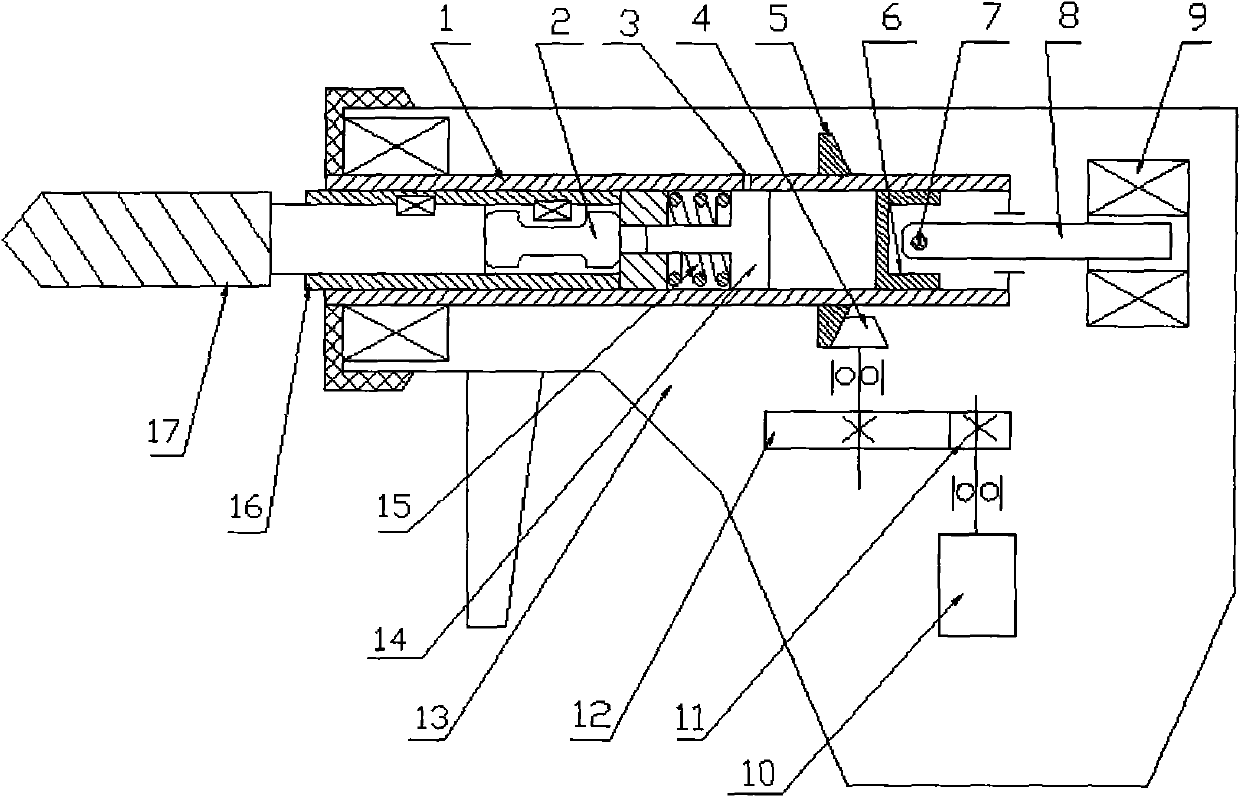

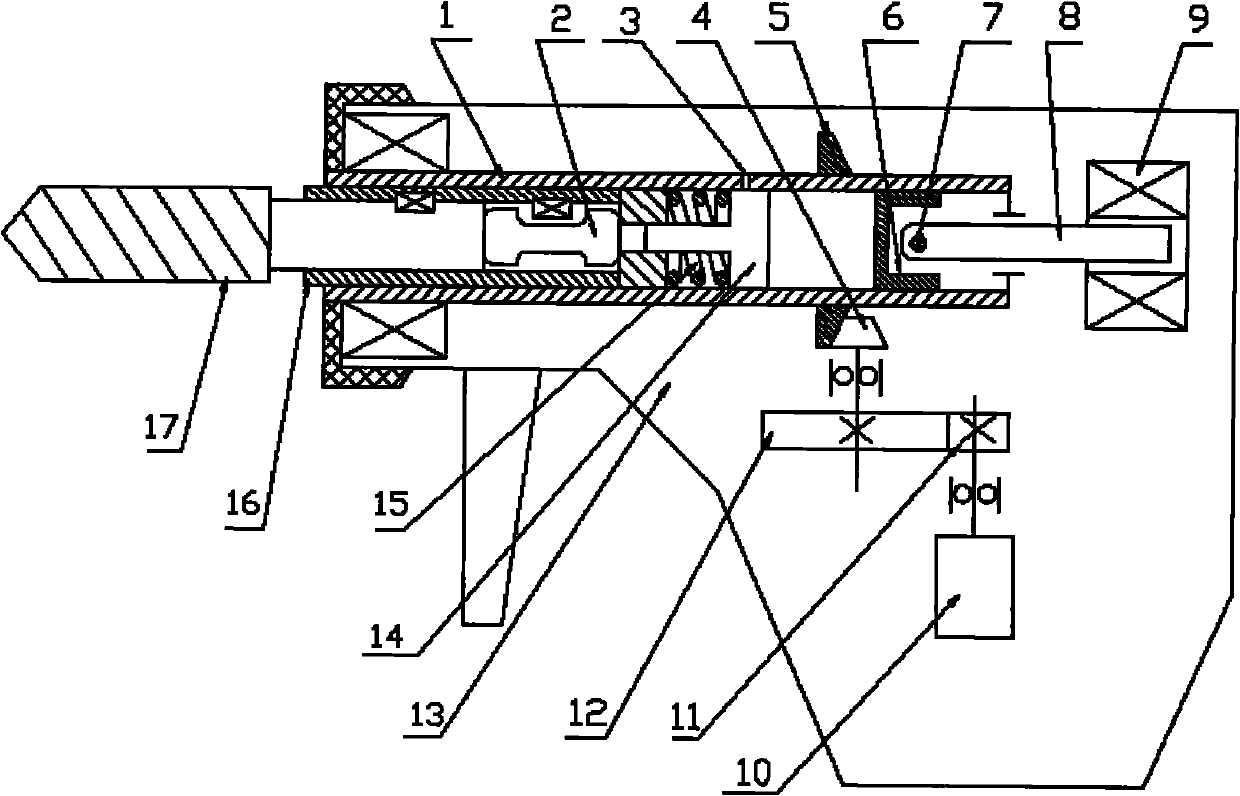

Vibration electric hammer

A technology of electric hammer and transmission piston, which is applied in the field of electric hammer and vibration electric hammer, which can solve the problems of complex structure, low service life, and large hand vibration, and achieve the effect of simple overall structure, long service life and small hand vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Install the fixed drill bushing (16) at the front end of the cylinder body (1), install the percussion hammer (2) at an appropriate position at the rear of the drill bushing (16), and install a compression spring ( 15), and install the transmission piston (14) together with the compression spring (15) inside the cylinder (1) at the rear of the drill sleeve (16), and the air hole (3) is opened outside the cylinder (1) On the top of the circle, the transmission piston (14) can just seal the air hole (3) in a free state; the large bevel gear (5) is installed and fixed on the appropriate position of the cylinder body (1), and the large bevel gear (5) and the small bevel gear Bevel gear (4), gear wheel (12), pinion gear (11), motor (10) form the relation of transmission chain successively; Rod iron core (8) links to each other with piston (6) by bearing pin (7), and electromagnet (9) is installed and fixed in the housing of appropriate position of cylinder body rear portion....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com