Damping-rigidness-controllable double-freedom-degree vibration active control platform

A technology of active control and degrees of freedom, applied in non-rotational vibration suppression, counterweight and other directions, it can solve the problems of single control direction, inconvenient system damping and stiffness adjustment, etc., and achieve the effect of small vibration range and good linearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

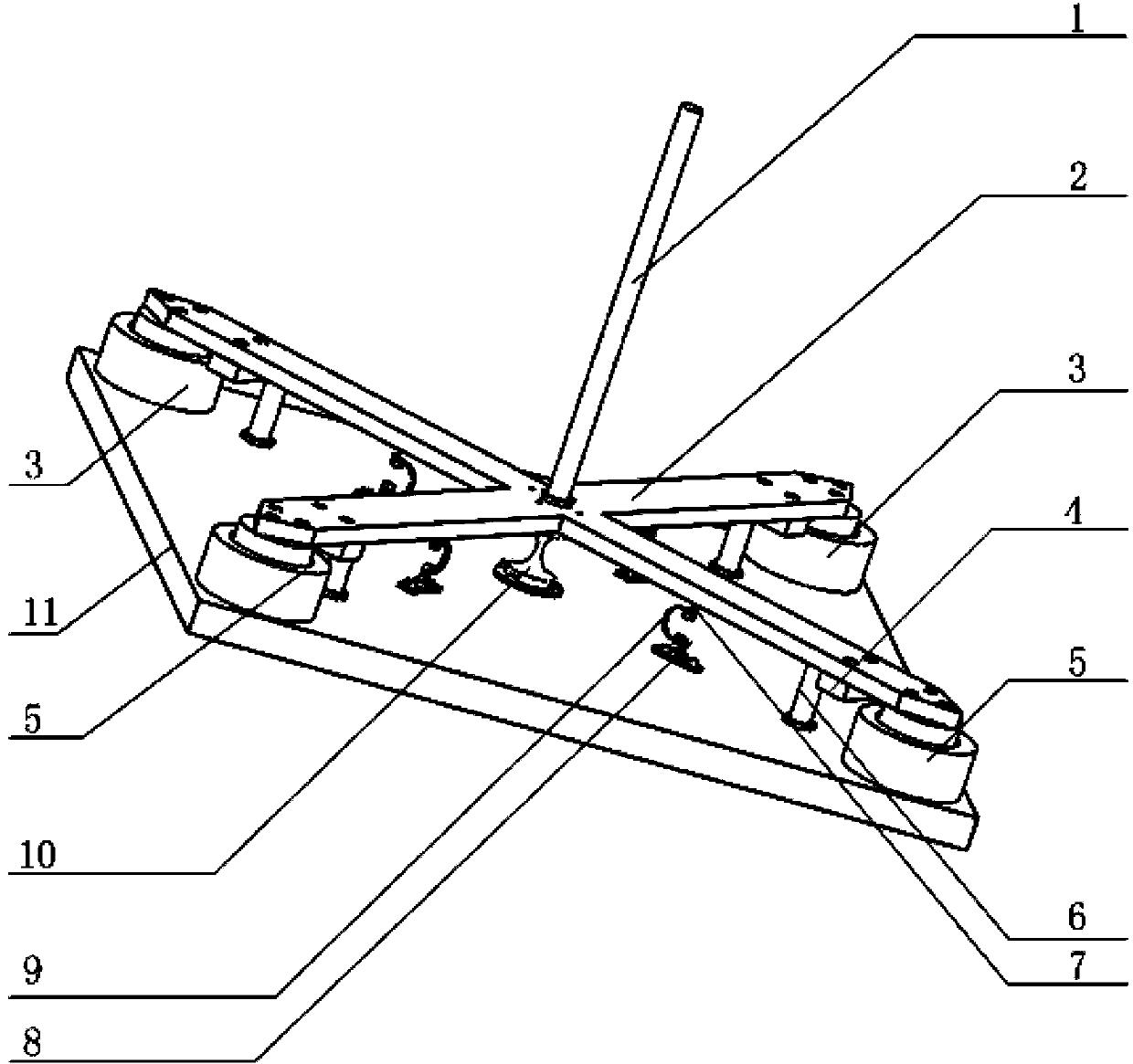

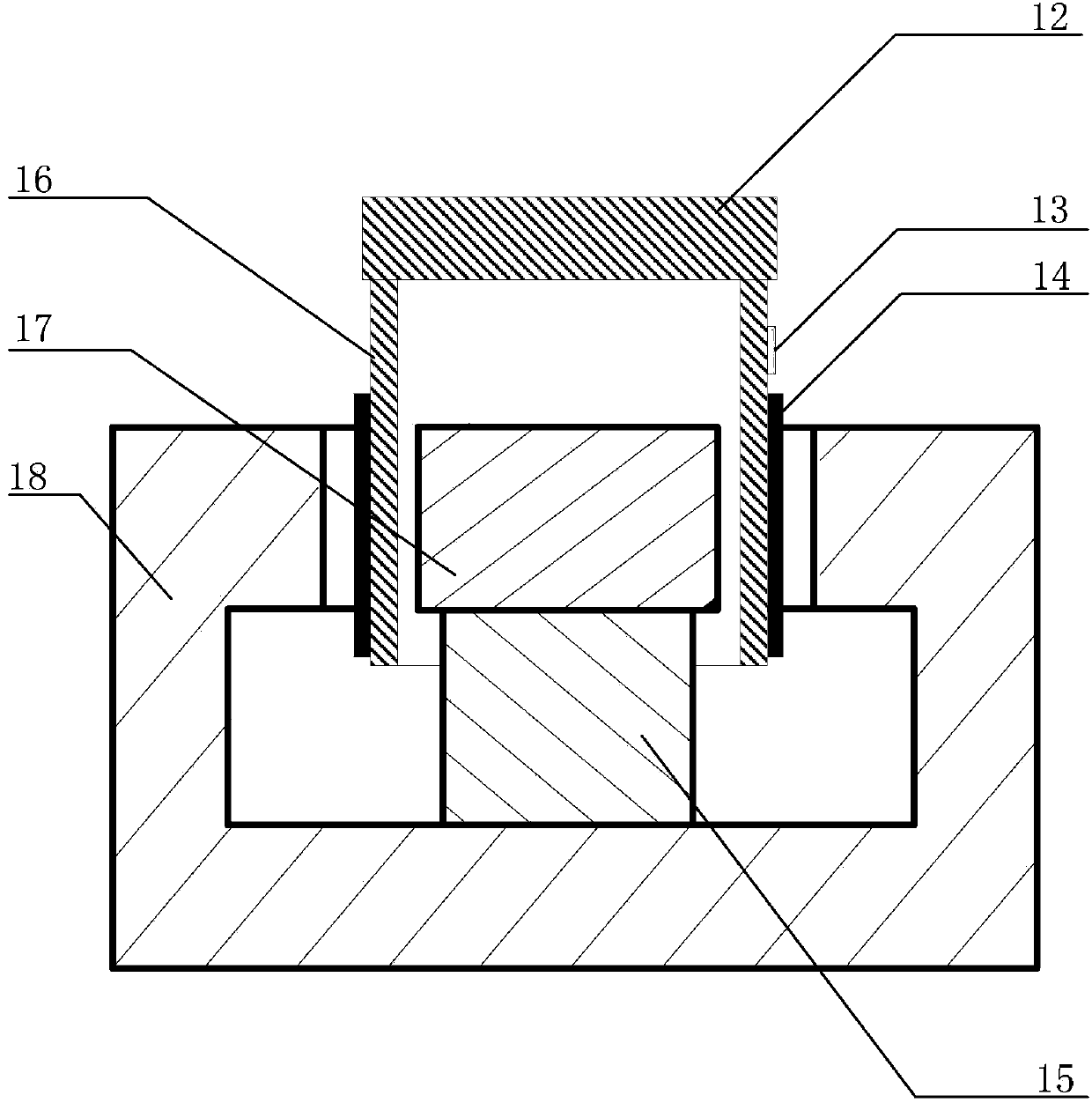

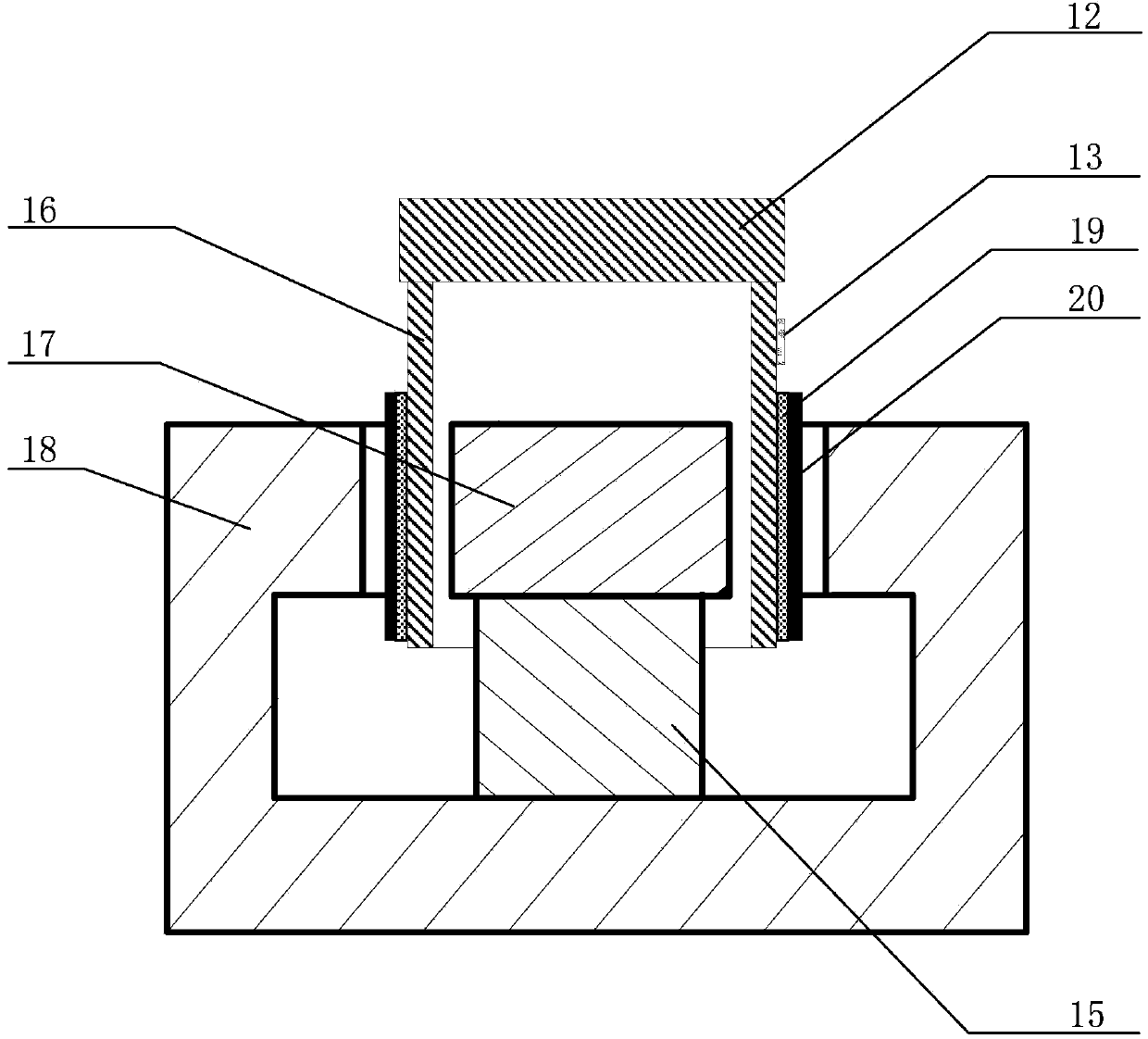

[0025] Such as figure 1 As shown, a dual-degree-of-freedom vibration active control platform with controllable damping stiffness of the present invention includes a cross beam skeleton 2 and a square base 11 connected by a flexible hinge 10, and the cross beams of the cross beam skeleton 2 are distributed on the square base 11 In the diagonal direction, a structural column 1 is installed at the center of the cross beam skeleton 2, and a sensor 3 and an actuator 5 are respectively connected between the lower part of the diagonal top of the cross beam skeleton 2 and the square base 11, and four limit columns 6 They are respectively placed between the cross beams of the cross beam skeleton 2 and the square base 11 and are close to the symmetrical positions of the sensor 3 or the actuator 5. There is a preset gap between the limit column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com