Vessel neck construction of a pressure vessel

A pressure vessel and neck technology, applied in the field of the vessel neck structure of pressure vessels, can solve problems such as sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

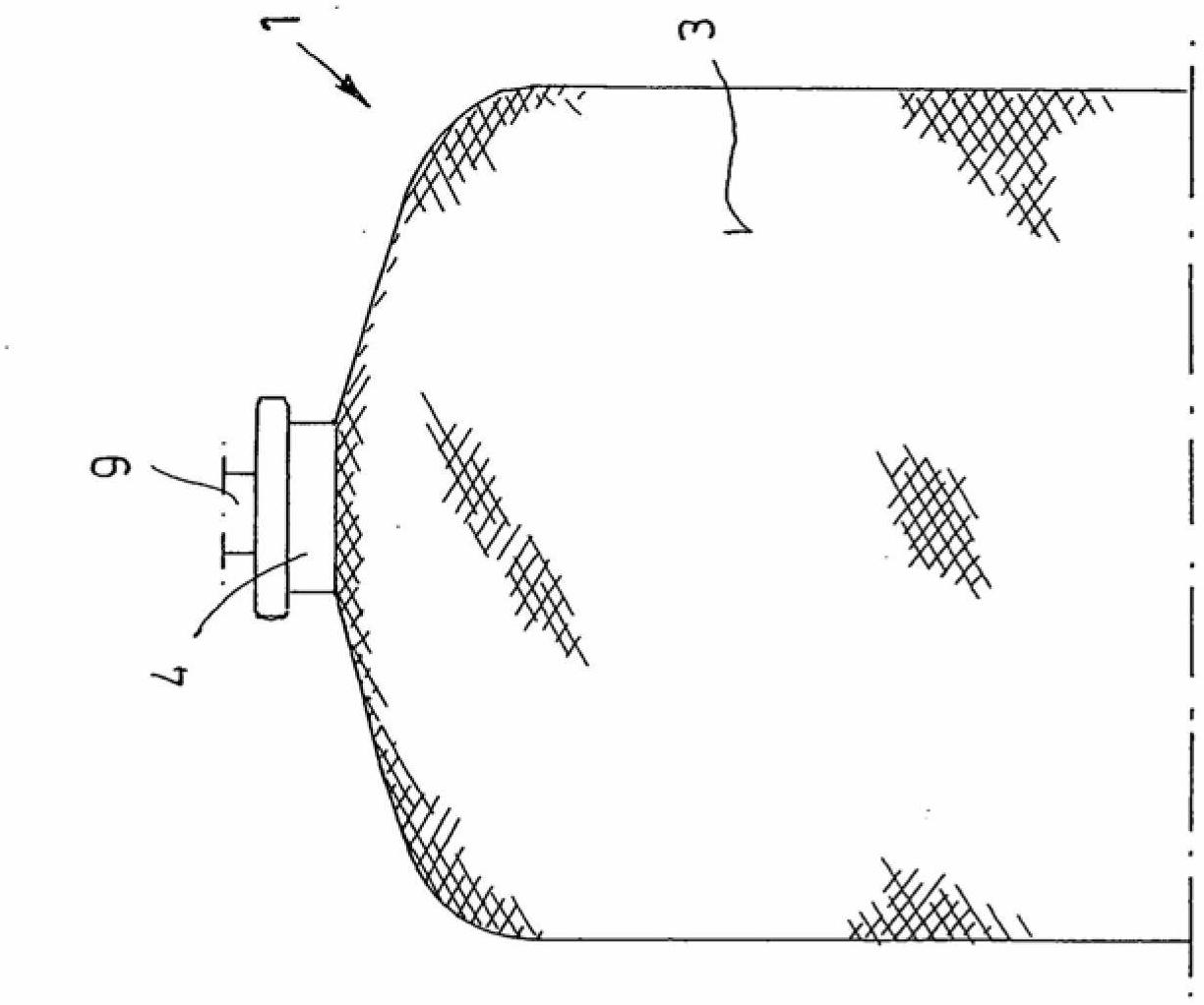

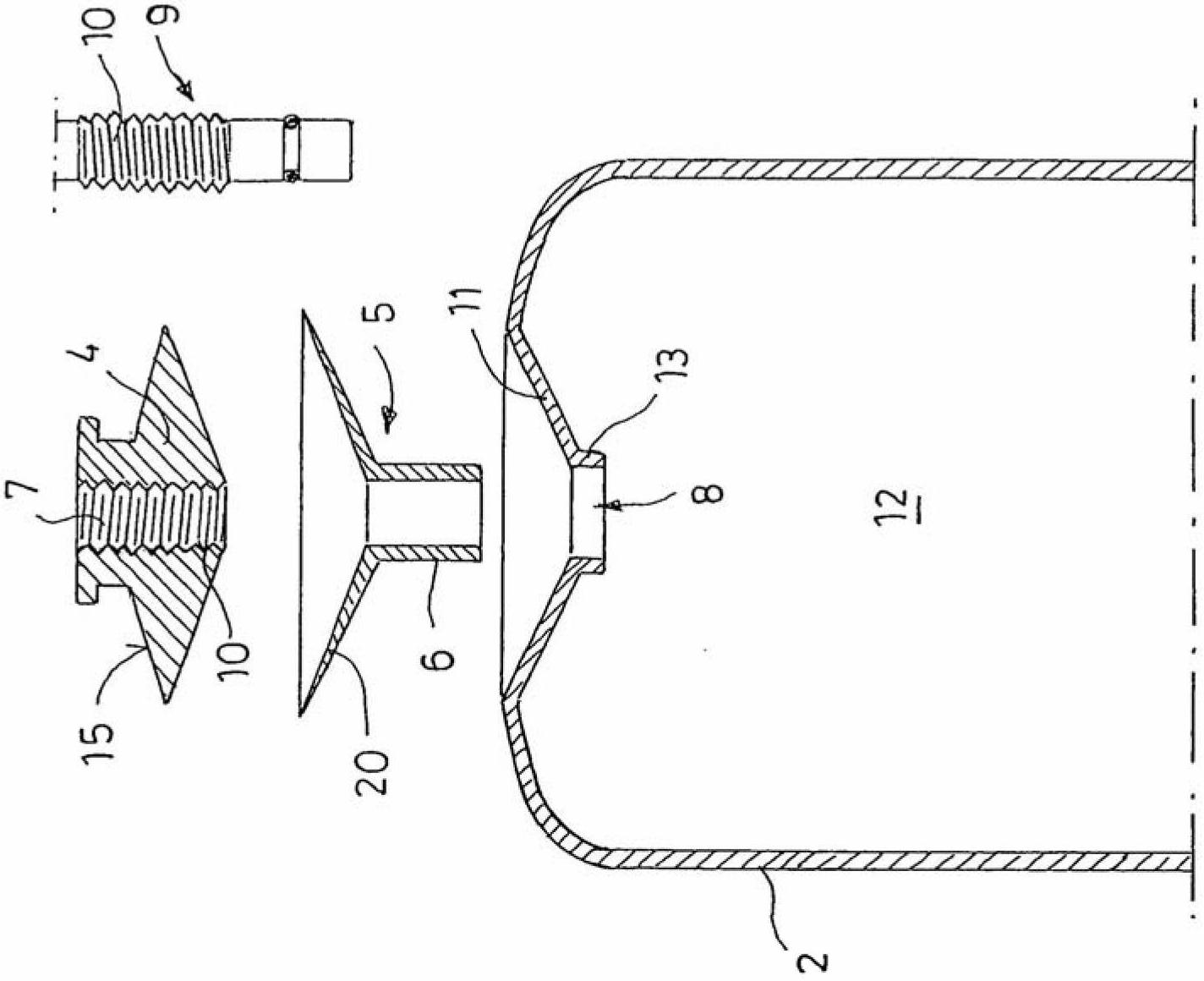

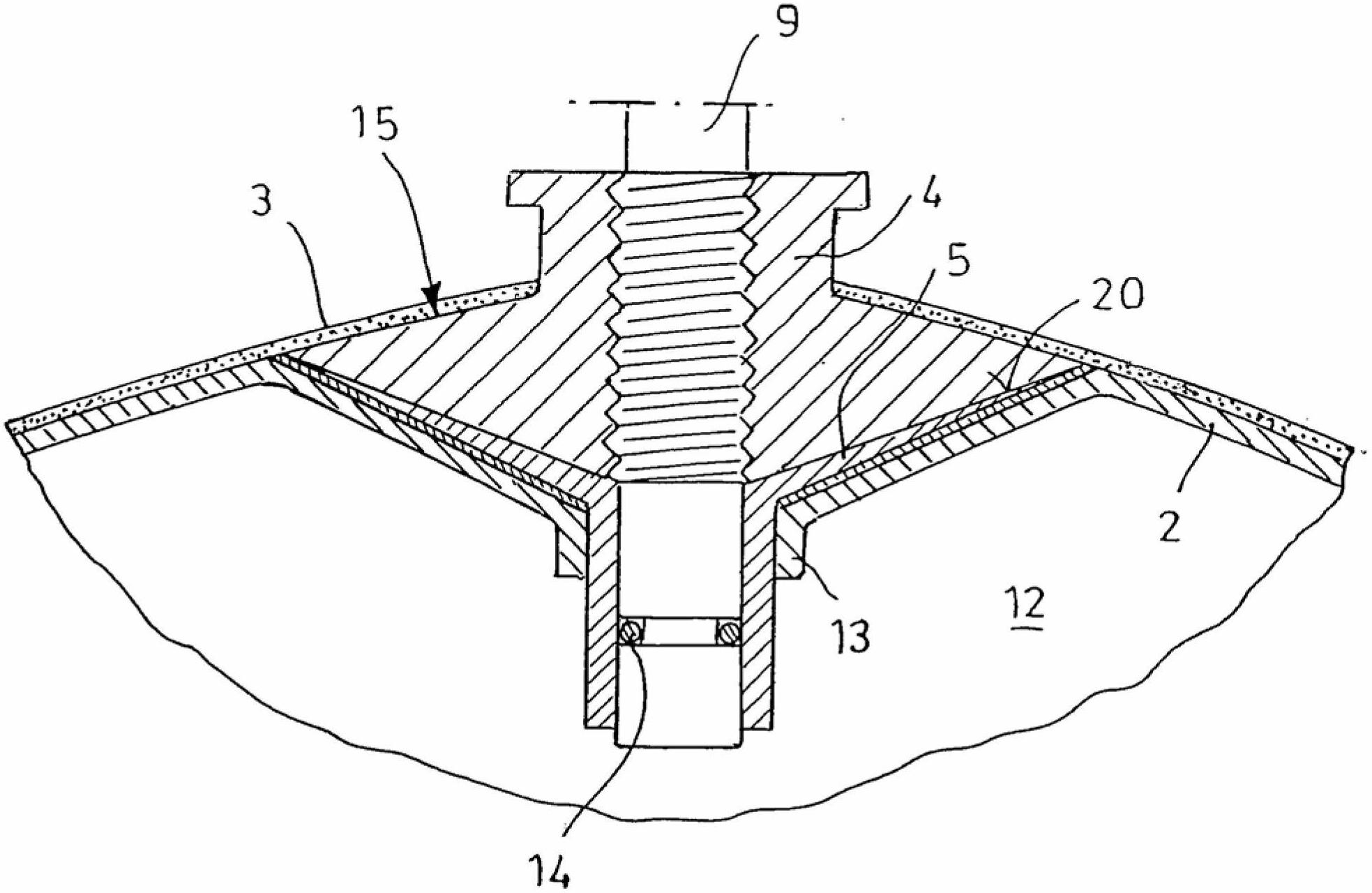

[0036] figure 1 The pressure vessel 1 shown in has a plastic inner container 2 preferably obtained by extrusion blow molding, which is surrounded by a support shell 3 made of fiber reinforcement embedded in a matrix made of synthetic resin.

[0037] Although according to the preferred embodiment the plastic inner container 2 is obtained by extrusion blow molding, it can also be obtained by a thermoforming process or by a rotational sintering process (thin shell moulding). Polyethylene, polypropylene, polyester, polyurethane, polyoxymethylene (POM), thermoplastic elastomer (TPE) or the like are conceivable as materials for the plastic inner container 2 .

[0038] The support cover can consist of carbon fibers, aramid threads, glass threads or the like. The support shell is preferably produced by winding the plastic inner container 2 with resin-impregnated fibres / threads. This procedure is known per se.

[0039] To simplify the illustration, the bearing cap 3 is only shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com