Assembly welding tool of high-precision frame structure

A frame structure, assembly welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as poor deformation control effect, and achieve the effect of preventing welding deformation and improving welding efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

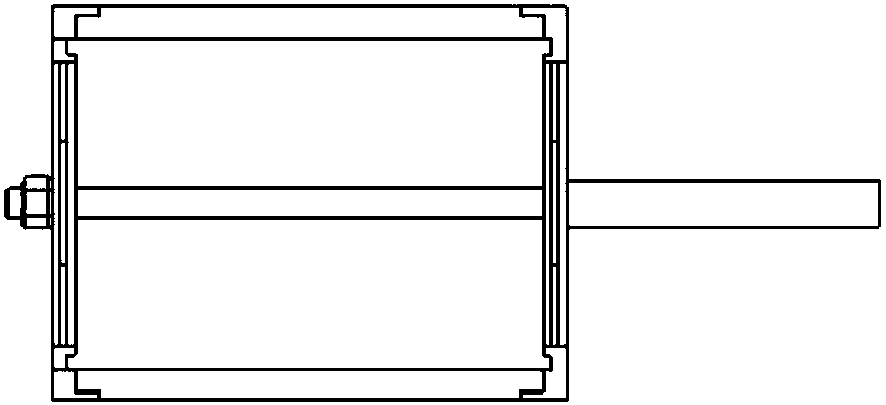

[0020] This embodiment is a welding assembly tool for the upper cover plate, the lower cover plate, the support bars on both sides and the rear panel of a certain airborne communication chassis frame. The length of the upper cover plate is l=310mm, the width w=152.5mm, and the height h=14mm. The length of the lower cover plate is l=310mm, the width w=152.5mm, and the height h=10mm. The external dimensions of the support bars on both sides are the same, the length is l=212mm, the width w=10mm, and the height h=10mm. The length of the rear panel is l=320mm, width w=217mm, and height h=41.8mm. After assembly, the amount of misalignment is guaranteed to be within 0.2mm and uniform, and the gap is guaranteed to be within 0.1mm and uniform. The part material is 5A06 aluminum alloy.

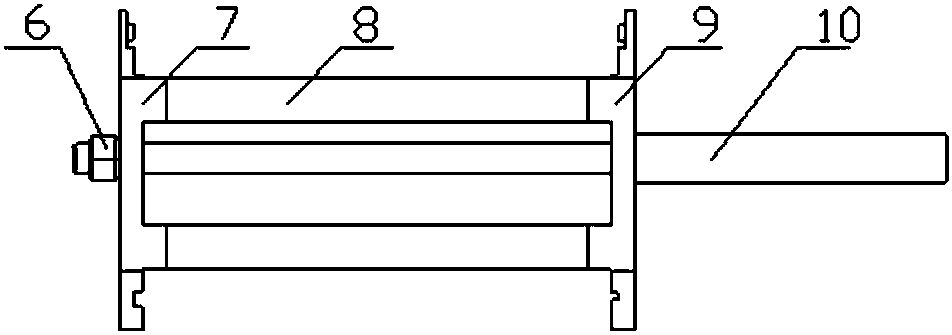

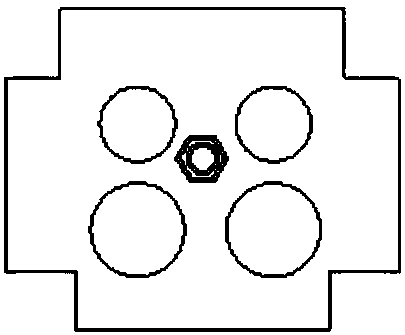

[0021] This embodiment includes two clamping plates 7 used in pairs, four pressing plates 8 and pull rods 10. The four pressure plates are divided into two groups, which are respectively fixedly connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com