Integral molding die and molding method for engine inner heat insulation layer

A heat insulation layer and engine technology, which is applied in the overall molding mold and molding field of the heat insulation layer in the engine, can solve the problems that the thickness of the heat insulation layer cannot be changed linearly, which affects the safety and reliability of the engine, and achieves no laps and flashes, and increases the resistance Ablation and erosion resistance, effect of ensuring assembly clearance and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the above objects, features and advantages of the present invention more obvious and comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

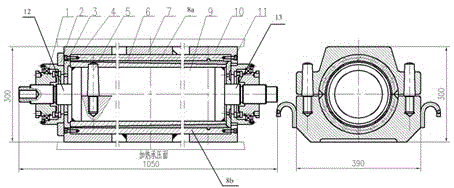

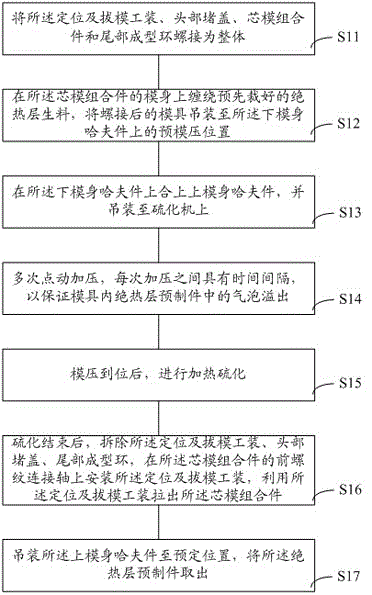

[0037] refer to figure 1 , the molding die of the present embodiment comprises: the upper mold body Huff part 8a, the lower mold body Huff part 8b, the core mold assembly 9, the tail forming ring 11, the head blocking cover 3, the positioning and drafting tooling 1, the head Ministry reinforced cover 4, middle reinforced cover 7, tail reinforced cover 10, tapered locating pin 5, draft washer 2.

[0038] Wherein, the upper mold body half part 8a and the lower mold body half part 8b are used in conjunction. The core mold assembly 9 includes a mold body and a front threaded shaft 12 and a rear threaded shaft 13 welded to the front and rear ends of the mold body. In this embodiment, the mold body is a hollow st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com