Balance adjusting device of turbofan engine rotor single-stage disc and adjusting method thereof

A turbofan engine and balance adjustment technology, which is applied in static/dynamic balance testing, measuring devices, testing of machine/structural components, etc., can solve the problem of large unbalance of tooling, poor guarantee of assembly clearance, and processing of multiple groups of tooling and other problems, to achieve the effect of reducing processing costs, reducing operating errors, and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

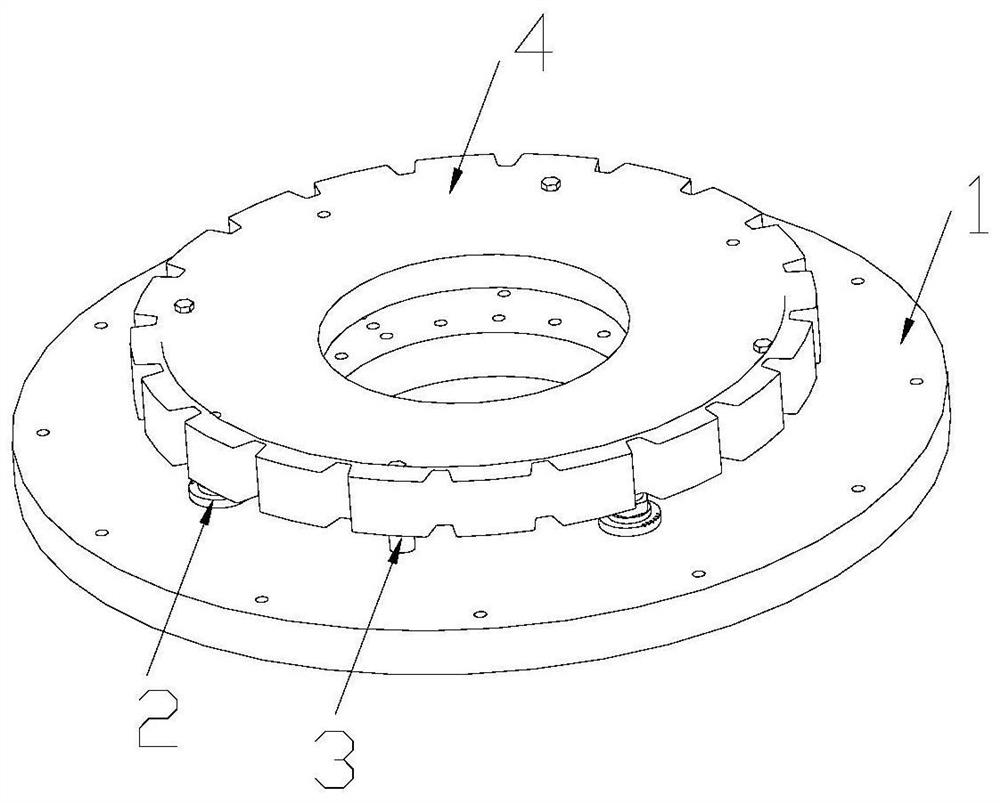

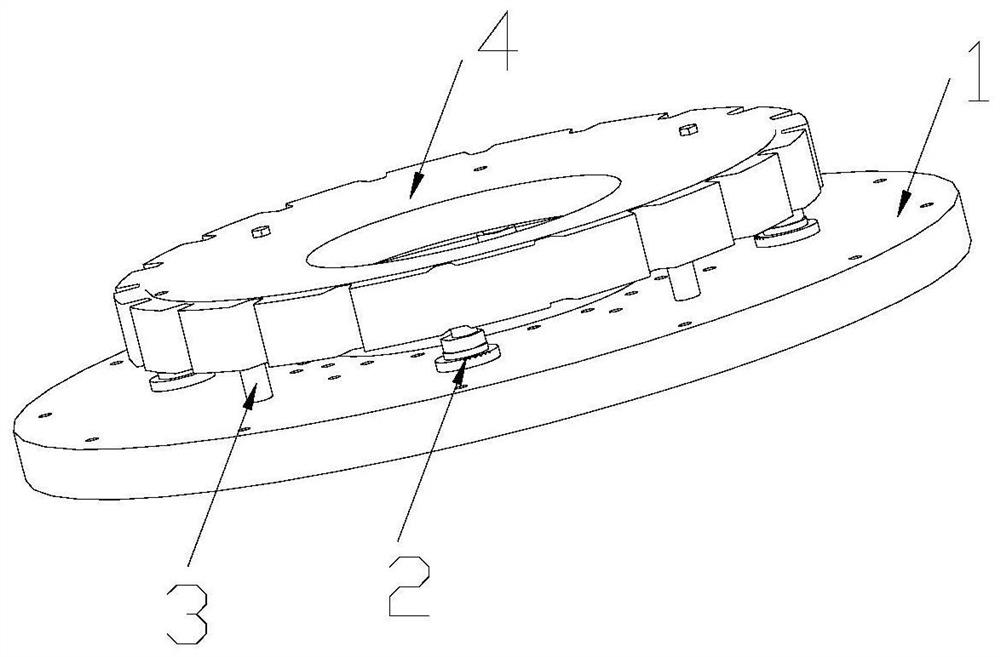

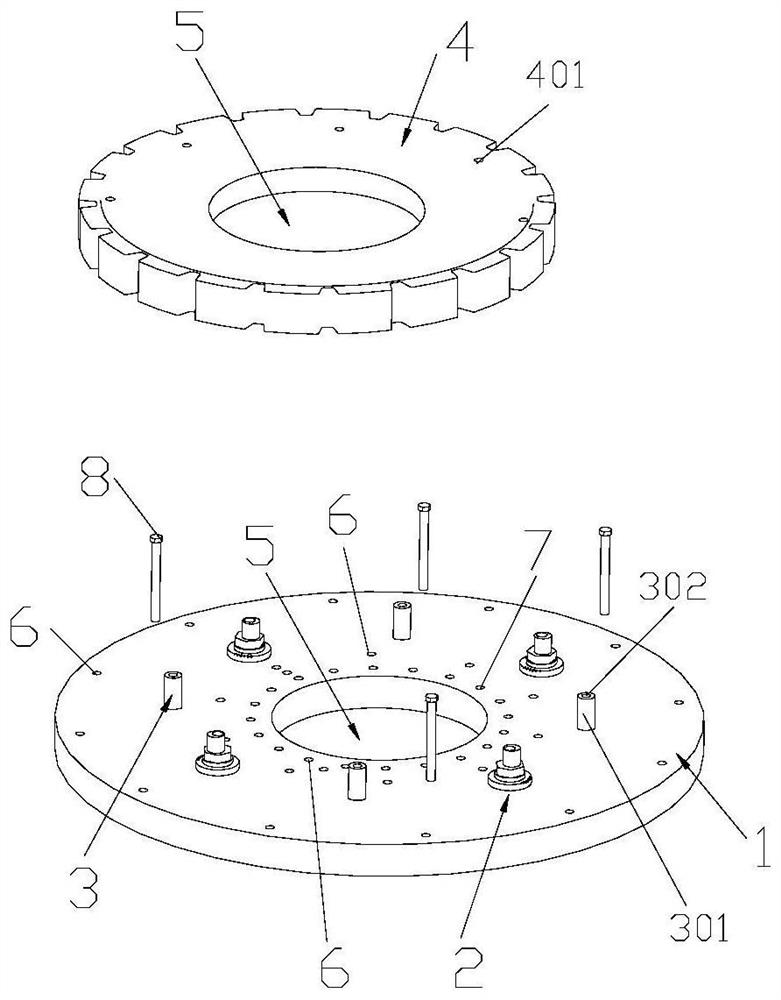

[0039] refer to Figure 1-4 , the present invention provides a technical solution:

[0040] Please refer to Figure 1-2 , a balance adjustment device for a single-stage disc of a turbofan engine rotor, comprising:

[0041] Balance base 1;

[0042] The eccentric adjustment assembly 2 installed on the balance base 1 and the support assembly 3 installed on the balance base 1;

[0043] A single-stage disc 4, the single-stage disc 4 is supported above the eccentric adjustment assembly 2, adjusts the distance between the eccentric adjustment assembly 2 and the center of the balance base 1, and moves the eccentric adjustment assembly 2 to the center of the balance base 1 through the support assembly 3 The single-stage disk 4 is connected with the balance base 1 to form a concentric structure up and down.

[0044]The balance adjustment device for the turbofan engine rotor single-stage disk of the present invention has few components, but it has good operability. When balancing, th...

Embodiment 2

[0061] A method for adjusting the balance of a single-stage disk of a turbofan engine rotor, using the balance device for a single-stage disk of a turbofan engine rotor for adjustment, including the following steps:

[0062] S1. Install the eccentric adjustment assembly 2: select a set of installation position units matching the diameter of the single-stage disk 4, and install four eccentric adjustment seats in the installation holes 6 of the installation position unit;

[0063] S2. Installing the supporting components 3: installing the four supporting components 3 in the mounting holes 6, and installing them on the same set of installation position units with the four eccentric adjustment seats, and alternately setting them with the eccentric adjusting components 2;

[0064] S3. Place the single-stage disk 4: support the single-stage disk 4 on the support head 203 of the eccentric adjustment assembly 2, measure the radial runout of the single-stage disk 4 to obtain the single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com