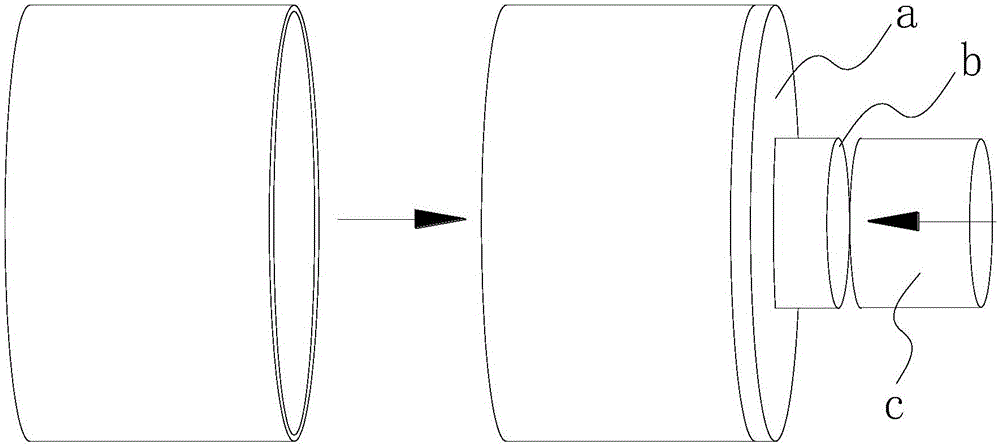

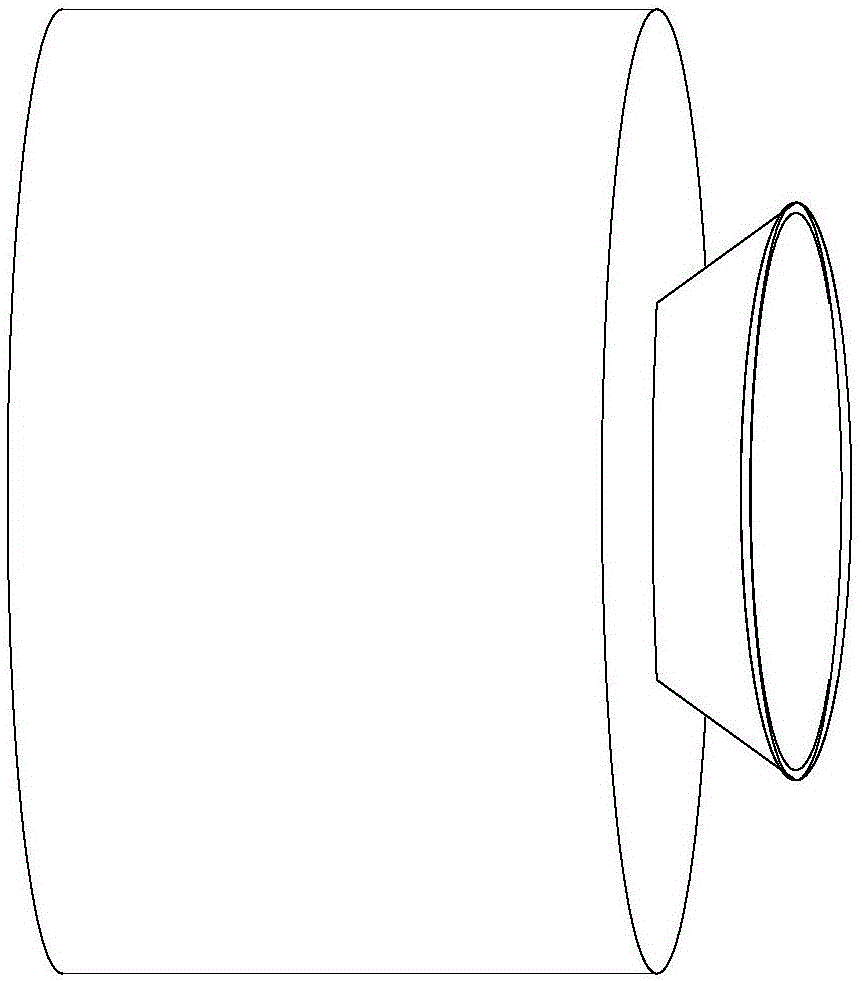

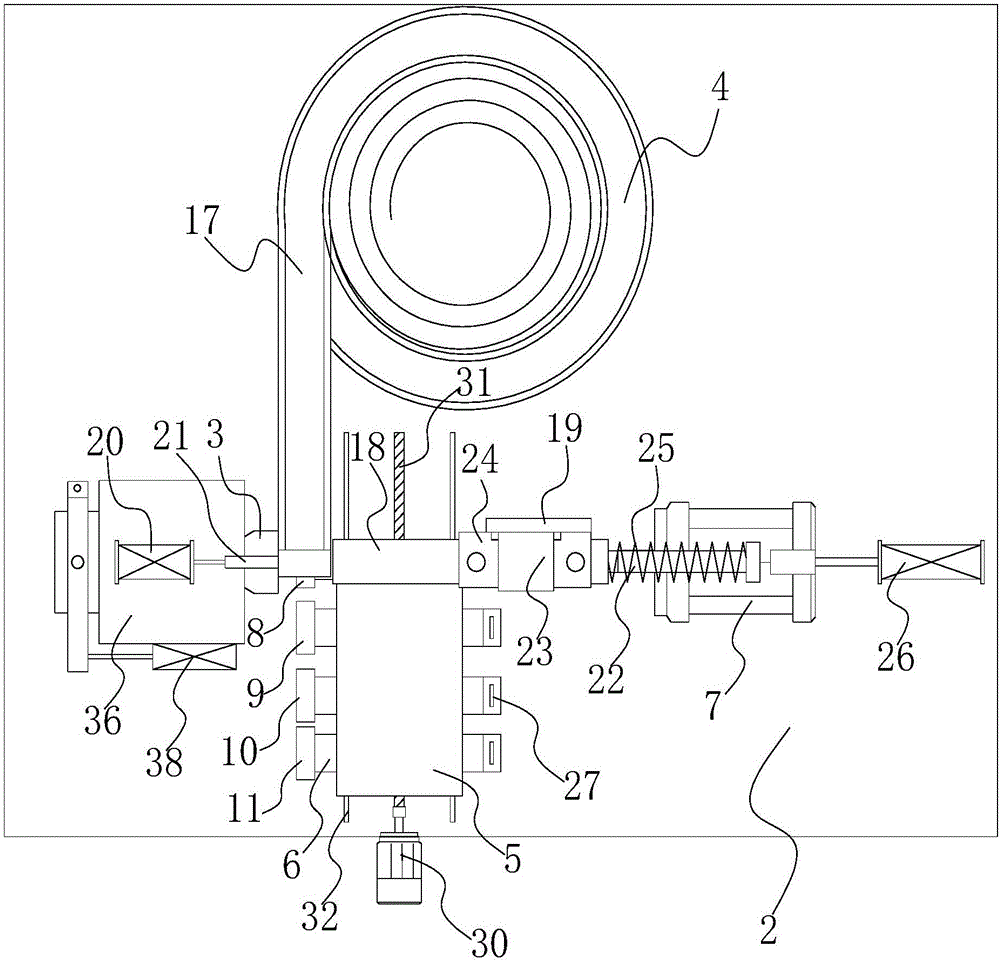

[0026] refer to Figure 3 to Figure 5 , the present invention comprises a frame 1, a workbench 2 positioned on the frame 1, a clamp 3 fixed on the workbench 2 for fixing the metal parts of the automobile air conditioner to be processed, and a vibrating feeding material for conveying the metal parts of the automobile air conditioner to be processed disc 4, the workbench 2 is provided with a feeding mechanism located on one side of the fixture 3, and the feed mechanism can send the metal parts of the automobile air conditioner to be processed output by the vibrating feeder tray 4 into the fixture 3, and the workbench 2 A sliding seat 5 is provided on the top, and four connecting rods 6 arranged in a horizontal space are arranged in the sliding seat 5. The sliding seat 5 is connected with a driving mechanism, and the driving mechanism can drive the sliding seat 5 to slide so that the The four connecting rods 6 cooperate with the fixture 3 one by one and are located on the same wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com