Waste graphite electrode crushing method through photothermal quick-heating pretreatment

A technology of waste graphite and crushing method, applied in the direction of grain processing, etc., can solve the problems of hindering the recycling of waste graphite electrodes, difficulty in recycling waste graphite electrodes, low material utilization rate, etc., and achieves reduction of time, low price and good cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

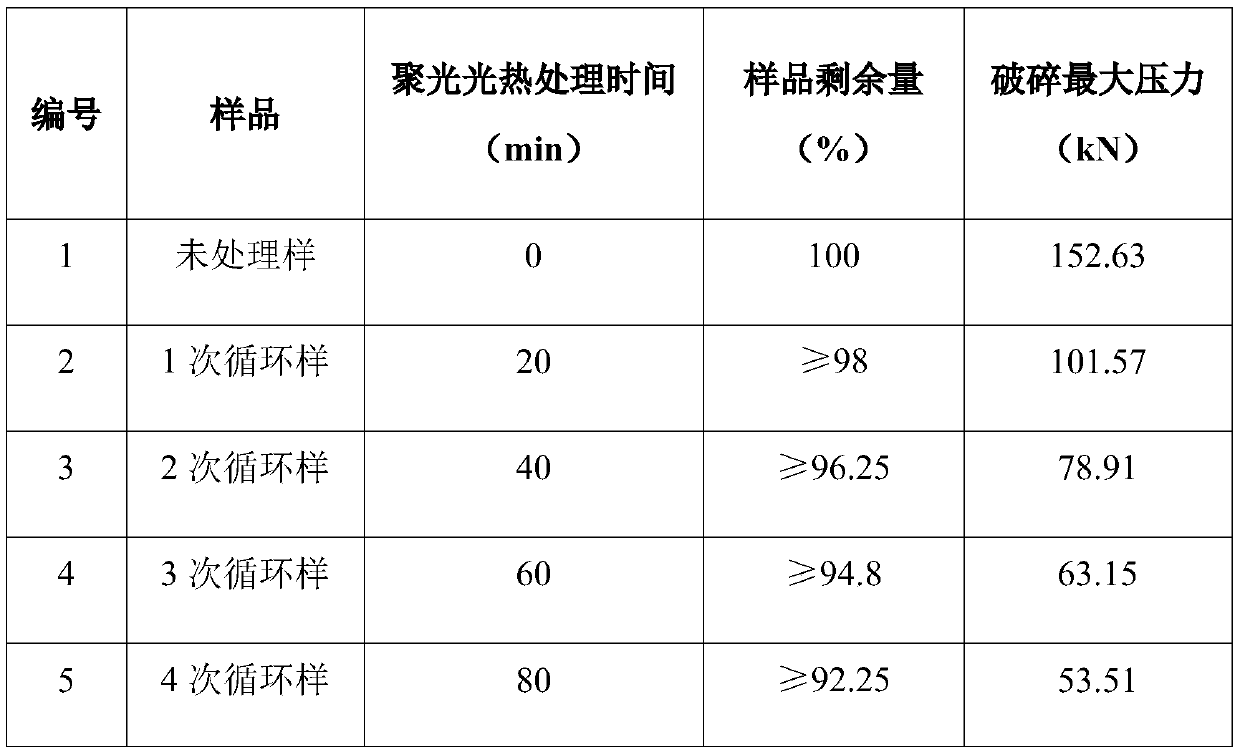

Examples

Embodiment Construction

[0022] The specific implementation of the waste graphite electrode crushing method using photothermal rapid temperature rise pretreatment according to the present invention will be described in detail below.

[0023]

[0024] In the present embodiment, the processing object is a graphite electrode rod with a diameter of 30 cm and a length of 100 cm; the solar trough concentrator of Saint-Principe is used as the photothermal heating device, and the opening width is 5770 mm (the reflectivity of the lens is ≥ 93.5%, and the converted light concentration ratio is about 78.6); and Shandong Yiqi mechanical hydraulic press is used as the crushing device.

[0025] The waste graphite electrode crushing method provided by this embodiment using photothermal rapid temperature rise pretreatment specifically includes the following steps:

[0026] Step 1. Fully immerse the graphite electrode rod in 15wt.% hydrogen peroxide solution;

[0027] Step 2. Set the graphite electrode rod soaked for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com