Self-decoupling high-sensitivity resonance silicon micro mechanical gyroscope

A high-sensitivity, silicon micro-mechanical technology, applied in the direction of gyroscopic effect for speed measurement, gyroscope/steering sensing device, speed/acceleration/shock measurement, etc., can solve the problems of difficult to process sensors, unfavorable increase in sensitivity, and high process requirements , to achieve good process compatibility, improve sensitivity, and reduce common mode interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

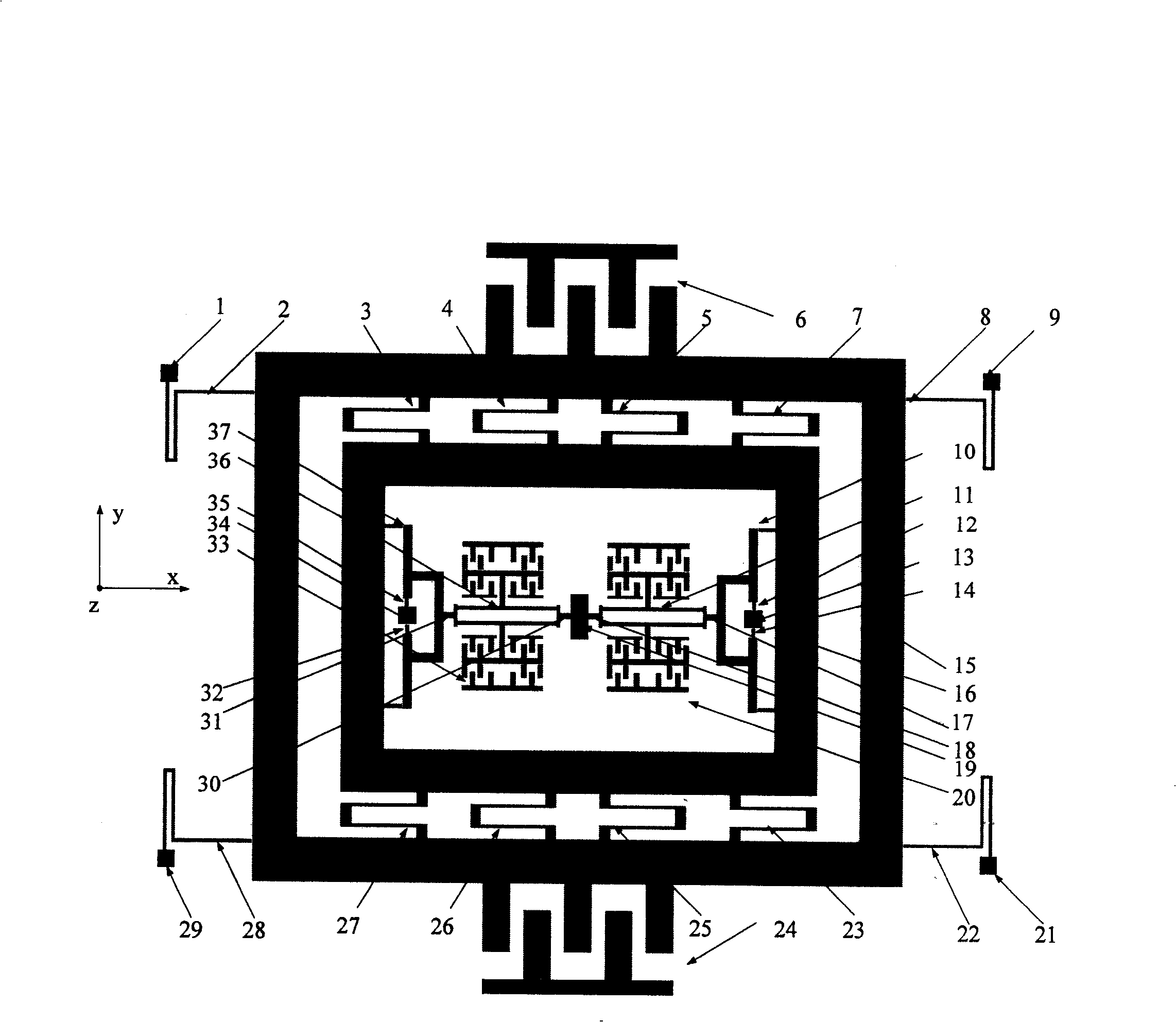

[0022] Such as figure 1 As shown, the silicon micromechanical gyroscope of the present invention includes: 15, 16 outer and inner mass blocks; 2, 8, 22, 28 cantilever beams symmetrically supporting the outer mass; 1, 9, 21, 29 are anchor points of the cantilever beam; 6, 24 is the driving comb of the outer mass (including movable comb and fixed comb); 3, 4, 5, 7, 23, 25, 26, and 27 are symmetrical folded beams connecting the inner and outer masses; 37 and 10 are symmetrical The lever magnifying structure; For reducing the energy consumption of anchor point, lever magnifying mechanism 37 is connected with anchor point 34 through thin neck structure (2 to 10 microns) 32,35, while lever magnifying mechanism 10 is through thin neck structure (2 to 10 micron) Micron) 12,14 is connected with anchor point 13; DETF36 is connected with anchor point 19 and lever mechanism 37 respectively through thin neck structure (2 to 10 micron) 30,31, and DETF11 symmetrical with DETF 36 passes thin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com