Parallel multi-head full-automatic reinforcing bar straightening and hoop bending device and use method thereof

A parallel and fully automatic technology, which is applied in the field of large-scale construction industry, can solve the problems of extended construction period, irregular arrangement, difficult transportation, etc., and achieve the effects of faster bending speed, higher production efficiency and high automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

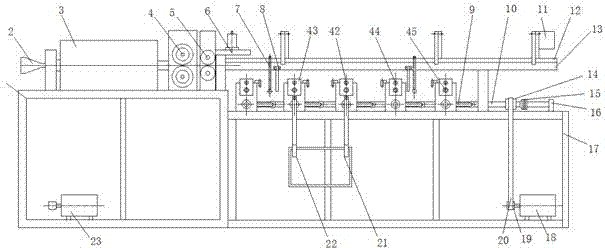

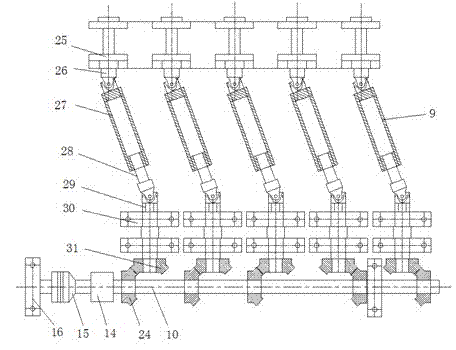

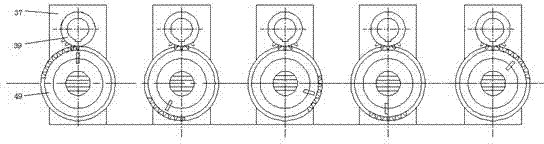

[0025] Such as Figure 1-5 As shown, the parallel multi-head automatic steel bar straightening and bending equipment includes straightening frame 1, guide cylinder 2, straightening cylinder 3, traction wheel 4, meter wheel 5, hydraulic cutting mechanism 6, material receiving rod 7, material pushing Plate 8, retractable universal joint transmission unit 9, main drive shaft 10, electromagnet 11, material bearing frame 12, flap 13, upper sprocket 14, clutch 15, main drive shaft seat 16, hoop frame 17 , hoop motor 18, lower sprocket 19, chain 20, right coupling bar 21, left coupling bar 22, straightening motor 23, main drive shaft bevel gear set 24; straightening frame 1 is provided with straightening tube 3 , the traction wheel 4, the meter wheel 5 and the hydraulic cutting mechanism 6, the guide cylinder 2 is fixed on the straightening cylinder 3, the side of the hydraulic cutting mechanism 6 is provided with a material holder 12 and a flap 13, a material receiving rod 7 and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com