Method and supporting tool for assembling a large ship tank head

A head and tank technology, which is applied in the field of large-scale tank head assembly, methods and supporting tools, can solve the problems affecting the production quality of ship tank heads, the accuracy cannot be guaranteed, and the material loss is large, so as to reduce the impact damage Probability, simple structure, and the effect of reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

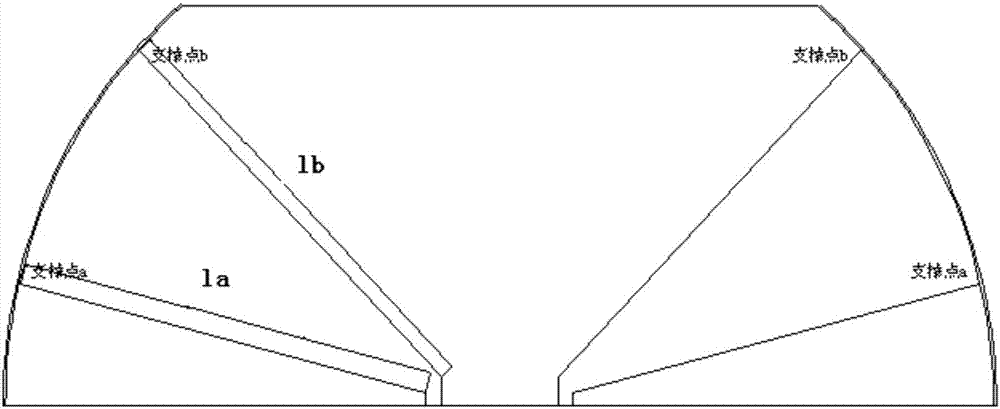

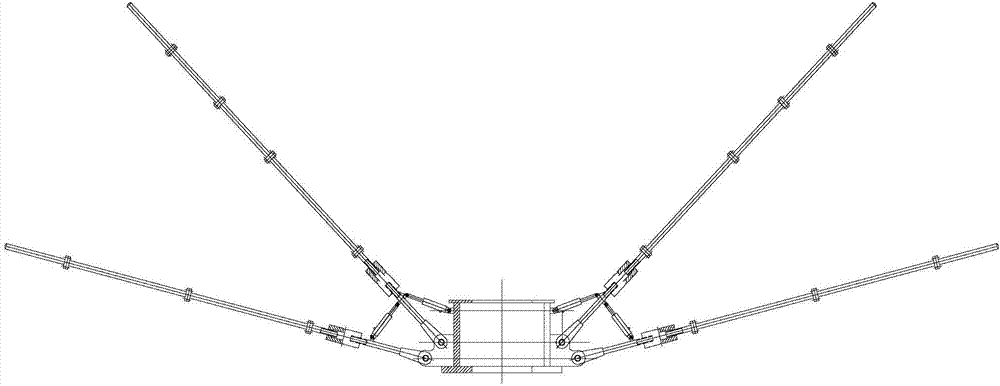

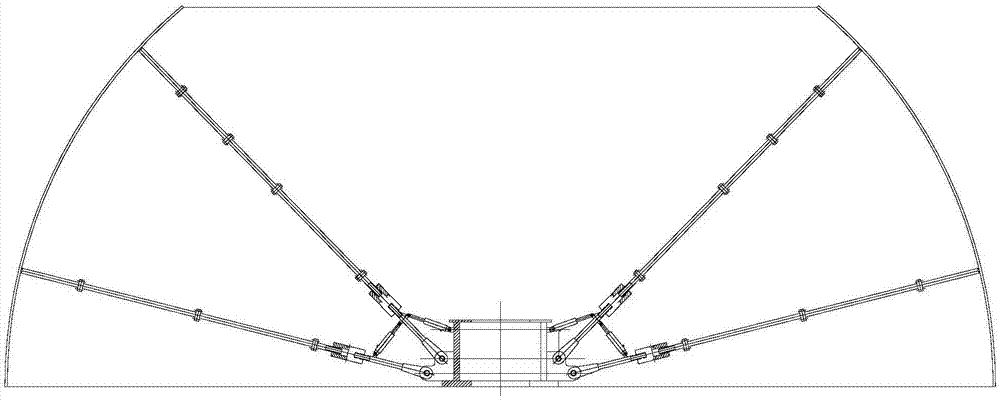

[0045] 1. First, let me introduce a supporting tool involved in this method.

[0046] The support tool includes a base body, and a plurality of one ends arranged on the base body are movably connected with the base body, and the other end is connected with a telescopic assembly leaning on a support point in a temperate zone or an extreme zone. The bottom ends of two adjacent telescopic assemblies are connected by a hydraulic rod The flexible connection is specifically that one end of the hydraulic rod is movably connected with the bottom of the telescopic assembly, and the other end is movably connected with the bottom of another adjacent telescopic assembly.

[0047] The telescoping assembly includes an adjusting nut, one end of which is threadedly connected to a screw at one end of the adjusting nut, and the other end of the screw is connected with several adjusting rods which are sequentially connected, and the top of the adjusting rod is provided with a top rod; the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com