Patents

Literature

122results about How to "Avoid large vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

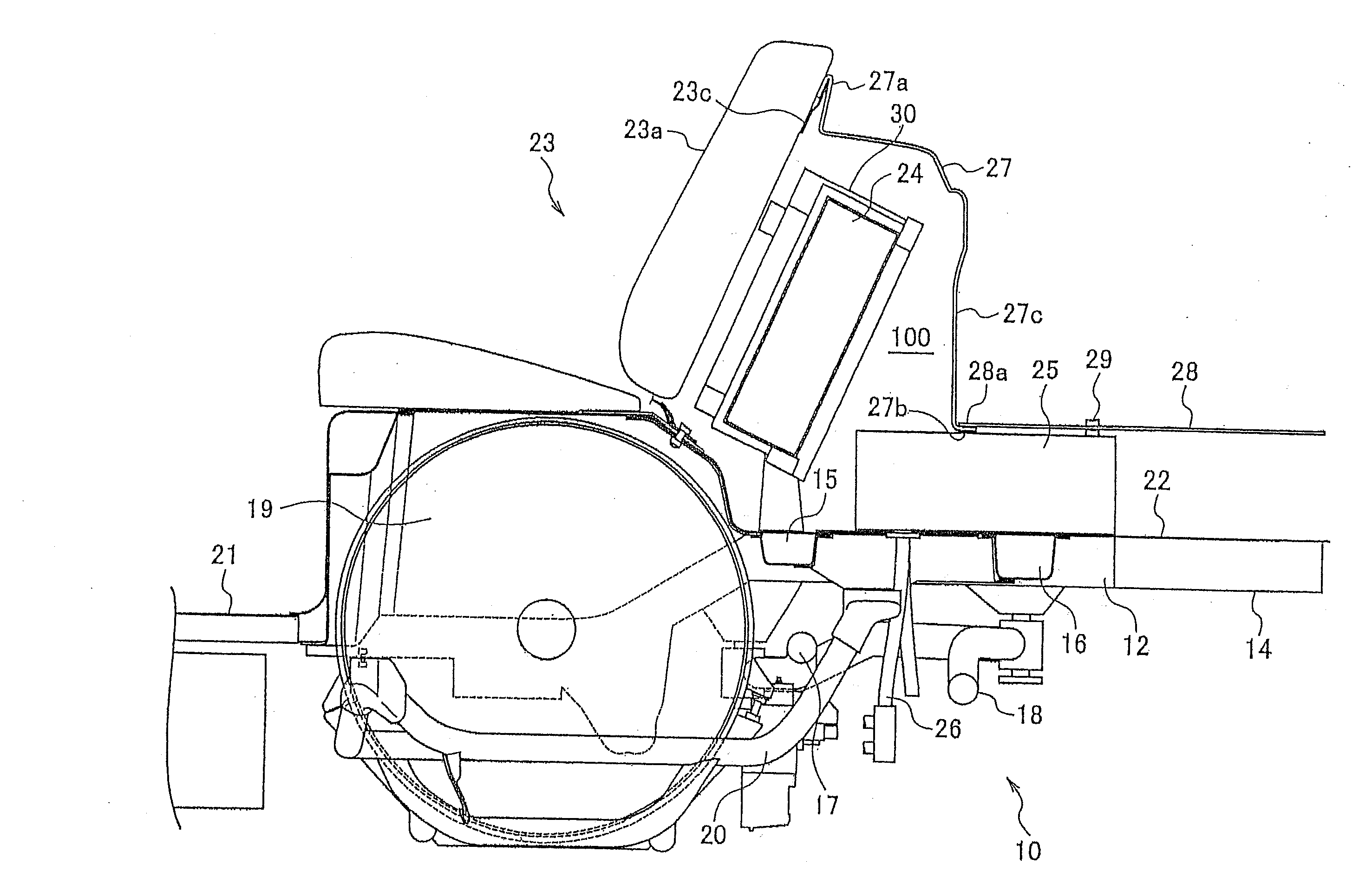

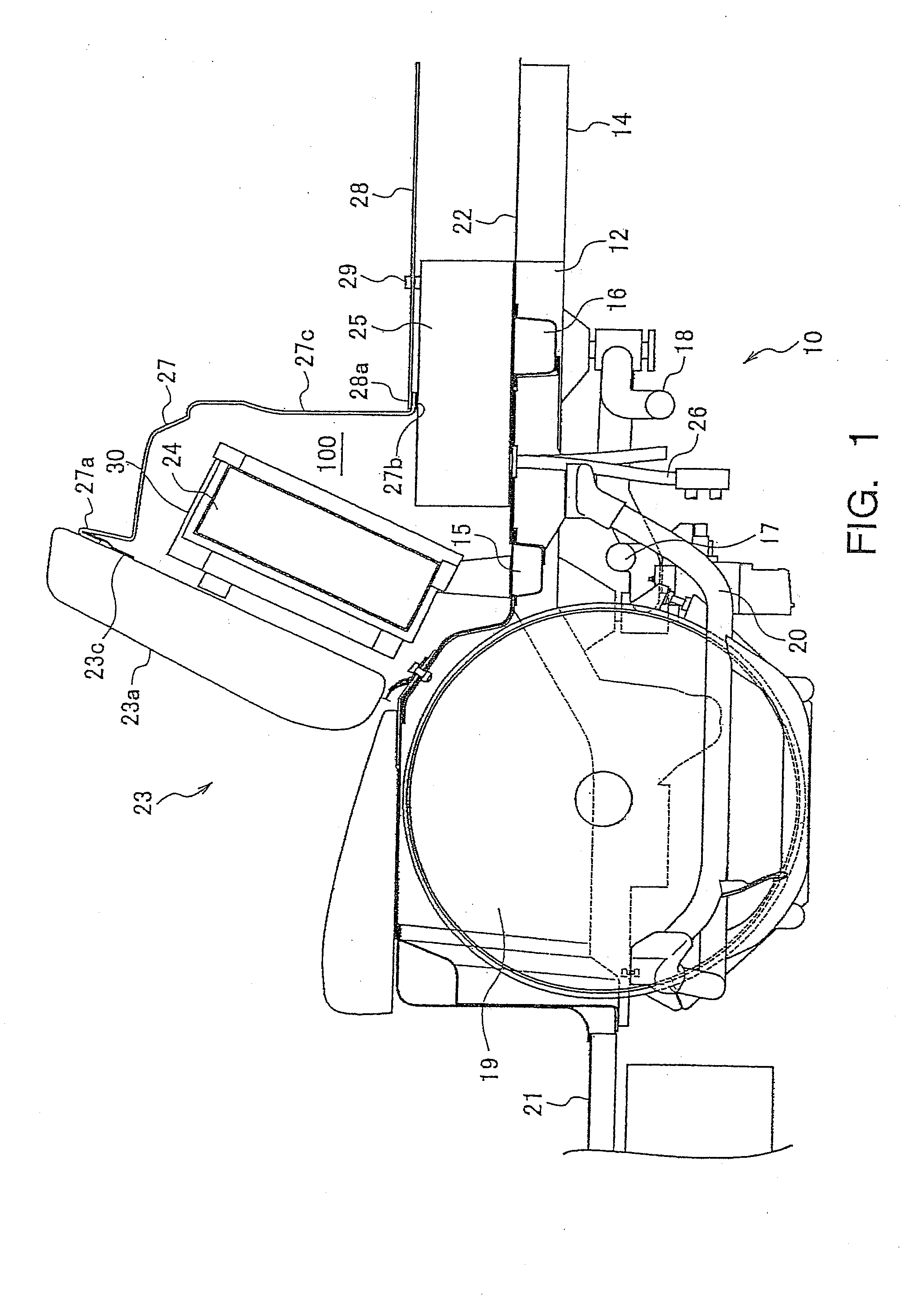

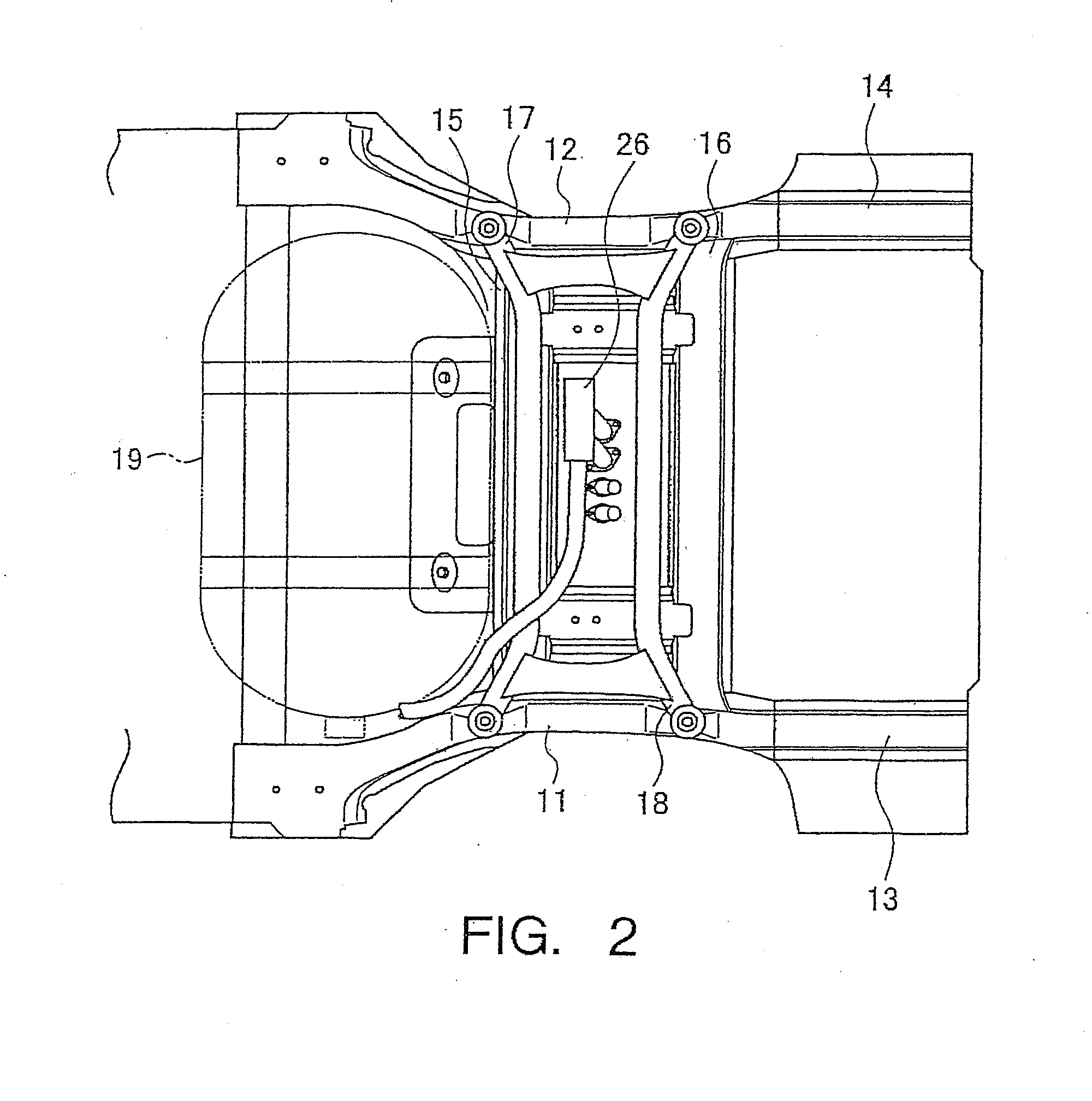

Rear vehicle structure

InactiveUS20080315572A1Avoid accessIncrease the difficultyUnderstructuresSuperstructure subunitsEngineeringElectrical and Electronics engineering

A rear vehicle structure has an electrical system unit, two side members, two extension parts, two cross members, a rear seat and a cover. The electrical system unit includes first and second electrical system units. Each extension part extends rearwardly from one of the rearward ends of one of the side members. The cross members are located above rear suspension members of the vehicle. The electrical system unit is fixedly attached to a top of at least one of the cross members. The rear seat is installed forward of the first electrical system unit. The second electrical system unit is located along a rearward surface of the rear seat. The cover is installed rearward of the second electrical system unit and has an upright panel that is oriented vertically to provide an enclosed space between a rearward surface of the second electrical system unit and the cover.

Owner:NISSAN MOTOR CO LTD

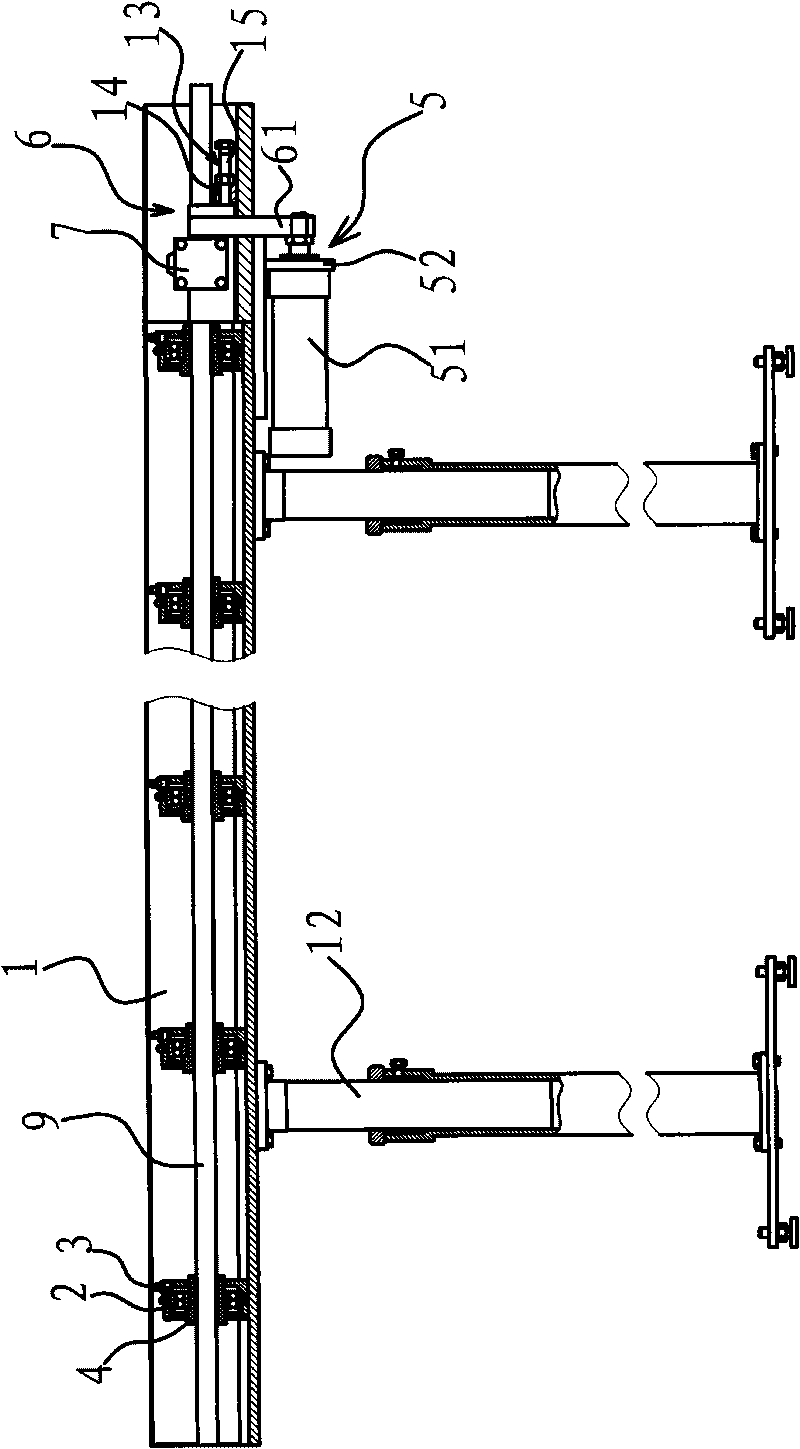

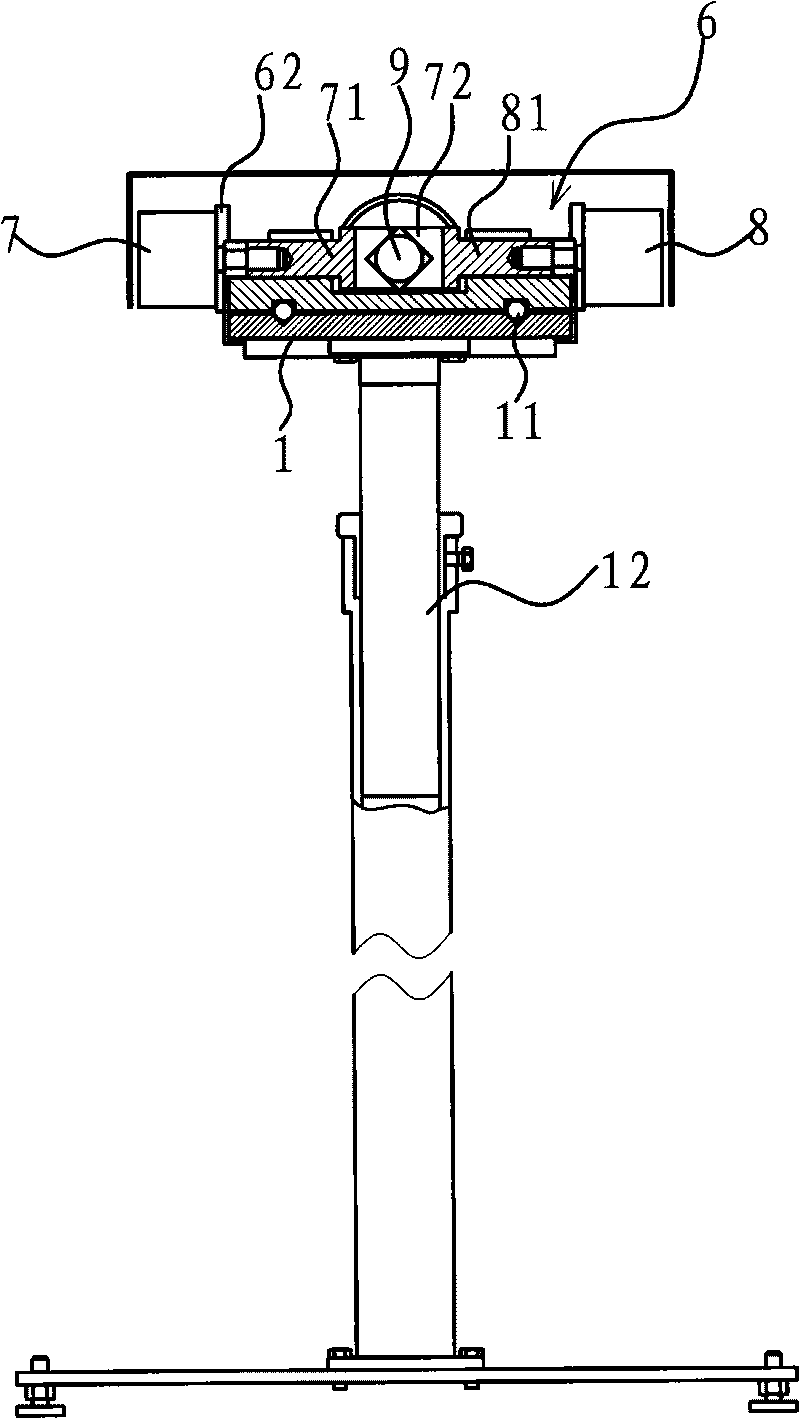

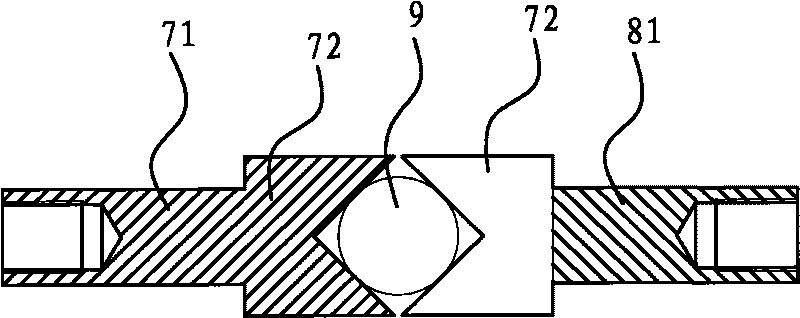

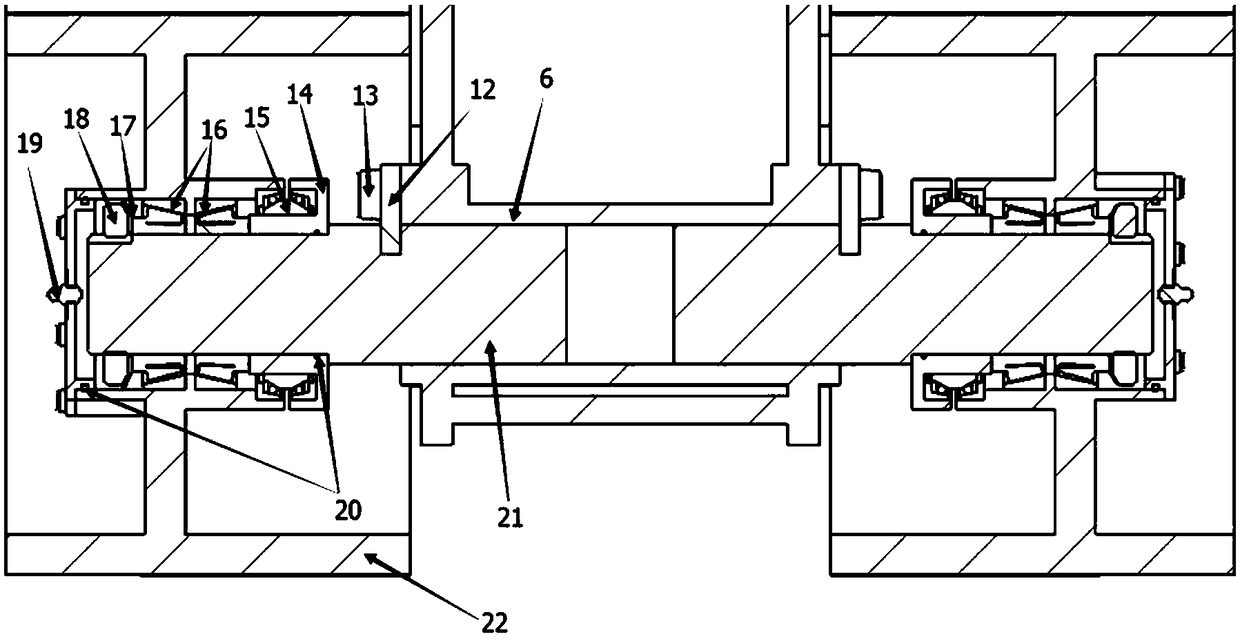

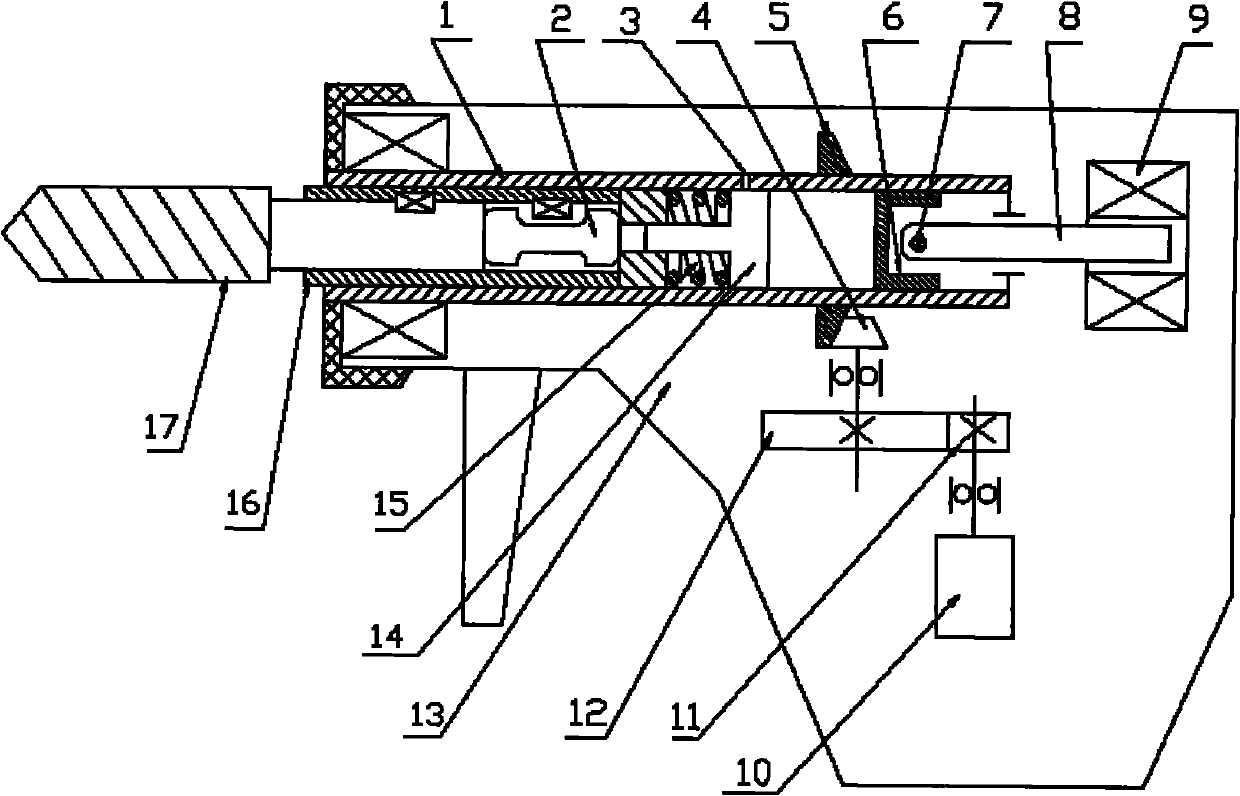

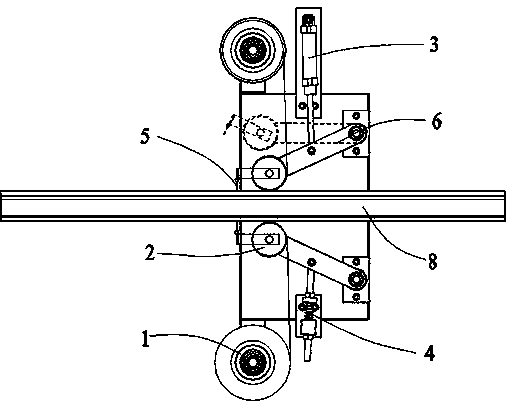

Bar conveying device

ActiveCN101722317AFeeding size is accurateAvoid large vibrationAutomatic conveying/guiding stockReciprocating motionEngineering

The invention provides a bar conveying device, belongs to the technical field of machinery, and solves the problems that the conventional bar conveying device has large vibration and low feeding precision in the process of conveying. The bar conveying device comprises a machine frame, wherein the machine frame is provided with a guide mechanism used for enabling a bar to move along one direction;the machine frame is also provided with a fixture capable of clamping the bar; and the fixture does linear reciprocating motion under the drive of a driving mechanism, stays in a state of clamping the bar when moving towards the bar moving direction, and stays in a loose state when returning towards the opposite direction. The bar conveying device has the advantages of high feeding precision, high feeding efficiency, little vibration, less noise, long service life and the like.

Owner:震环机床集团有限公司

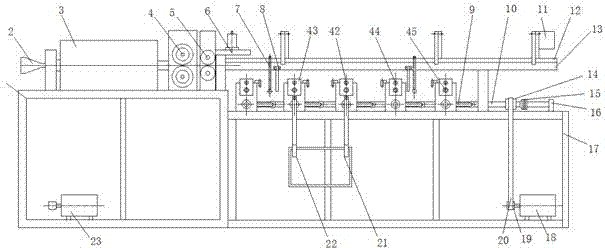

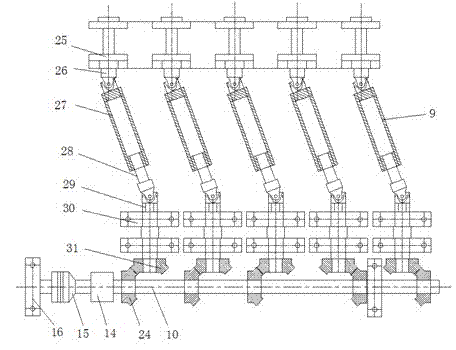

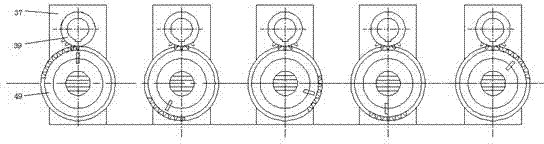

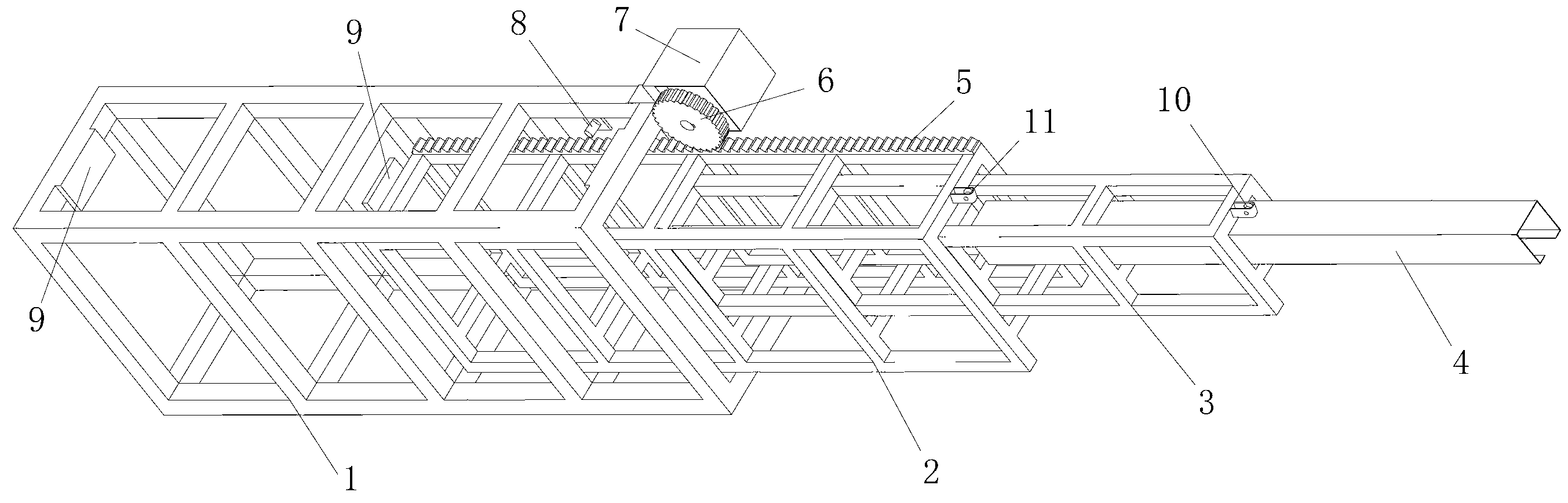

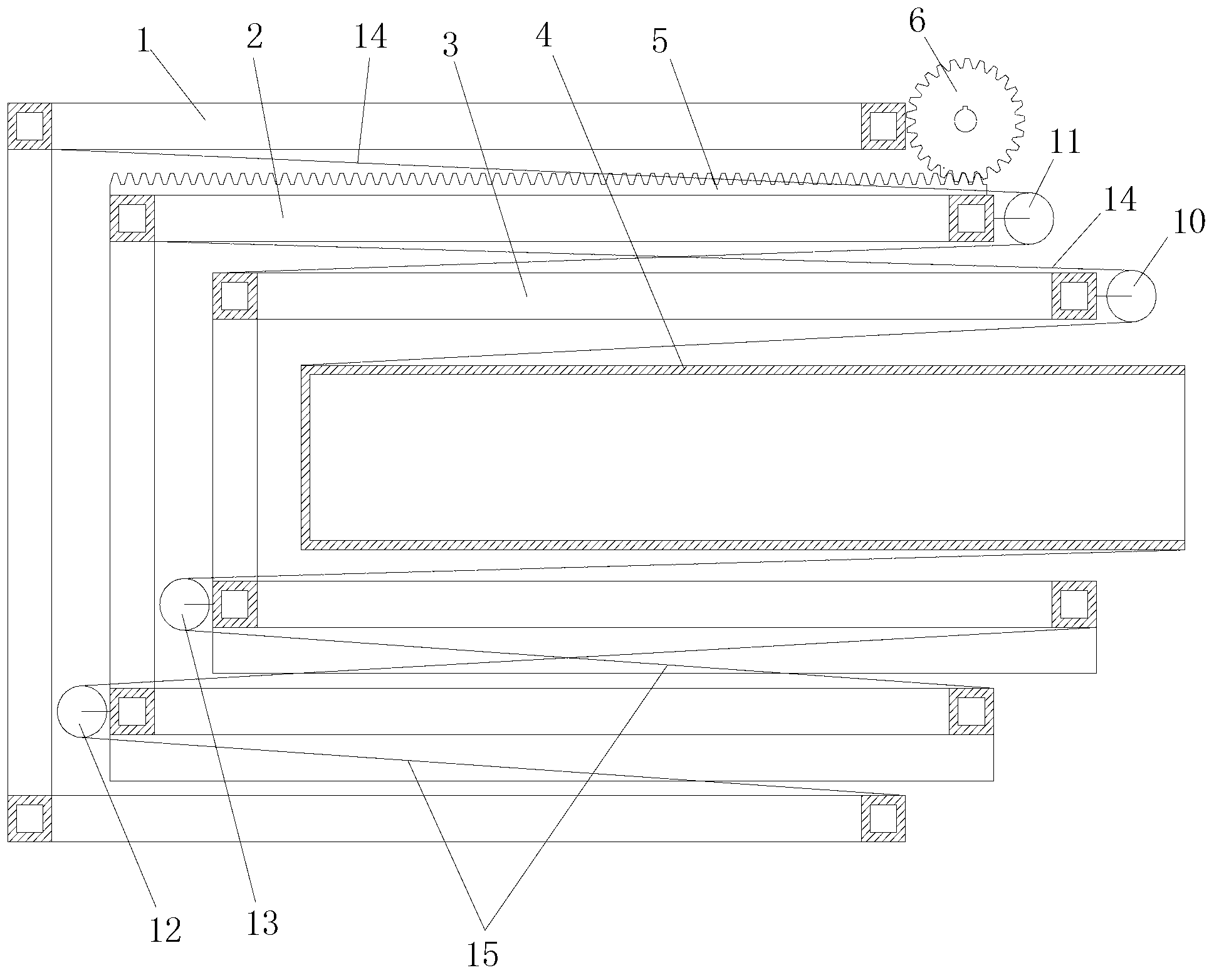

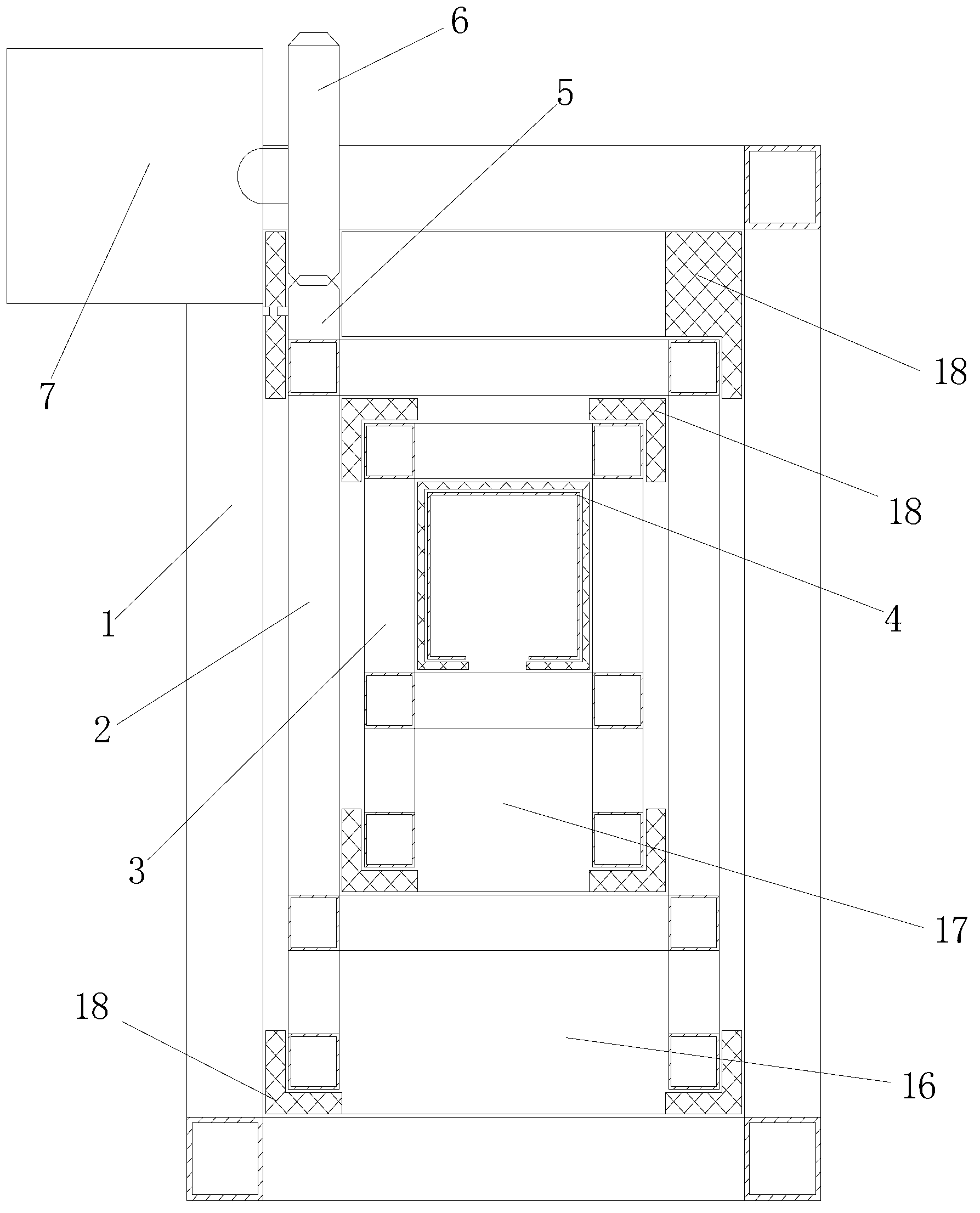

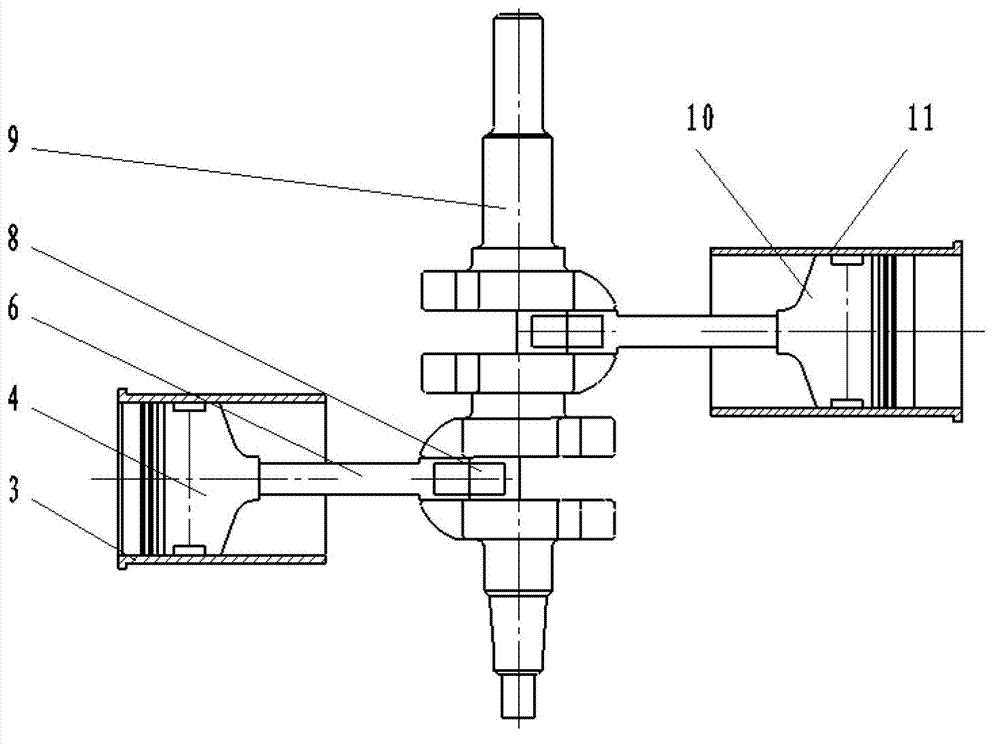

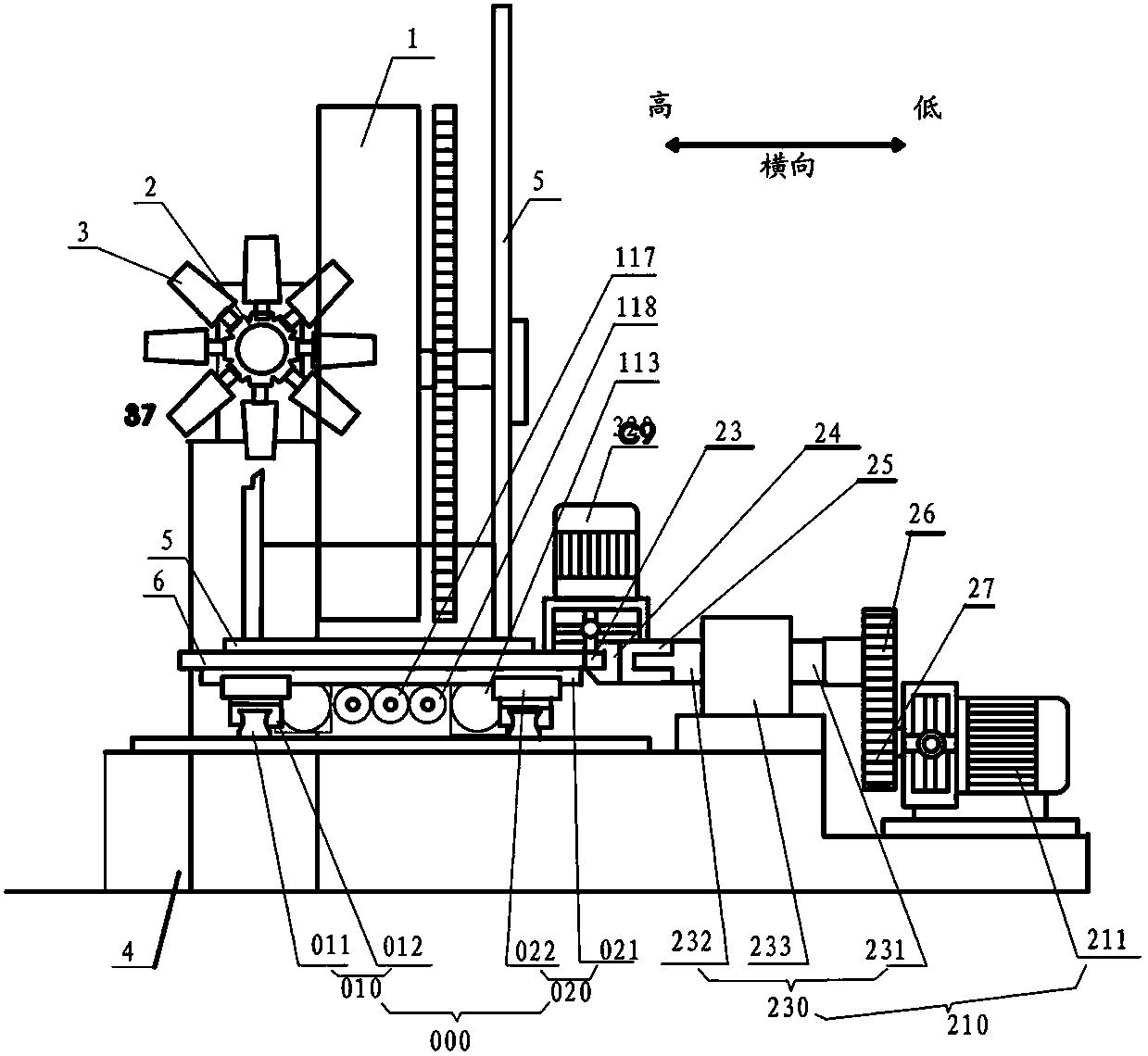

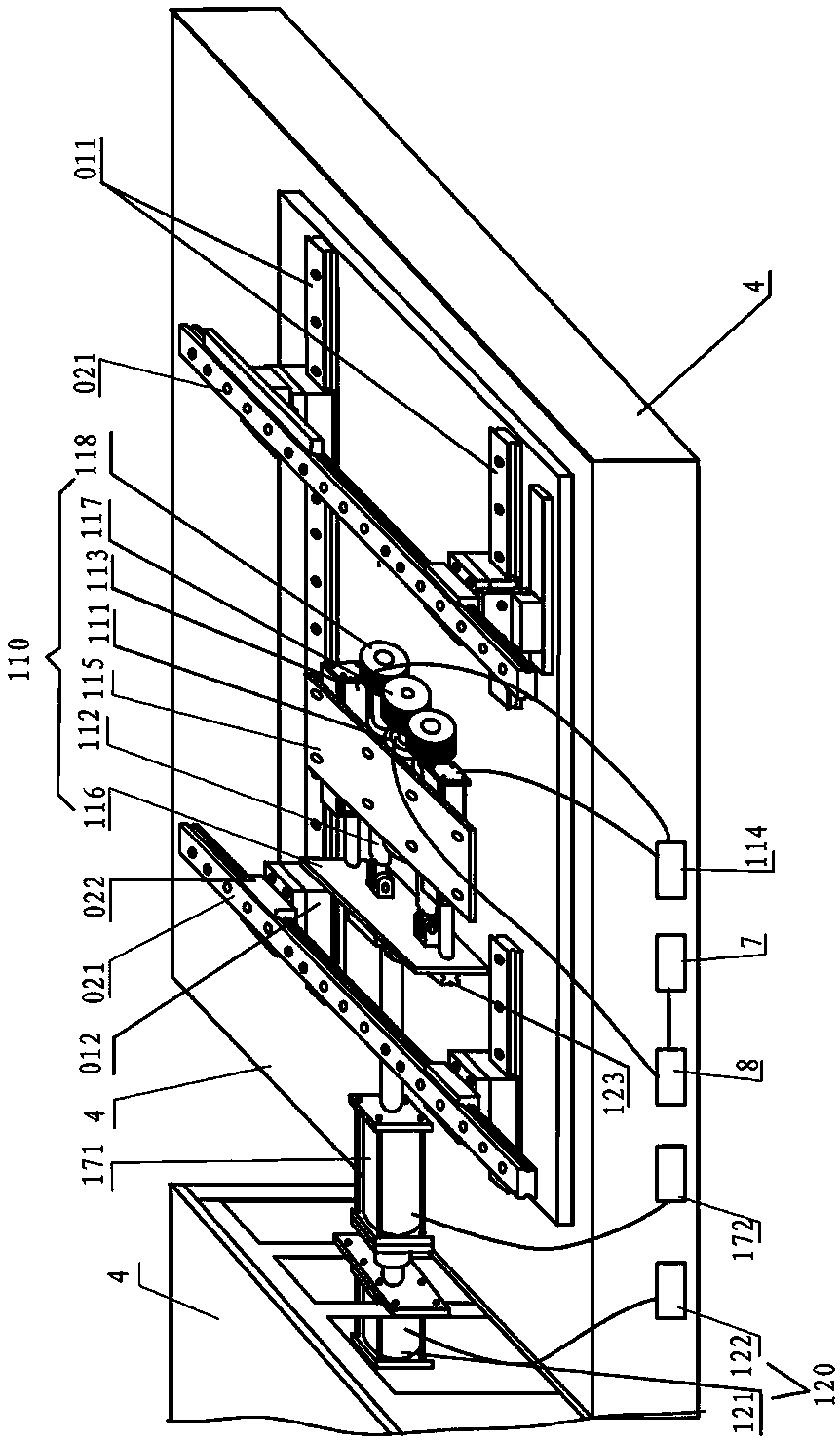

Parallel multi-head full-automatic reinforcing bar straightening and hoop bending device and use method thereof

The invention discloses a parallel multi-head full-automatic reinforcing bar straightening and hoop bending device and a use method thereof. The parallel multi-head full-automatic reinforcing bar straightening and hoop bending device comprises a straightening rack, a guiding cylinder, a straightening cylinder, a traction wheel, a metering wheel, a hydraulic cutting mechanism, a material bearing frame, a clutch, a bending mechanism, a stretchable universal joint transmission unit, a center post front-and-back stretchable unit, an upper incomplete gear and a lower incomplete gear. The parallel multi-head full-automatic reinforcing bar straightening and hoop bending device and the use method thereof are suitable for straightening and hoop bending of cold-rolled and hot-rolled deformed bars and hot-rolled round steel. According to the parallel multi-head full-automatic reinforcing bar straightening and hoop bending device and the use method thereof, five stretchable universal joints are utilized to be connected in parallel, the five universal joints are driven to transmit power to a lower gear shaft through bevel gear drive of a main driving shaft, and high synchronism is achieved by combining the advantage of high precision of the incomplete gears; a shaft shoulder is arranged on a designed center post so that the phenomenon of clamping caused by entering of reinforcing bar oxide skin and sundries can be avoided. Whole equipment has the advantages of being low in use failure rate, low in energy consumption, free of damage to ribs, low in noise, little in vibration, efficient in application, reliable in operation, light, flexible, convenient to move and the like.

Owner:吴伟忠

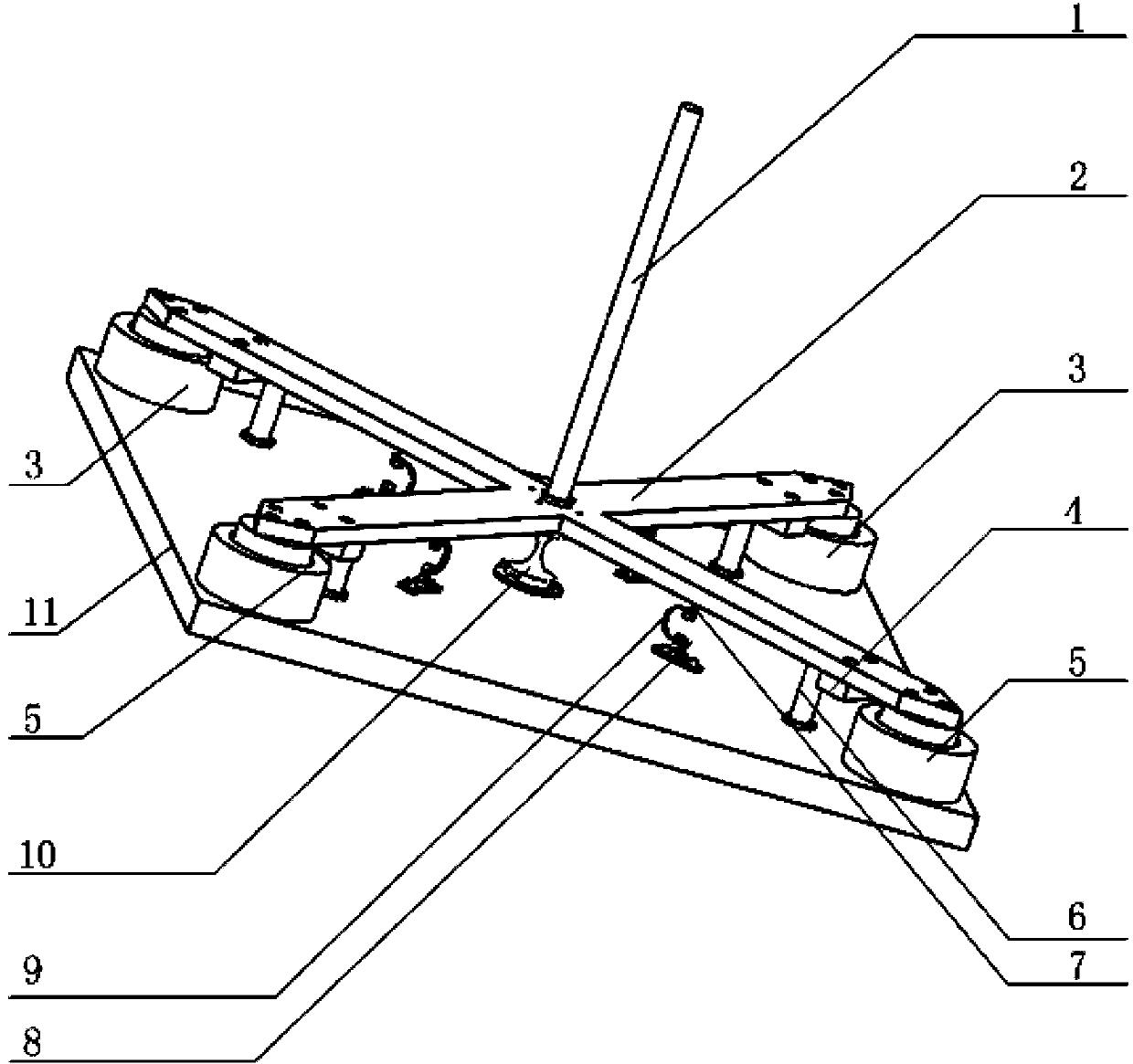

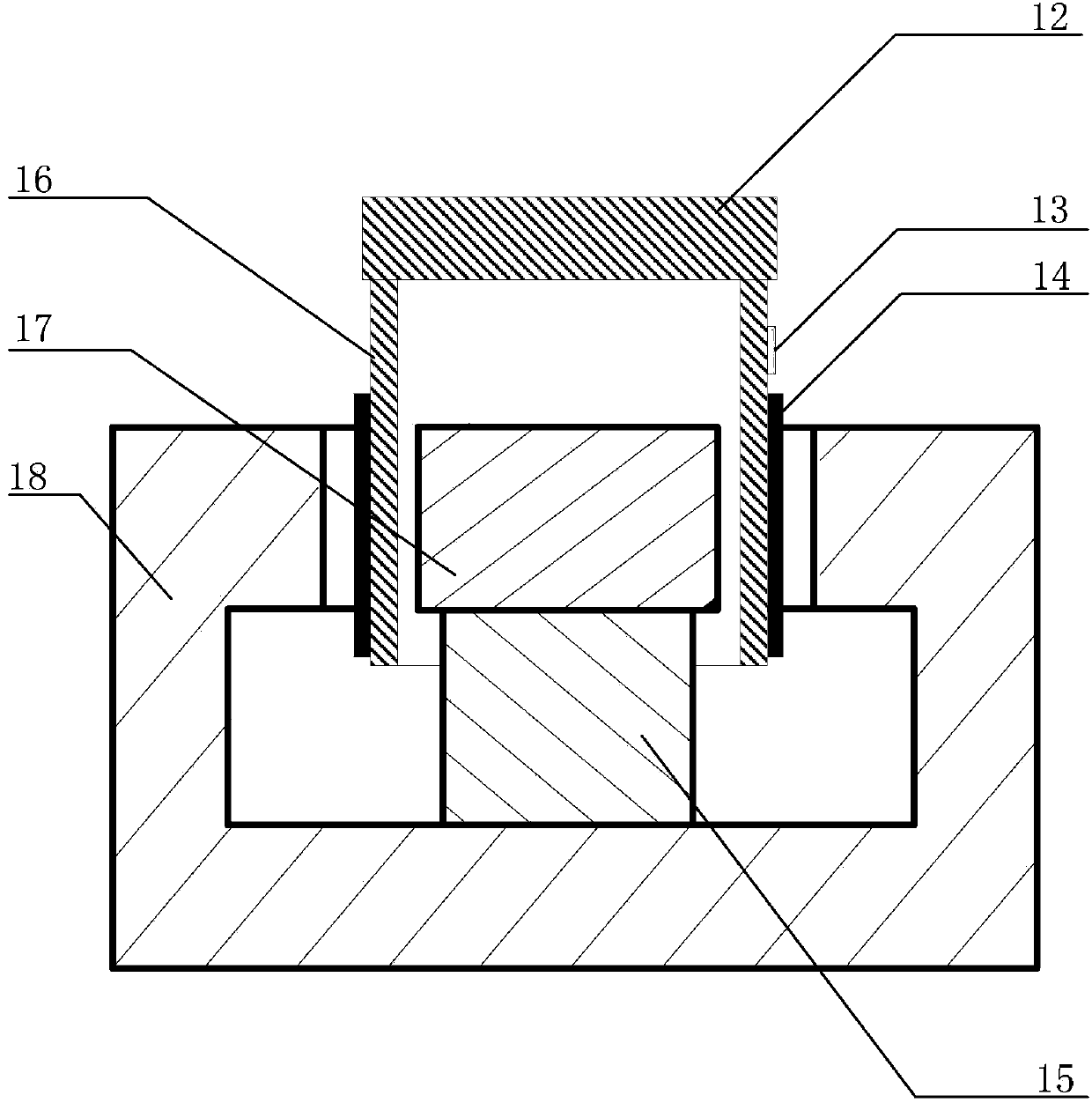

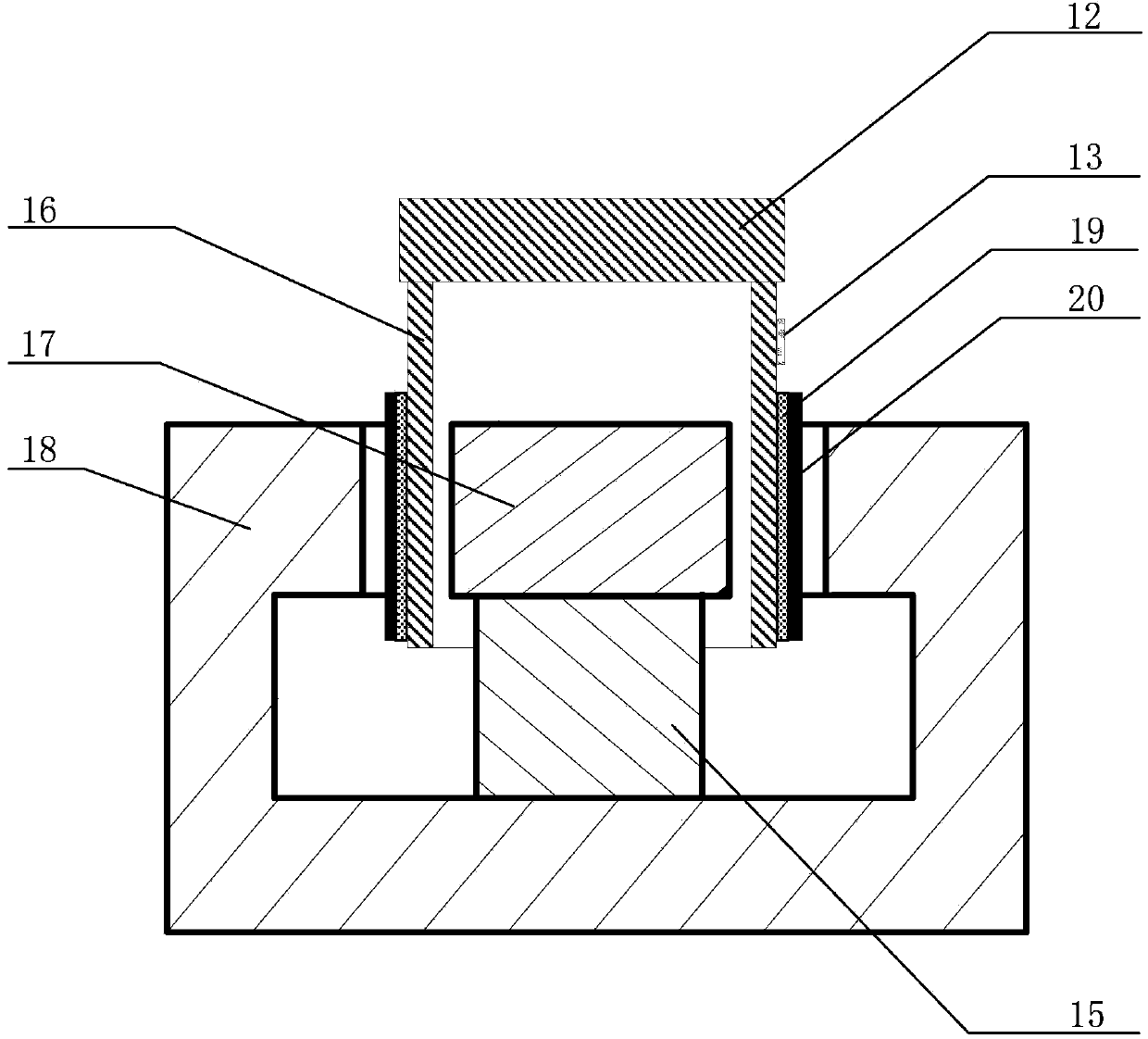

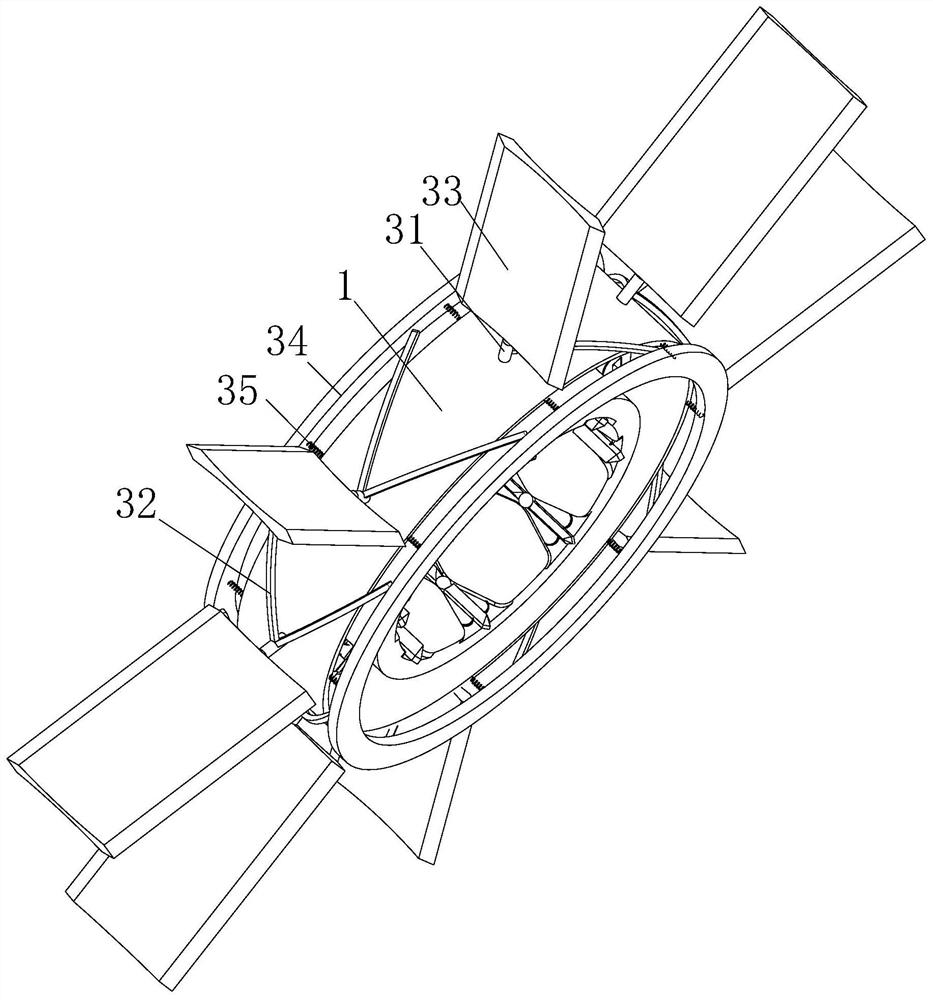

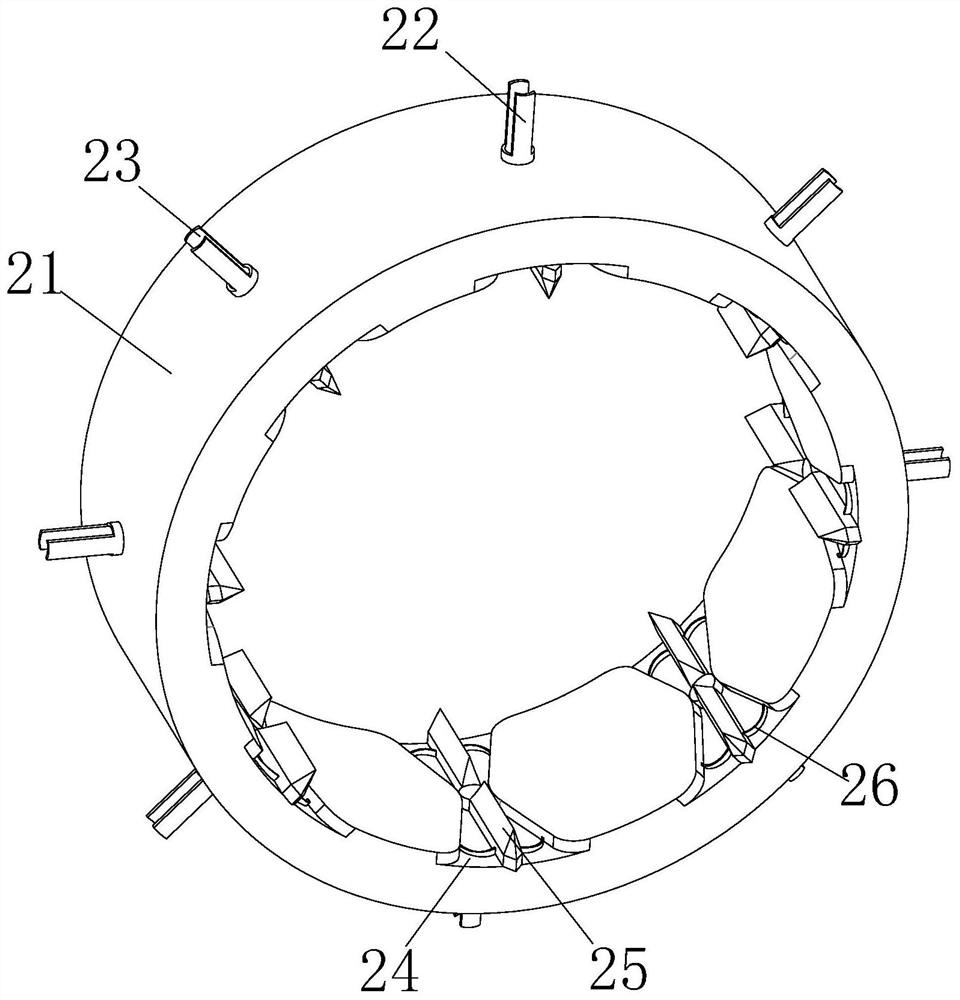

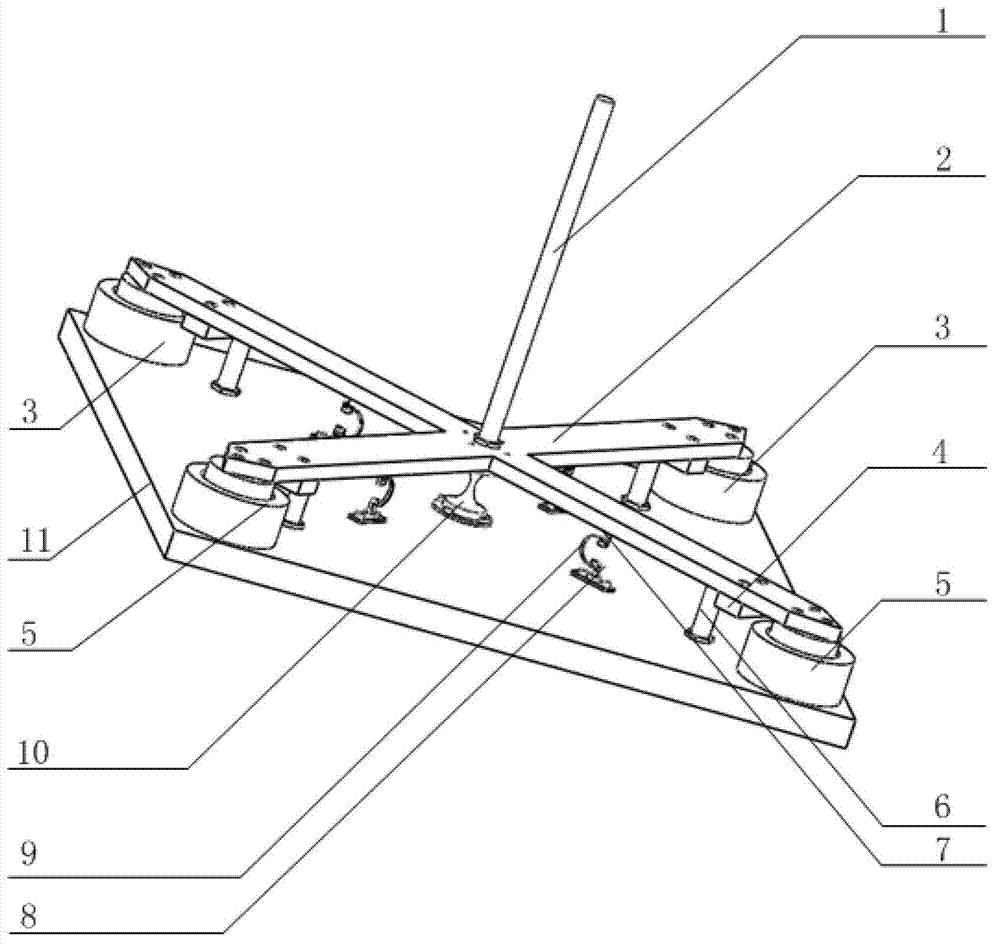

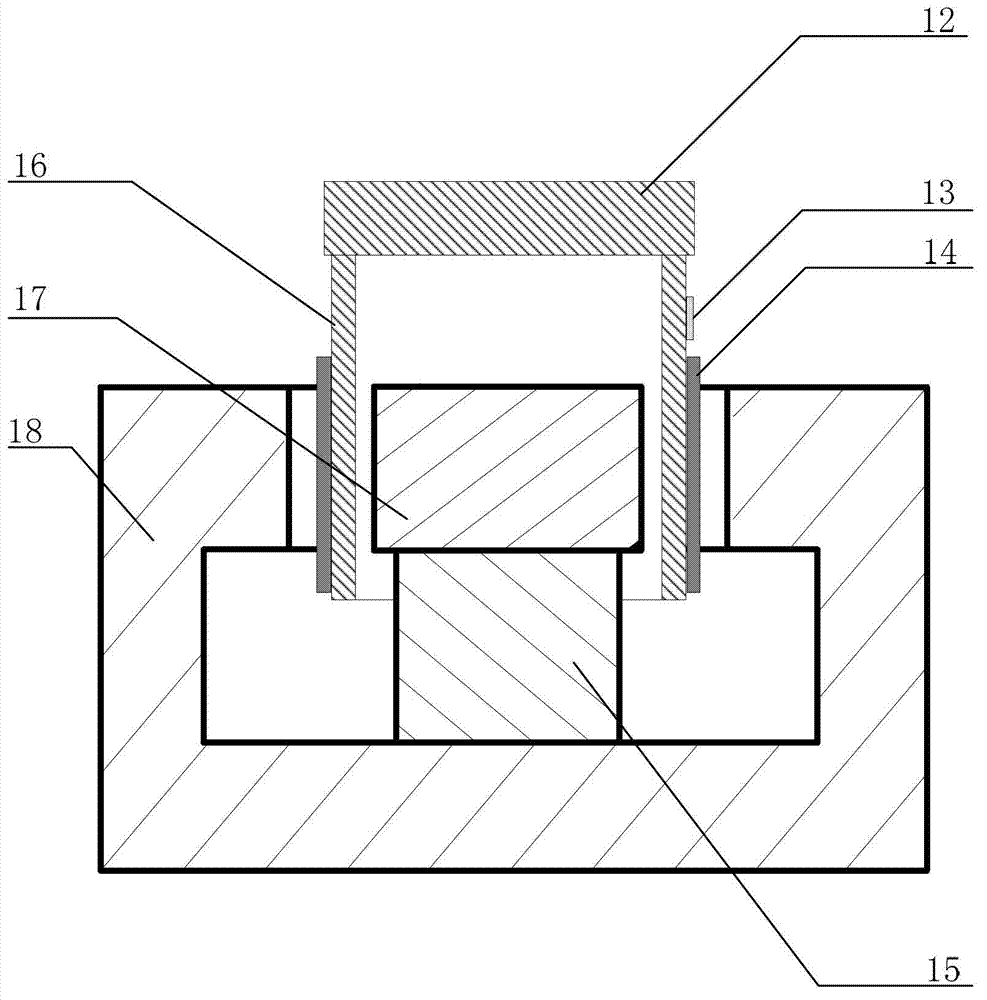

Damping-rigidness-controllable double-freedom-degree vibration active control platform

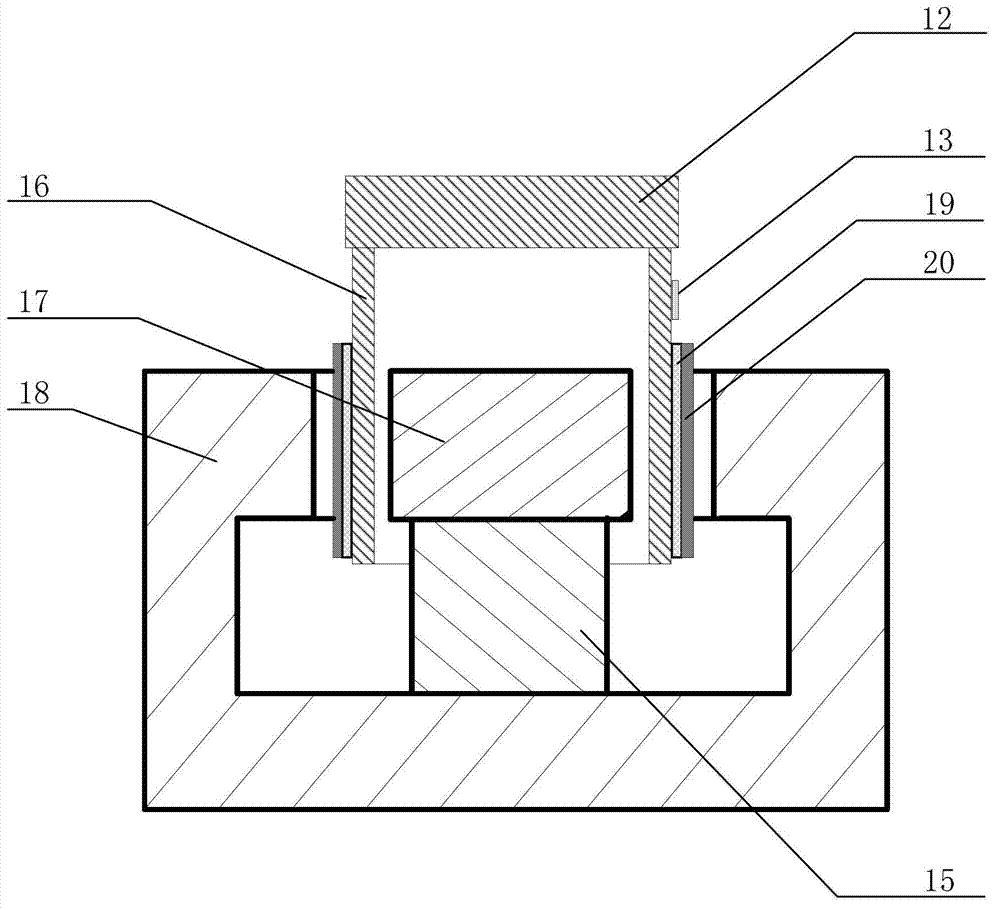

ActiveCN103398138AGood linearitySmall vibration rangeNon-rotating vibration suppressionCounterweightsEngineeringActuator

A damping-rigidness-controllable double-freedom-degree vibration active control platform comprises a cross-shaped beam frame and a square base which are connected through a flexible hinge. A cross-shaped beam of the cross-shaped beam frame is distributed in the diagonal directions of the square base. A structure column is arranged at the center of the cross-shaped beam frame. Sensors and actuators are connected between the lower portions of the diagonal top ends of the cross-shaped beam frame and the square base respectively. Four limiting columns are arranged between the cross-shaped beam of the cross-shaped beam frame and the square base respectively. Prearranged gaps are reserved between the limiting columns and the cross-shaped beam frame. Four balancing weights are fixed on the lower portion of the cross-shaped beam frame between the sensors or the actuators and the limiting columns respectively. Twisting limiting spring pieces are arranged at the symmetrical positions on the lower portion of the cross-shaped beam frame between the limiting columns and the flexible hinge. The electromagnetic type sensors and the electric-damping electric-rigidness actuators are used to achieve detecting of angular speed and actuating, the flexible hinge and the spring piece with changeable thickness are combined to achieve controllable damping and rigidness in a quantifying mode, and double-freedom-degree vibration active control in the x direction and the y direction of the structure is achieved.

Owner:XI AN JIAOTONG UNIV

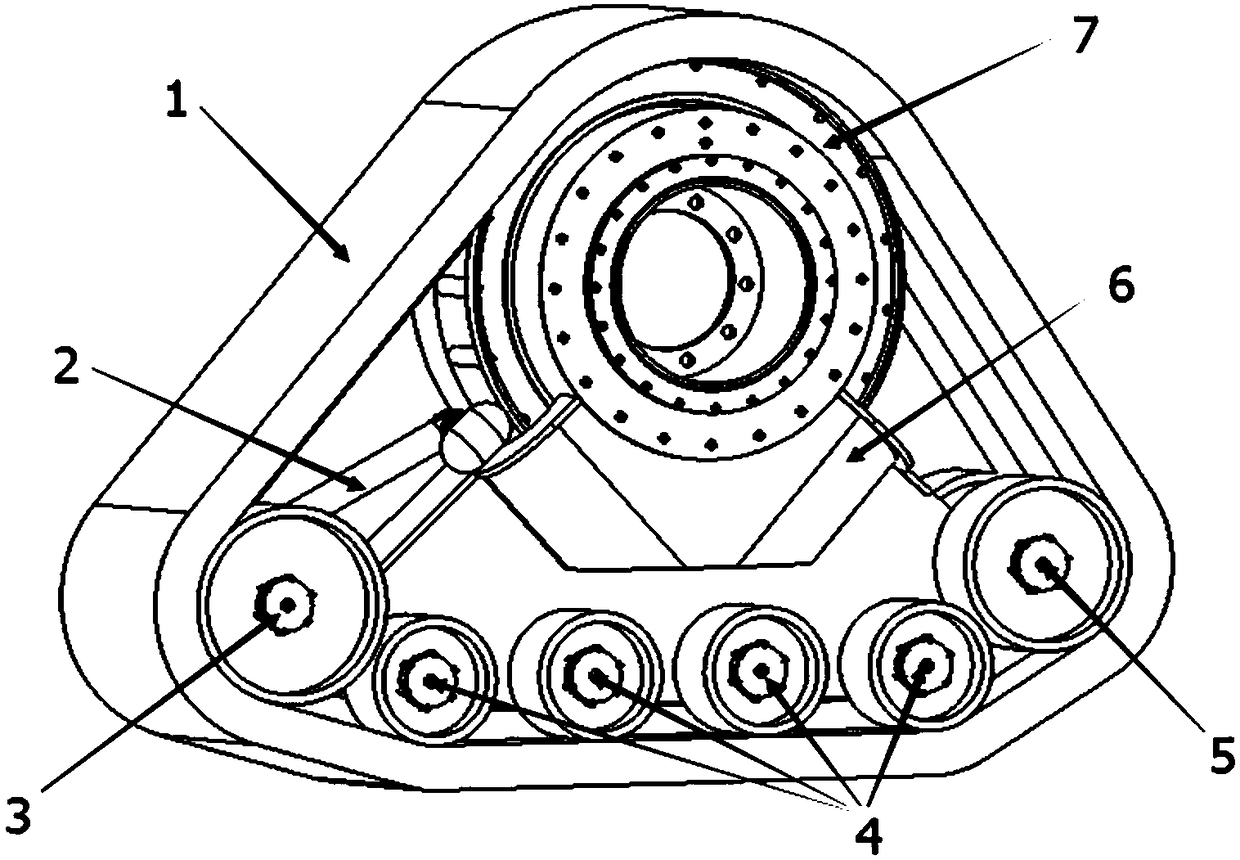

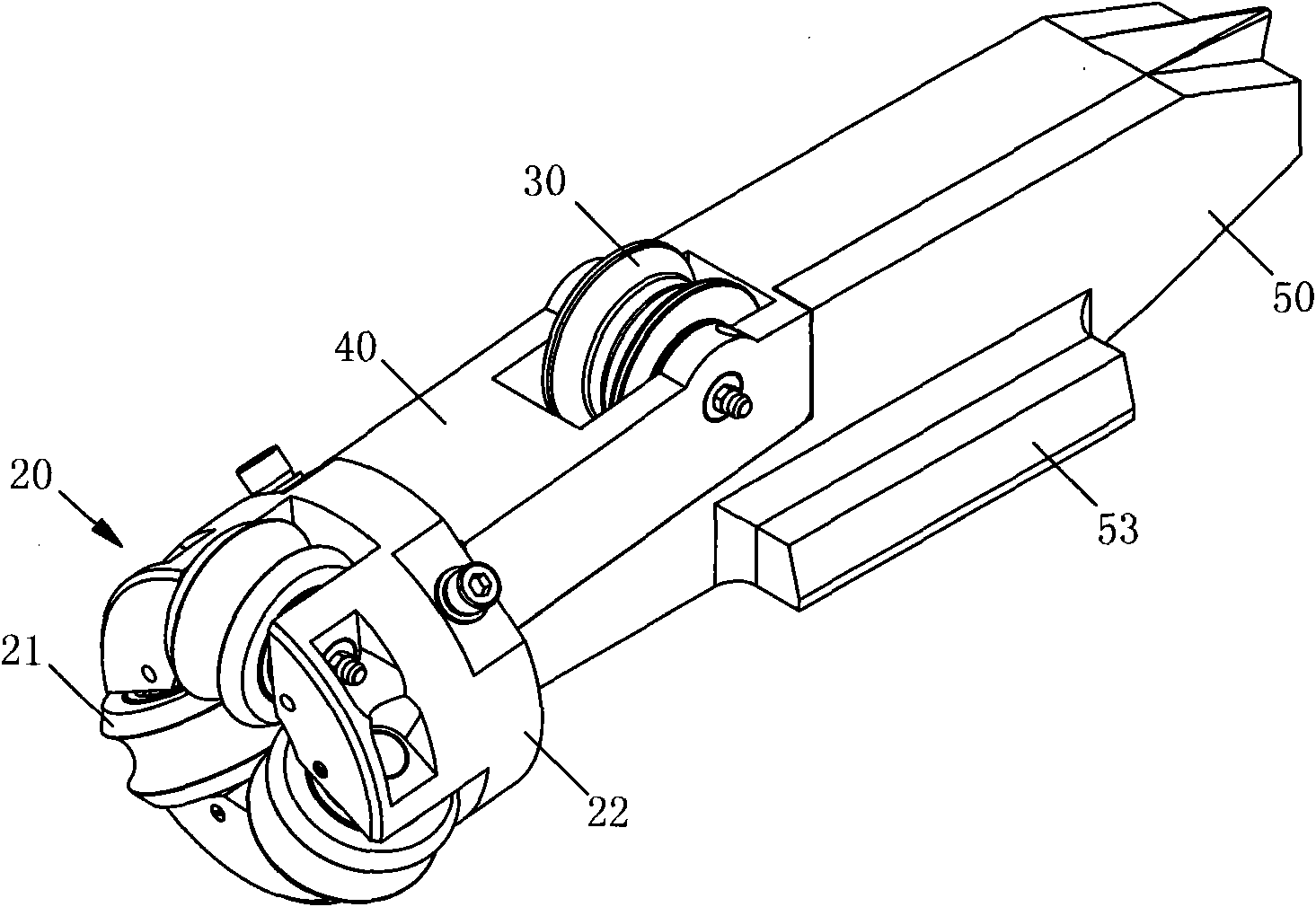

High-speed and heavy-duty replaceable triangular crawler wheel assembly

InactiveCN108340978AWith integrated tracksReduce labor intensityEndless track vehiclesDrive wheelForming gas

The invention discloses a high-speed and heavy-duty replaceable triangular crawler wheel assembly. The high-speed and heavy-duty replaceable triangular crawler wheel assembly comprises a rubber crawler, a supporting frame, a driving wheel, guiding wheels, tensioning guiding wheels, tensioning devices and load-bearing wheels. The outer ring of the high-speed and heavy-duty replaceable triangular crawler wheel assembly is covered with the rubber crawler. The driving wheel, the guiding wheels, the tensioning guiding wheels, the tensioning devices and the load-bearing wheels are arranged on the supporting frame. The driving wheel is located at the upper portion of the rubber crawler and is connected with a chassis wheel shaft. The guiding wheels and the tensioning guiding wheels are located atthe two ends of the bottom of the rubber crawler, and the load-bearing wheels are arranged on the middle of the rubber crawler. The tensioning devices comprise oil cylinders, energy accumulators andtensioning wheel connecting frames. The oil cylinders are connected with the energy accumulators to form gas-liquid springs. The oil cylinders are connected to oil cylinder seats of the supporting frame, the lower ends of the tensioning wheel connecting frames are connected with the supporting frame to form hinge points, the tensioning guiding wheels are arranged on the middles of the tensioning wheel connecting frames, and the oil cylinders are connected with the upper ends of the tensioning wheel connecting frames. The high-speed and heavy-duty replaceable triangular crawler wheel assembly is simple and reasonable in structure, good in stability, capable of realizing fast replacement and assembling, capable of meeting the requirements of high-speed and heavy-duty, and capable of improving the ability of vehicles to deal with complex geological conditions, such as muddy and soft conditions.

Owner:XUZHOU YANDA TRANSMISSION & CONTROL TECH

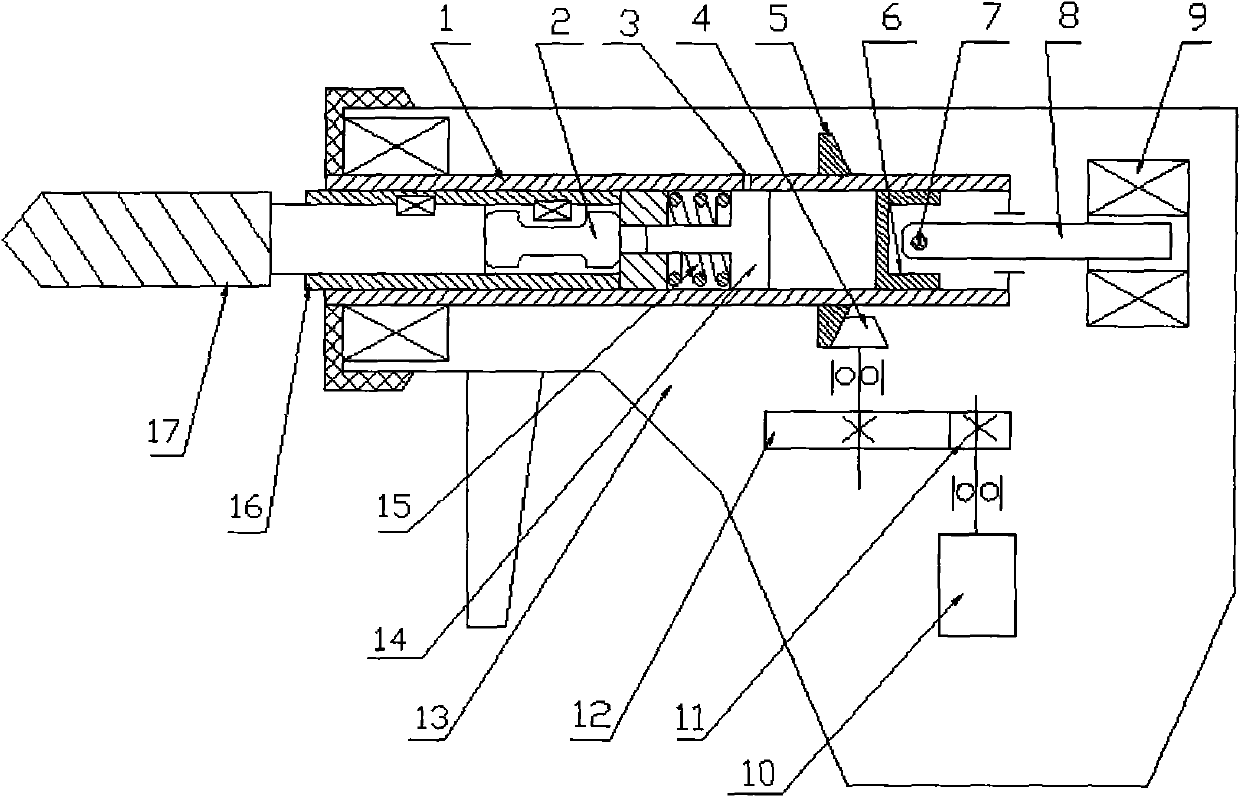

Vibration electric hammer

InactiveCN102019453AThe overall structure is simpleSmall vibrationPortable percussive toolsPortable drilling machinesElectric machineryPiston

The invention provides a vibration electric hammer, wherein a drill sleeve is fixedly mounted at a front end of a cylinder body; an impacting hammer is mounted on a proper position on a rear part of the drill sleeve; a compression spring is mounted the proper position of a drive piston; the drive piston and the compression spring are mounted in the cylinder body at the back of the drill sleeve; an air hole is arranged on an upper surface of an outer circle of the cylinder body; the drive piston can seal the air hole at a free state; large bevel gears are fixedly mounted at the proper position of the cylinder body; the large bevel gears, small bevel gears, large gears, small gears and a motor sequentially form a drive chain relationship; the piston is mounted at the proper position at the back of the cylinder body; a connecting rod iron core is connected with the piston via a pin shaft; and an electromagnet is fixedly mounted in a shell at the proper position at the back of the cylinder body.

Owner:韩圣才

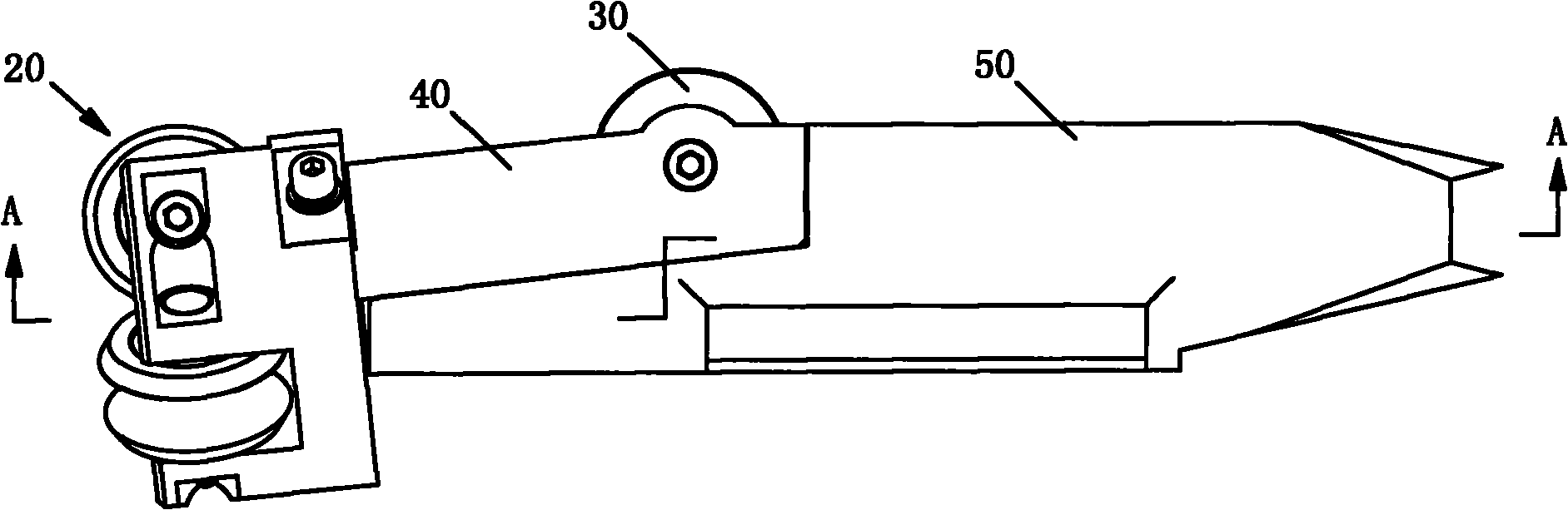

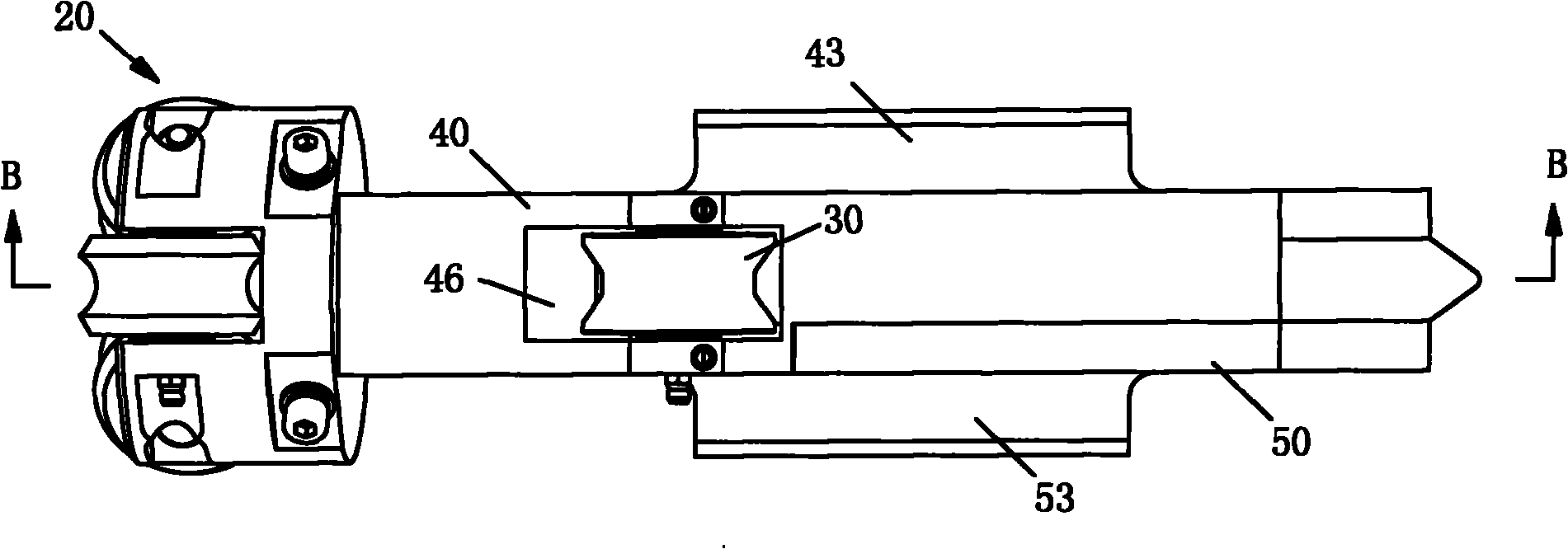

Core fixing type pinch roll guide

InactiveCN101786108AAvoid large vibrationAvoid stacking, etc.Guiding/positioning/aligning arrangementsEngineeringMechanical engineering

The invention relates to a pinch roll guide for guiding rolled pieces into a laying head. A guide groove for the rolled pieces to pass through is arranged in the guide and is communicated with the inlet and the outlet of the guide; a tail guide roll set is arranged at the tail of the guide and comprises a plurality of branched guide rolls; annular grooves are formed along the circumferential directions of the branched guide rolls; the groove surfaces of the annular grooves on each of the branched guide rolls enclose a full circle for the rolled pieces to pass through; the branched guide rolls are fixed on guide roll seats; and the guide roll shafts of the branched guide rolls are rigidly matched with the guide roll seats. The technical scheme shows that the guide roll shafts of the branched guide rolls are rigidly matched with the guide roll seats for fixing the branched guide rolls, thus the closeness of the full circle can be kept all the time, and the elastic change can not occur. The rigid matching can achieve the purpose of forcibly fixing cores of the rolled pieces, has high guide precision, good rigidity and small vibration, avoids impact, surface scratches and scuffing caused by off tracking generated when the rolled pieces enter the full circle, and simultaneously avoids large amplitude vibration of the guide, or distortion and stacking of the rolled pieces and other phenomena.

Owner:HEFEI BAISHENG SCI & TECH

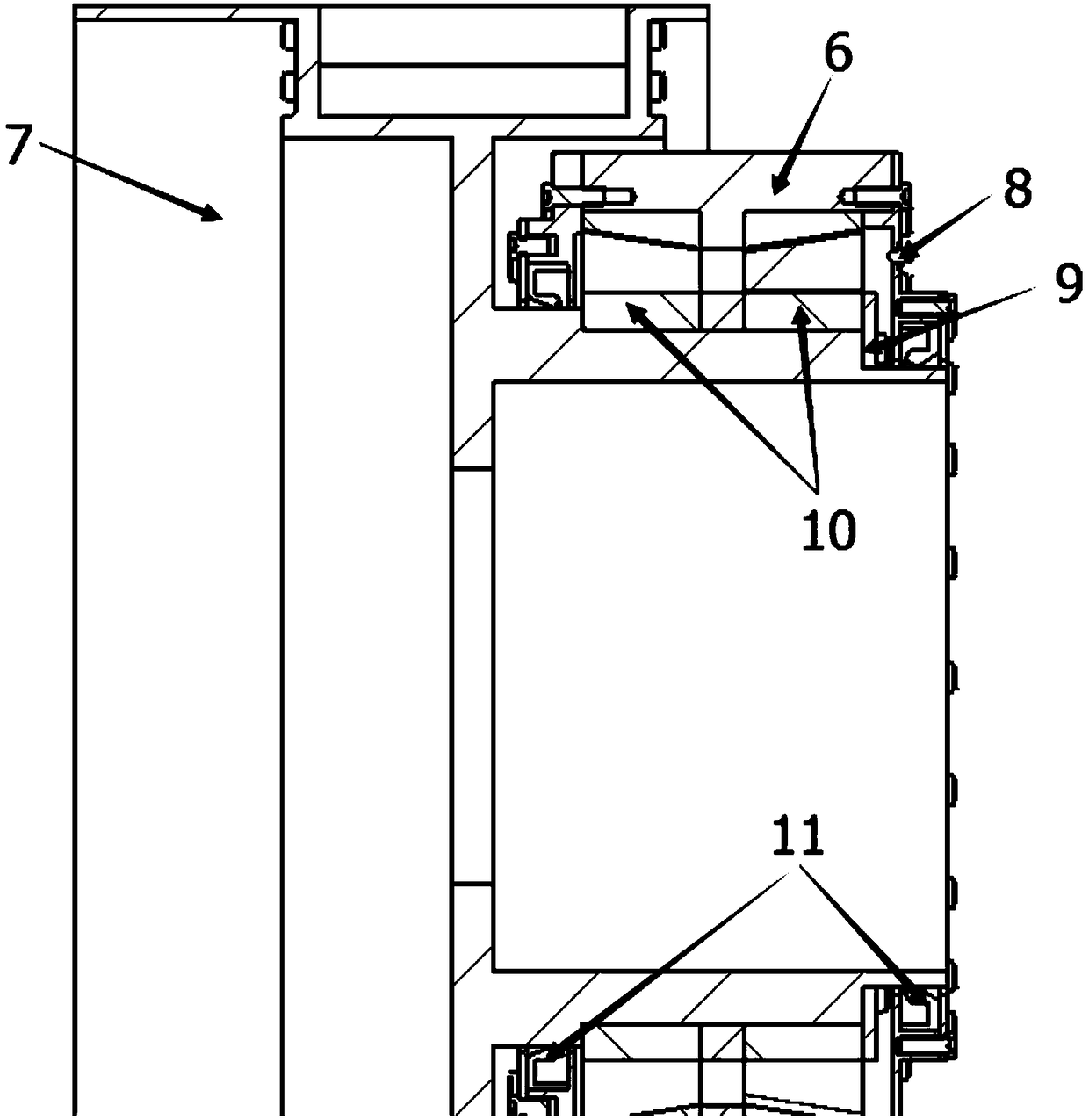

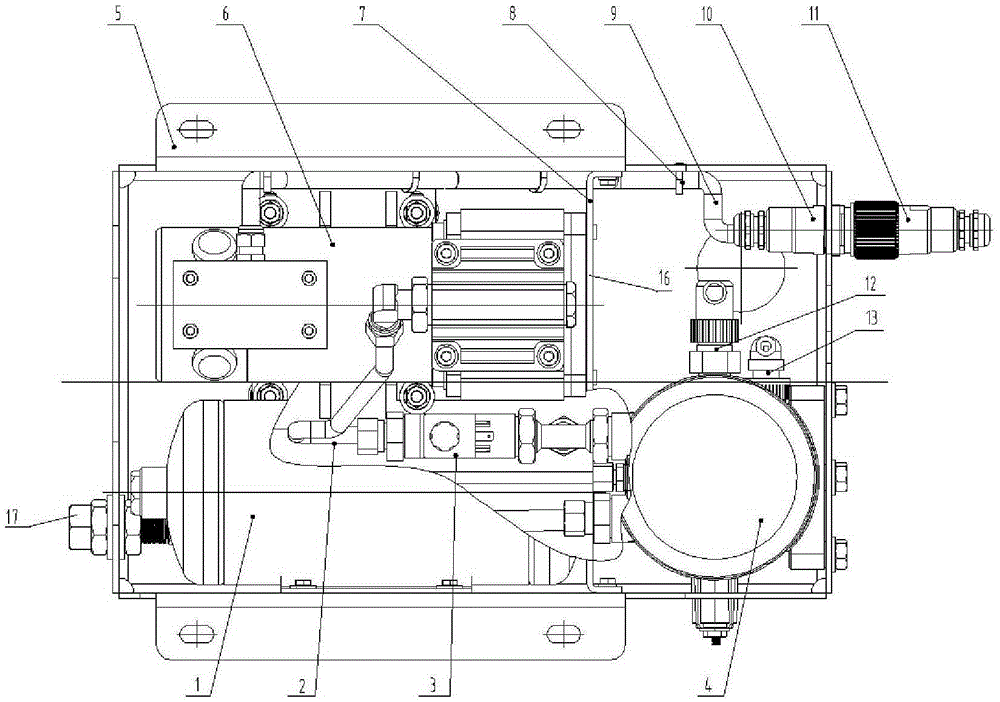

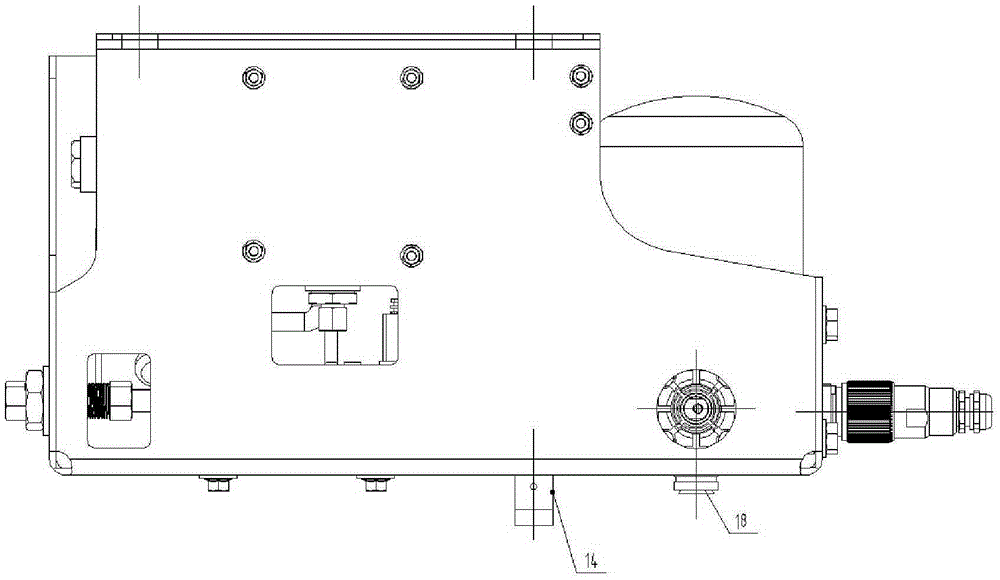

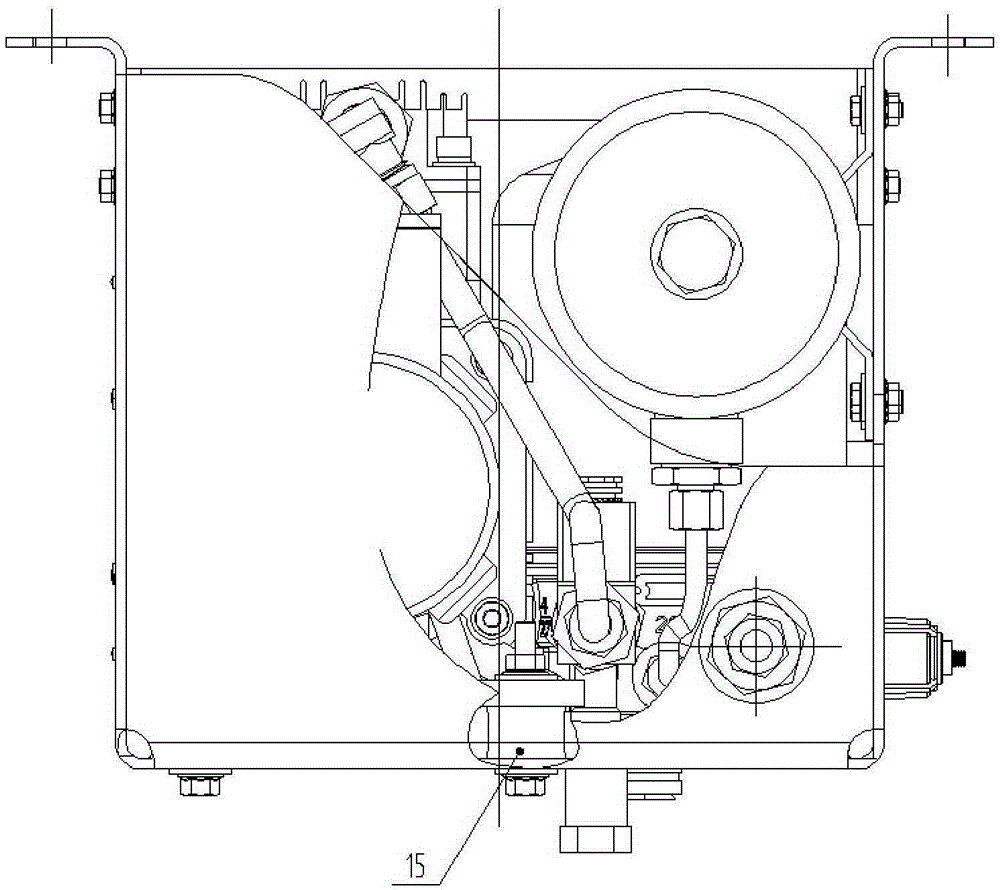

Bow raising air source system of railway vehicle

InactiveCN105329107ABurnout is not easyBurnout phenomenon is not easy to causePower current collectorsGas compressorAir compressor

The invention relates to a bow raising air source system of a railway vehicle. The bow raising air source system of the railway vehicle comprises an installing frame which is provided with an air compressor. One end of the air compressor is connected with a socket through a cable, and the socket is connected with the compressor and supplies power to the air compressor through a plug. The other end of the air compressor is connected with a check electromagnetic valve through an air guiding pipe. The check electromagnetic valve is connected with the air inlet end of a drier and a safety valve through the air guiding pipe. A heater and a pressure switch are installed on the drier. A regenerative opening of the drier is connected with an air storage barrel through the air guiding pipe. The output end of the drier output supplied air through the air guiding pipe. A support is connected with the installing frame. The bow raising air source system of the railway vehicle is compact and reasonable in structure and firm in installation, an assembly is light, the motor burnout phenomenon cannot be caused easily, vibration is small, and the air leakage and electric leakage phenomena cannot be caused easily because vibration is small.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

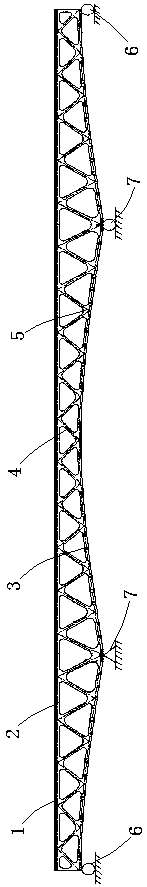

Large-span steel truss combined continuous beam structure and construction method thereof

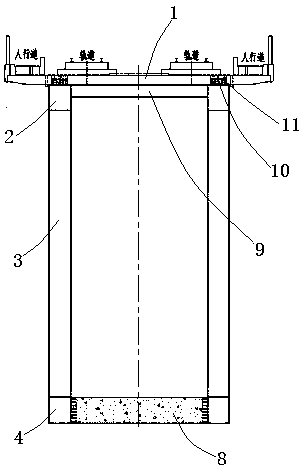

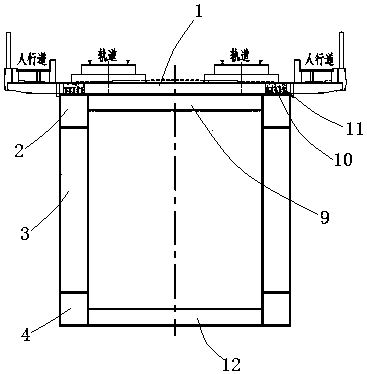

PendingCN110777643AAvoid large vibrationAvoid noiseBridge structural detailsBridge erection/assemblyContinuous beamBridge deck

The invention provides a large-span steel truss combined continuous beam structure. The beam structure comprises a concrete deck slab, two steel trusses, a side span fulcrum and a middle fulcrum; thesteel trusses comprise upper chord members and lower chord members, wherein a plurality of web members are connected between the upper chord members and the lower chord members; the upper chord members are of horizontal straight rod structures, an upper parallel-connection structure is arranged between the two upper chord members, and the concrete deck slab is connected with the upper chord members of the steel trusses; and the lower chord members are in parabolic shapes, a concrete bottom plate is arranged between the two lower chord members in a side span overall length area and a middle span negative bending moment area, and a lower parallel-connection structure is arranged between the two lower chord members in a middle span remaining area. According to the beam structure, a steel truss beam is adopted as main stressed structure, the concrete deck slab is combined with the upper chord members, the concrete bottom plate is arranged in the side span and main span partial areas and combined with the lower chord members, so that the light weight and high strength characteristics of a steel structure are fully exerted, the beam structure can adapt to larger bridge spans, the residual creep down deflection value of the combined beam is extremely small, and the structure total height of the combined beam is smaller than that of other concrete combined structure bridges.

Owner:CREEC WUHAN SURVEY DESIGN & RES

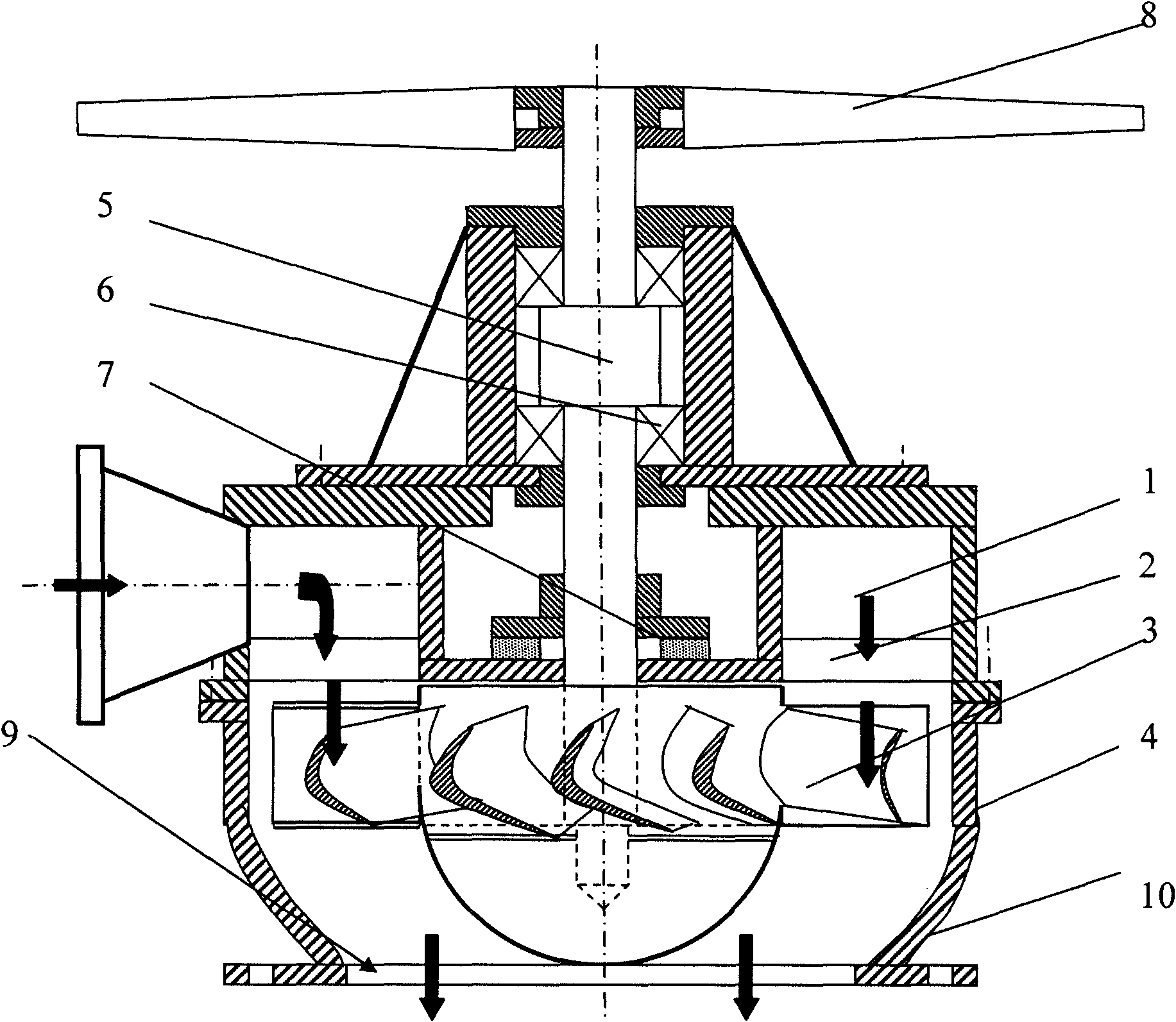

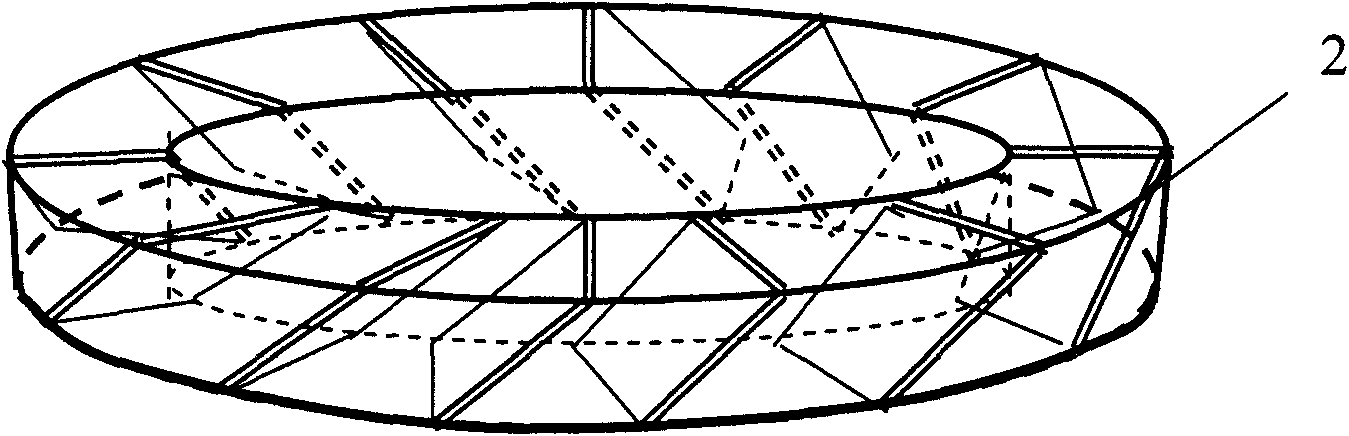

Cylindrical impulse-type hydraulic drive special for fan of cooling tower

ActiveCN101586573AUnique structureNovel working principlePump installationsNon-positive displacement fluid enginesCooling towerWater channel

The invention relates to a cylindrical impulse-type hydraulic drive special for a fan of a cooling tower, which can effectively solve the problems of low conversion efficiency of energy of a hydraulic turbine, large plane dimension and mismatching rotary speed, the technical proposal thereof for solving the problems is that: a water channeling chamber, a water guide chamber, a turbine and a spindle are included, the water guide chamber below the water channeling chamber is inside provided with an annular axial guide vane, water stream directly enters the guide vane through the water channeling chamber and enters, after the direction thereof is changed by the guide vane, a turbine chamber positioned at the lower part thereof in a non-impact importing manner, the turbine chamber is inside provided with an impulse-type turbine, the water stream is discharged out through a water outlet of a draft tube subsequent to the work of the turbine, the water channeling chamber, the water guide chamber and the turbine chamber have the same diameter and are arrayed cylindrically from top to bottom, the upper part of the turbine chamber passes through the water channeling chamber and is provided with a combined bearing by being sealed on the spindle of the turbine, and the spindle of the turbine is directly connected with the shaft of the fan; the invention is unique in structure, high in efficiency, small in size, weak in vibration, better suitable for being mounted on industrial cooling tower and mainly used for taking the place of former fan drive motor, thus achieving the purposes of saving energy, guaranteeing safety and reducing maintenance.

Owner:河南新飞纪元节能科技股份有限公司

Telescopic truss structure for field operation

ActiveCN103181257AAvoid forceAvoid looseningAgricultural undercarriagesPlant genotype modificationEngineeringPulley

The invention discloses a telescopic truss structure for field operation, which comprises a power device, a transmission mechanism and a plurality of trusses sequentially sleeved from outside to inside in a sliding manner. Meanwhile, except for a first stage of truss and a truss on the innermost layer, the outer end of each truss on other layers is provided with an extending pulley and the inner end of the truss is provided with a retracting pulley; an extending steel wire rope is arranged on each extending pulley; both ends of each extending steel wire rope are respectively fixed at the inner ends of two trusses adjacent to the truss with the corresponding extending pulley; each retracting pulley is provided with a retracting steel wire rope; and both ends of each retracting steel wire rope are respectively fixed at the outer ends of two trusses adjacent to the truss with the corresponding retracting pulley. The telescopic truss structure adopts the telescopic structure, so as to effectively improve a spraying range of spraying operation for each time, can also stably and reliably bear required field operation tools, and has high operating efficiency.

Owner:SOUTH CHINA AGRI UNIV

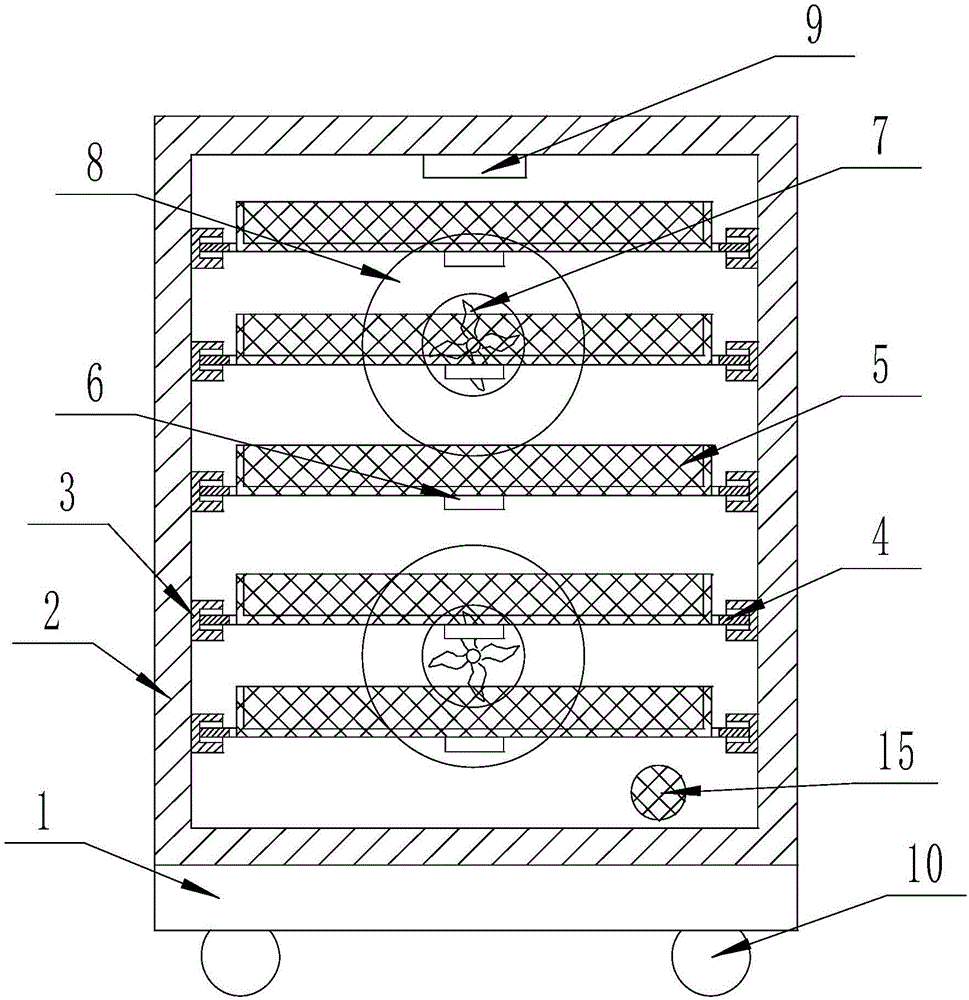

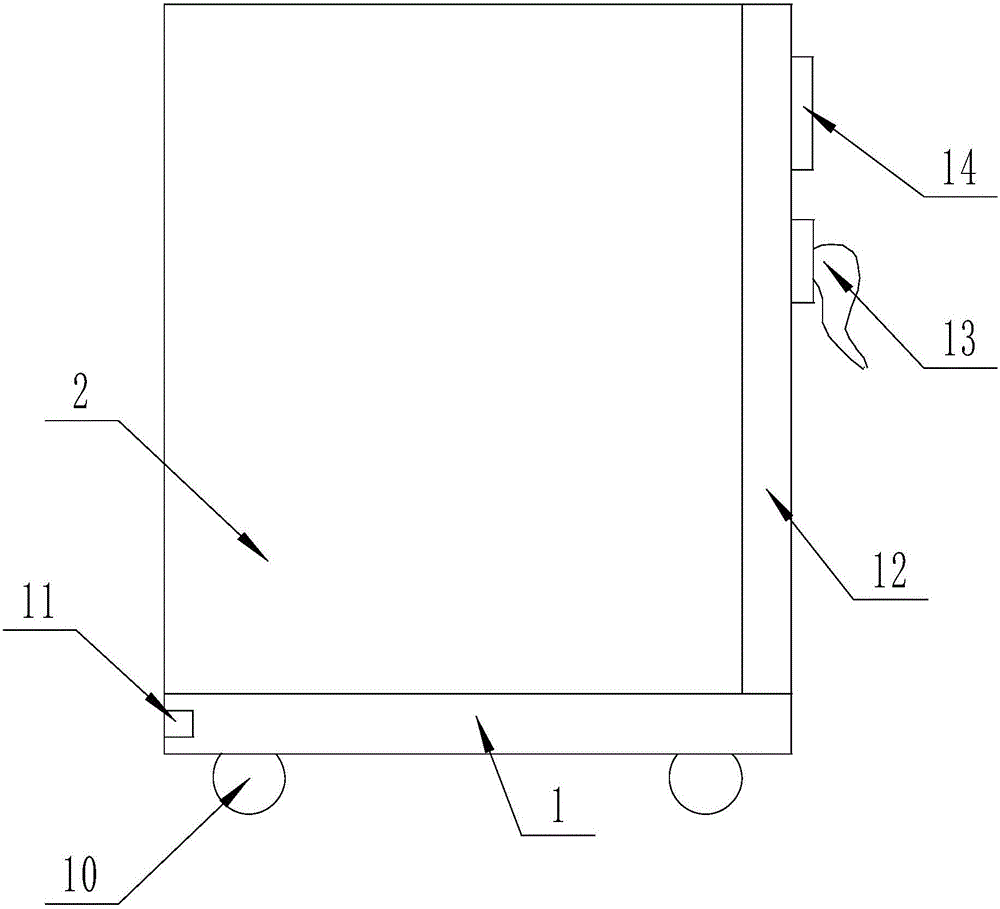

Edible mushroom drying device

The invention discloses an edible mushroom drying device which comprises a base. A rectangular box is arranged on the upper surface of the base, multiple pairs of uniformly-distributed sliding grooves are formed in the surface on the inner side of the rectangular box, a placement plate is arranged in each pair of the uniformly-distributed sliding grooves, a number one rectangular opening is formed in the upper surface of each placement plate, a screen groove is embedded in each number one rectangular opening, a vibration block is arranged on the lower surface of each screen groove, a pair of electric heating fans are arranged at the center of the rear surface of the rectangular box, an air expanding port is arranged on the front surface of each electric heating fan, and a temperature-humidity sensor is arranged at the center of the upper surface of the rectangular box. The edible mushroom drying device has the advantages that edible mushrooms can be slightly vibrated during drying to increase heated area so as to be dried comprehensively, drying efficiency can be improved, and temperature and humidity in the device can be monitored.

Owner:湖南永爱生物科技有限公司

PVC (Polyvinyl Chloride) profile laminator

ActiveCN103407272APlay a role in compressionCause damageLamination ancillary operationsLaminationPolyvinyl chlorideEngineering

The invention discloses a PVC (Polyvinyl Chloride) profile laminator comprising a rack, two groups of compression roller assemblies, an adjustable pressing mechanism, a fixed pressing mechanism and a film reel roller, wherein the film reel roller is fixed on the rack; the adjustable pressing mechanism and the fixed pressing mechanism are respectively arranged at two ends of the rack; the adjustable pressing mechanism is connected with one group of compression roller assembly; and the fixed pressing mechanism is connected with the other group of compression roller assembly. By using the PVC profile laminator disclosed by the invention, the upper surface and the lower surface can be simultaneously laminated; the laminating pressures on the surfaces of different profiles can be met through adjusting the pressure of the adjustable pressing mechanism; the fixed pressing mechanism is pressed by using a spring connecting rod so that little vibration is caused, and the laminating process is kept stable; and the film reel roller is made of elastic rubber, is in flexible contact with a protective film, can be used for playing a role in pressing the protective film and cannot damage the surfaces of the profiles. The PVC profile laminator is also provided with a cleaning brush for cleaning and pressing again, so that the laminating quality is improved. The laminator is firm and durable, little in vibration, low in fault rate and long in service life.

Owner:长春联塑实业有限公司

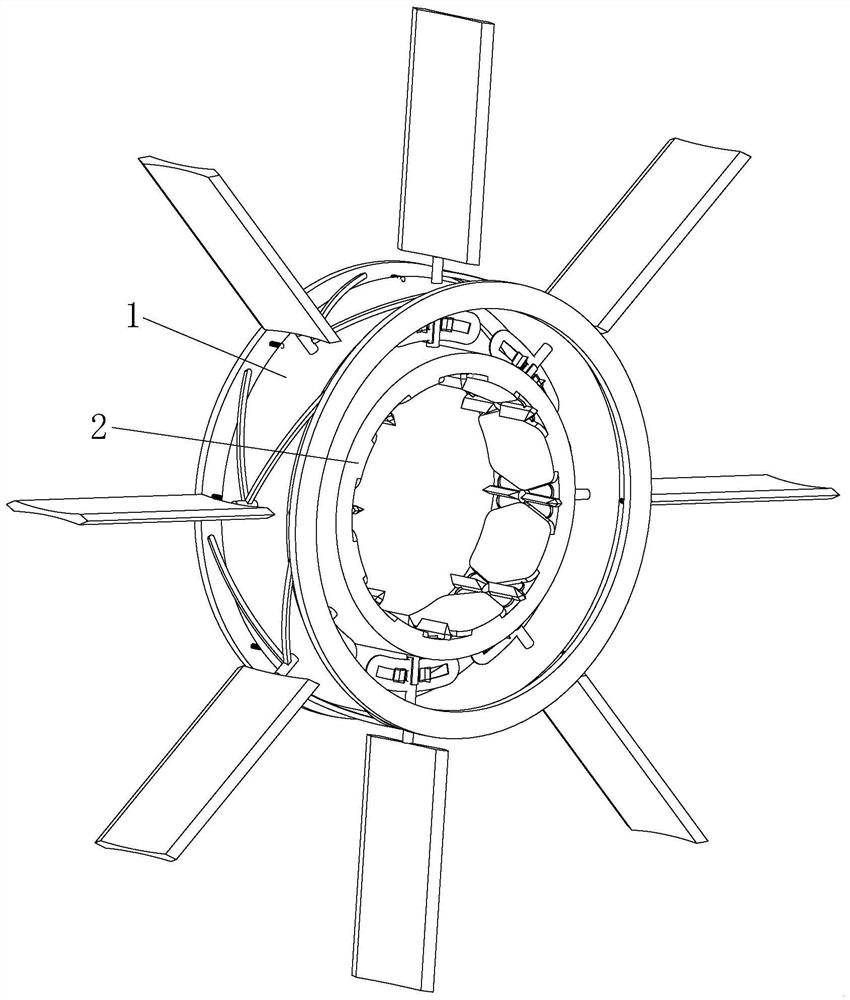

Cable deicing device

ActiveCN113078602AEffective dropTo achieve the purpose of deicingOverhead installationWind energy generationEngineeringStructural engineering

The invention relates to the technical field of electric power, and discloses a cable deicing device, which comprises a rotating sleeve, wherein a deicing mechanism used for deicing is arranged in the rotating sleeve, a rotating mechanism used for rotating is arranged on the rotating sleeve, the deicing mechanism comprises a deicing sleeve, fixing sleeves, a scraper and an elastic piece, the deicing sleeve is sleeved in the rotating sleeve, the rotating sleeve and the deicing sleeve are coaxially arranged, the fixing sleeves are fixedly installed on the outer wall of the deicing sleeve, transverse grooves are formed in the side walls of the fixing sleeves, the fixing sleeves are evenly distributed on the outer wall of the deicing sleeve, and the transverse grooves penetrate through the two sides of the fixing sleeves. According to the invention, the purpose of deicing is achieved through the deicing mechanism so as to effectively fall off a just-formed ice layer, then the deicing device rotates in a reciprocating mode through the rotating mechanism so as to achieve the purpose of deicing back and forth, and the blades are effectively prevented from being frozen.

Owner:BEIJING BICHENGDA CABLE ACCESSORIES

Method for restricting rotation of rotary machinery rotor

InactiveCN105508498AAvoid large vibrationSolve the vibration suppressionRotating vibration suppressionRolling contact bearingsElastomerVibration amplitude

The invention discloses a method for restricting rotation of a rotary machinery rotor. The method comprises the following steps: firstly determining the maximum rotation position of a rotor in a small rotary machinery rotor system; subsequently fixing a magneto-rheological elastomer dynamic vibration absorber on the rotor system so as to perform the operation for restricting the vibration, wherein the magneto-rheological elastomer dynamic vibration absorber is used according to the following steps: fixing the magneto-rheological elastomer dynamic vibration absorber at the maximum rotation position of the rotor, and starting the system of the magneto-rheological elastomer dynamic vibration absorber to reduce vibration amplitude of the rotor and restrict the vibration, wherein the value of rigidity ka of the magneto-rheological elastomer dynamic vibration absorber is regulated by specifically utilizing the characteristic that the rigidity of a magneto-rheological elastomer is controllable, so that the inherent frequency is nearly equal to the vibration frequency of the rotary machinery rotor system. According to the method disclosed by the invention, the equipment is good in controllability and low in fault rate; the system is good in operation stability; the method can be used for restricting the vibration of the rotary machinery rotor system.

Owner:NORTHEASTERN UNIV

Sole soil cleaning device

ActiveCN113133736AImprove scraping effectSpeed up the fallFootwear cleanersStructural engineeringMechanical engineering

The invention relates to the technical field of cleaning, and discloses a shoe sole soil cleaning device which comprises a cleaning box, a drawer and a partition plate, the drawer is slidably installed on one side of the cleaning box, the partition plate is fixedly installed in the cleaning box, two sets of cleaning mechanisms and two sets of shaking mechanisms are arranged in the cleaning box, the two sets of cleaning mechanisms and the two sets of shaking mechanisms are located on the two sides of the partition plate correspondingly, each cleaning mechanism comprises a sinking frame, a rubber pull rope, a longitudinal extrusion rod, a supporting plate, an auxiliary air bag, a transverse extrusion rod, a collision block, an extension spring, a collision ball, a connecting rod, a swing spring, a transverse plate, a rotating ball, an auxiliary rod and a memory metal plate, and the sinking frames are located in the cleaning box, the rubber pull rope is fixedly installed in the sinking frame. According to the shoe sole cleaning device, the memory metal plate and the arc-shaped metal plate are used for cleaning shoe sole soil, and meanwhile a better cleaning effect is achieved.

Owner:惠州市雅致鞋业有限公司

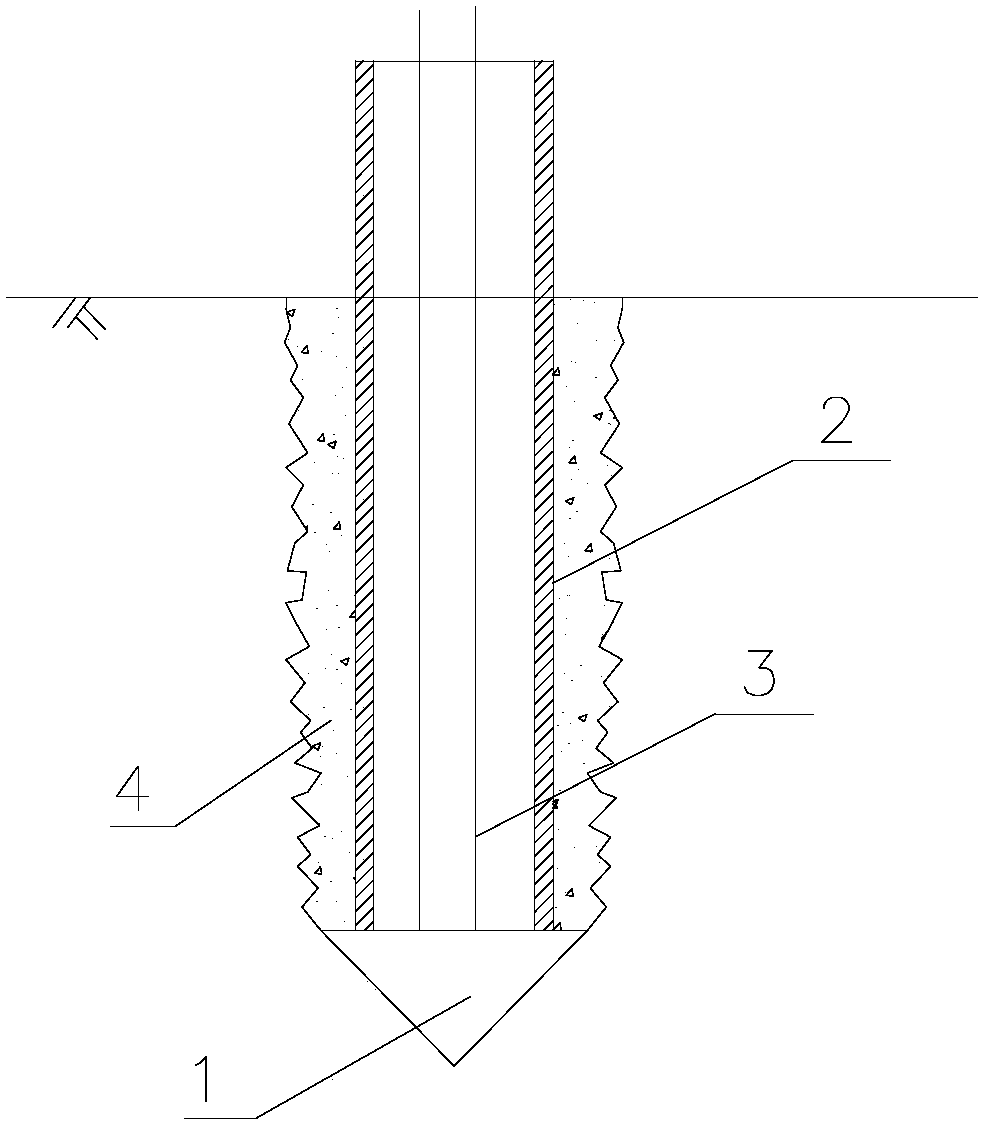

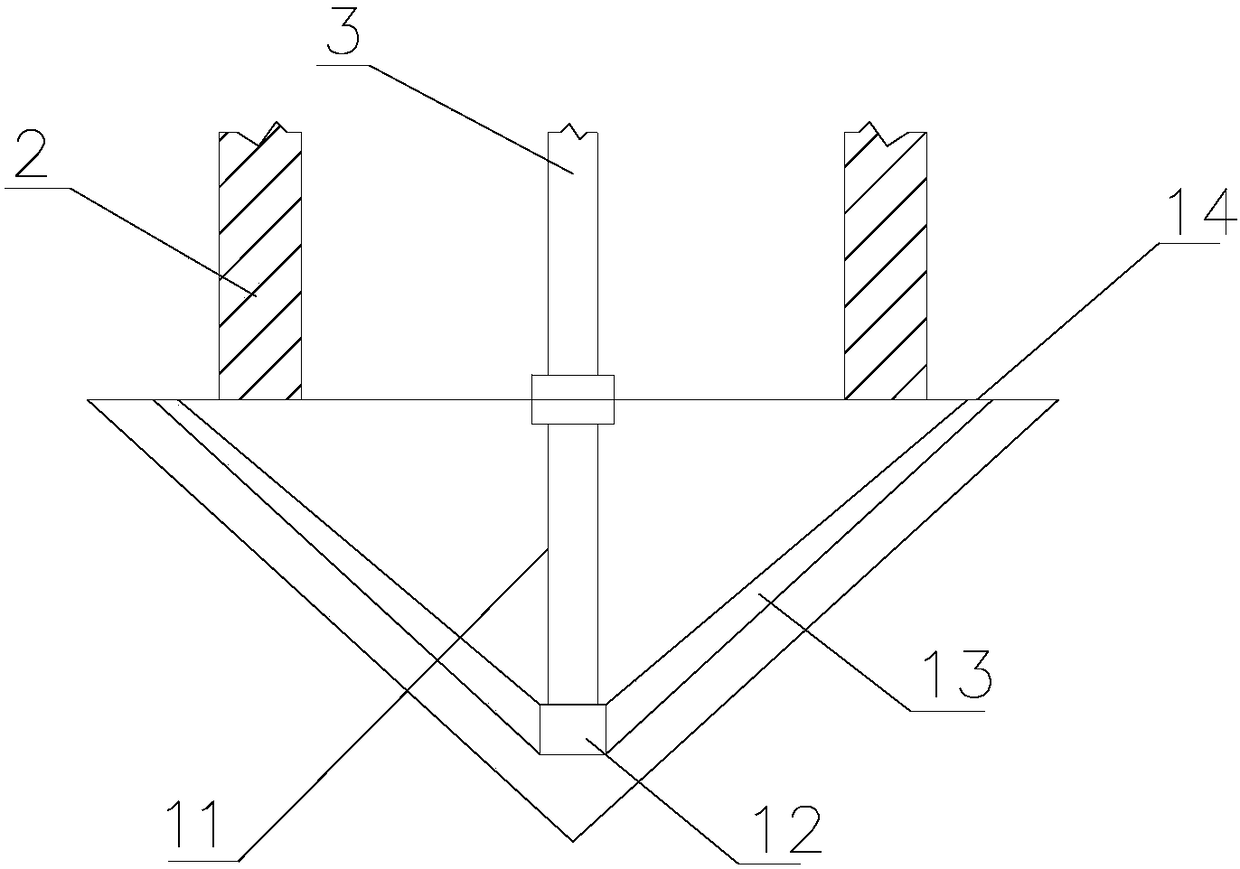

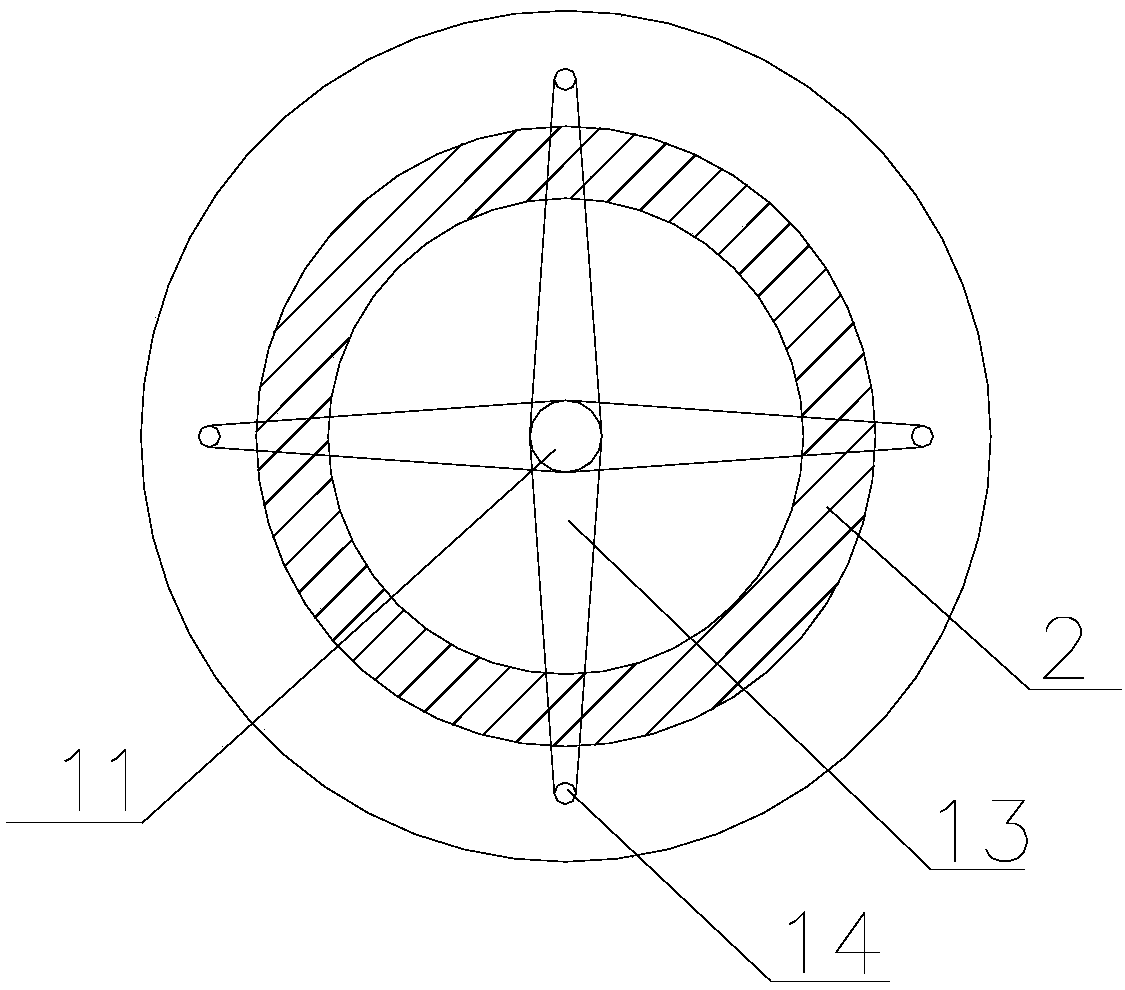

Synchronous-grouting pre-stressed pipe pile and construction method thereof

PendingCN108179743AReduced bearing capacity requirementsReduce the difficulty of pile pressingBulkheads/pilesPre stressPre stressing

The invention relates to a synchronous-grouting pre-stressed pipe pile. The synchronous-grouting pre-stressed pipe pile comprises a special pile shoe device, a prefabricated pipe pile, a grouting pipedevice and a grouting layer; the special pile shoe device comprises a main grouting pipe, branch pipe joints, branch pipes and grout discharging holes; the upper end of the main grouting pipe is connected with the grouting pipe device; the lower end of the main grouting pipe is connected with the branch pipes via the branch pipe joints; each branch pipe is connected with the corresponding grout discharging hole; the grout discharging holes are uniformly distributed at an equal interval in the outer side of a pipe pile juncture at the edge of a pile shoe; the grouting pipe device is arranged inside a cavity of the prefabricated pipe pile; and the grouting pipe device comprises a four-claw hook, an upper end interface, a grouting pipeline and a lower end interface. The synchronous-groutingpre-stressed pipe pile provided by the invention has the beneficial effects that the synchronous-grouting pre-stressed pipe pile is a novel pile foundation which is formed by adopting a pile jacking-in method and is additionally provided with a special pile shoe based on an original pre-stressed pipe pile; by synchronous grouting, the sidewall of the pipe pile can be lubricated by grouting liquid,so the difficulty of pile pressing is reduced, and the requirements on the bearing capacity of a place and the requirements on pile pressing equipment are reduced.

Owner:ZHEJIANG UNIV CITY COLLEGE

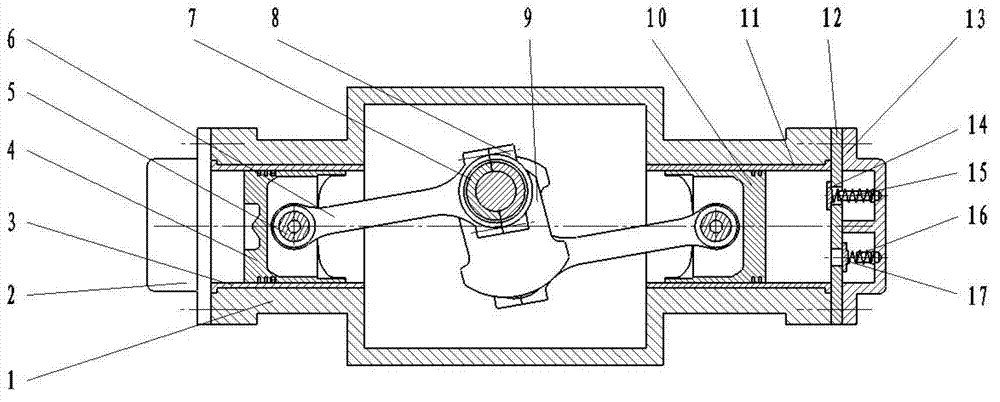

Dynamic balance type internal combustion air compressor

InactiveCN102966511ASolve the vibrationSolve the noisePiston pumpsPositive-displacement liquid enginesAir compressionExhaust valve

The invention belongs to the technical field of compressor equipment, and relates to a dynamic balance type internal combustion air compressor, wherein a power cylinder cover component and a machine body are fixedly connected; the sealing of a power piston and a power cylinder sleeve is realized through a piston ring; the power piston component and a connecting rod body are connected by a piston pin, and further constitute a revolution pair; the connecting rod bodies and a spheroidal graphite cast iron crank shaft of bearing bushes installed in the interiors of connecting rod heads constitute the revolution pairs; the connecting rod bodies and the connecting rod heads are connected into a whole body; an air compression cylinder cover component, a steel valve plate and the machine body are connected into an integral structure; an air compression cylinder sleeve and the machine body are connected; the sealing of an air compression piston component and the air compression cylinder sleeve is realized through the other piston ring; the air compression piston component and the other connecting rod body are connected by the other piston pin, and further constitute the revolution pair; and a suction valve block reset spring and an exhaust valve block reset spring are guided through the utilization of a guide shaft. In addition, the dynamic balance type internal combustion air compressor is reliable in principle, simple in structure, low in preparation cost, high energy conversion efficiency, friendly to the environment, strong in balance function and wide in application.

Owner:QINGDAO UNIV

Striking-off device for two sides of ditch for water conservation

InactiveCN108729415AAvoid large vibrationWill not affect the effect of scrapingArtificial water canalsFoundation engineeringElectric machineryEngineering

The invention relates to a striking-off device, in particular to a striking-off device for the two sides of a ditch for water conservation. According to the striking-off device for the two sides of the ditch for water conservation, the force intensity is uniform when cement on the two side faces of the ditch is struck off, and the striking-off speed is high. The striking-off device for the two sides of the ditch for water conservation comprises a bottom plate, wheels, vertical rods, a holding rod, first sliding rails, first sliding blocks, a frame body and the like. The wheels are mounted at the four corners of the bottom of the bottom plate correspondingly. The vertical rods are mounted on the left side and the right side of the top of the bottom plate correspondingly. The holding rod ismounted at the top ends of the vertical rods. The first sliding rails are mounted on the left side and the right side of the bottom of the bottom plate correspondingly. According to the striking-off device for the two sides of the ditch for water conservation, the frame body is driven by a first motor to move forwards and backwards continuously, and thus the frame body can drive a roller to strikeoff the cement on the two side faces in the ditch; and a beating hammer is driven by a second motor to beat the frame body, thus the cement can be more compact, and accordingly, the effects that theforce intensity is uniform when the cement on the two side faces of the ditch is struck off, and the striking-off speed is high are achieved.

Owner:李风花

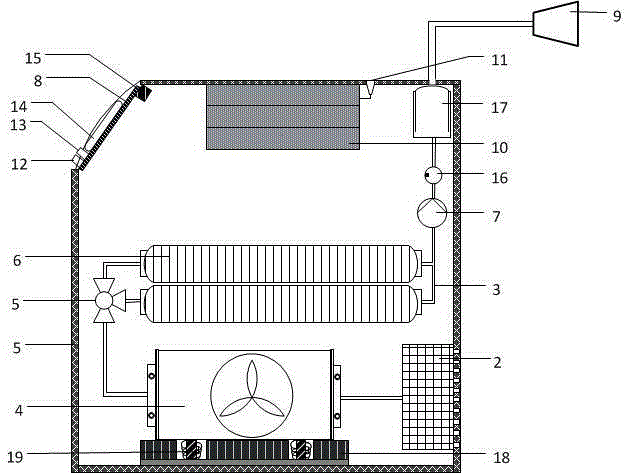

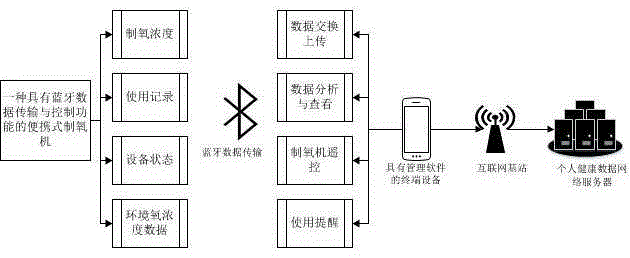

Portable oxygen generator with Bluetooth data transmission and control functions

InactiveCN105288806AReduce weightSmall sizeRespiratorsWireless commuication servicesData transmissionControl function

The invention discloses a portable oxygen generator with the Bluetooth data transmission and control functions and relates to the field of medical health care instruments. The portable oxygen generator with the Bluetooth data transmission and control functions aims at achieving the portable, intelligent and data networking functions of the oxygen generator. The portable oxygen generator is mainly and technically characterized in that sound insulating and noise lowering materials, an output oxygen concentration detection sensor and a built-in rechargeable lithium battery are additionally arranged in a machine case, a Bluetooth chip control circuit board is designed so that wireless data transmission can be achieved, a user reads and analyzes oxygen generation data through a terminal device provided with management software and controls the on-off state and gas flow adjustment of the oxygen generator, data are stored in an Internet server, and intelligent analysis and management of personal health data are achieved.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

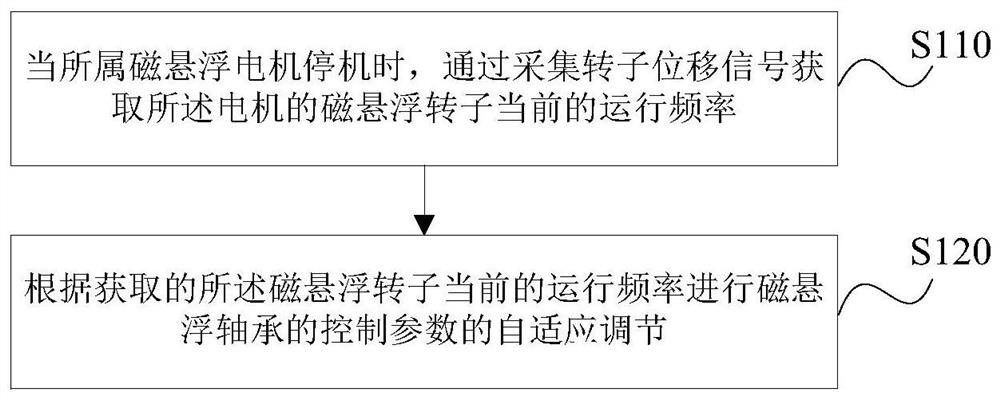

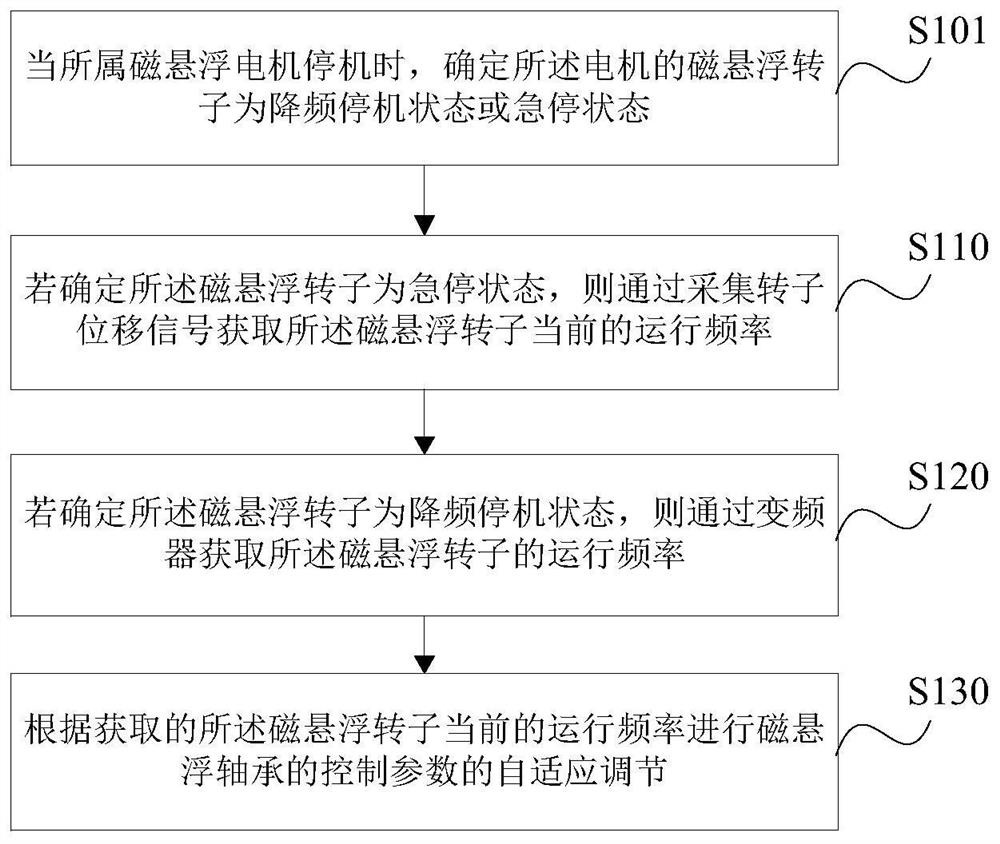

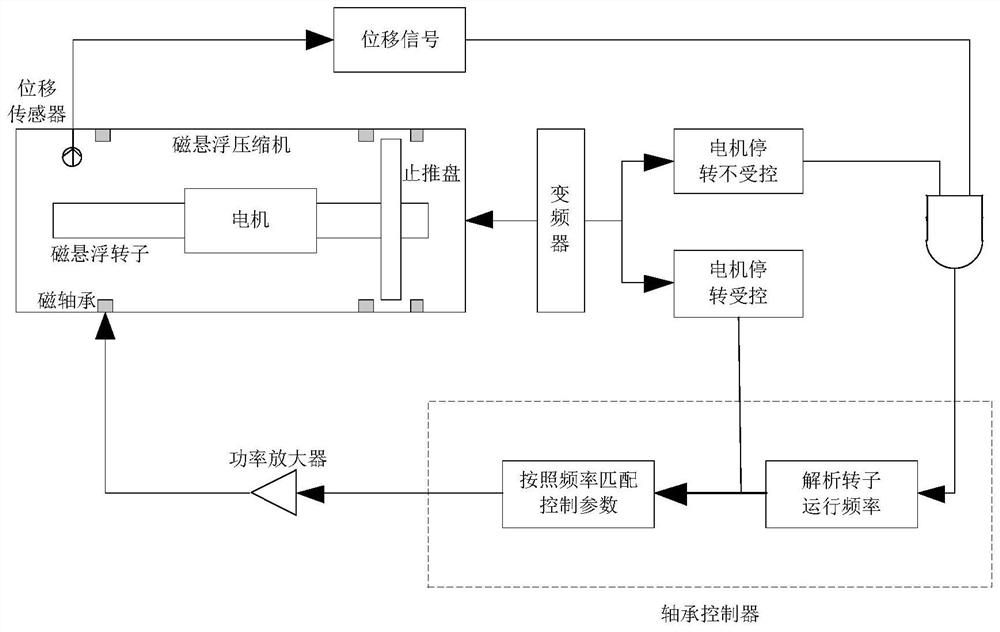

Magnetic suspension bearing control parameter adjusting method and device, storage medium and controller

ActiveCN111654209AGuaranteed uptimeAvoid large vibrationMagnetic holding devicesBearingsElectric machinerySelf adaptive

The invention provides a magnetic suspension bearing control parameter adjusting method and device, a storage medium and a controller, and the method comprises the steps: obtaining the current operation frequency of a magnetic suspension rotor of a motor by collecting a rotor displacement signal when the magnetic suspension motor stops; and according to the obtained current operation frequency ofthe magnetic suspension rotor, performing self-adaptive adjustment of control parameters of the magnetic suspension bearing. According to the scheme provided by the invention, the operation stabilityand reliability of the magnetic suspension rotor can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

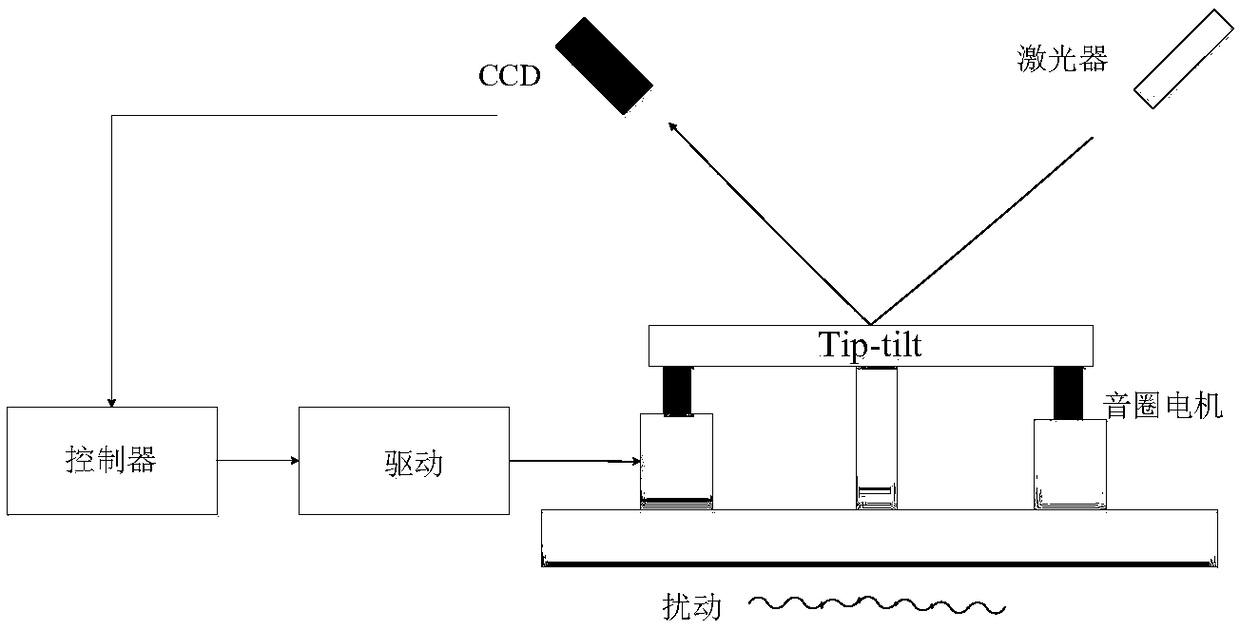

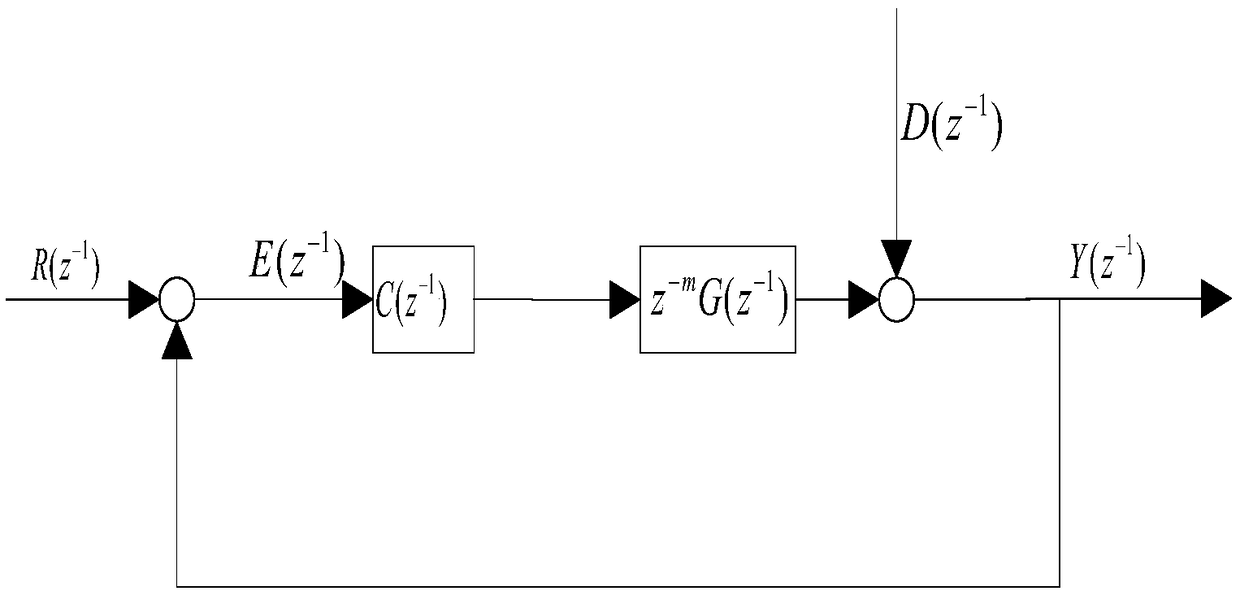

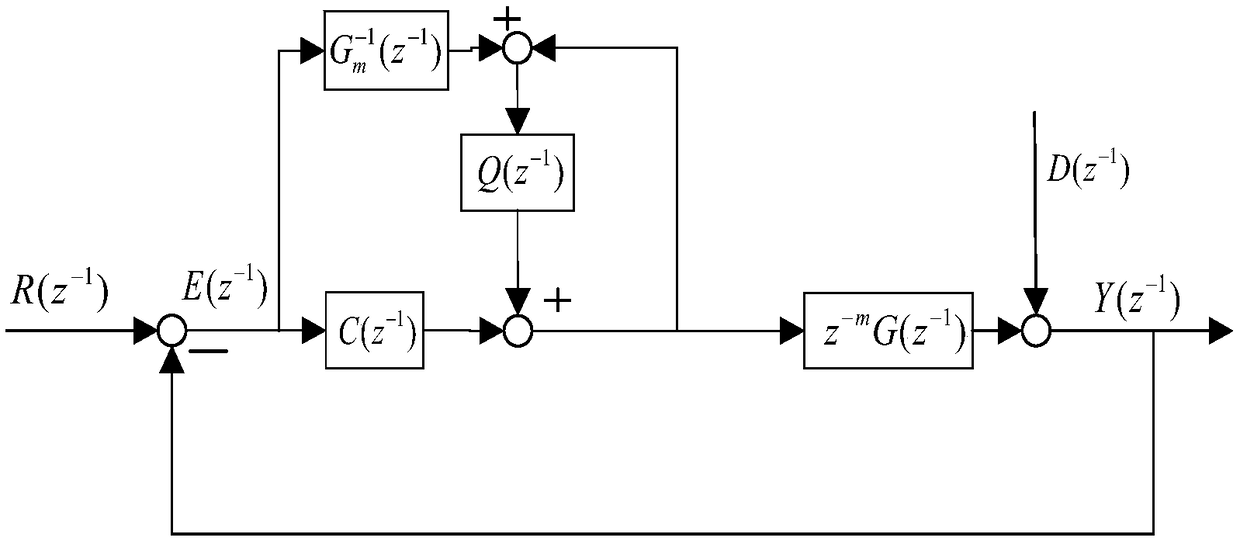

Tilting mirror vibration suppression method based on improved disturbance observer

ActiveCN108646568ALow costOptimizing the Sensitivity FunctionAdaptive controlControl systemClosed loop

The invention discloses a tilting mirror vibration suppression method based on an improved disturbance observer. Since mechanical vibrations of an astronomical telescope make the closed-loop performance of a telescope control system decline and these vibrations cannot be well remedied by a classical control structure, the method adopts a tilting mirror to suppress the vibrations. According to themethod, by designing an improved Q filter., a sensitivity function of a tilting mirror control system is optimized, the large-amplitude vibrations are effectively suppressed, and the influence of a water bed effect on the system performance is reduced. Under the case that the system disturbance frequency is known, the control method can achieve optimal correction, and the disturbance suppression capability of the system is effectively improved. According to the method, the system is optimized from a control algorithm, only one image sensor is needed, and the cost is saved. At the same time, the method is clear, the structure is simple, there is no dependence on models, and the method is easy to operate and implement.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

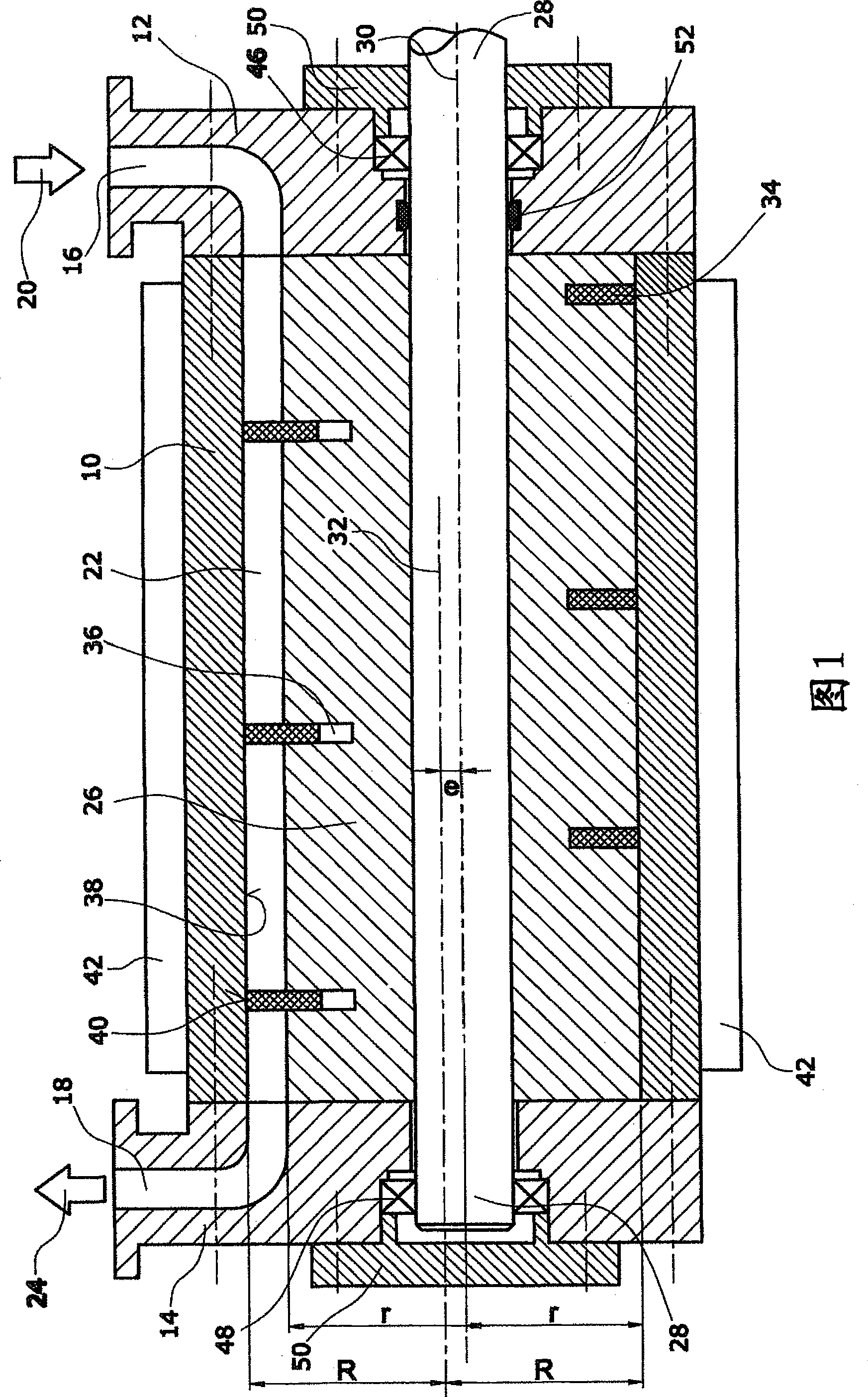

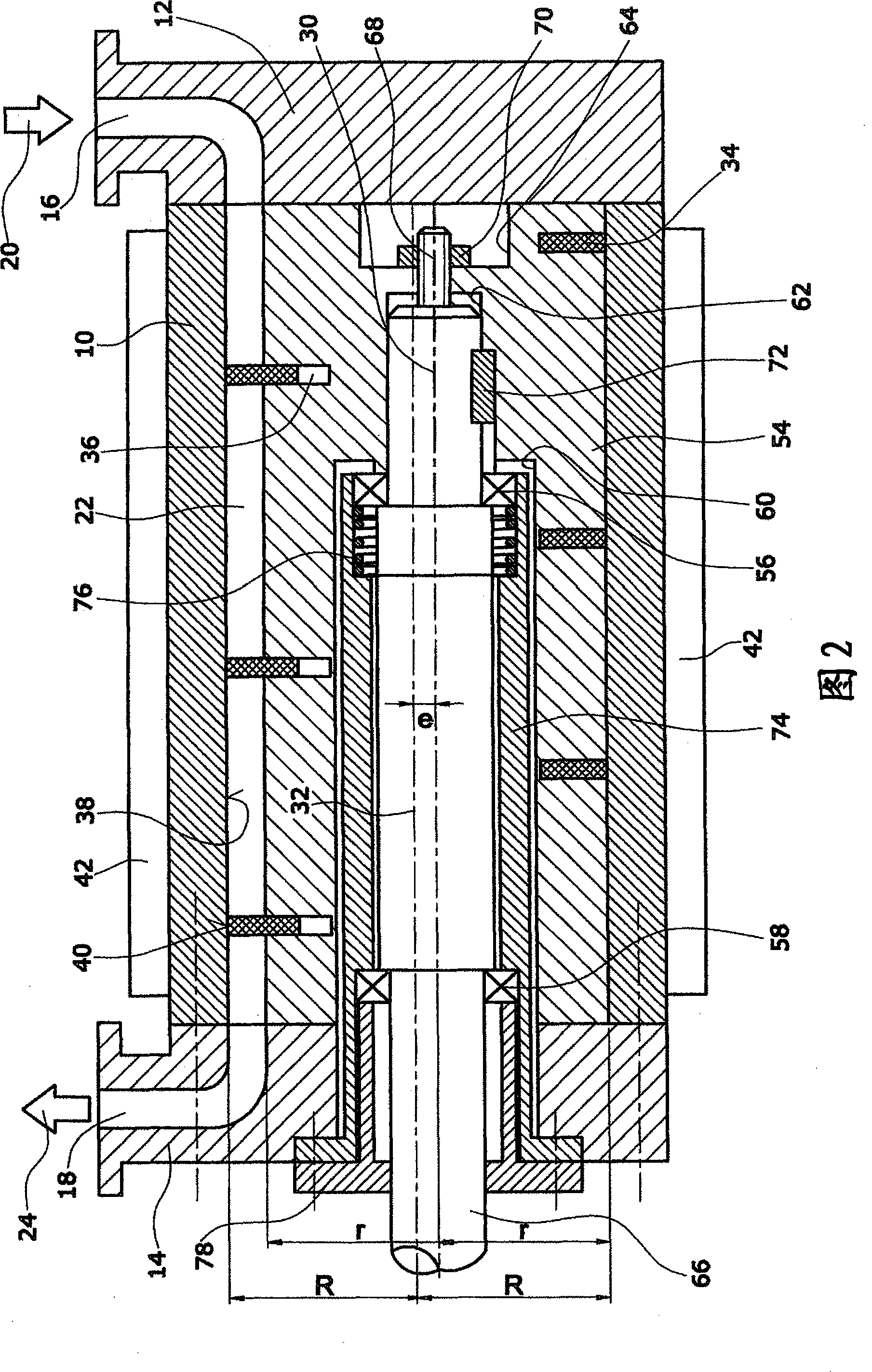

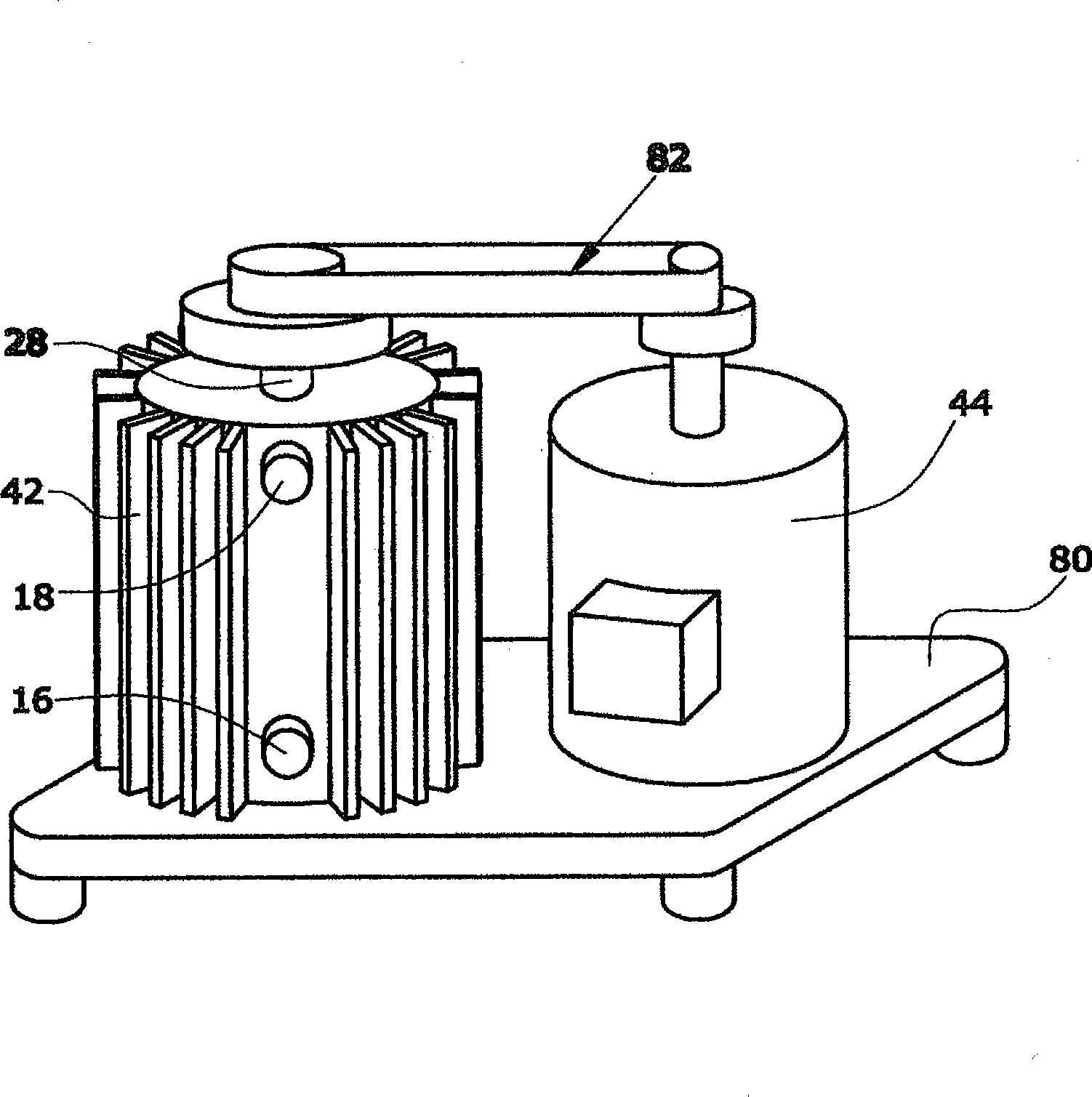

Vacuum pump

InactiveCN101371044AImprove suction performanceCheap constructionRotary piston pumpsRotary piston liquid enginesInterior spaceEngineering

A vacuum pump for producing a vacuum in a space which is to be evacuated has a housing (10) having a cylindrical inner space (22). An expeller (26) is arranged eccentrically in the inner space (22). A helical sealing element (34) is provided between the expeller (26) and an inner wall (38) of the housing (10) for forming at least one crescent-shaped conveying space. The housing (10) or the expeller (26) are connected to a drive device (44) for producing a relative rotary movement between the housing (10) and the expeller (26). According to the invention, the vacuum pump is configured as a dry-running vacuum pump.

Owner:OERLIKON LEYBOLD VACUUM

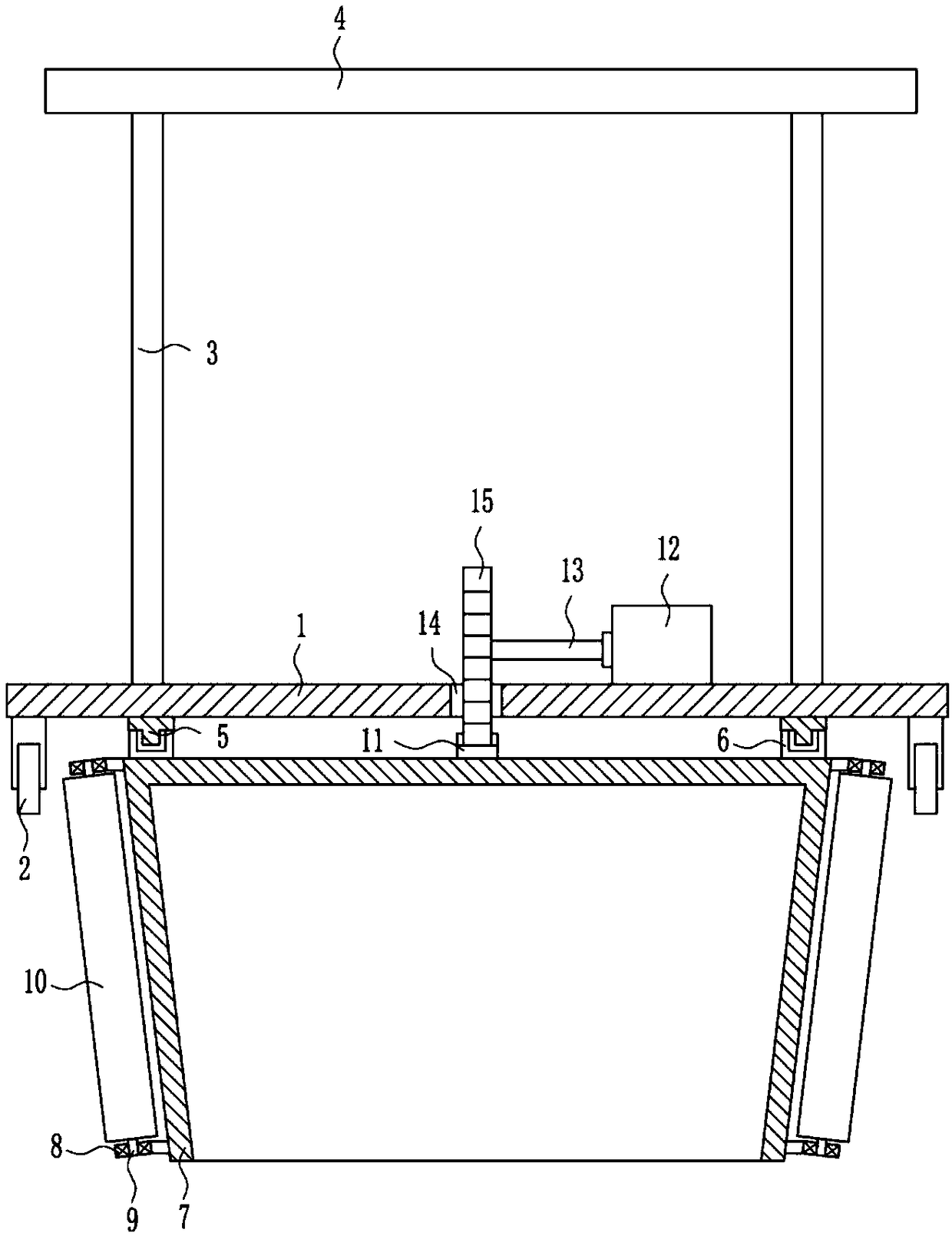

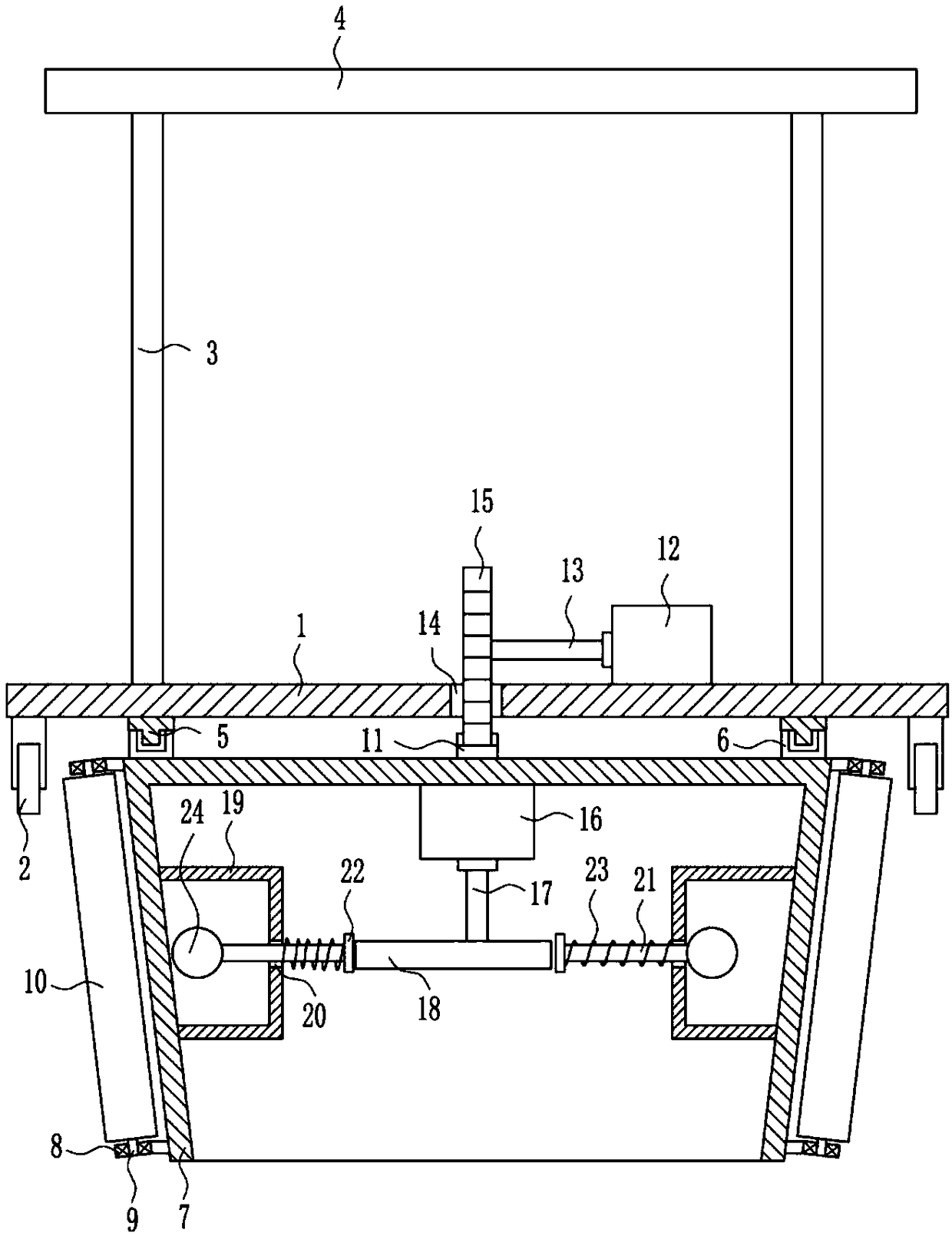

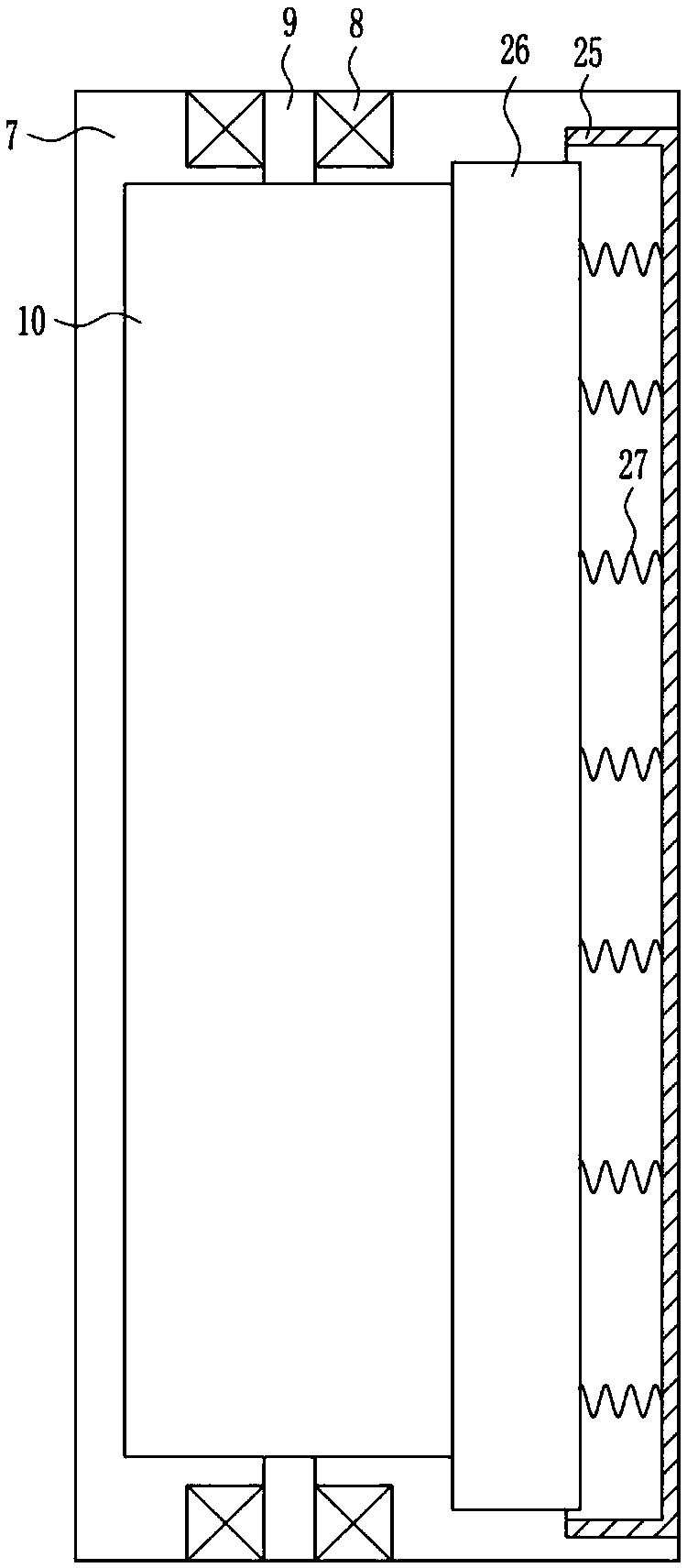

Oil tank with shock absorption supporting leg

InactiveCN102797604AImprove fatigue strengthIncrease stiffnessNon-rotating vibration suppressionMachines/enginesFuel tankThermal deformation

The invention discloses an oil tank with a shock absorption supporting leg. The oil tank comprises the shock absorption supporting leg and an oil tank body, wherein the shock absorption supporting leg is arranged at the bottom of the oil tank body and made of nylon materials. According to the oil tank, the shock absorption supporting leg is made of the nylon materials which can prevent static and has high fatigue resistance, rigidity and thermal deformation resistance and is embedded into the oil tank; the shock absorption supporting leg has high fatigue resistance and rigidity, and the thermal deformation is small, so that the shock absorption supporting leg is difficult to drop and difficult to deform after being heated; and the oil tank shocks slightly and is easy to manufacture and low in cost.

Owner:SUZHOU BAISHENG POWER MACHINE

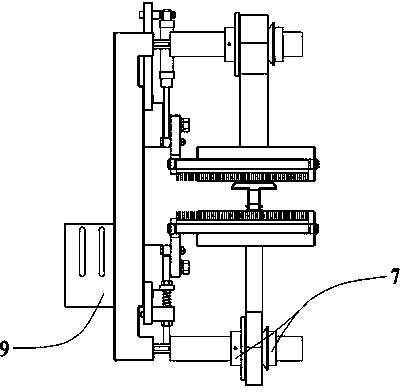

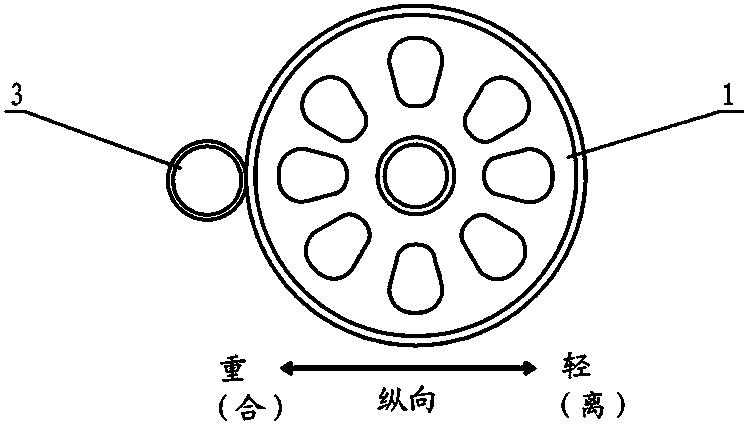

Embedded numerical-control printing pressing force adjustment and clearance tolerance elimination device

InactiveCN104339828ASmall vibrationEasy to replace rubber and maintenanceRotary pressesPrinting press partsEngineeringEmbedded controller

The invention relates to printing machinery, in particular to an embedded numerical-control printing pressing force adjustment and clearance tolerance elimination device which comprises a printing device and a printing main unit, wherein the printing device is arranged on a base and provided with a multi-station stepping indexing turntable and a die handle, and the printing main unit is arranged on a main unit support and provided with a transfer print large drum wheel. The device is characterized in that a two-dimensional orthogonal sliding seat is arranged on the base, the main unit support is arranged on the two-dimensional orthogonal sliding seat through a main unit seat plate, an embedded controller is provided with a longitudinal moving device for eliminating a clearance and a touch screen and controls the longitudinal moving device for eliminating the clearance, and the longitudinal moving device for eliminating the clearance is arranged between the base and the main unit seat plate, controls the main unit seat plate to move along the direction perpendicular to the axis of the die handle, and eliminates the tolerance clearance. The embedded numerical-control printing pressing force adjustment and clearance tolerance elimination device is convenient to operate and small in vibration and meets the accuracy requirement of high-speed running of a cup printing machine, the cup printing machine prints 450-650 cups per minute, and the cup printing speed is doubled as compared with that of an existing device.

Owner:GUANGDONG LONGXING PACKAGING IND

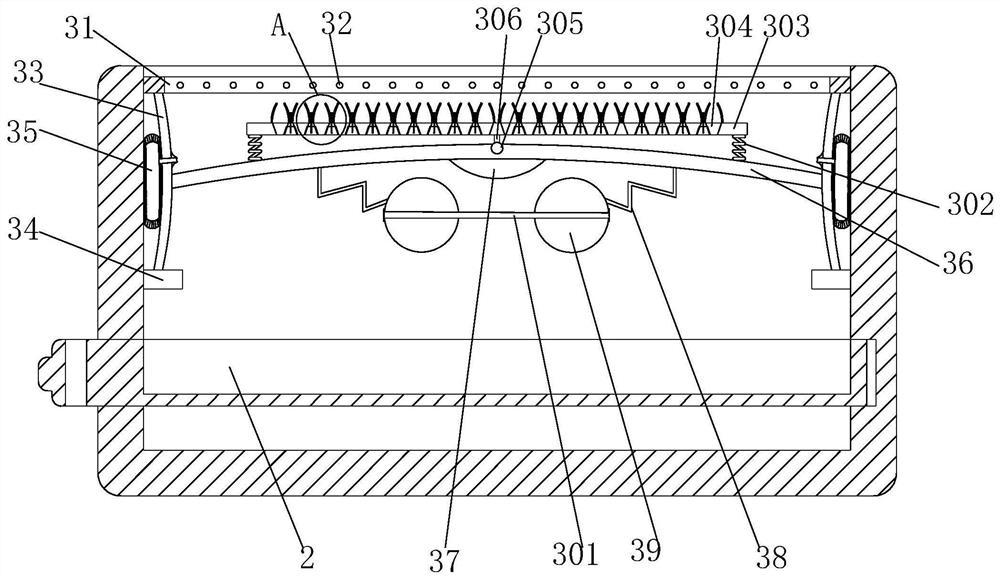

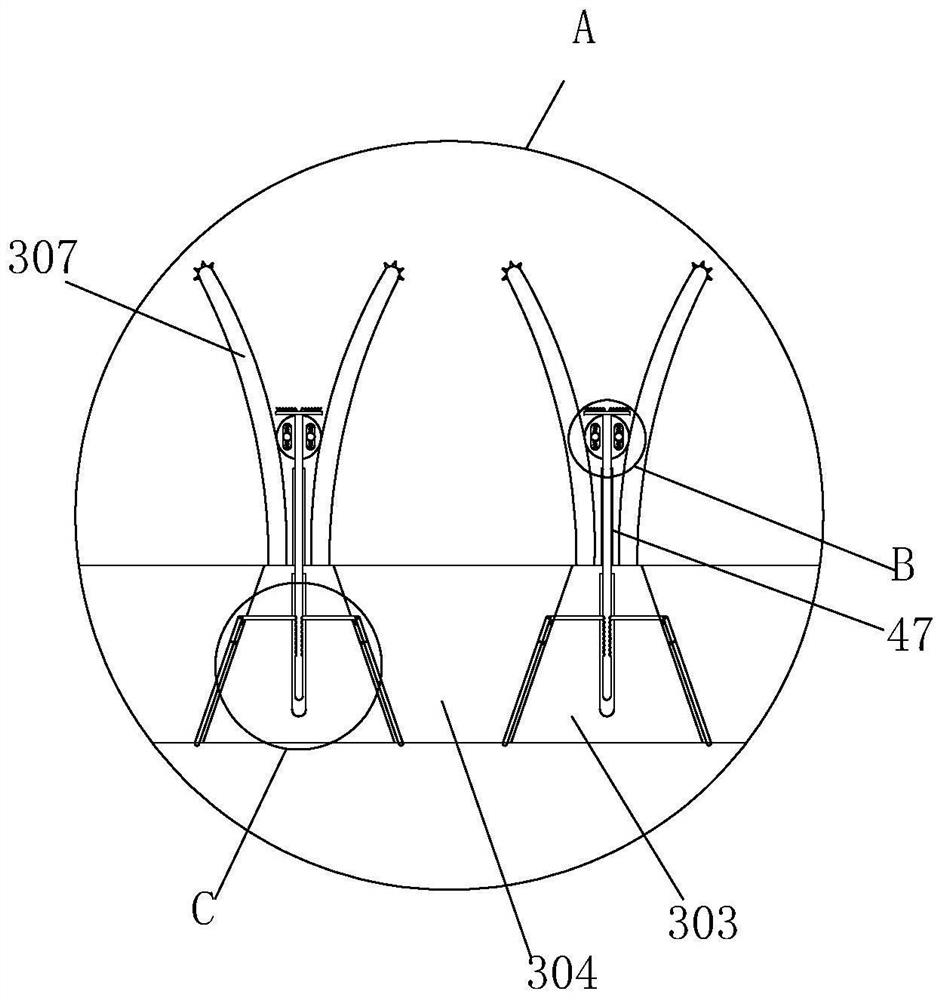

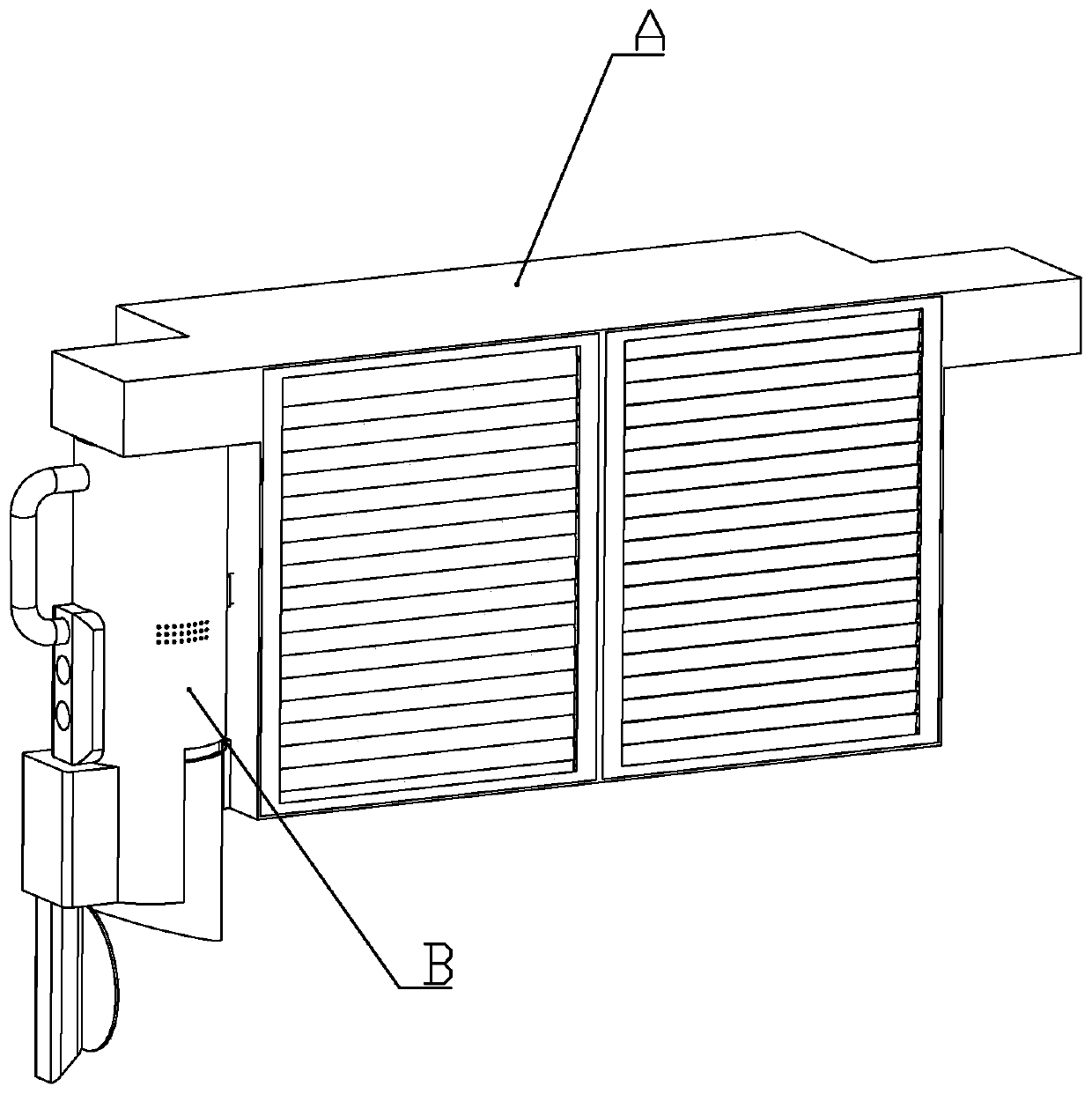

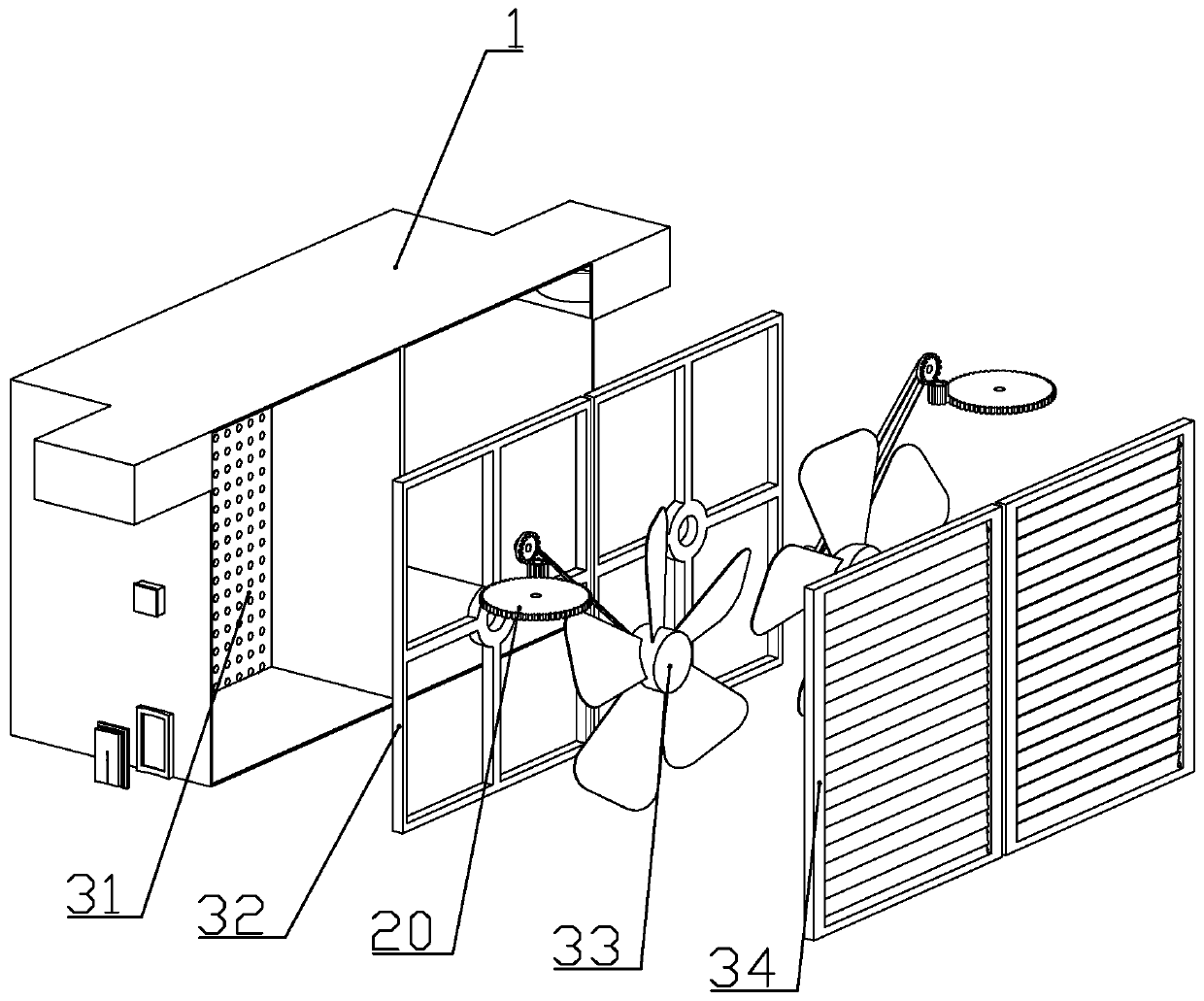

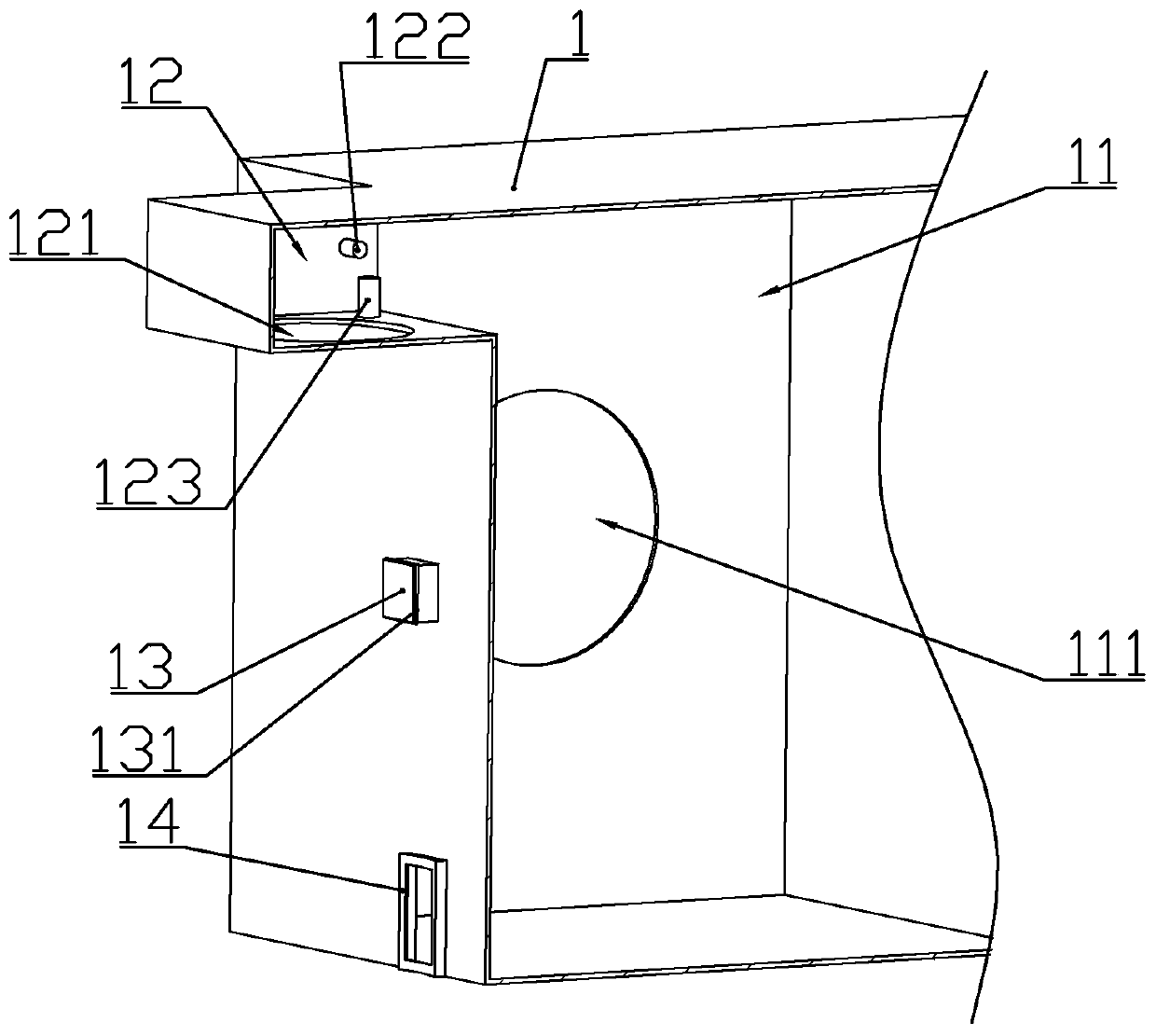

Fresh air system driven by external equipment

ActiveCN110960141AAvoid large vibrationAffect restSuction filtersLighting and heating apparatusElectric machineGear wheel

The invention discloses a fresh air system driven by external equipment. The fresh air system comprises a main machine. The main machine comprises a shell and two ventilation fans with opposite air blowing directions. Transmission assemblies capable of driving the ventilation fan to rotate are installed at the upper ends of the left and right sides of the shell. A dust collector capable of drivingthe transmission assembly to work is detachably installed on the side wall of the shell. The dust collector comprises a dust collector shell, a draught fan slidably connected into the dust collectorshell, a dust collection box and a motor driving the draught fan to work. An output shaft of the motor is fixedly connected with a driving turntable in transmission with a transmission gear disc; a fan driving assembly for driving the fan to slide along the axis of the dust collector shell is mounted in the dust collector shell; the front end of the dust collector shell is rotationally connected with a dust collection cover capable of abutting against the open end of a dust collection box. The dust collector is hung on the outer side of the main machine, so that the motor can drive the main machine to work, and meanwhile, the dust collector can be used as a dust collection tool after being taken down.

Owner:BEIJING SIJI MICOE SOLAR ENERGY TECH

Damping-rigidness-controllable double-freedom-degree vibration active control platform

ActiveCN103398138BAvoid damageAchieve Vibration ControlNon-rotating vibration suppressionCounterweightsShaped beamDiagonal

A damping-rigidness-controllable double-freedom-degree vibration active control platform comprises a cross-shaped beam frame and a square base which are connected through a flexible hinge. A cross-shaped beam of the cross-shaped beam frame is distributed in the diagonal directions of the square base. A structure column is arranged at the center of the cross-shaped beam frame. Sensors and actuators are connected between the lower portions of the diagonal top ends of the cross-shaped beam frame and the square base respectively. Four limiting columns are arranged between the cross-shaped beam of the cross-shaped beam frame and the square base respectively. Prearranged gaps are reserved between the limiting columns and the cross-shaped beam frame. Four balancing weights are fixed on the lower portion of the cross-shaped beam frame between the sensors or the actuators and the limiting columns respectively. Twisting limiting spring pieces are arranged at the symmetrical positions on the lower portion of the cross-shaped beam frame between the limiting columns and the flexible hinge. The electromagnetic type sensors and the electric-damping electric-rigidness actuators are used to achieve detecting of angular speed and actuating, the flexible hinge and the spring piece with changeable thickness are combined to achieve controllable damping and rigidness in a quantifying mode, and double-freedom-degree vibration active control in the x direction and the y direction of the structure is achieved.

Owner:XI AN JIAOTONG UNIV

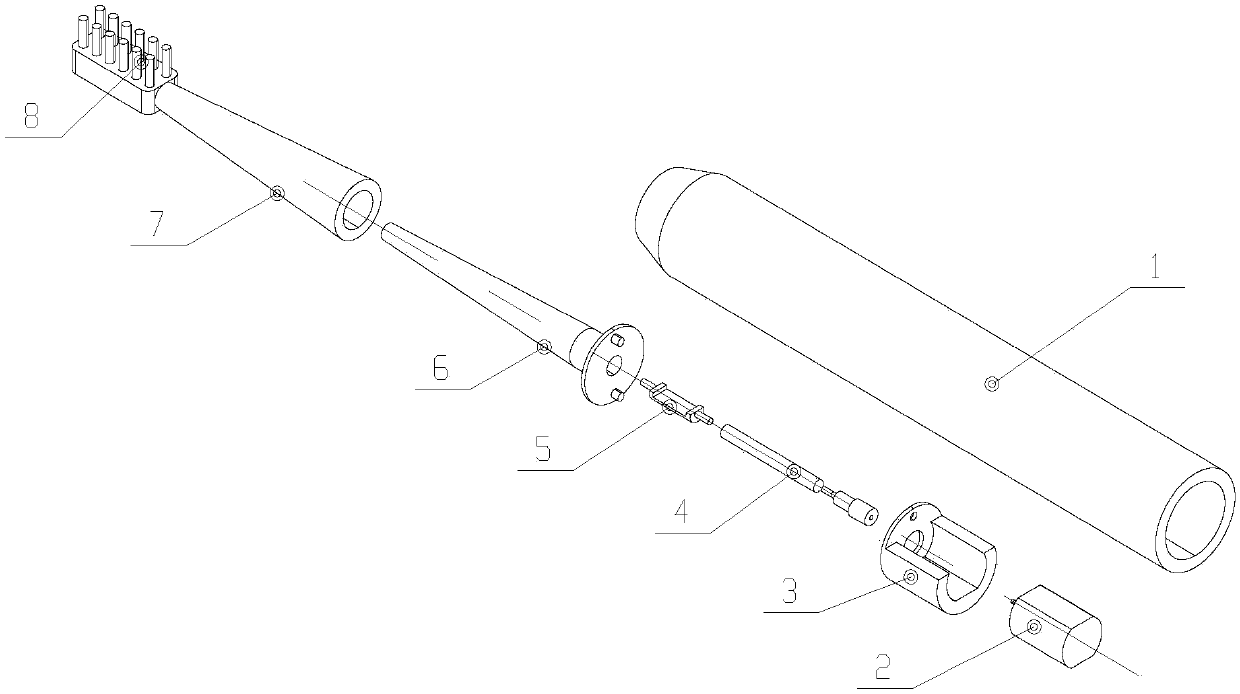

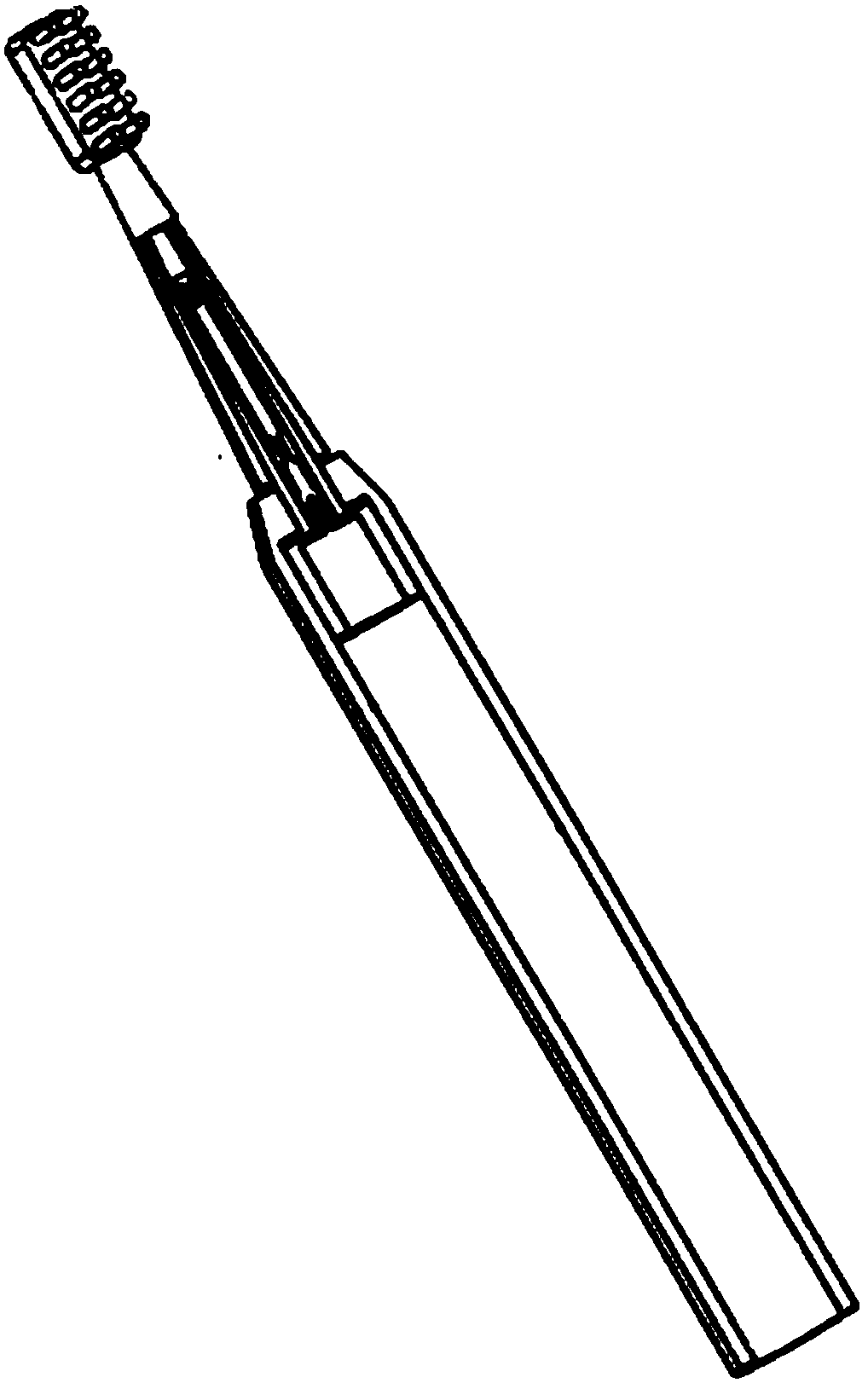

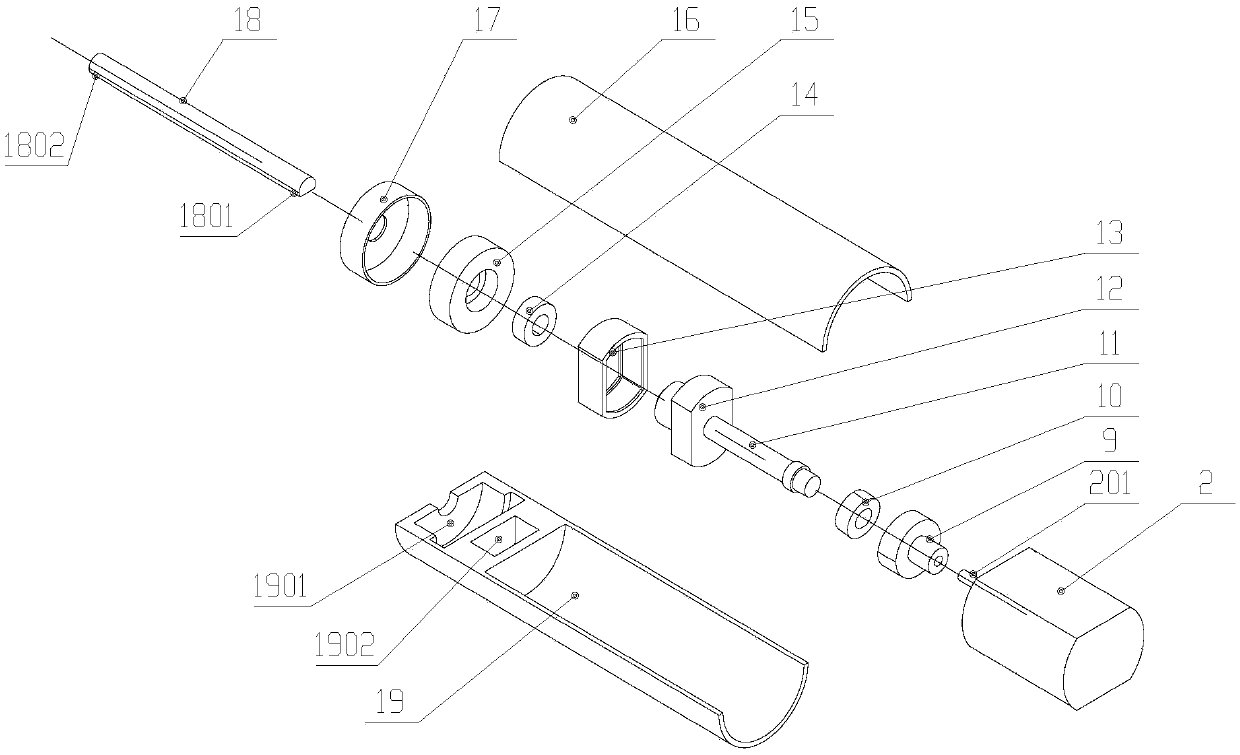

Electric toothbrush eccentric rod sound wave machine and working method thereof

PendingCN111067652ALarge swingStable strengthCleaning using liquidsTooth cleaningElectric machineryEngineering

The invention provides an electric toothbrush eccentric rod sound wave machine and a working method thereof. An eccentric rod sound wave machine body is arranged in a machine body; the eccentric rod sound wave machine body comprises a group of involution type shells; a micromotor is arranged at one ends, away from a toothbrush handle, of the involution type shells, a motor shaft is arranged at theoutput end of the micromotor and points to the toothbrush handle, and the motor shaft is connected with one end of a positioning connecting shaft rod through an eccentric bearing seat; a positioningconnecting shaft seat is arranged at the other end of the positioning connecting shaft rod, and a positioning connecting shaft seat soft rubber sleeve is arranged on the outer ring of the positioningconnecting shaft seat; a concentric bearing seat, a bearing B and a metal shaft are sequentially arranged in the concentric bearing seat soft rubber sleeve from outside to inside; one end, away from the toothbrush handle, of the metal shaft is connected with the positioning connecting shaft rod; and the other end of the metal shaft is arranged in the toothbrush handle. The electric toothbrush eccentric rod sound wave machine can achieve the effect of an electric toothbrush adopting a magnetic suspension motor, and overcomes the defects that the brush head handle of an original resonance electric toothbrush is thick and large, the vibration swing amplitude is small, the brush head handle is prone to touching teeth and the tooth brushing force is not in place.

Owner:上海天封科技有限公司

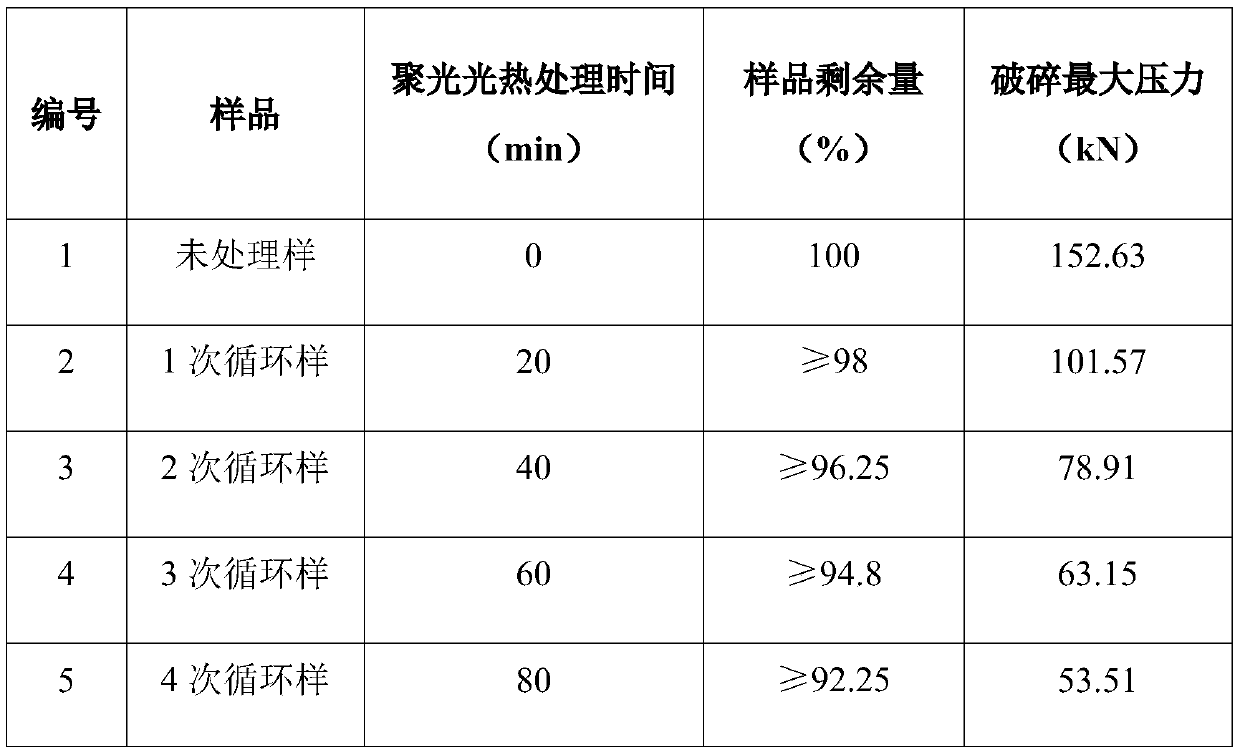

Waste graphite electrode crushing method through photothermal quick-heating pretreatment

ActiveCN109847896ALow priceReduce acidity and alkalinityGrain treatmentsChemical structureGraphite electrode

The invention provides a waste graphite electrode crushing method through photothermal quick-heating pretreatment. The waste graphite electrode crushing method is characterized in by comprising the following steps that 1, a waste graphite electrode is completely immersed in a hydrogen peroxide solution to be soaked for a period of time; 2, the waste graphite electrode is subjected to photothermalquick-heating through a focused light beam; 3, water is sprayed to the waste graphite electrode subjected to photothermal heating for quick cooling; and 4, the cooled waste graphite electrode is overall placed on a crushing device to be overall crushed. According to the waste graphite electrode crushing method, by utilizing quick gasification expansion decomposition of water molecules and hydrogenperoxide molecules in the quick heating process and a small amount of reaction with graphite, the physical and chemical structure inside the waste graphite electrode is destroyed, then by utilizing amethod of water spraying for quick cooling, the destroy degree of the physical and chemical structure of the waste graphite electrode is further increased, more cracks are formed, and thus one-time overall crushing of the graphite electrode under the low pressure is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

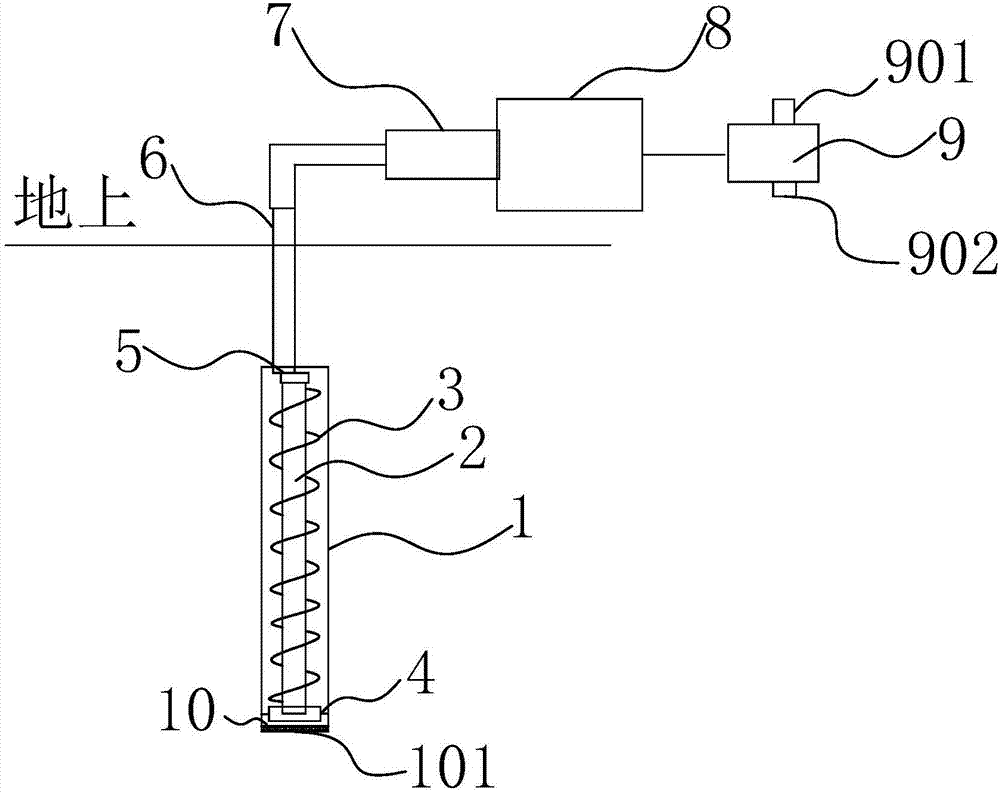

Micro spiral pump system

The invention discloses a micro spiral pump system. The micro spiral pump system is characterized in that the system comprises a pump head (1) and a pump body (7) connected with the pump head (1) through a connecting pipeline (6), and a spiral rotary shaft (2) is arranged in the pump head (1). Compared with the prior art, the micro spiral pump system has the advantages that a screw rod is replaced with the spiral rotary shaft, water flow is driven by spiral blades, the centrifugal force of the spiral blades is small compared with the action of the screw rod, therefore, vibration is slight, and a universal joint is not prone to damage; besides, a filtering screen is additionally installed at a water inlet end, so that impact of gravel to the universal joint in the pump body is reduced, a good effect is achieved, durability of the pump head is improved, and the service life of the pump head is prolonged; and a motor is provided with a converter which can selectively input two voltages, electricity can be transmitted to a 48-60V socket through a storage battery in case of a power failure, the production requirement that operation continues in case of the power failure is met, and the operating efficiency of the pump body is improved.

Owner:余雷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com