Buckled type automatic stamp taking-out and putting-in device

A buckle-type stamping technology, which is applied in printing, stamping, etc., can solve the problems of high production cost, bulky mechanism, and large equipment volume, and achieve stable and reliable stamp pick-and-place work, easy and accurate automatic printing, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

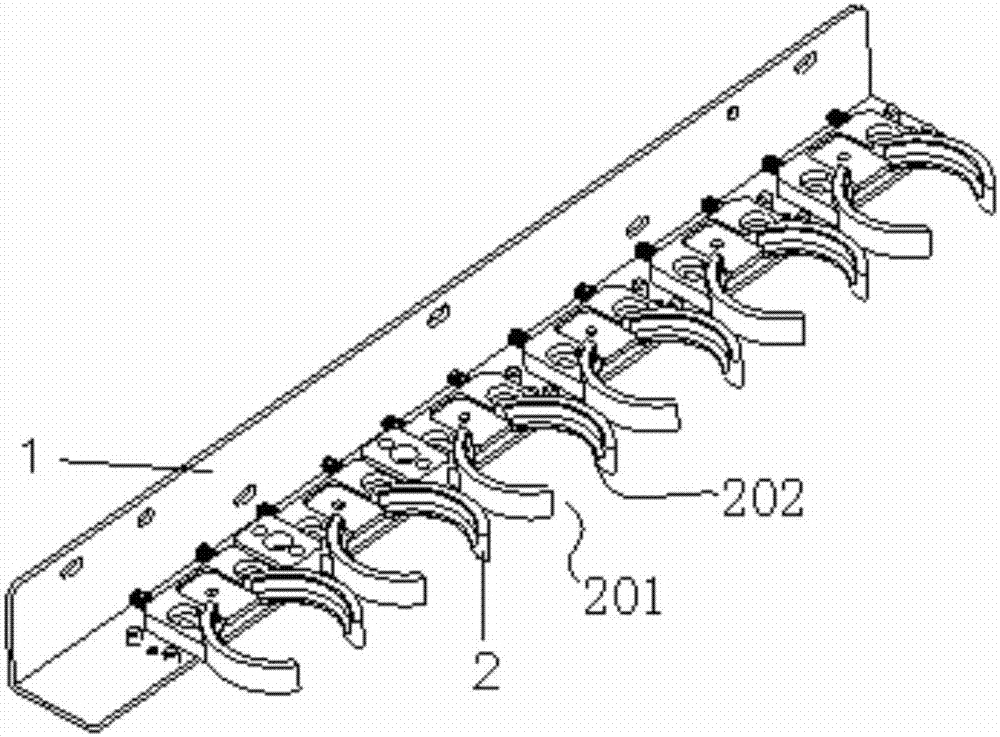

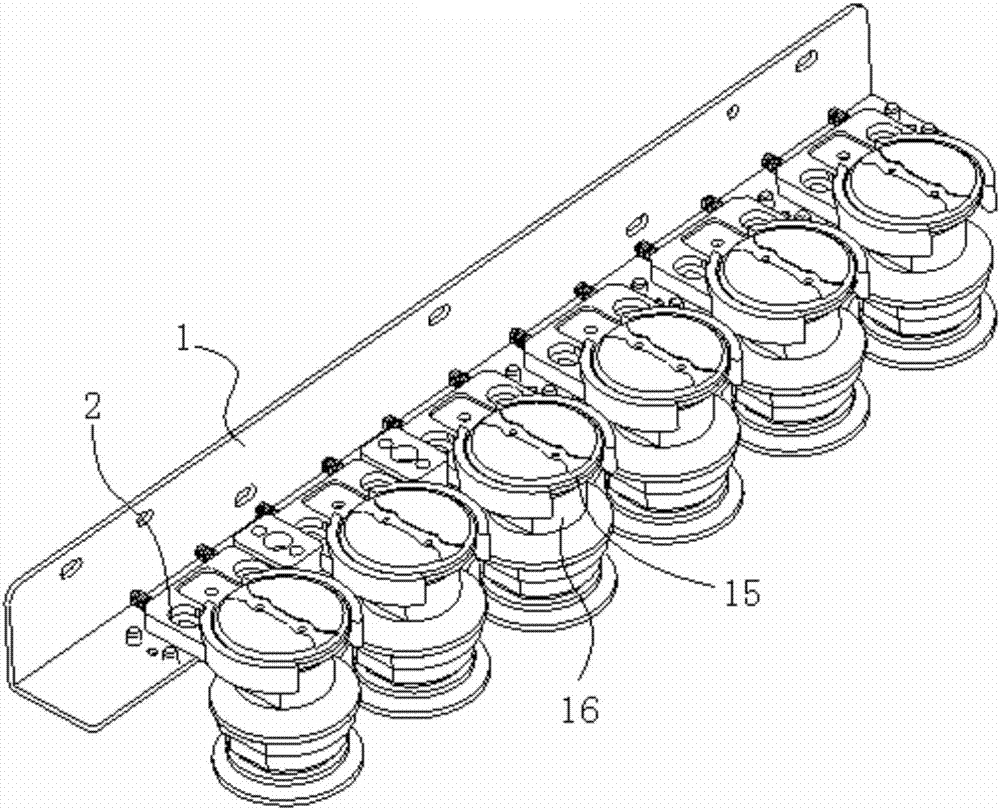

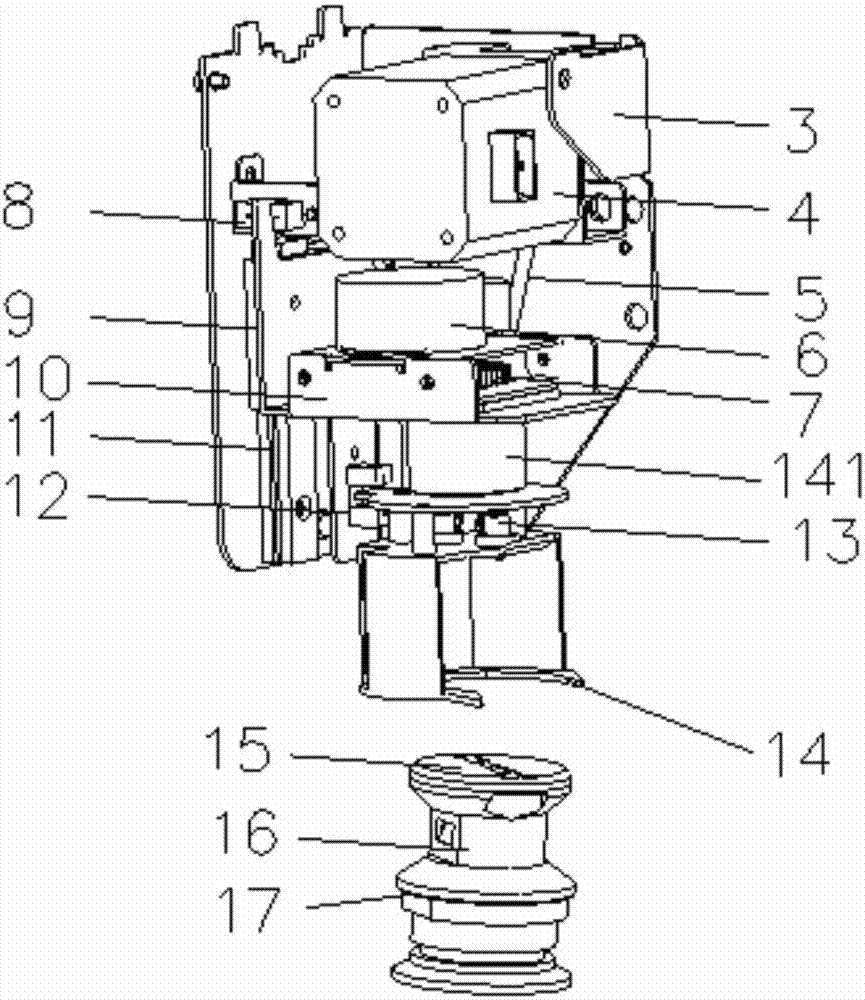

[0025] see Figure 1 to Figure 4 , a kind of buckle-type automatic stamp pick-and-place device in the present embodiment is the preferred solution of the present invention, specifically including a stamp library support 1, a stamp holder 2, a stamp-taking main support 3, an elevating motor 4, and a synchronous belt module 5. Rotating motor 6, gear reduction module 7, lifting position sensor 8, slider 9, slider bracket 10, guide rail 11, rotation position sensor 12, ball plunger 13, chapter claw 14 and other components.

[0026] From the storage of seals and the functions of using seals, it can be divided into two parts: the stamp library and the stamp-taking mechanism.

[0027] Such as figure 1 and figure 2 As shown, the stamp library includes a chapter library bracket 1 and a number of stamp holders 2. The chapter library bracket 1 is used to fix the stamp holder 2. It is a strip-shaped bracket structure. 2 is used to position and place the seal, and several stamp holders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com