Patents

Literature

58results about How to "Achieve Vibration Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

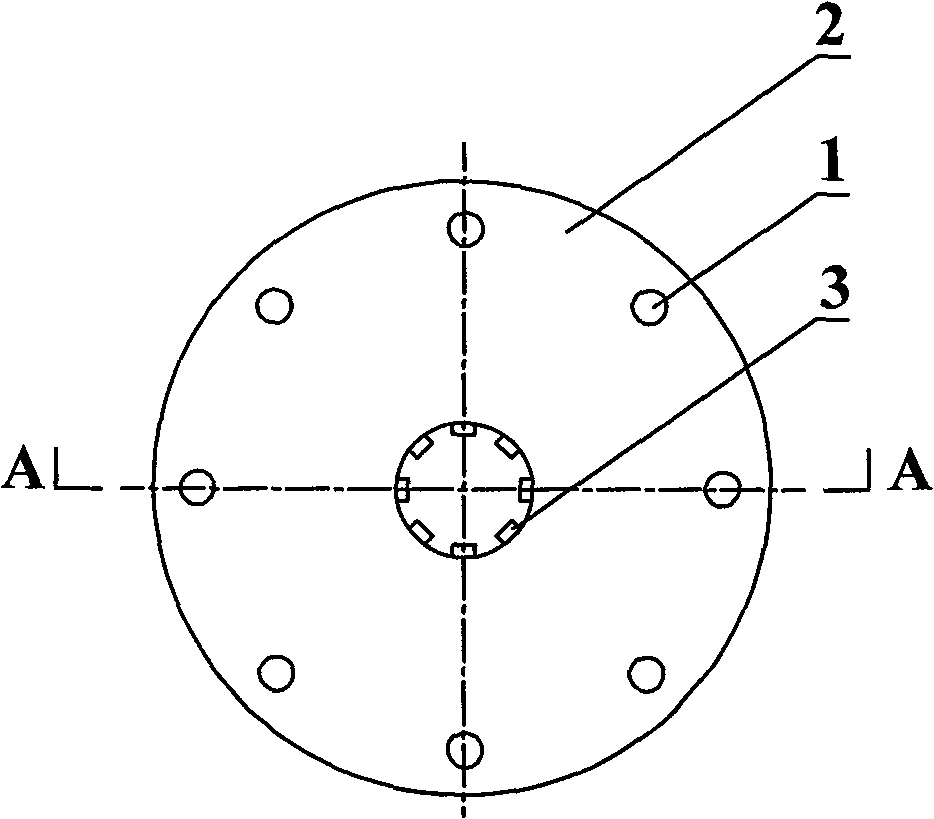

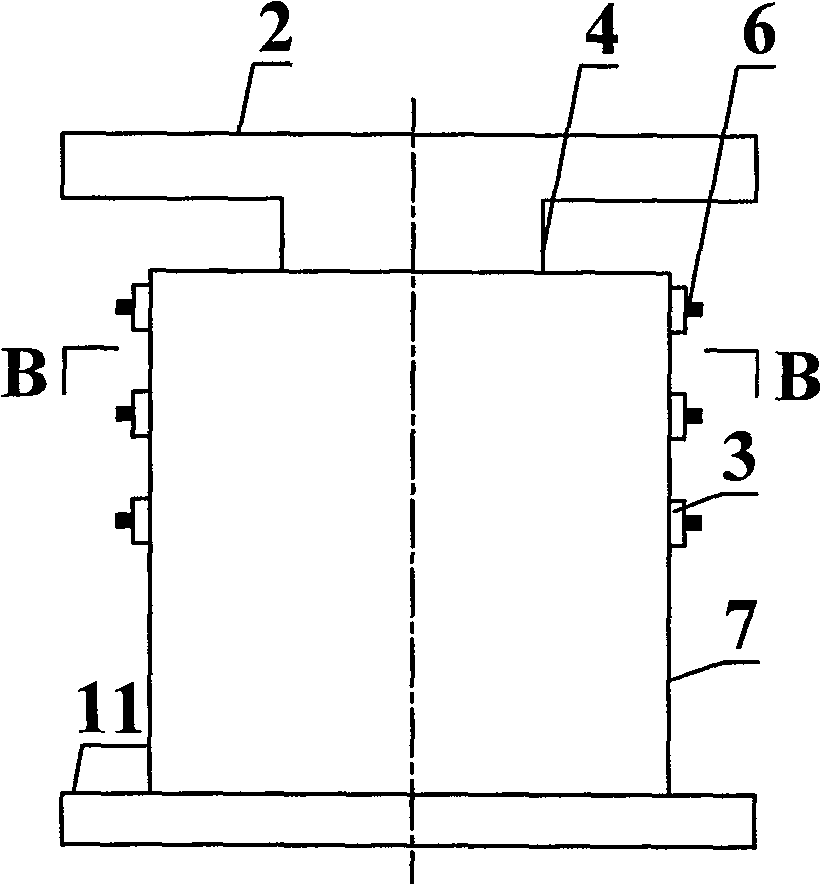

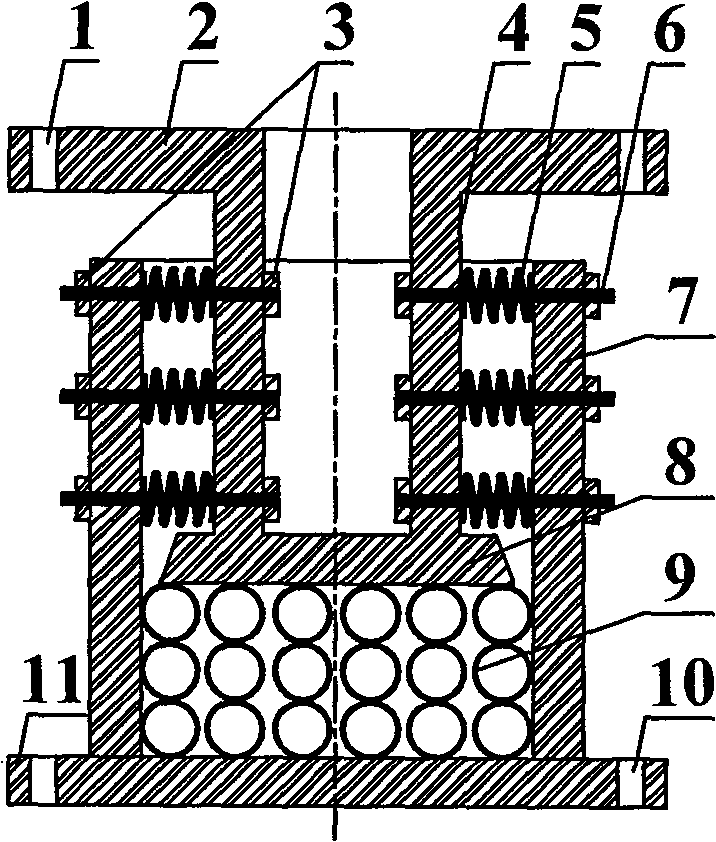

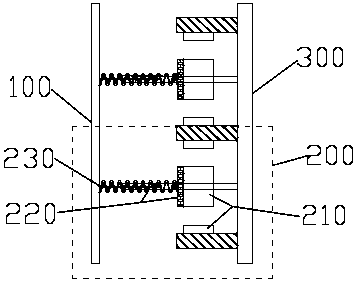

Mixed type shape memory alloy multi-dimensional vibration isolator

InactiveCN101575882ASimple structureEasy to install and disassembleShock proofingHybrid typeVibration control

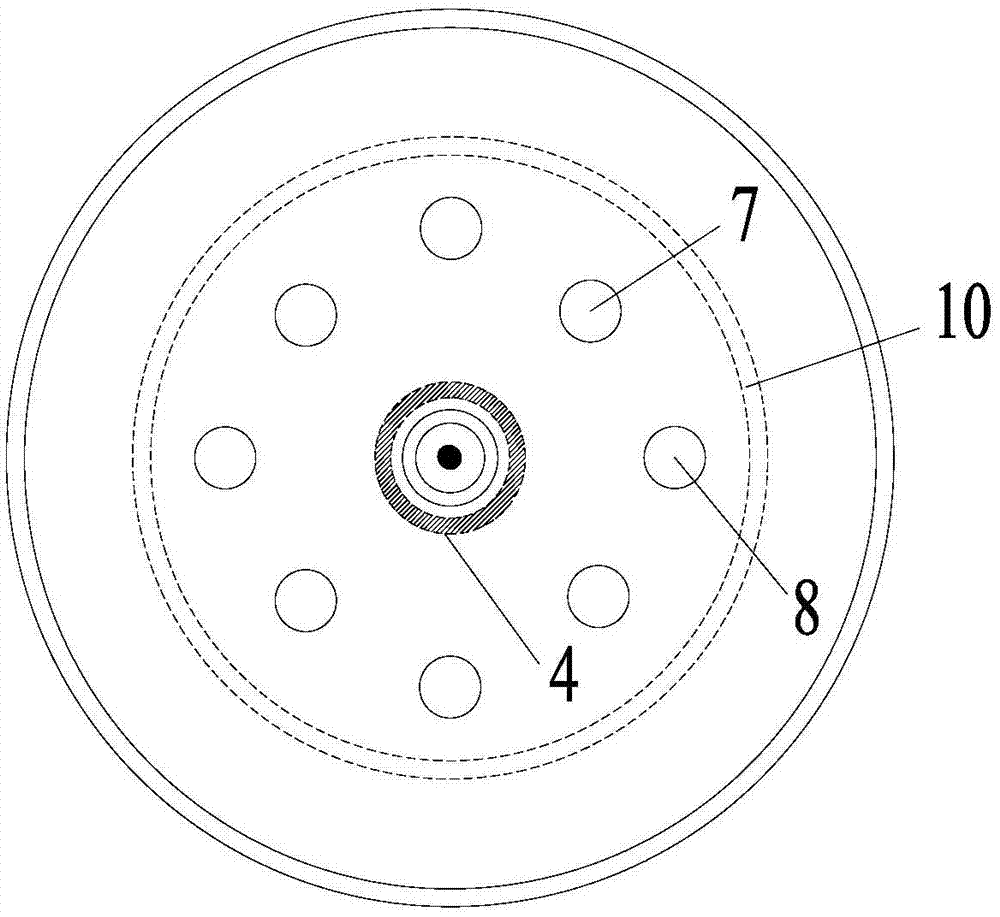

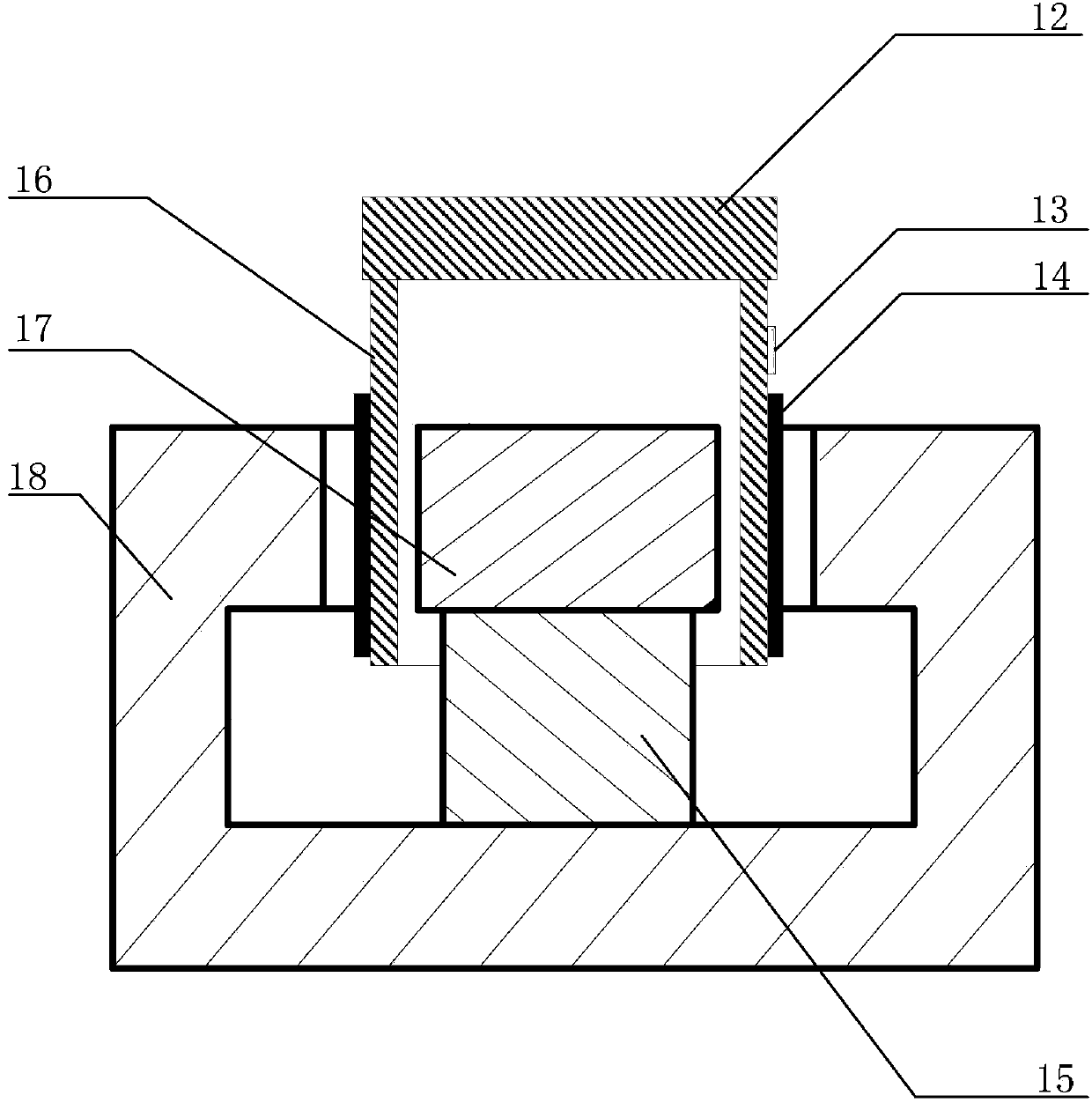

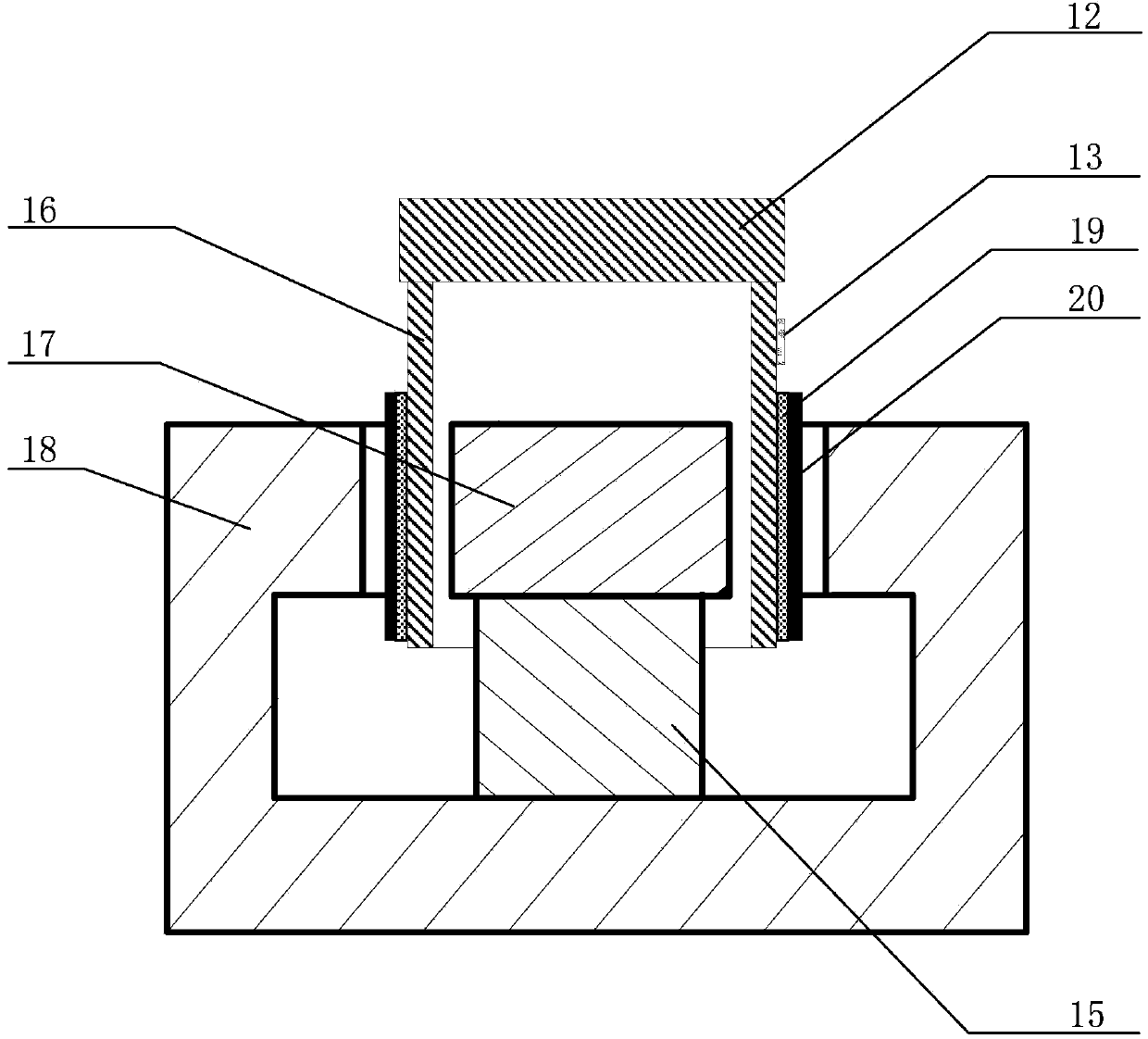

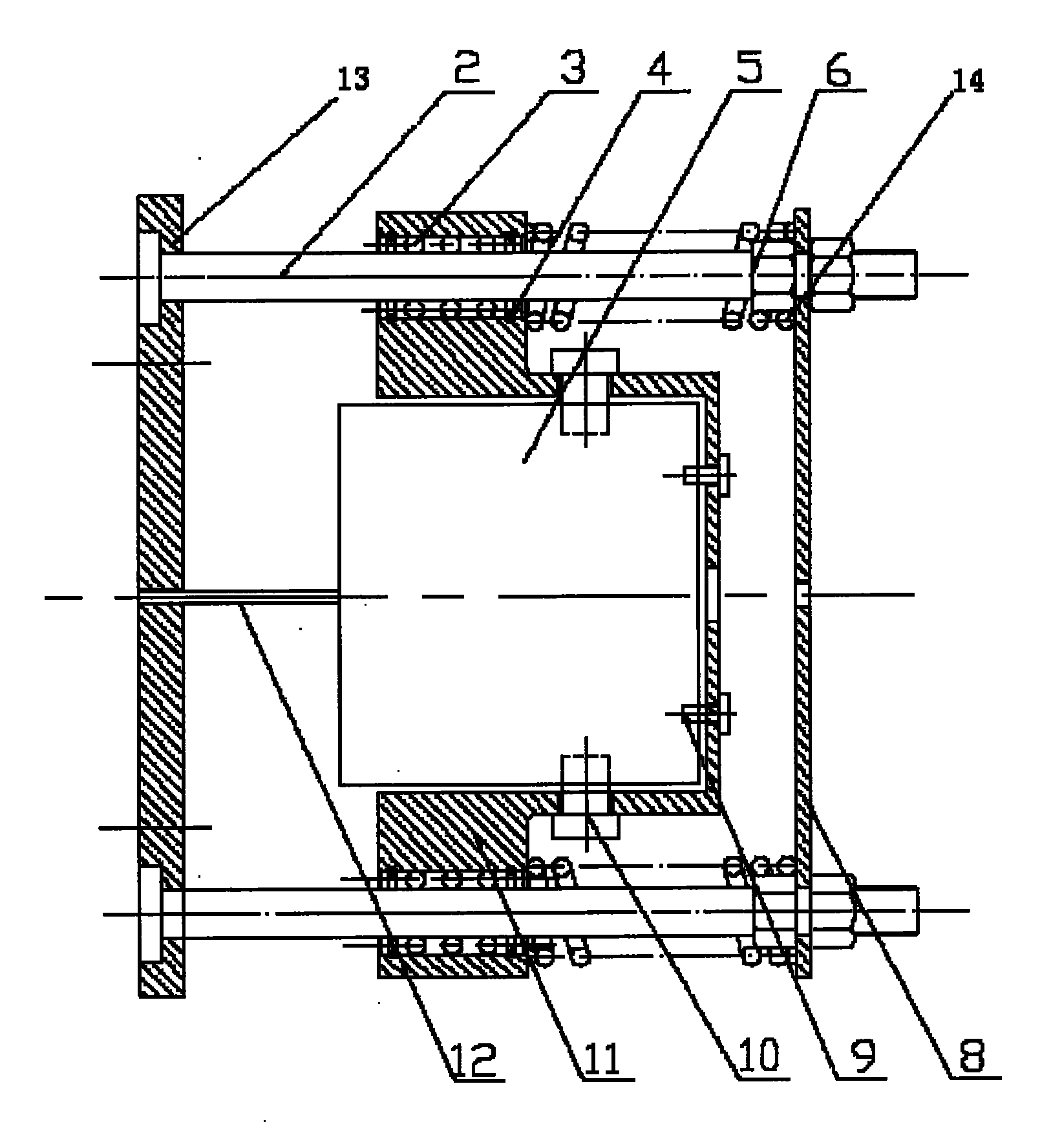

The invention relates to a mixed type shape memory alloy multi-dimensional vibration isolator, which belongs to the technical field of civil engineering. The vibration isolator mainly comprises an upper flange, an internal cylinder, martensite shape memory alloy energy-consuming springs, austenite shape memory alloy twisted lines, an external cylinder, a base plate, thin-wall shape memory alloy hollow balls and a lower flange. The vibration isolator is characterized in that the upper end of the internal cylinder is connected with the upper flange while the lower end is connected with the base plate, the lower end of the external cylinder is connected with the lower flange, the internal cylinder is connected with the external cylinder through three layers of the martensite shape memory alloy energy-consuming springs and the twisted lines, and the shape memory alloy twisted lines are penetrated in the shape memory alloy energy-consuming springs; each layer contains eight groups of the shape memory alloy energy-consuming springs and the twisted lines which are arranged symmetrically along the circumferential radial direction of the internal cylinder; three layers of the thin-wall shape memory alloy hollow balls are placed in the external cylinder; and the vibration isolator is fixed on a part of which the structure needs vibration control by the upper flange and the lower flange. The vibration isolator has the advantages of comprehensively utilizing the hyperelasticity and the high damping characteristic of shape memory alloys and achieving the multi-dimensional direction vibration control.

Owner:DALIAN UNIV OF TECH

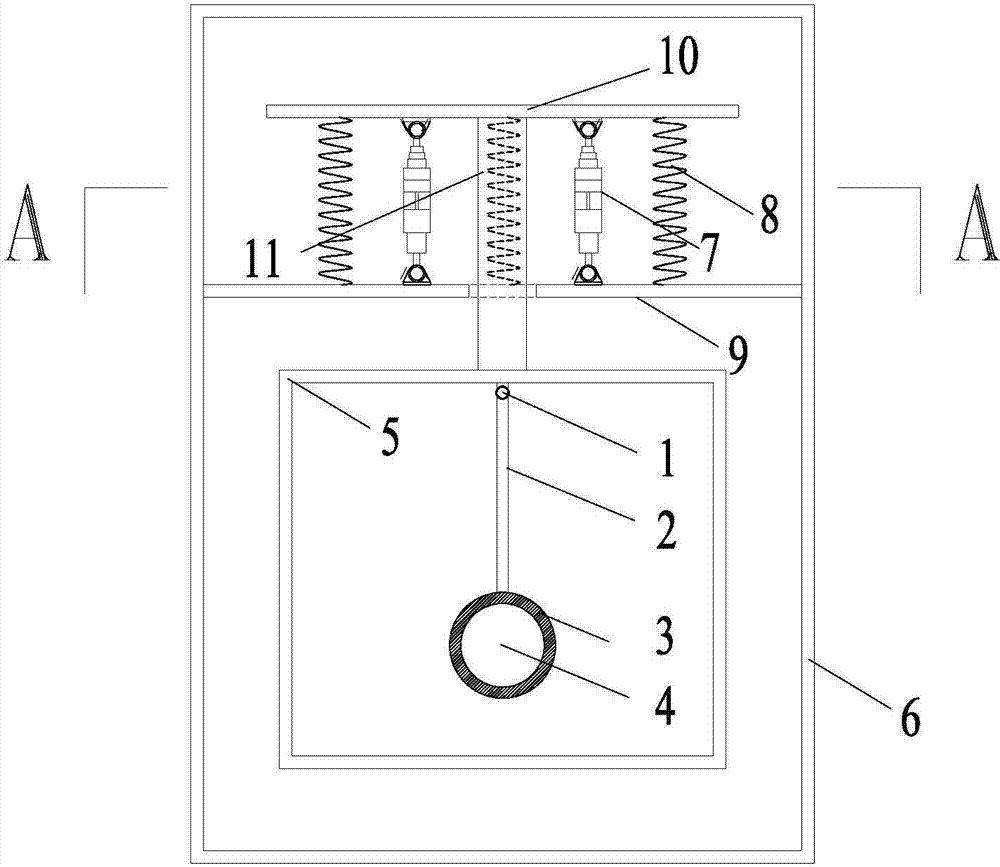

Suspension type multidimensional impact vibration reduction damper

The invention discloses a suspension type multidimensional impact vibration reduction damper which comprises an external container box. A partition plate with a circular hole is horizontally arranged in the external container box and divides the external container box into two spaces, fluid viscous dampers and springs are arranged on the partition plate, the upper ends of the fluid viscous dampers and the upper ends of the springs are connected with a circular plate which does not make contact with the external container box, the lower ends of the fluid viscous dampers and the lower ends of the springs are connected to the partition plate, the center of the circular plate is provided with a rigid connecting rod which penetrates through the circular hole in the center of the partition plate and is connected with an internal cylinder box, the bottom end of the rigid connecting rod is connected with an internal metal box, a rigid hanging rod is arranged in the internal metal box, and the bottom of the rigid hanging rod is connected with a mass ball. The suspension type multidimensional impact vibration reduction damper can reduce the multidimensional vibration response of a structure under the action of an earthquake or a wind load and can effectively make up for the hidden danger brought by the uncertain direction when a load is generated.

Owner:SHANDONG UNIV

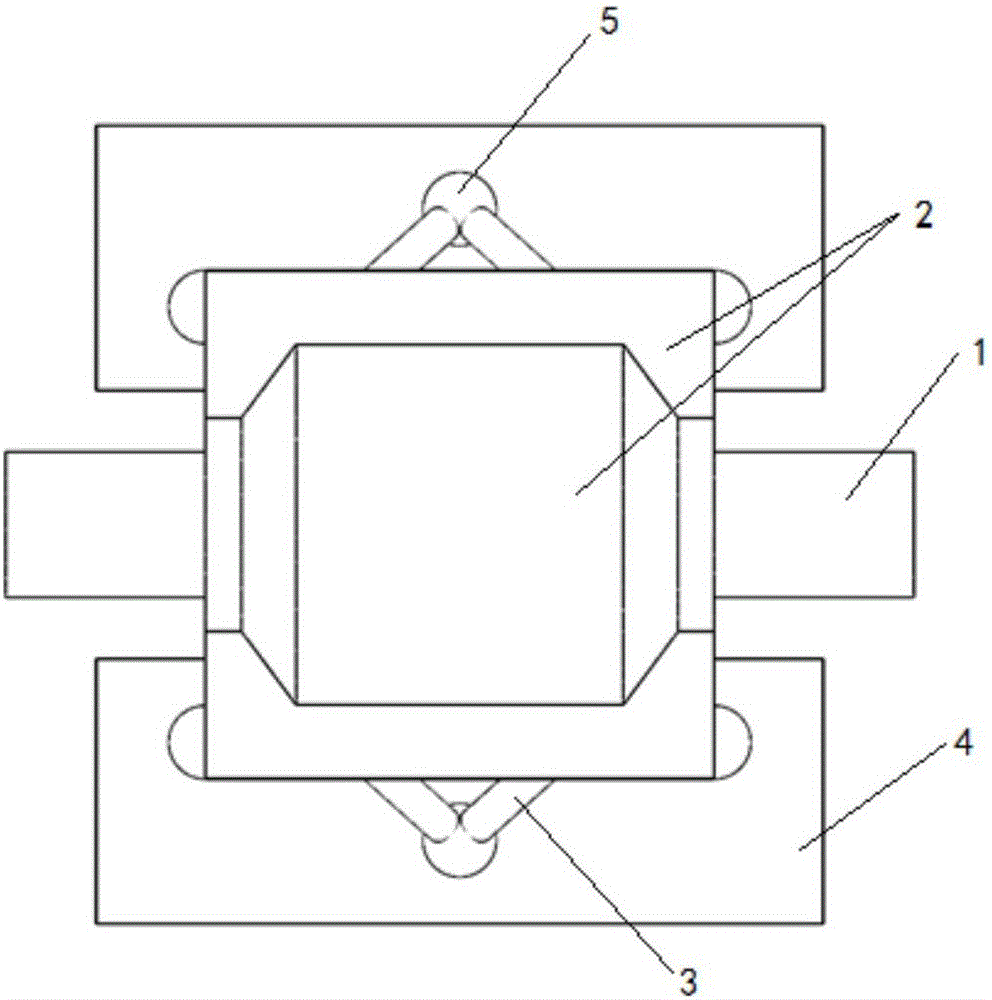

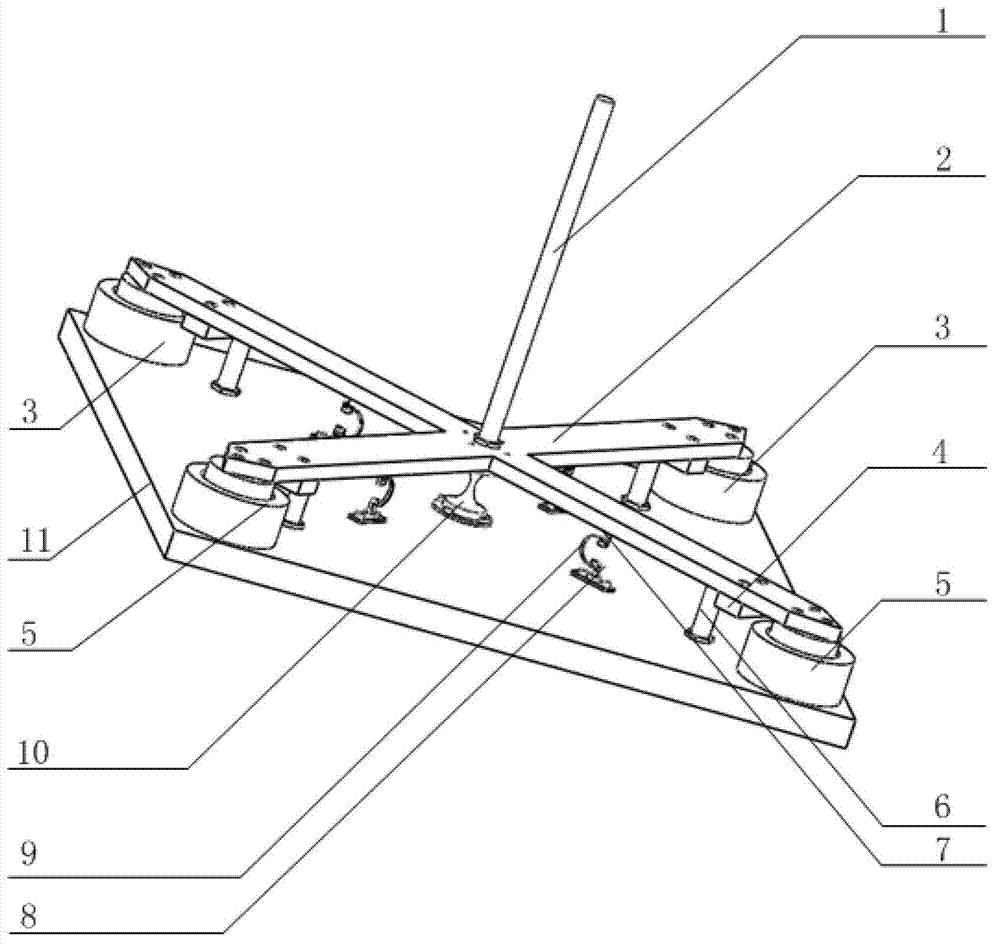

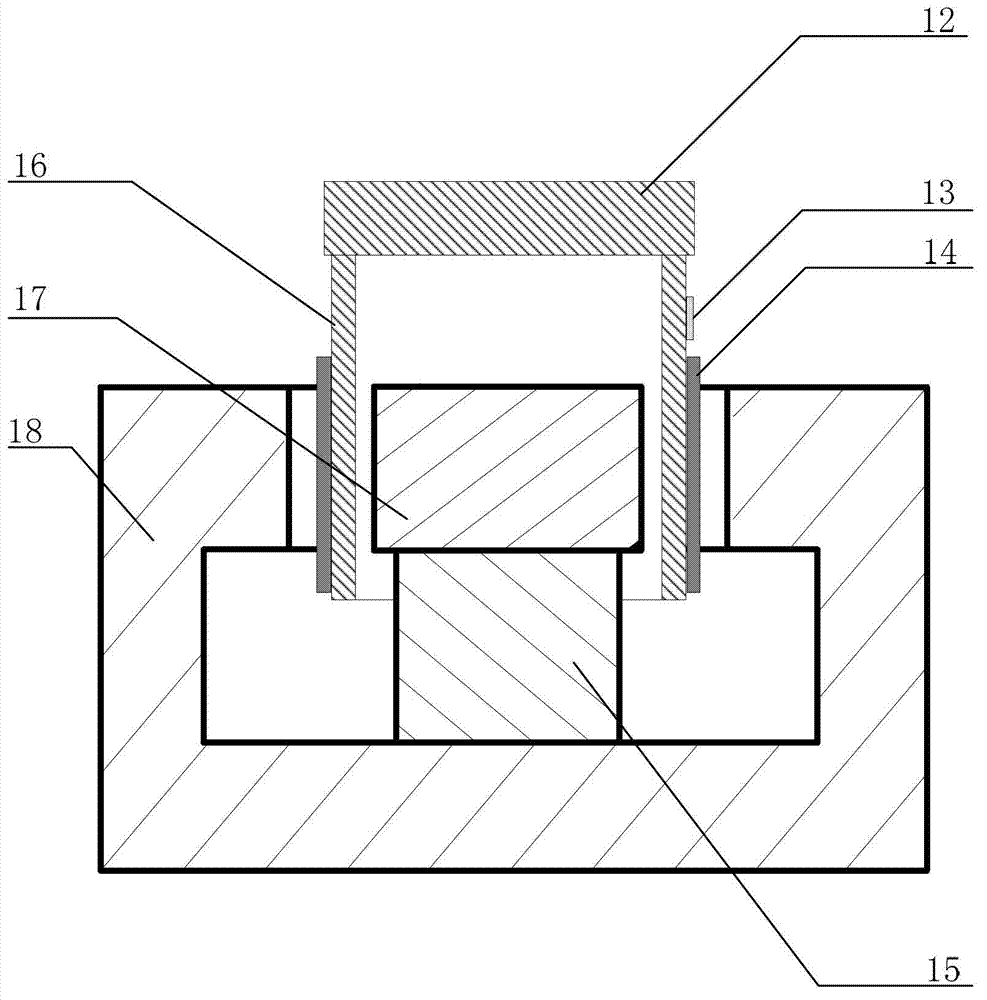

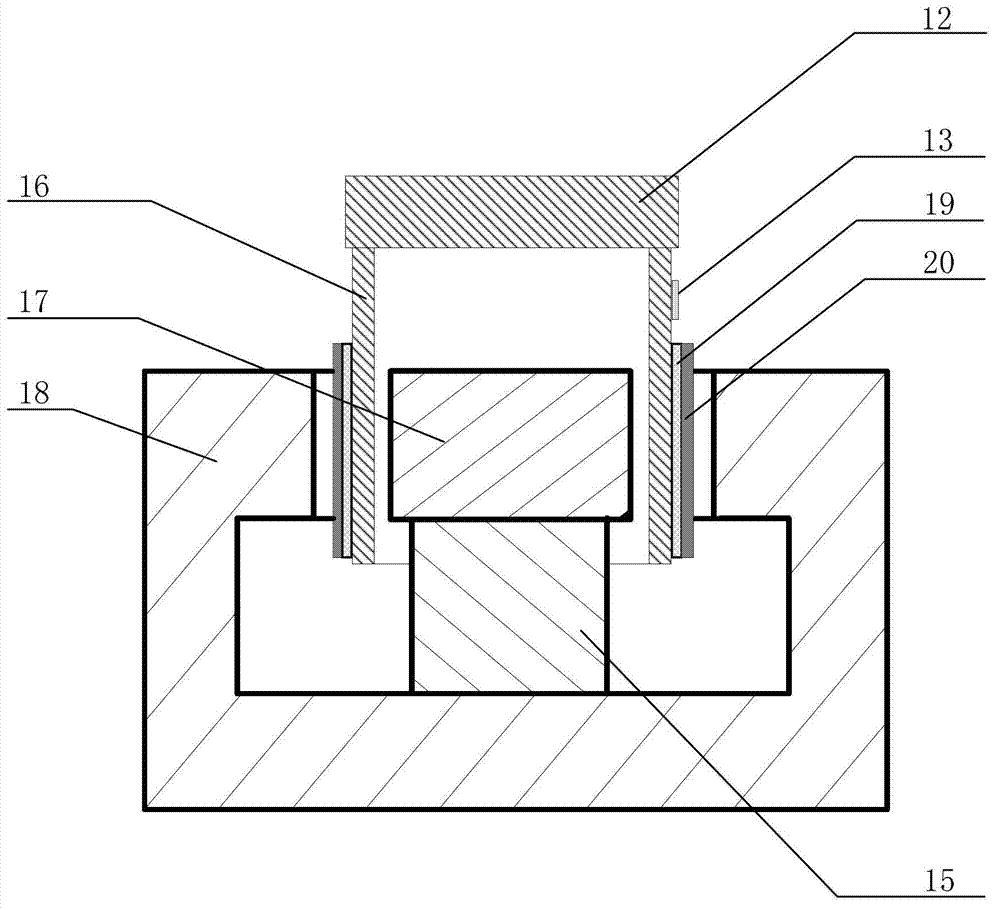

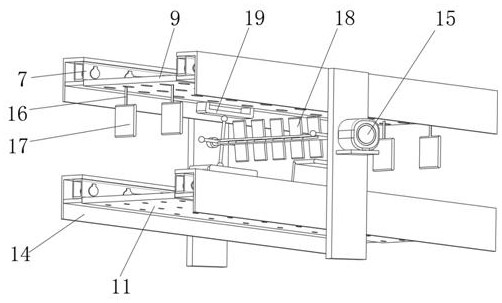

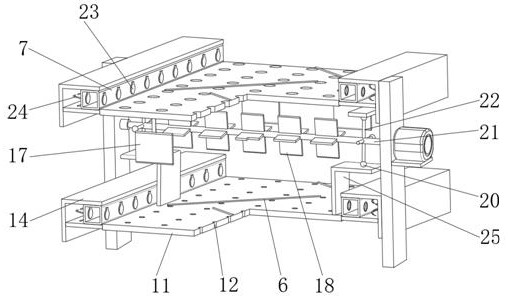

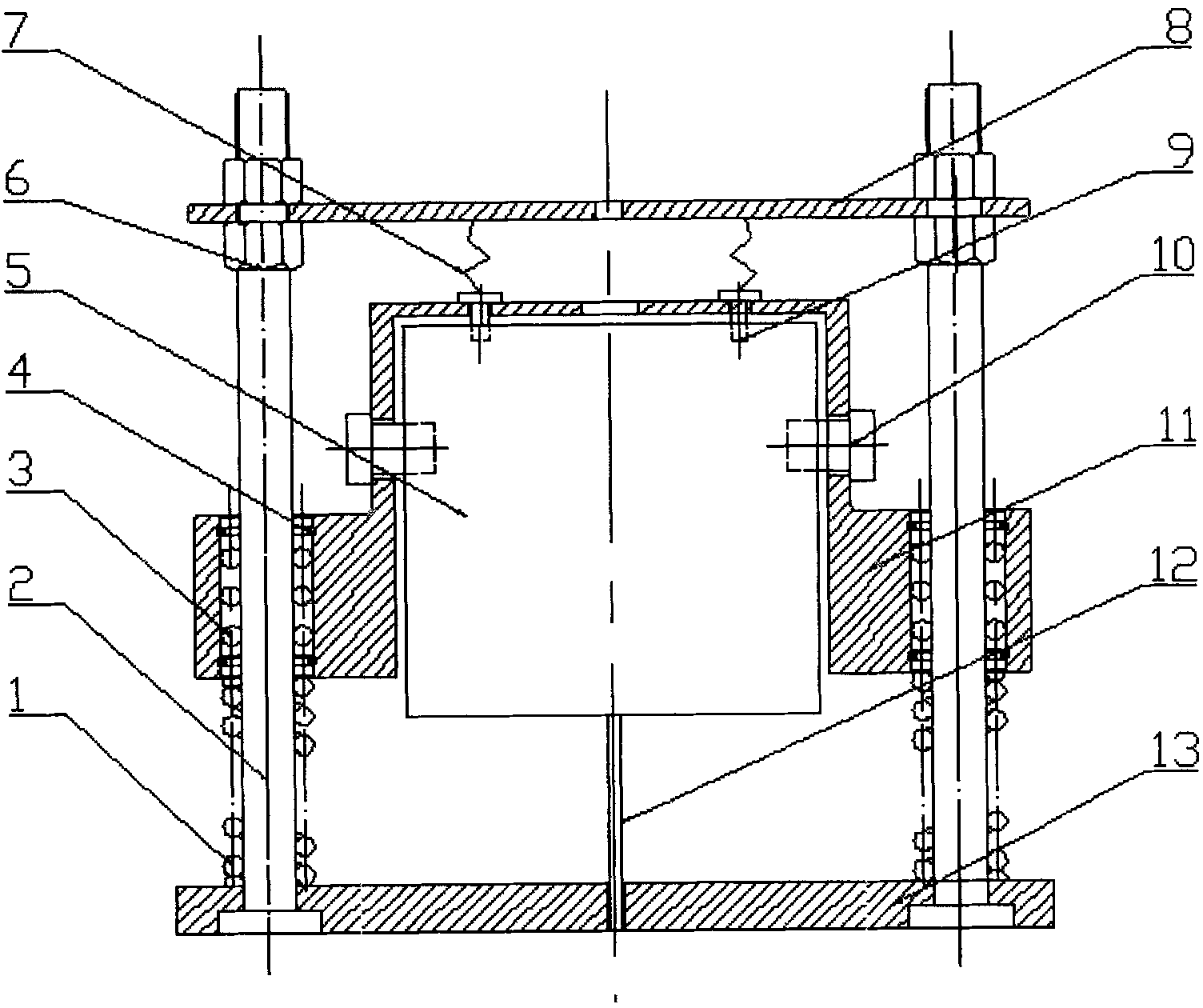

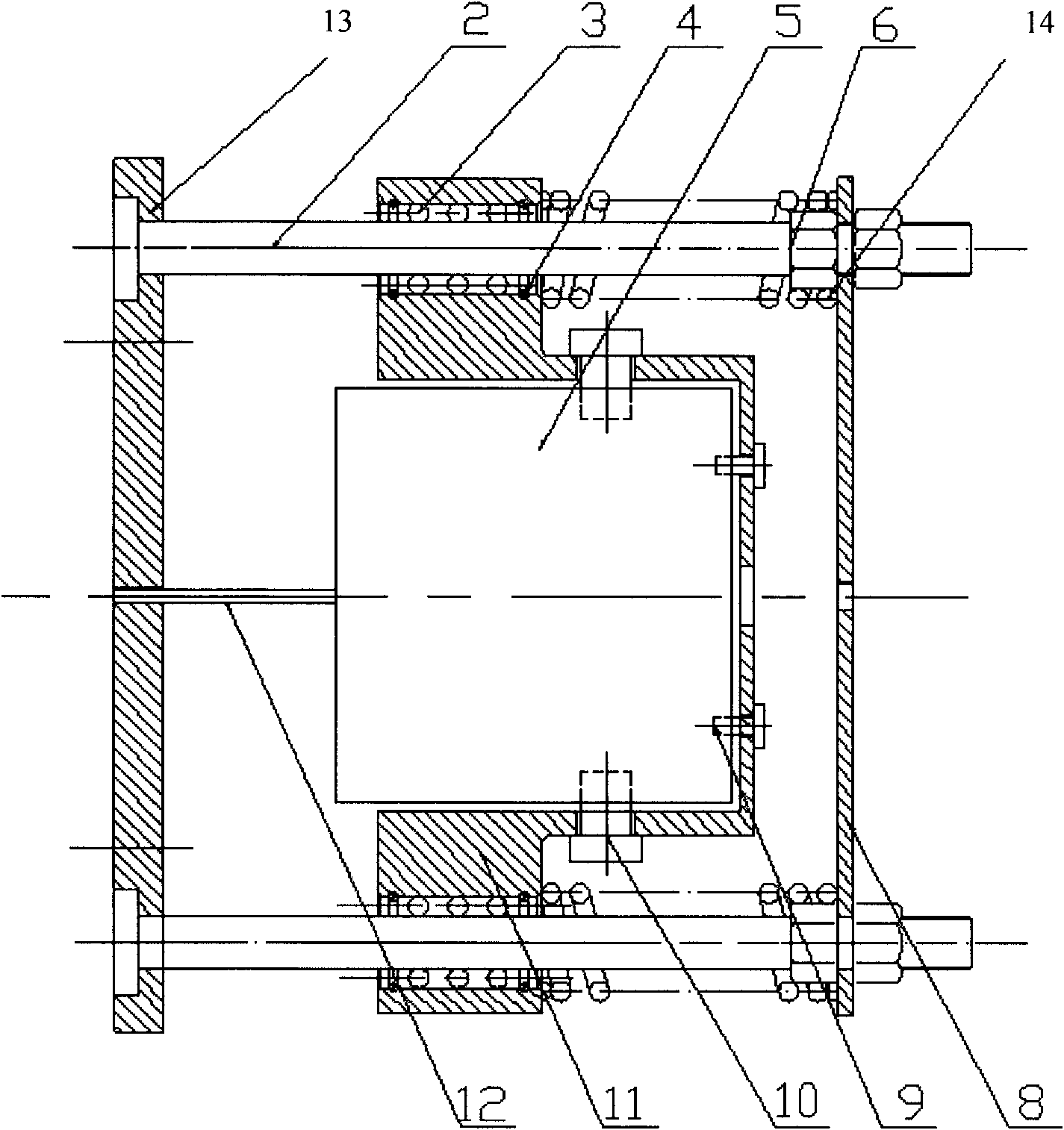

Damping-rigidness-controllable double-freedom-degree vibration active control platform

ActiveCN103398138AGood linearitySmall vibration rangeNon-rotating vibration suppressionCounterweightsEngineeringActuator

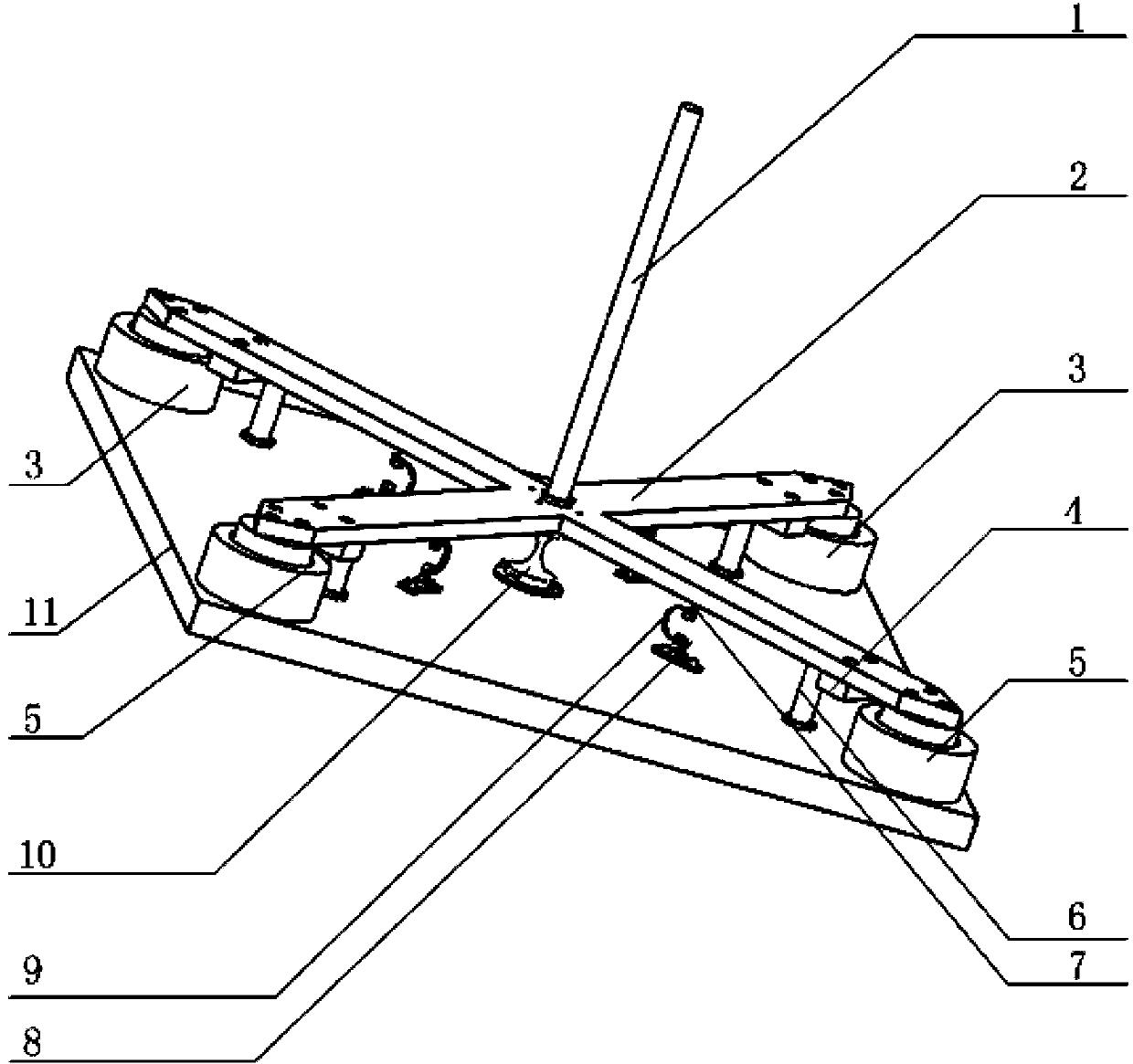

A damping-rigidness-controllable double-freedom-degree vibration active control platform comprises a cross-shaped beam frame and a square base which are connected through a flexible hinge. A cross-shaped beam of the cross-shaped beam frame is distributed in the diagonal directions of the square base. A structure column is arranged at the center of the cross-shaped beam frame. Sensors and actuators are connected between the lower portions of the diagonal top ends of the cross-shaped beam frame and the square base respectively. Four limiting columns are arranged between the cross-shaped beam of the cross-shaped beam frame and the square base respectively. Prearranged gaps are reserved between the limiting columns and the cross-shaped beam frame. Four balancing weights are fixed on the lower portion of the cross-shaped beam frame between the sensors or the actuators and the limiting columns respectively. Twisting limiting spring pieces are arranged at the symmetrical positions on the lower portion of the cross-shaped beam frame between the limiting columns and the flexible hinge. The electromagnetic type sensors and the electric-damping electric-rigidness actuators are used to achieve detecting of angular speed and actuating, the flexible hinge and the spring piece with changeable thickness are combined to achieve controllable damping and rigidness in a quantifying mode, and double-freedom-degree vibration active control in the x direction and the y direction of the structure is achieved.

Owner:XI AN JIAOTONG UNIV

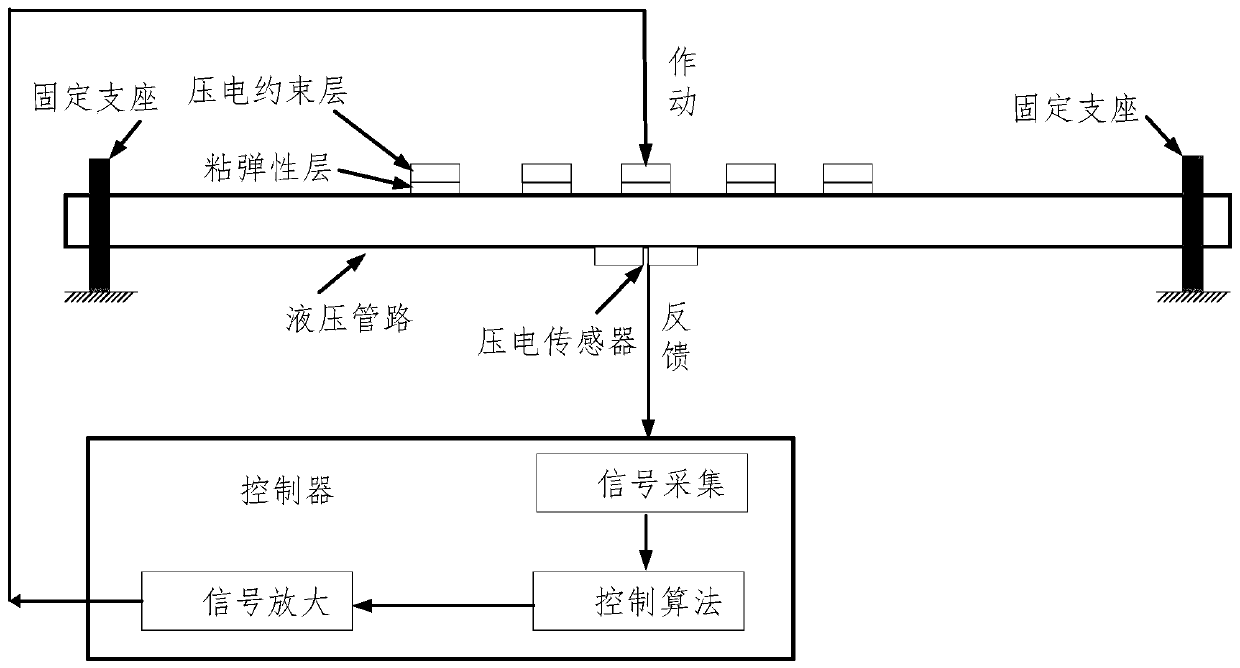

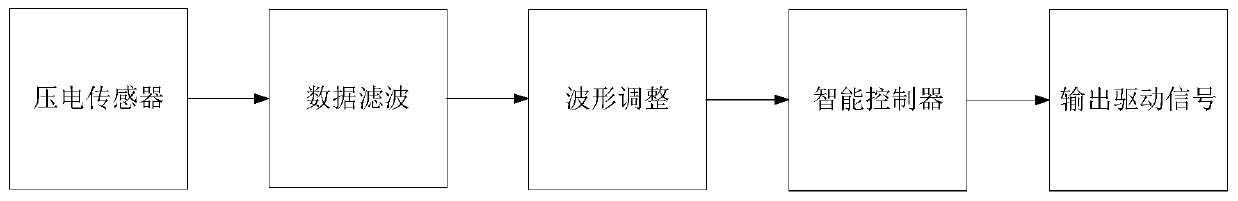

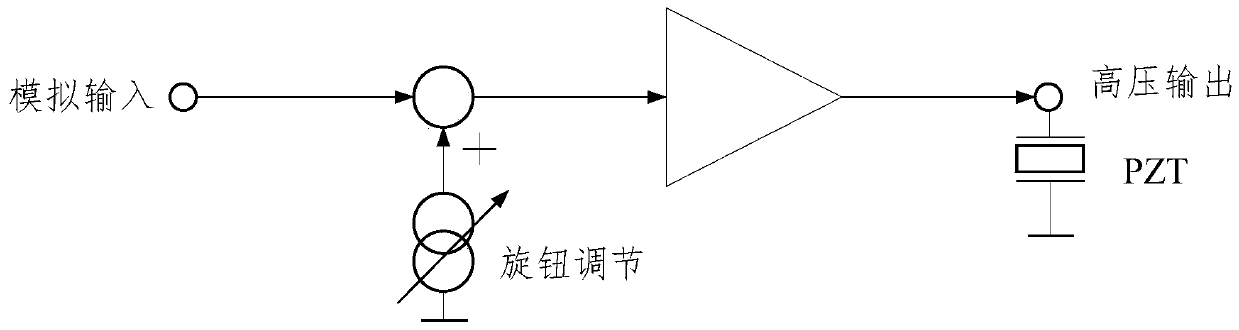

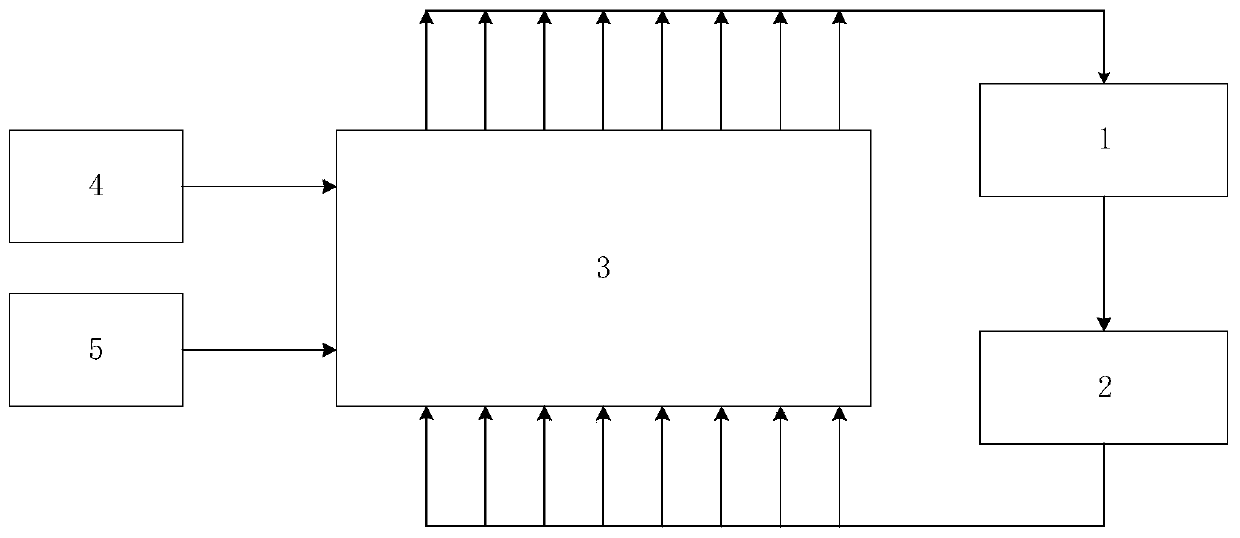

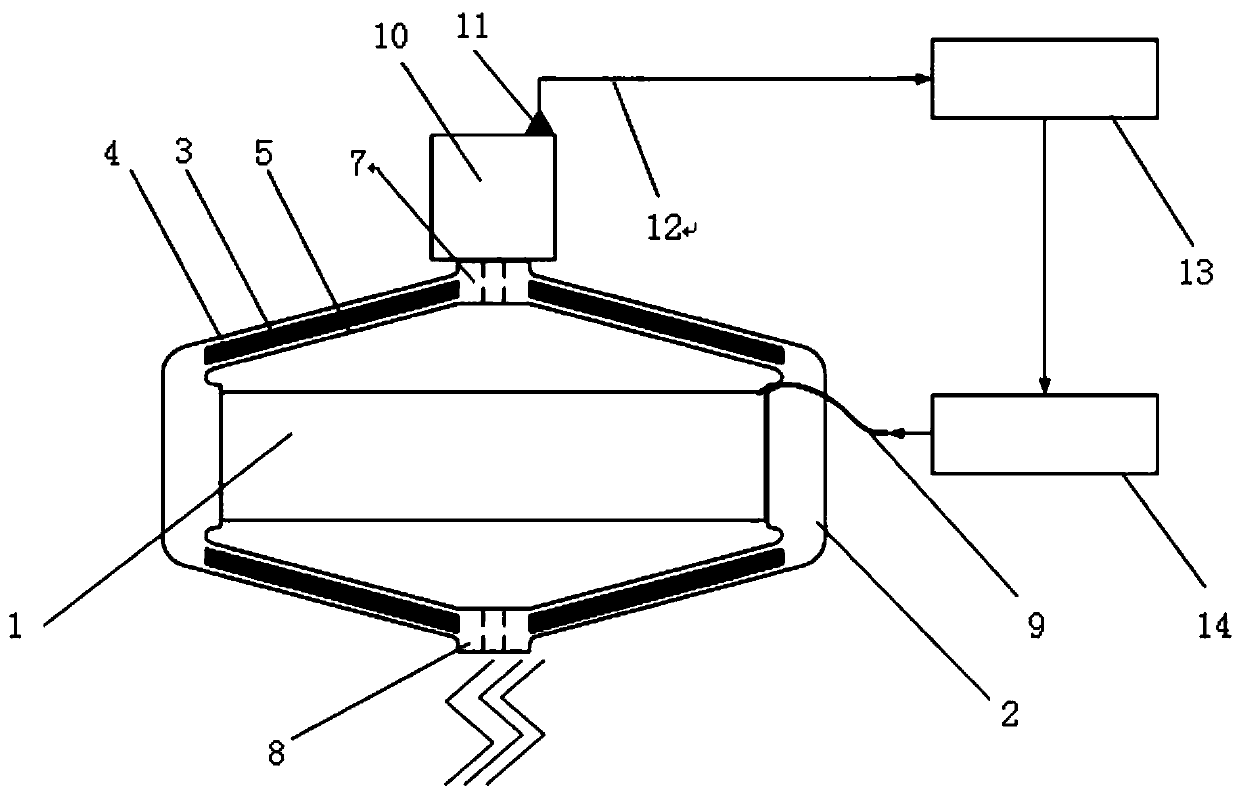

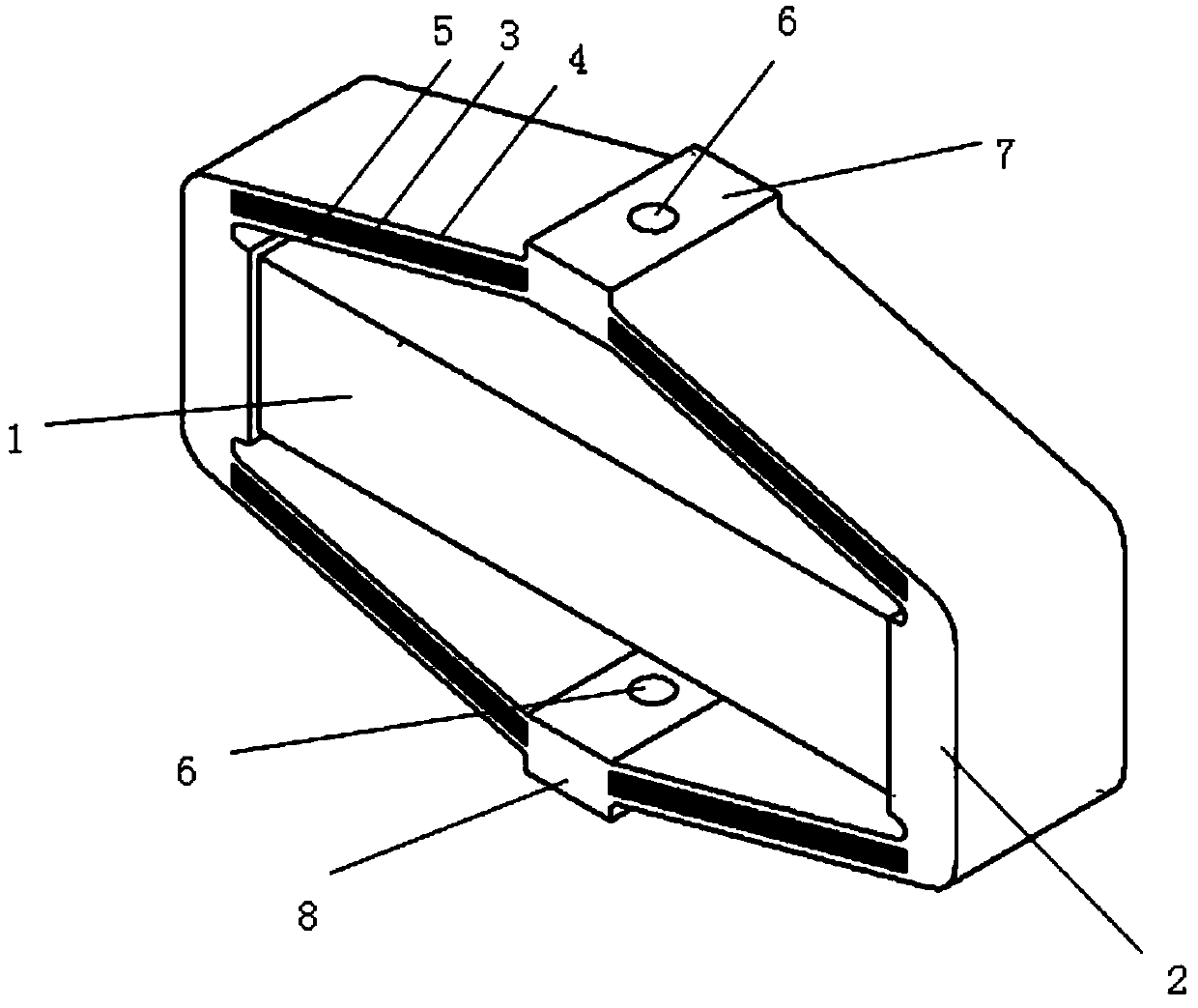

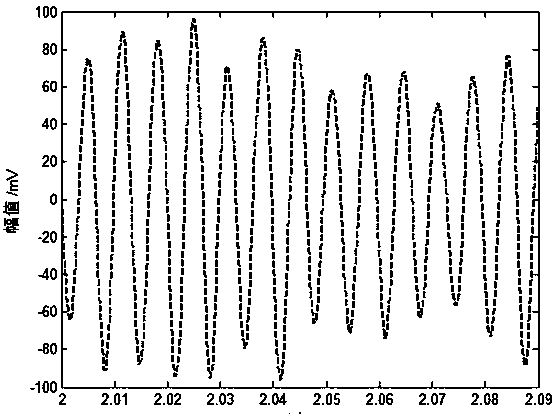

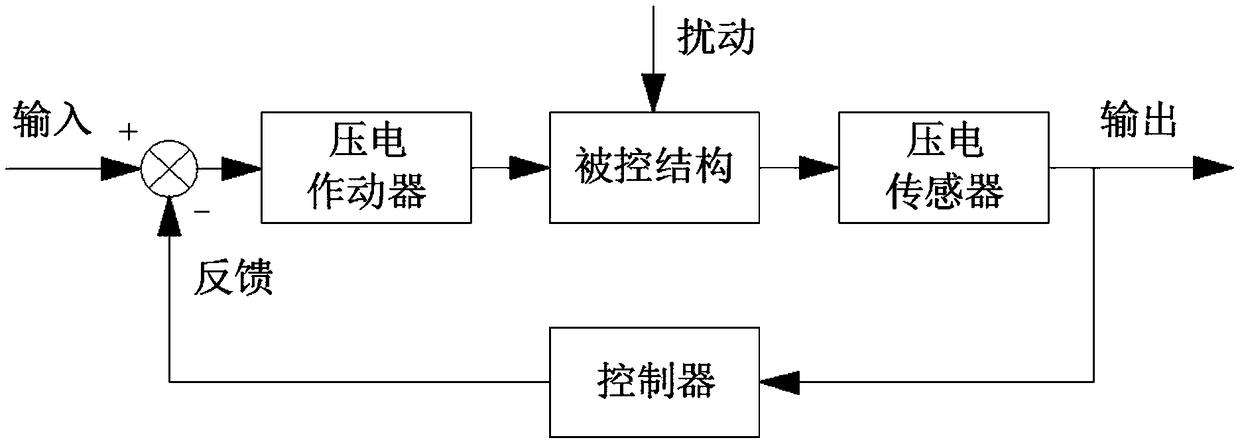

Pipeline vibration active control system with band gap characteristic

InactiveCN111522372ASimple structureAchieve Vibration ControlMechanical oscillations controlPipe elementsVibration amplitudeVibration control

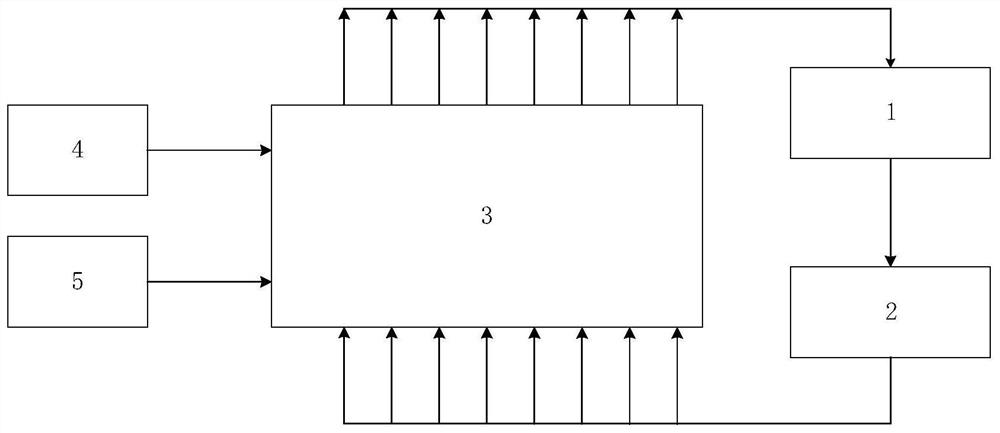

The invention discloses a pipeline vibration active control system with a band gap characteristic, and belongs to the technical field of vibration control in the field of machinery. The system adoptsthe band gap characteristic of a periodic structure and an intelligent damping material to control pipeline vibration. The system comprises a pipeline, a piezoelectric sensor, a signal conversion unit, an upper computer, an active controller, a voltage amplifier, a viscoelastic damping layer and piezoelectric ceramic, wherein the viscoelastic damping layer is periodically attached to the outer wall of the controlled pipeline. The piezoelectric sensor receives a vibration signal of the pipeline, the vibration signal is input to the active controller and the upper computer through the signal conversion unit to be calculated to obtain a feedback signal, the feedback signal is transmitted to the piezoelectric ceramic piece attached to the outer wall of the controlled pipeline through the voltage amplifier, and the piezoelectric ceramic piece deforms to enable the viscoelastic damping material to generate shear deformation. Due to the band gap characteristic of the periodic structure, the propagation of vibration of a specific frequency is attenuated in the structure. The two effects are combined to reduce the vibration amplitude of the pipeline.

Owner:DALIAN UNIV OF TECH

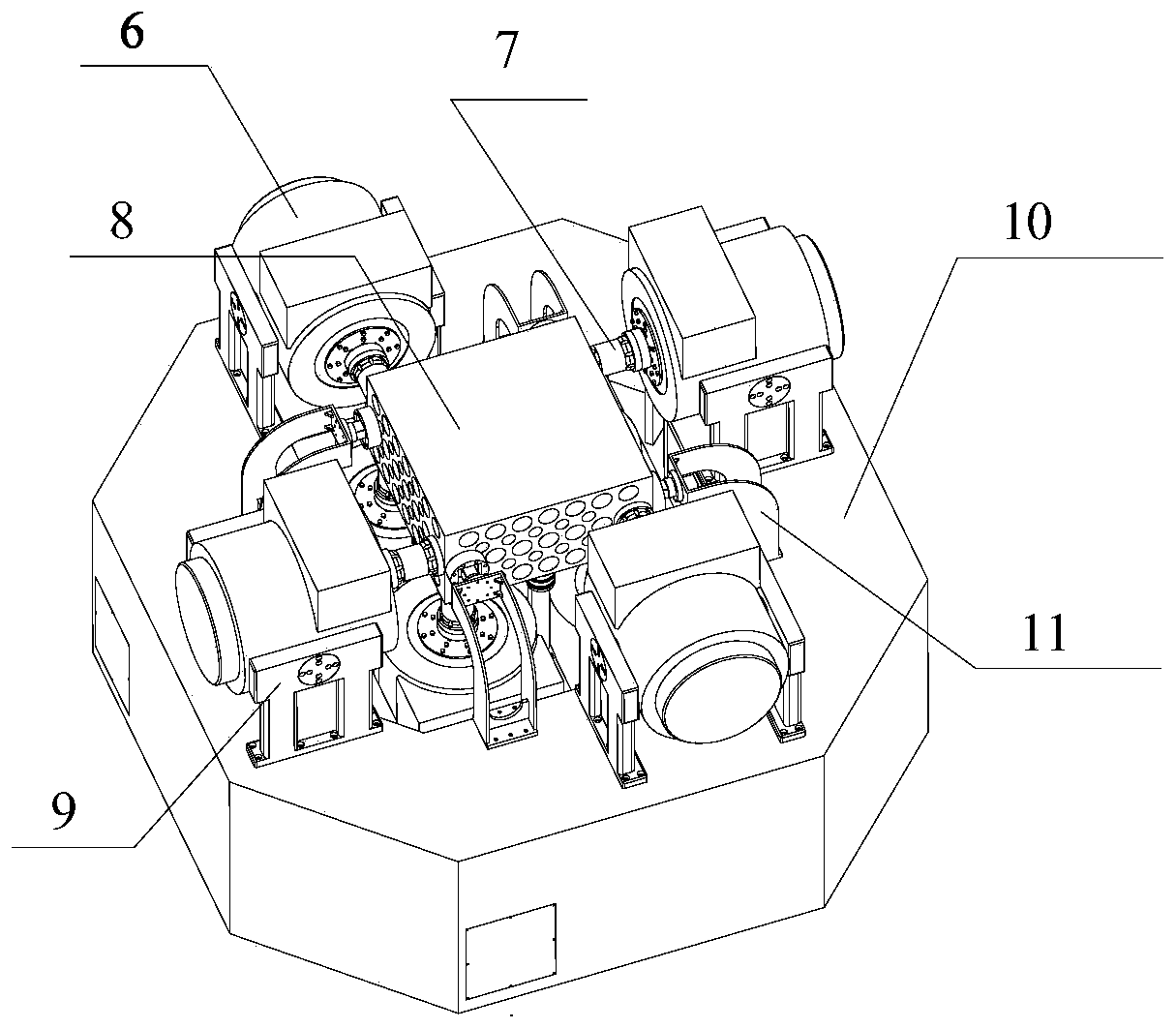

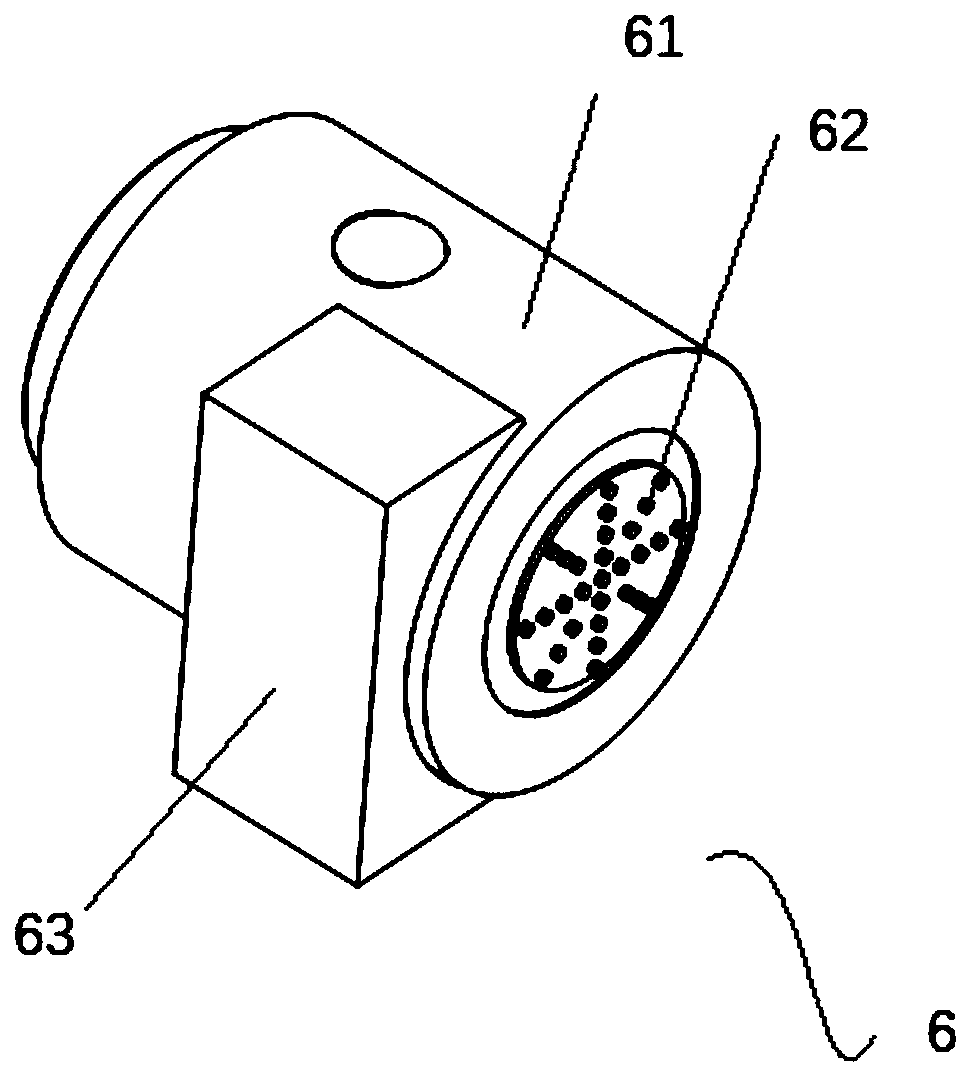

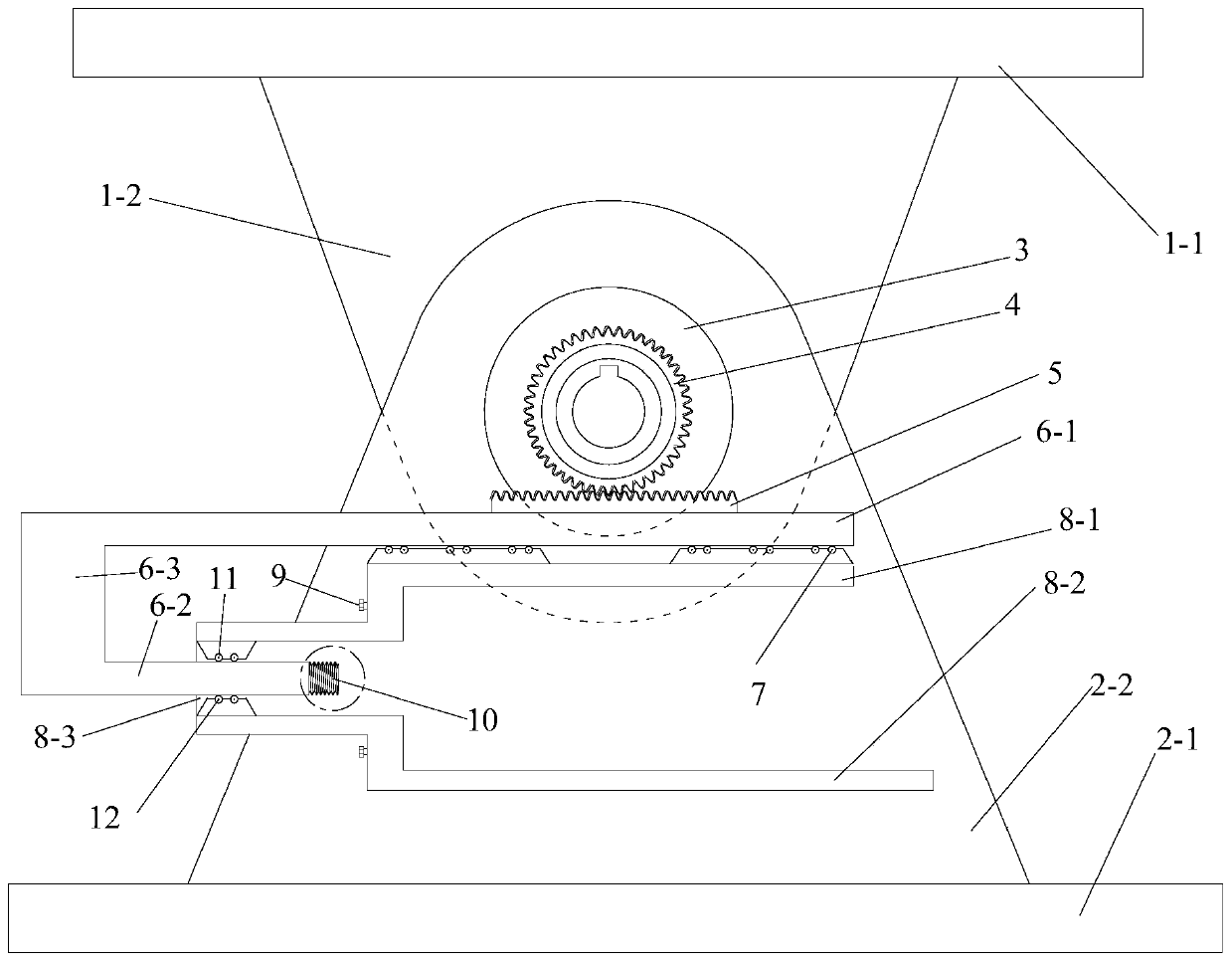

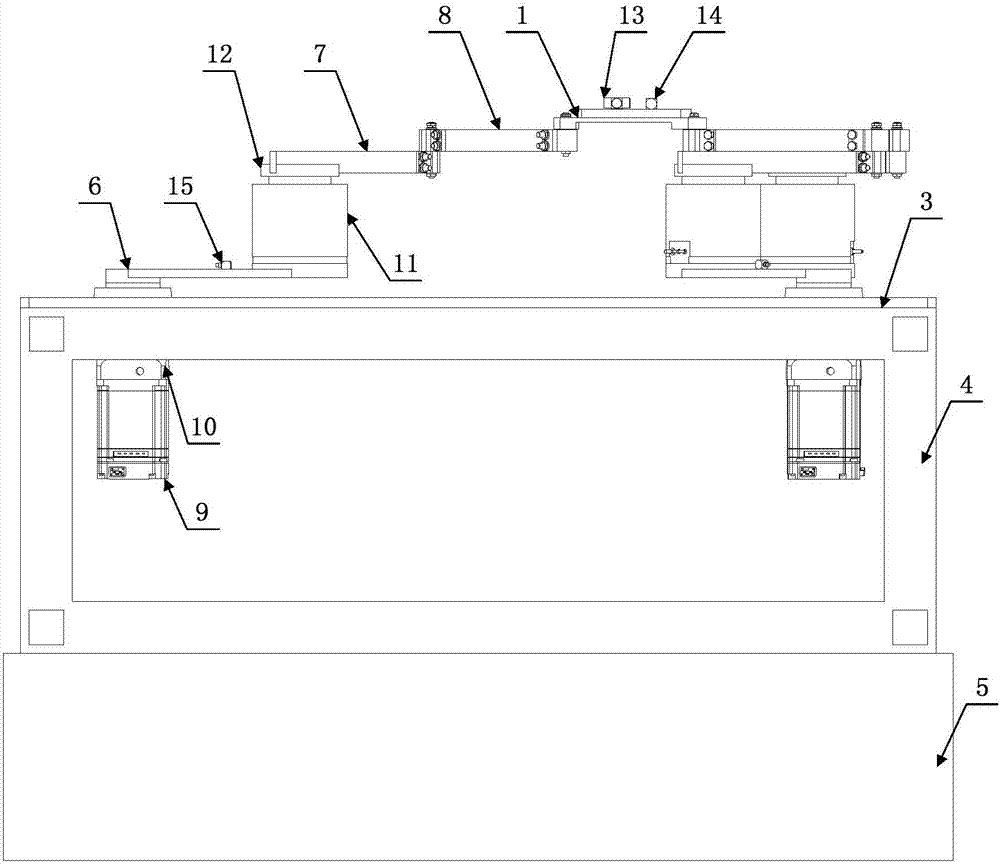

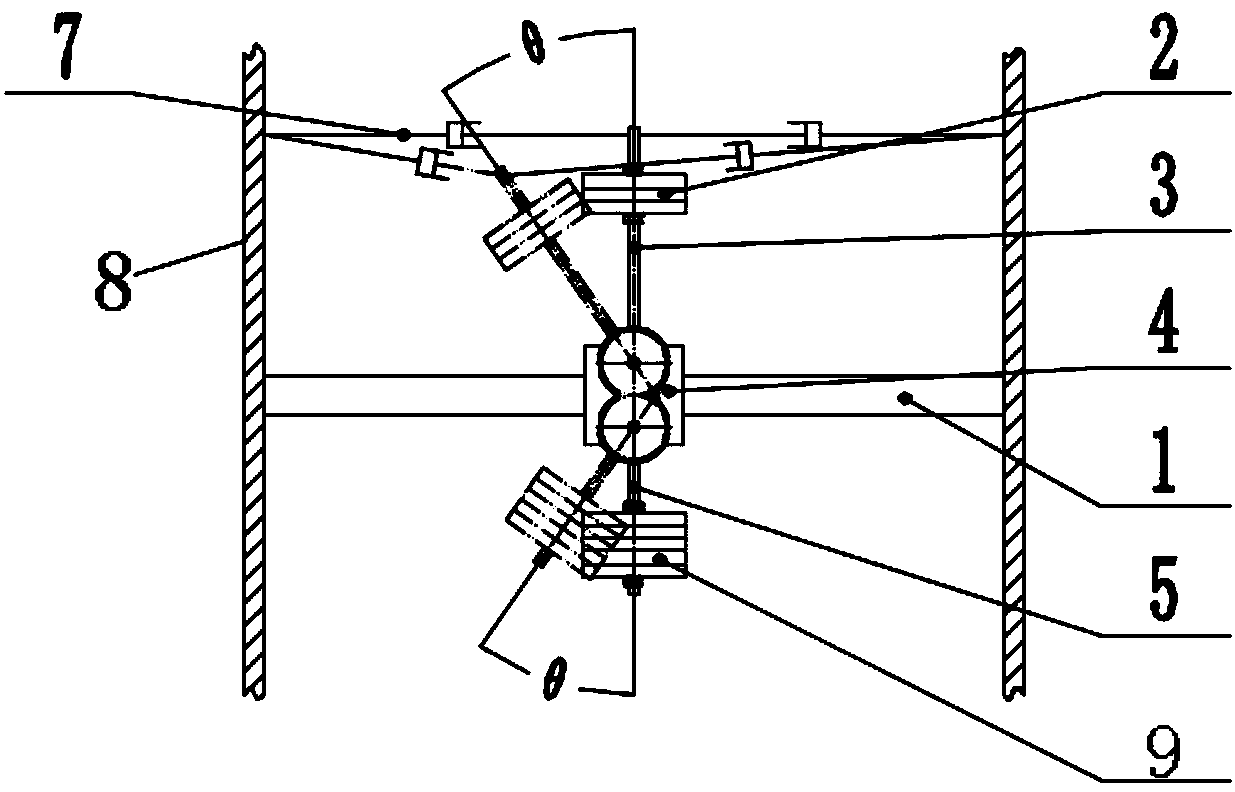

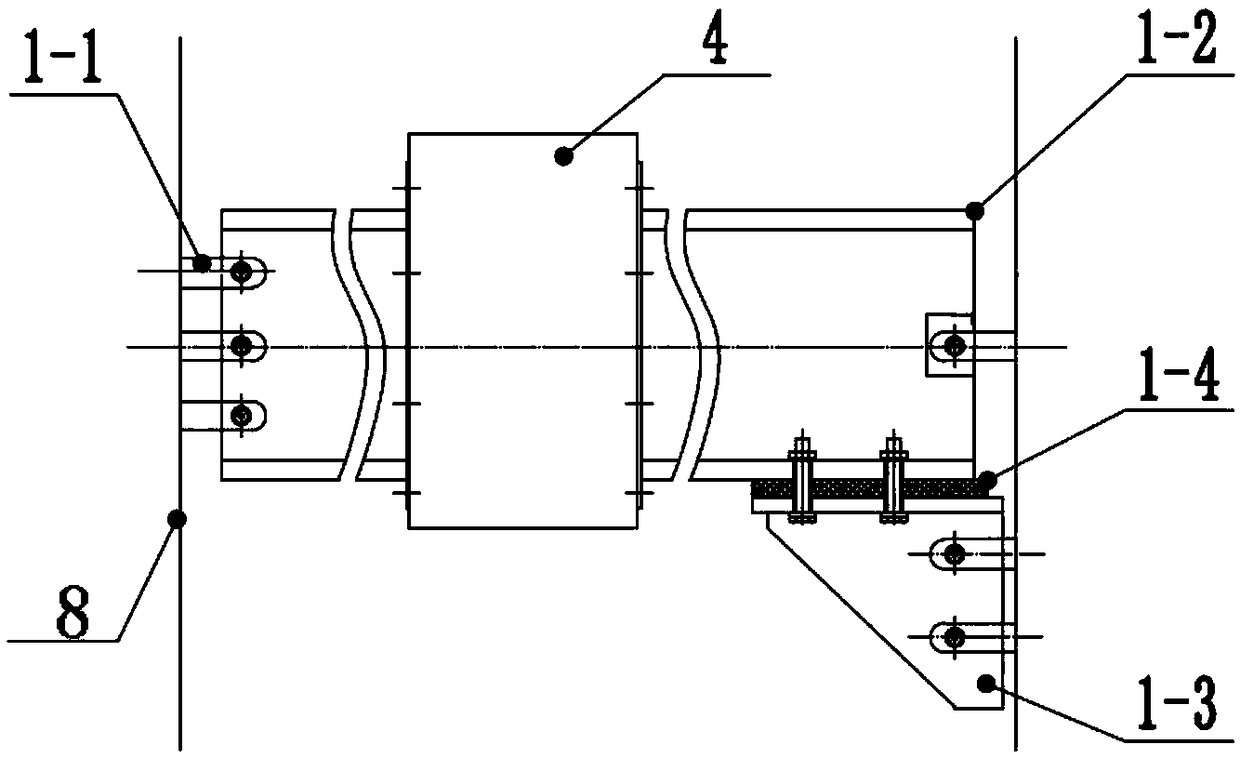

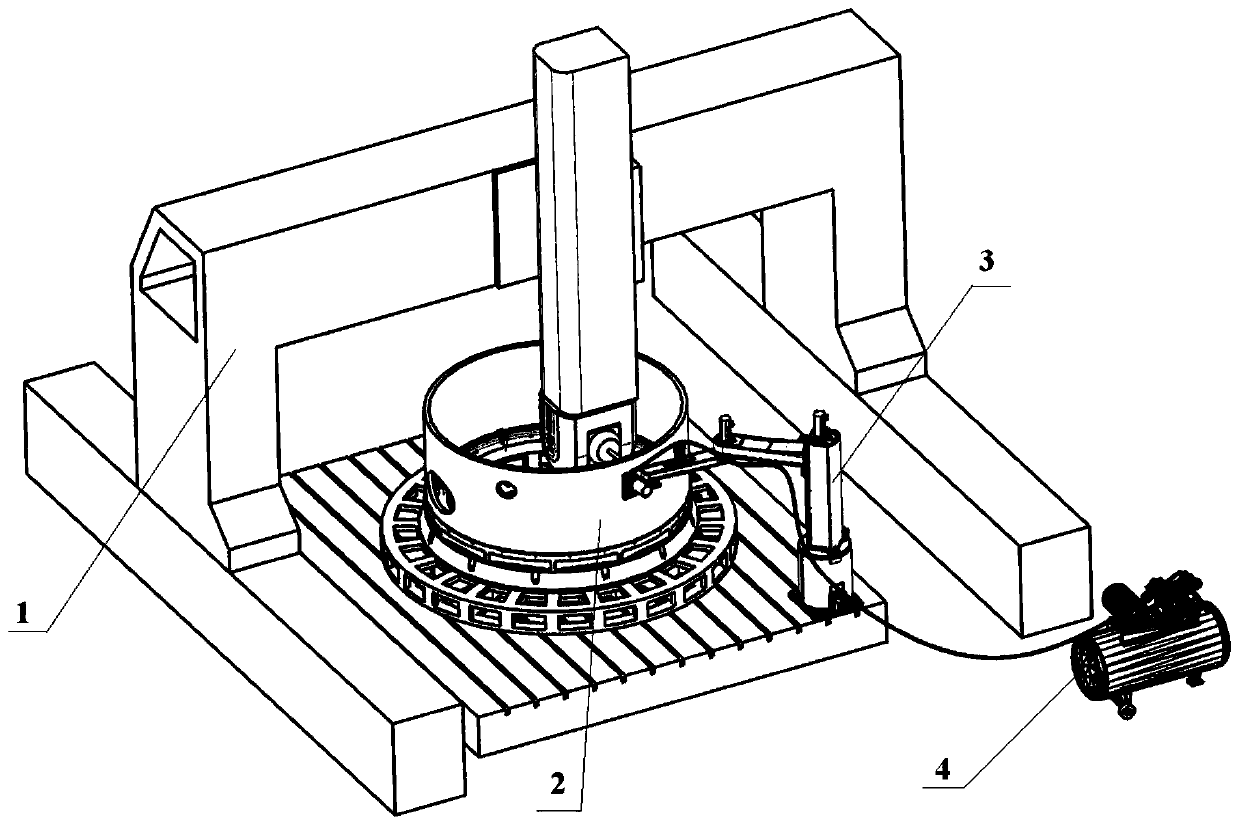

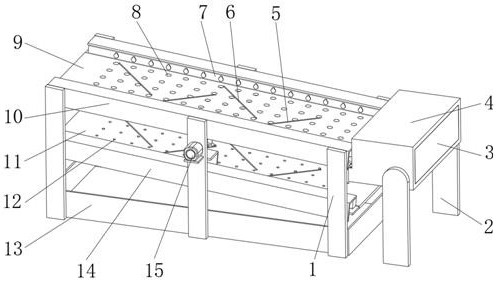

Tri-axial and six-degree-of-freedom vibration test device

ActiveCN110243563AAchieve Vibration ControlLarge thrustVibration testingTrunnionSix degrees of freedom

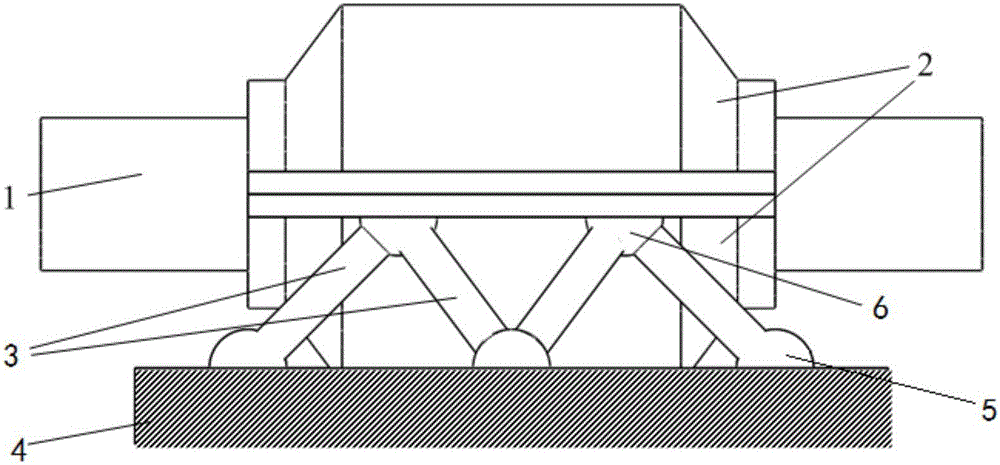

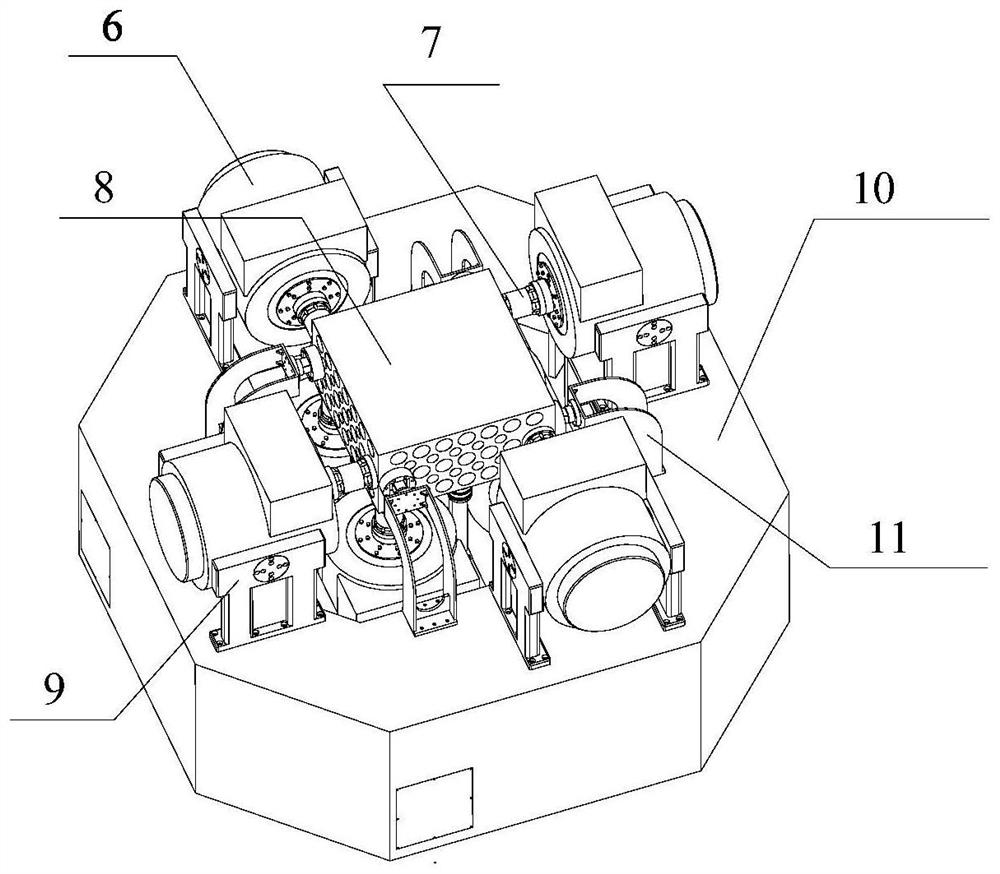

The invention discloses a tri-axial and six-degree-of-freedom vibration test device. The device comprises a MIMO controller, a power amplifier system, a vibration platform, a vapor system and a hydraulic system; the MIMO controller generates a driving voltage signal, and then inputs the driving voltage signal into the vibration platform through the power amplifier system, and meanwhile, the response on a vibration plane is fed back to the MIMO controller; the vapor system is connected with the vibration platform, the hydraulic system is connected with the vibration platform, and the vibration platform comprises electric vibration tables, hydrostatic pressure bearings, a vibration board, trunnion brackets, a base and a ball hinge over-displacement protection device; the electric vibration tables are connected with the base through the corresponding trunnion brackets; and the electric vibration tables are connected with the vibration board through the hydrostatic pressure bearings; the electric vibration tables are connected to lower surface of the vibration board and various laterals of the vibration board through the hydrostatic pressure bearings; and the vibration board is connected with the base through the ball hinge over-displacement protection device and an auxiliary support device.

Owner:CHINA AERO POLYTECH ESTAB

One-way damping hinge device and method for controlling passive vibration of structure by using same

ActiveCN109826480AImproved Vibration Control EfficiencySmooth transmissionProtective buildings/sheltersShock proofingVibration controlControl theory

The invention discloses a one-way damping hinge device, which comprises an upper connecting support, a lower connecting support and a hinge shaft, wherein the hinge shaft is fixedly connected with theupper connecting support; the hinge shaft is rotatably connected with the lower connecting support; a gear rack transmission mechanism, a damper mounting frame and a U-shaped transmission curved rodwhich is fixedly connected with an input rod of a damper are arranged on the lower connecting support; the gear rack transmission mechanism comprises a driving gear and a driven gear rack which are meshed with each other; the driving gear is fixedly connected with the hinge shaft; the driven gear rack is fixedly connected with the U-shaped transmission curved rod; and rollers are arranged betweenthe damper mounting frame and the U-shaped transmission curved rod. In addition, the invention also provides a method for controlling passive vibration of a structure by using the one-way damping hinge device. According to the one-way damping hinge device, the gear transmission principle is utilized, so that the capability of the building structure to resist vibration load can be effectively improved, the vibration control efficiency of the building structure is improved, and a new and effective method is provided for the vibration control of the structure in the field of civil engineering.

Owner:CHANGAN UNIV

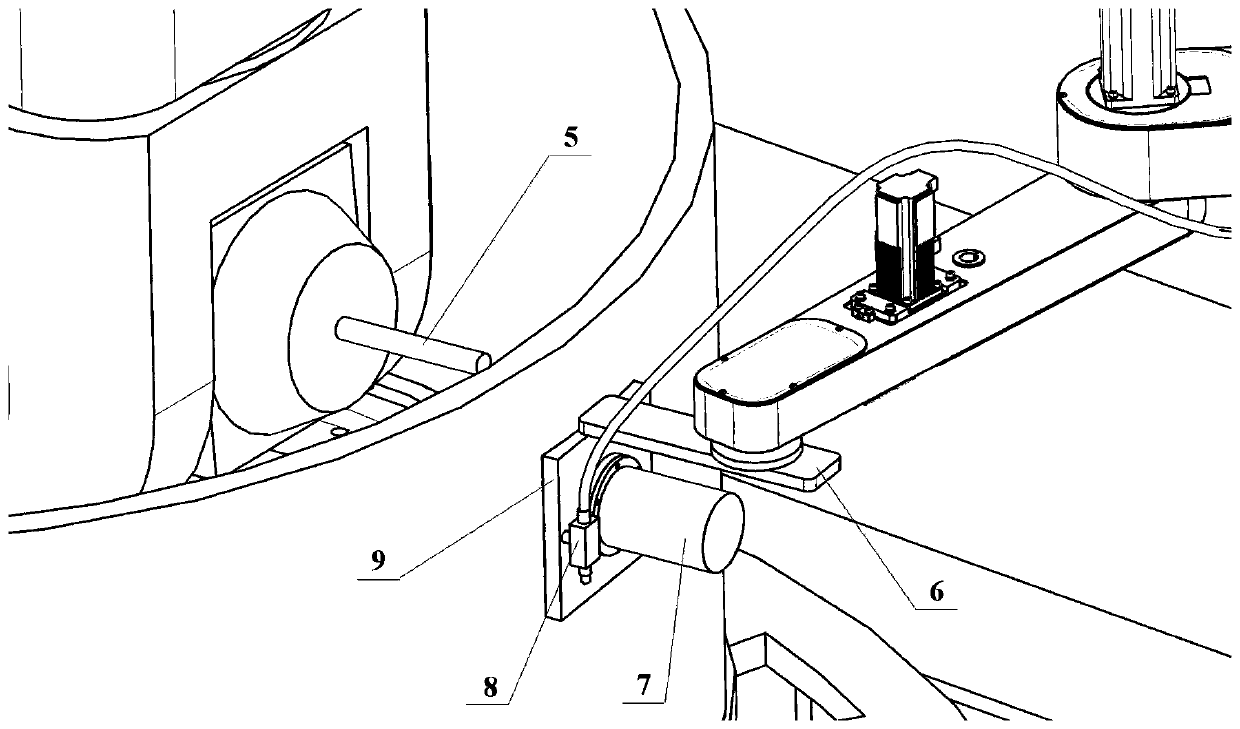

Two-stage distributed combined dynamic vibration absorber vibration reduction method aiming at thin-wall part multi-mode time-varying cutting vibration control

InactiveCN106271861ASolve the problem of not damping vibration wellGood vibration reduction effectMaintainance and safety accessoriesSingle stageOptimal control

The invention provides a two-stage distributed combined dynamic vibration absorber vibration reduction method aiming at thin-wall part multi-mode time-varying cutting vibration control and belongs to the technical field of damping vibration reduction. According to a first stage, multiple sets of or multiple dynamic vibration absorbers are arranged on mode formation sensitive points on a thin-wall structure part to achieve control over part multi-mode cutting vibration probably excited by cutting force on the whole cutting path in the cutting machining process. According to a second stage, multiple sets of dynamic vibration absorbers arranged on each mode formation sensitive point are tightly attached, the inherent frequencies of all dynamic vibration absorbers in the multiple sets (multiple) dynamic vibration absorbers are unequal, and therefore optimal control over time-varying cutting vibration caused by part inherent frequency migration caused by removal of a workpiece material in the cutting process is achieved. Compared with single-stage vibration absorbers, the two-stage distributed combined dynamic vibration absorbers have the advantages of being good in vibration reduction effect, large in bandwidth, good in robustness and the like, and can be installed and adjusted at a time to achieve effective control over vibration generated in the whole cutting process.

Owner:BEIJING UNIV OF TECH +1

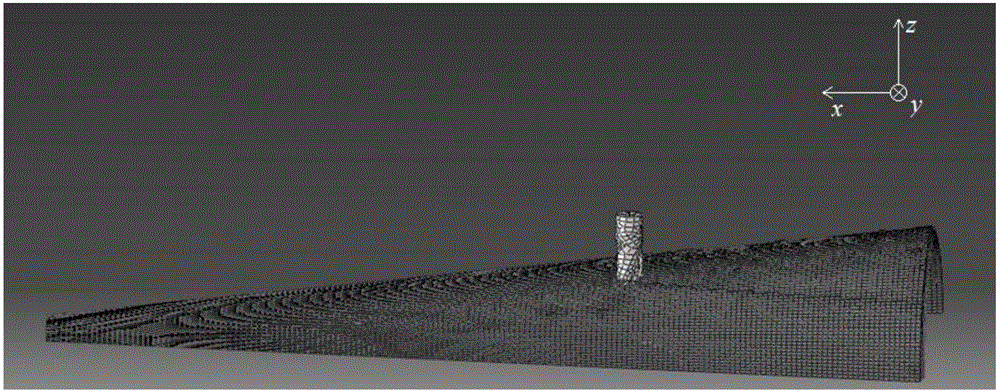

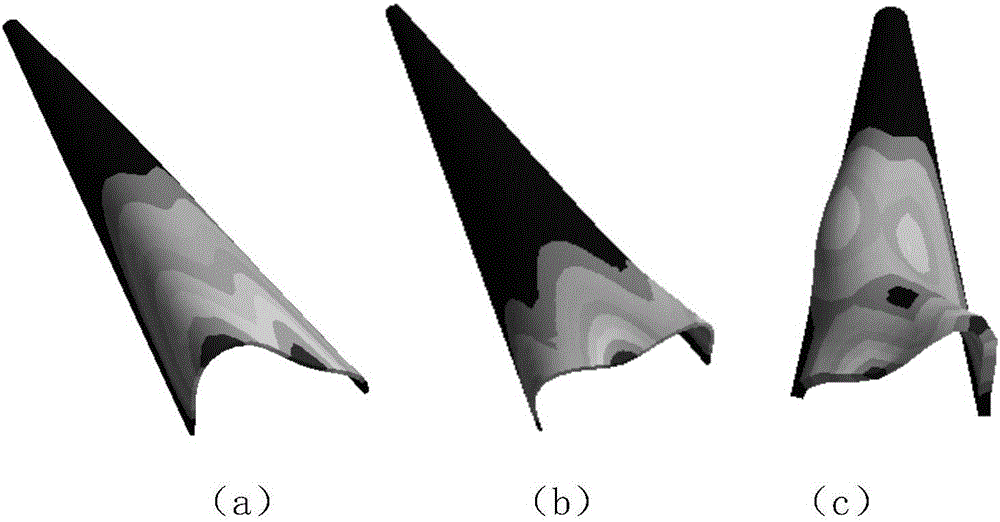

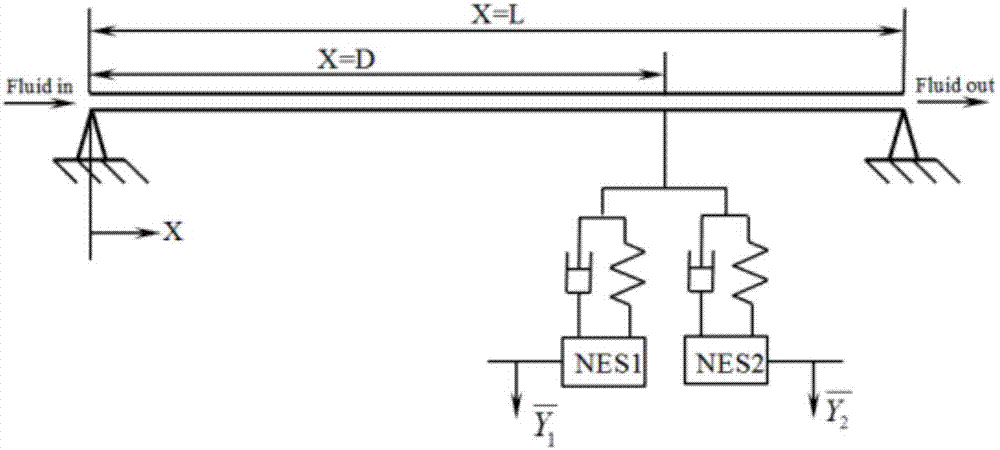

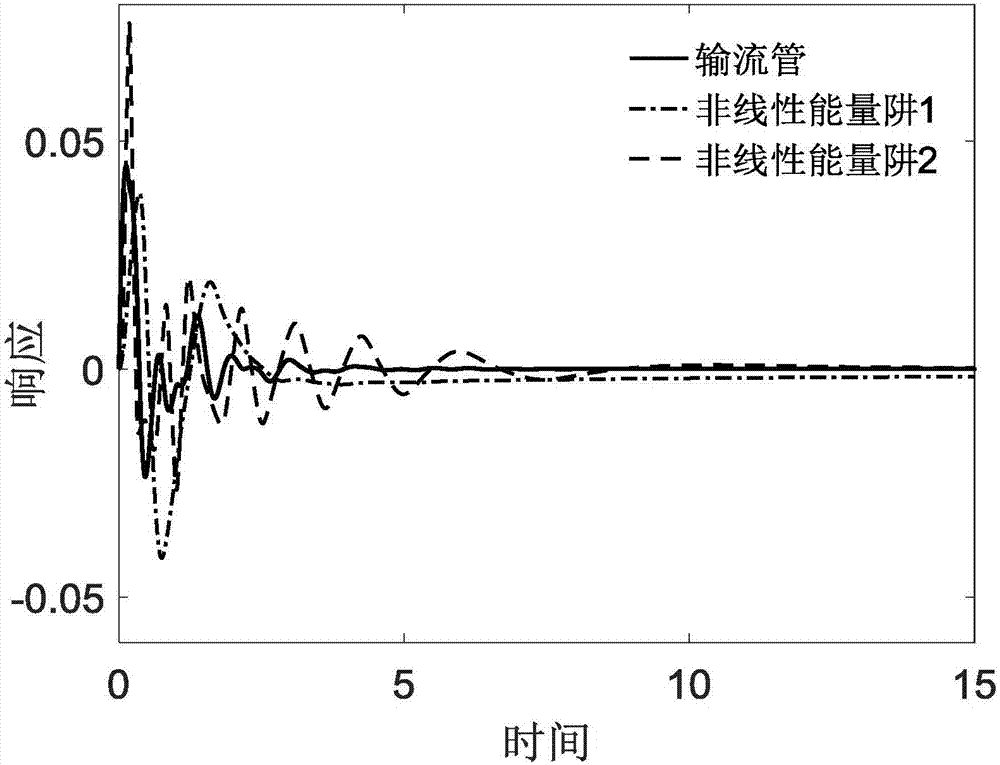

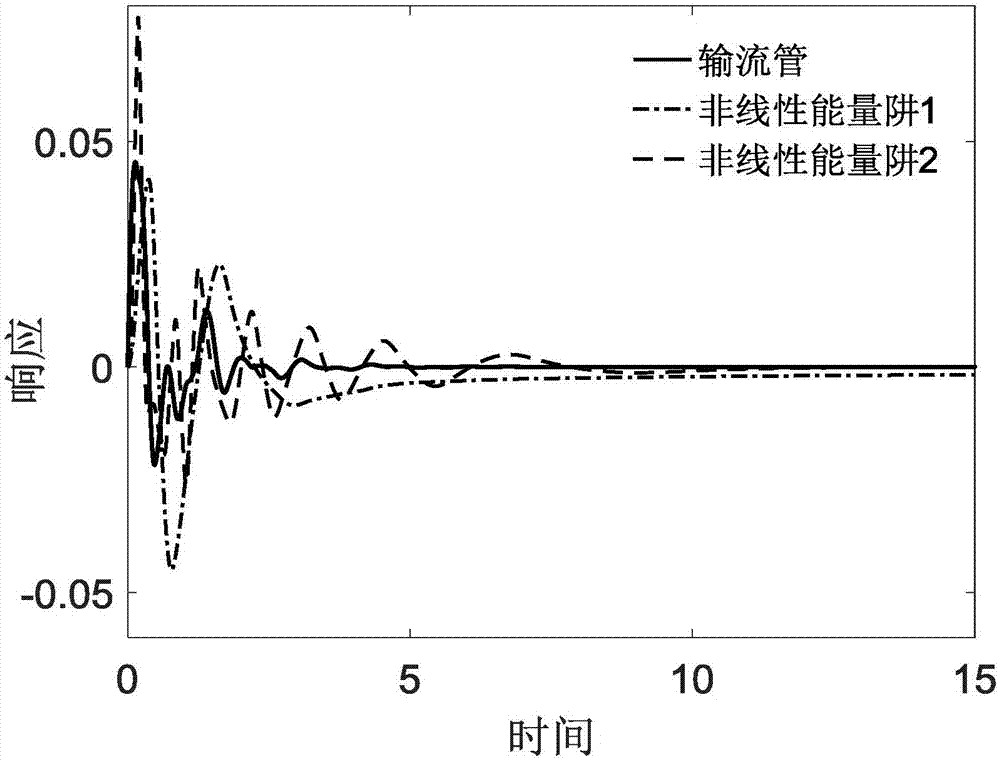

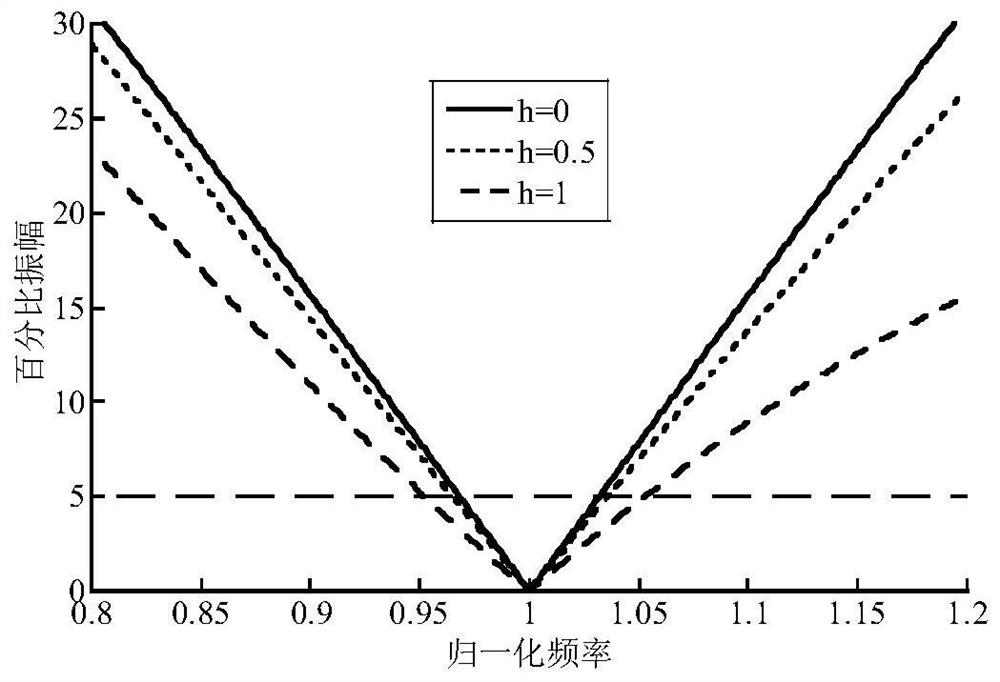

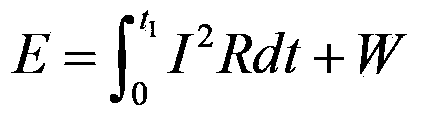

Method and device for designing and optimizing passive vibration controller for fluid conveying pipe vibration control

ActiveCN107169220ASimple structureLow reliabilityDesign optimisation/simulationMulti-objective optimisationEnergy transferVibration control

The invention discloses a method for designing and optimizing a passive vibration controller for fluid conveying pipe vibration control, and aims at solving the excessive vibration problem of fluid conveying pipes, providing the advantages of being free of external energy input and simple in installation operation, and breaking through the problem that the passive controller are relatively large in mass. The passive controller consists of parallel nonlinear energy traps; in order to verify the vibration control effect of the vibration controller, a mathematic model of a fluid conveying pipe-vibration controller system is established on the basis of a target energy transfer theory; and after dimension reduction and discretization are carried out on a dimensionless model through a standard Galerkin method, numerical simulation of the system is completed under a boundary condition of the system. Results indicate that the vibration controller is capable of rapidly and effectively dissipating the vibration energy of the fluid conveying pipes via a mass which is 5% of the mass of the whole system. Finally, the control is optimized through a ratio function of the energy dissipated by the controller and the total energy of the system; and the optimization result indicates that the precision requirement for mounting positions is not high in a certain range.

Owner:DALIAN UNIV OF TECH

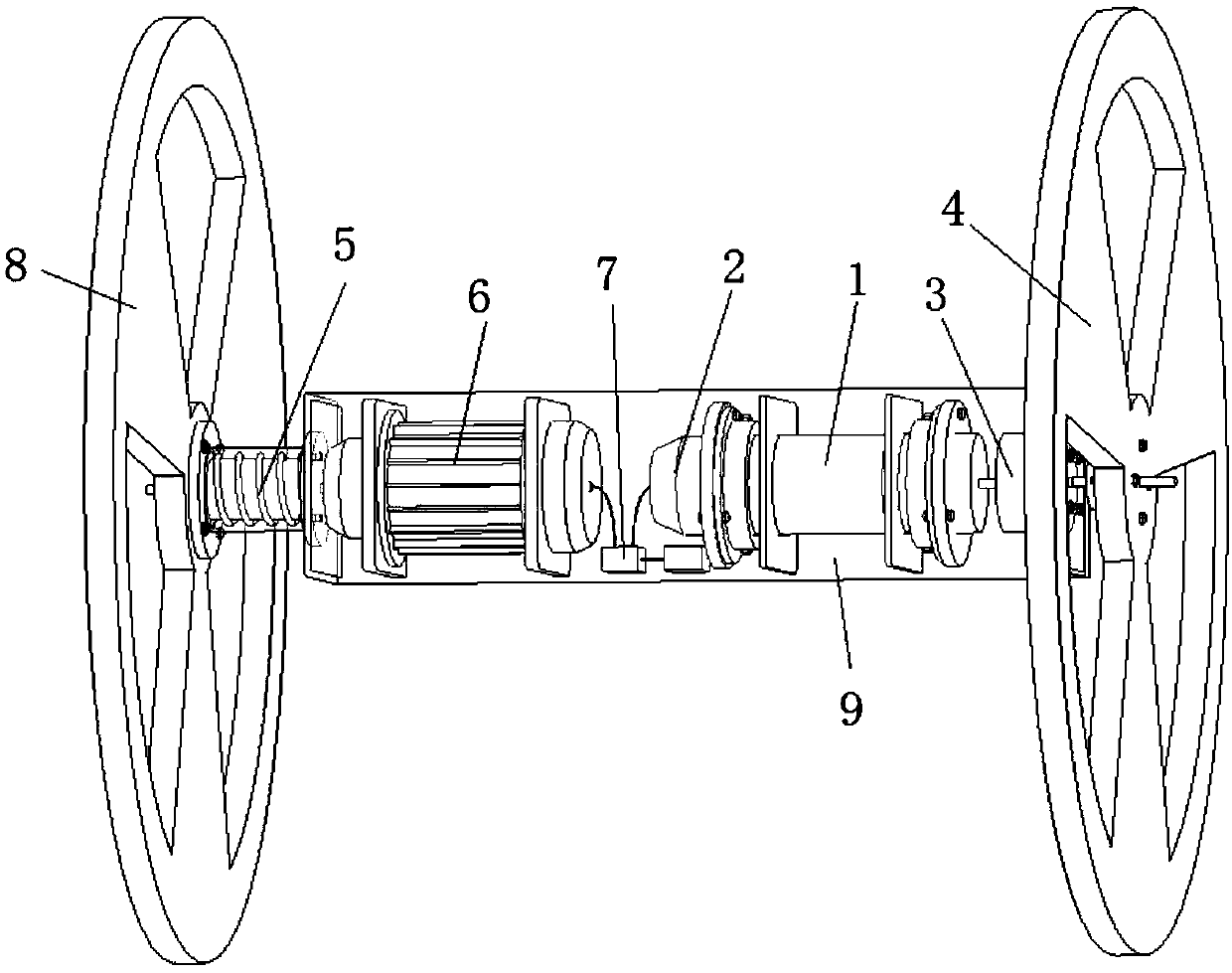

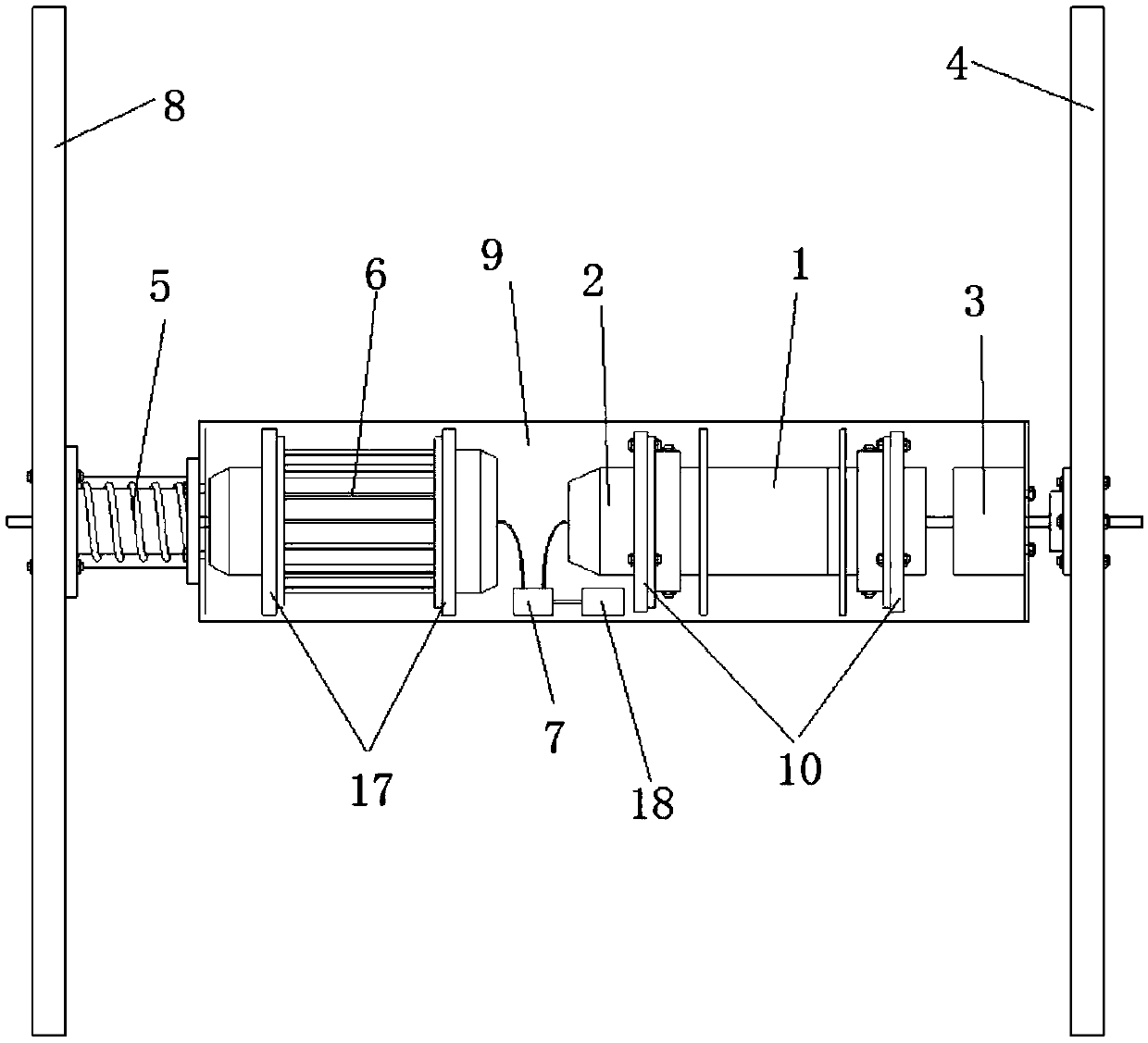

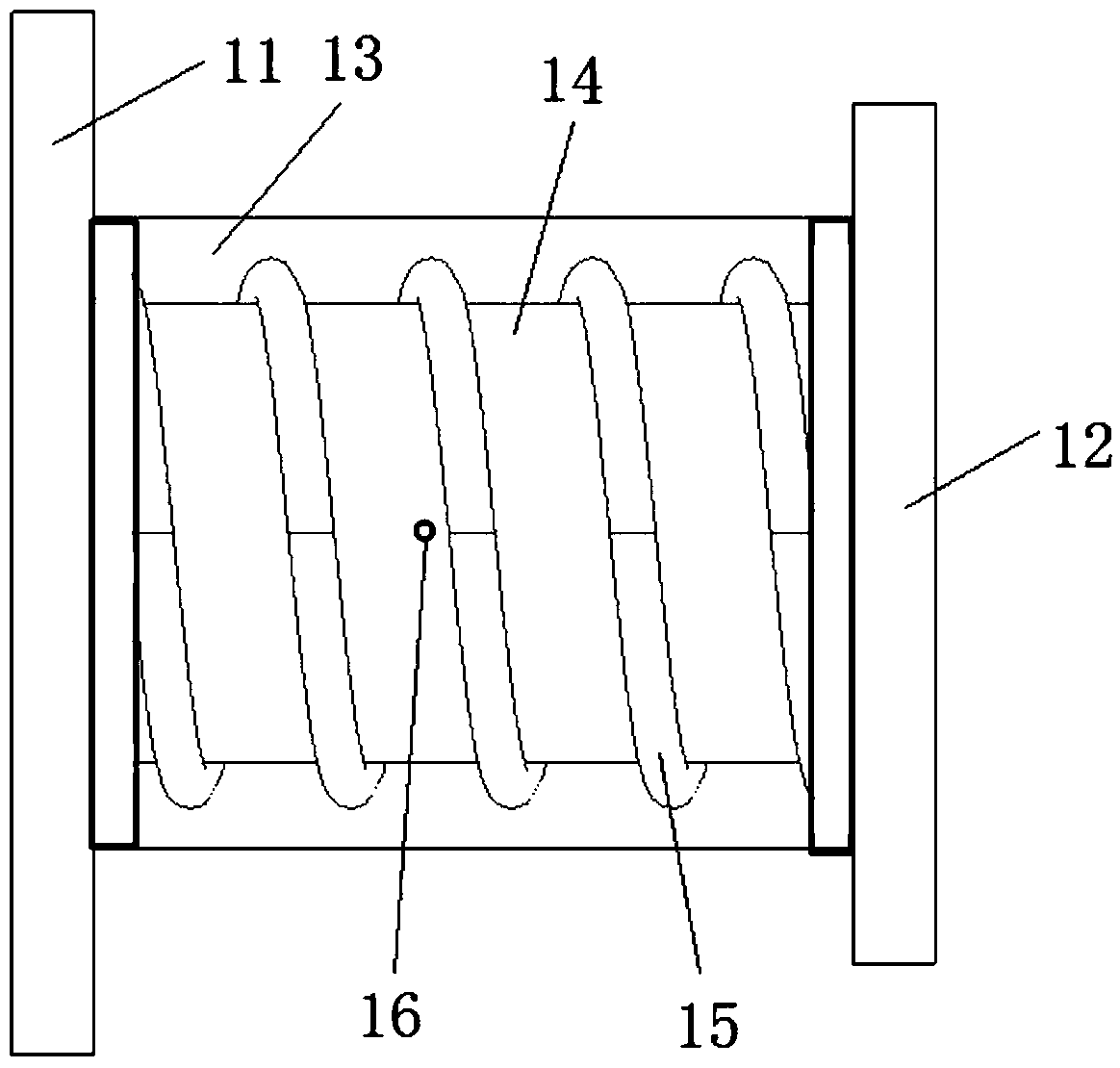

Self-powered active and passive composite rotational inertia drive control system

PendingCN109630612AAchieve synergyAchieve Vibration ControlVibration suppression adjustmentsVibration controlExternal energy

The invention relates to the field of vibration suppression in the system and discloses a self-powered active and passive composite rotational inertia drive control device. The device comprises an active output module and a passive output module, wherein the active output module includes a driver, an encoder, a transmission, and an active rotational inertia disc; the passive output module includesa torsional variable damping box, a generator, an energy storage unit and a passive rotation inertia disc; a system pipe cavity is arranged between the active rotational inertia disc and the passiverotational inertia disc; and the active output module and the passive output module are symmetrically distributed along the center of the system pipe cavity. By adopting the self-powered technology, the synergy between the active output module and the passive output module can be achieved with no need to rely on any external energy; according to the device, the active and passive composite controlcan be achieved, vibration control under complex conditions can be achieved, and the stability of combination with the passive control art is better than active control only.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

An active and passive integrated vibration reduction and isolation device suitable for large amplitude and wide frequency band

InactiveCN106286693BAchieve Vibration ControlLarge amplitudeSpringsNon-rotating vibration suppressionElectricityVibration control

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

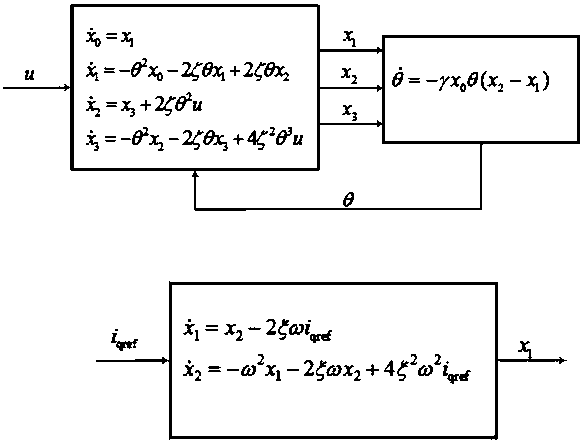

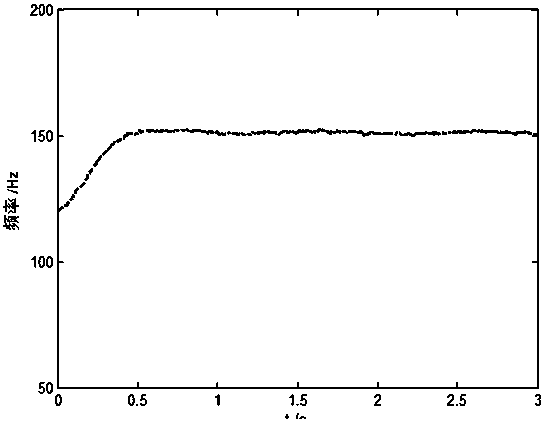

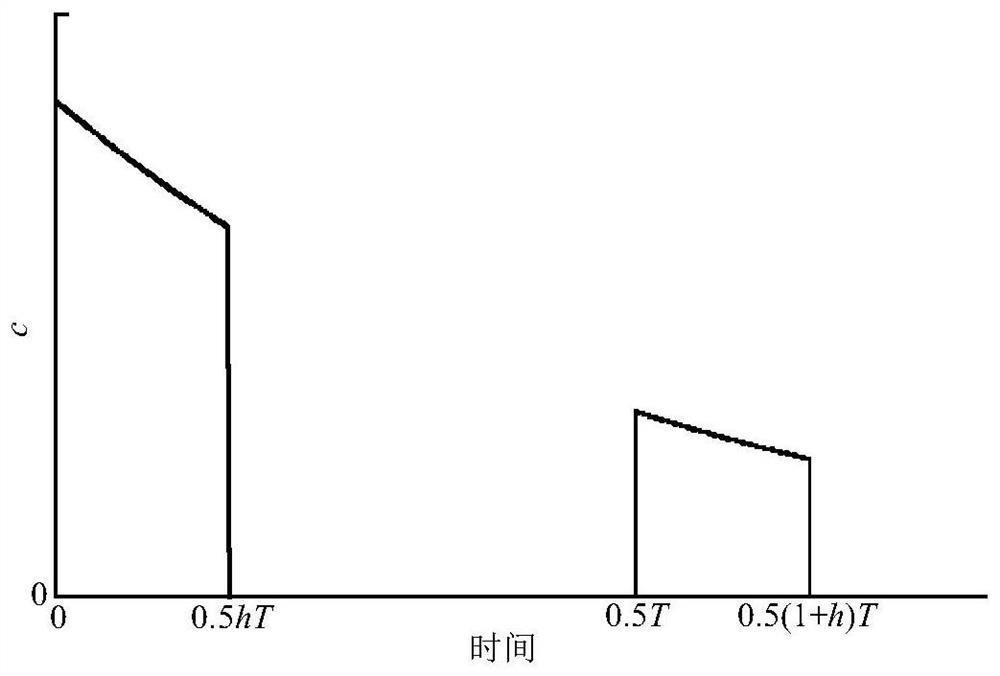

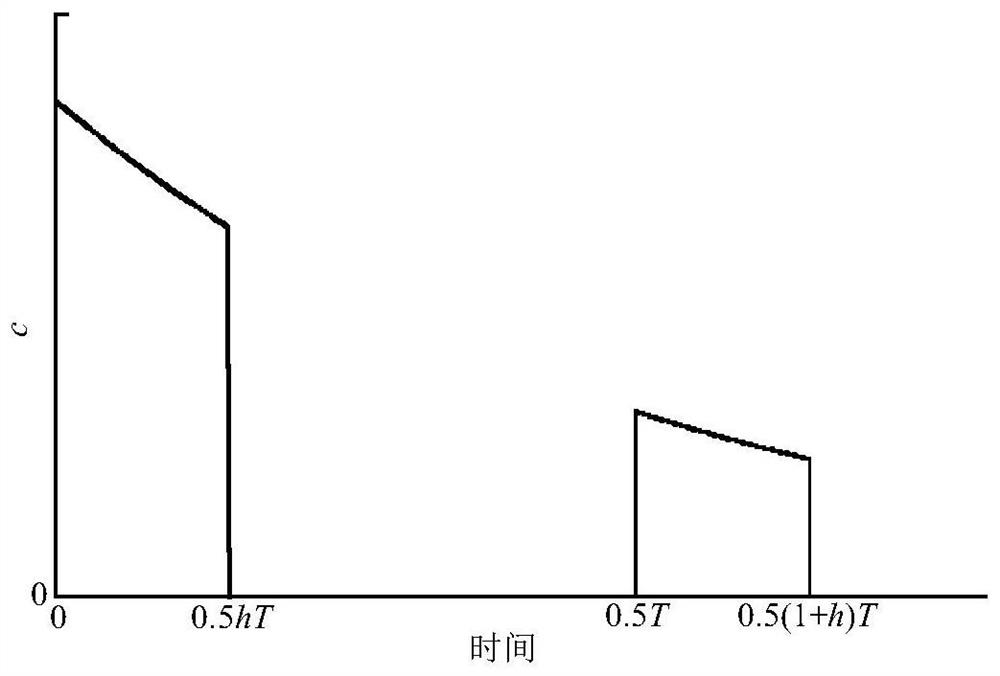

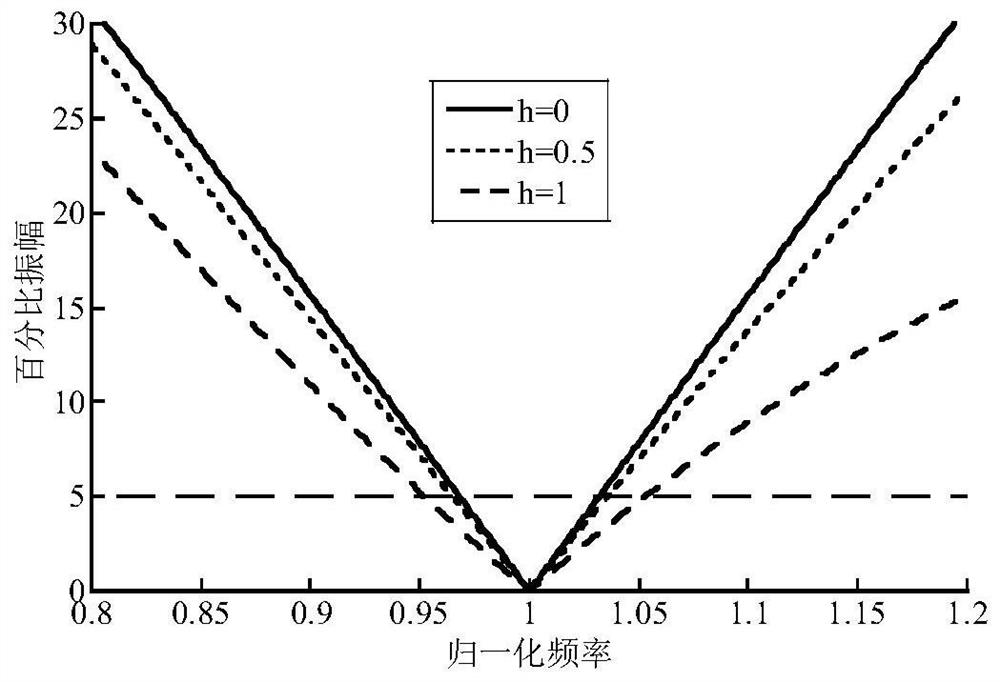

Adaptive resonance suppressing method for rotary machine

InactiveCN107733313AStrong real-timeAchieve Vibration ControlMotor control for motor oscillations dampingRotary machineSelf adaptive

The invention aims to provide an adaptive resonance suppressing method for a rotary machine in order to solve the problem of failure of resonance suppressing of the rotary machine possibly caused by the fact that a wave trap resonance suppressing method is poor in real-time performance and cannot identify resonance frequency and work condition change online. According to the method, firstly, mathematical expressions of a fourth-order system, an adaptive law and a wave trap are provided; vibration signals are taken as input, a fourth-order system state equation and the adaptive law are executediteratively, and angular frequency of resonance signals can be tracked dynamically; secondly, after frequency tracking enters a steady state, frequency and amplitude of the resonance signals are calculated according to angular frequency convergency values and state variables; finally, trap frequency is set according to the angular frequency convergency values, front trap processing is performed on current loop given signals, and synchronous component of quadrature-axis current and resonance is inhibited. The method is high in real-time performance and the machine can be inlaid in a motor driver to realize vibration control.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

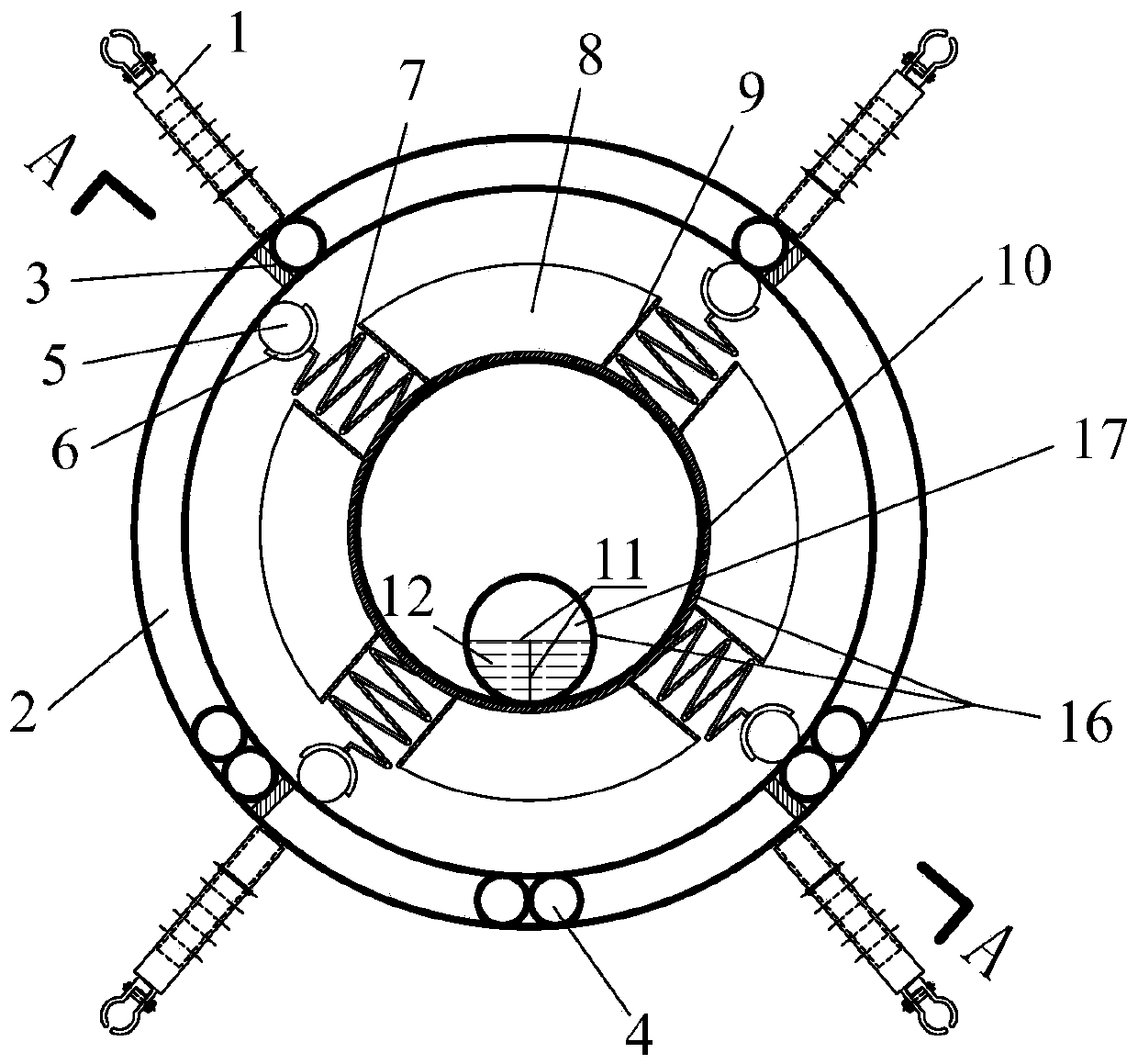

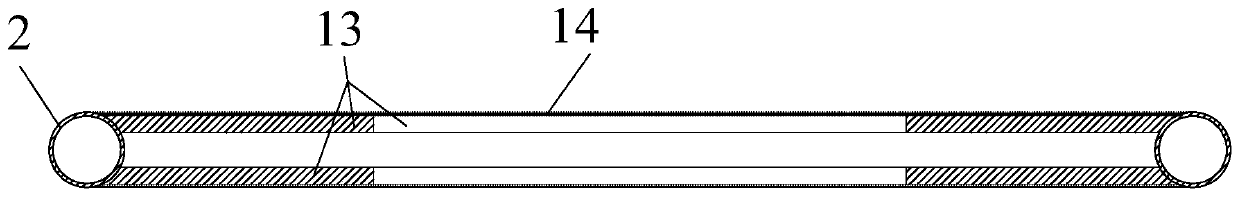

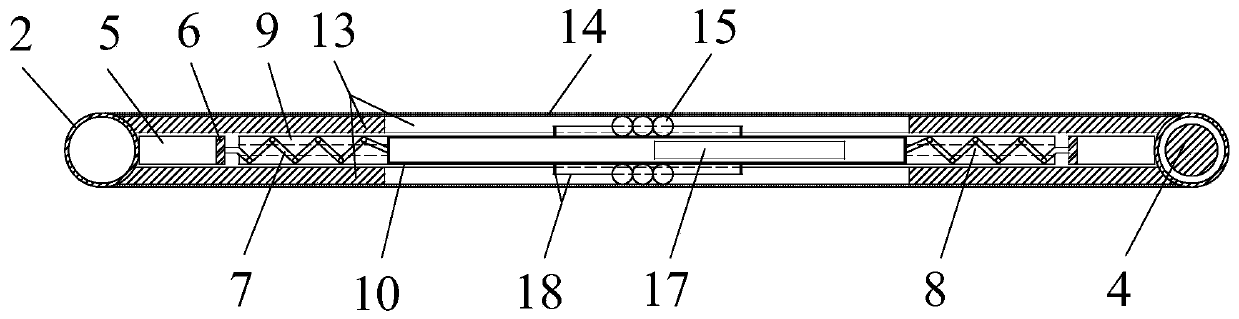

Multi-level composite energy-consuming anti-dancing moving spacer bar

ActiveCN110380374AGood energy consumptionGood durabilityMaintaining distance between parallel conductorsMagnetEngineering

The invention discloses a multi-level composite energy-consuming anti-dancing moving spacer bar. The multi-level composite energy-consuming anti-dancing moving spacer bar includes a spacer bar body and a clamping fixture used for connecting split wires, wherein the spacer bar body includes an annular tube, a partition and a mass ball are arranged inside the annular tube, an inner ring of the annular tube is connected with upper and lower annular permanent magnets, a movable cylinder is arranged on an inner side, an outer ring of the movable cylinder is connected with a conductor plate, the conductor plate extends into a passage between the upper and lower permanent magnets, the movable cylinder and the annular tube are connected by a spring and a roller, and a drum equipped with the damping fluid is arranged in the movable cylinder.

Owner:SHANDONG UNIV

Motor vibration method, terminal and storage medium

InactiveCN110769096AImprove the vibration effectAchieve Vibration ControlTelephone set constructionsComputer hardwareVibration control

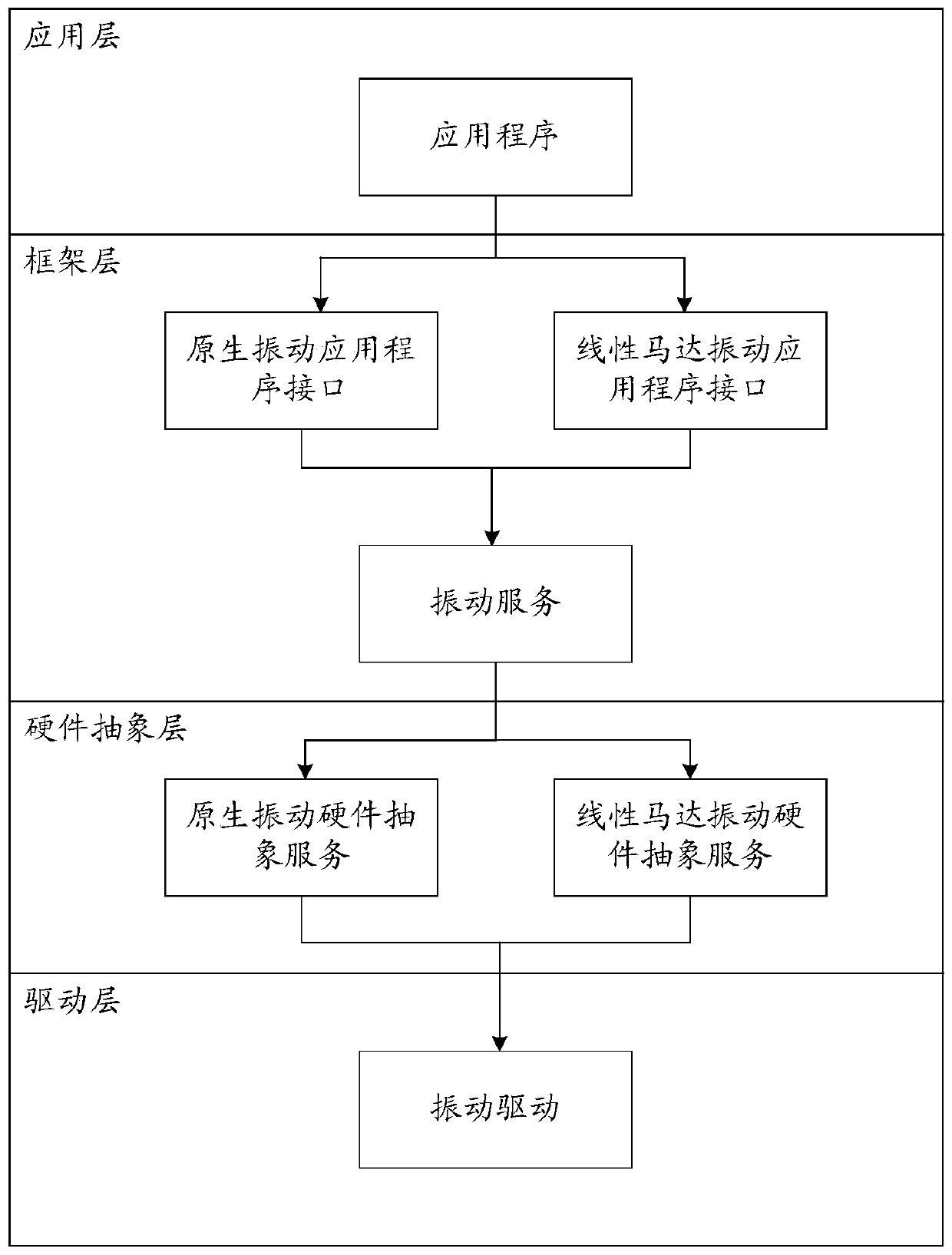

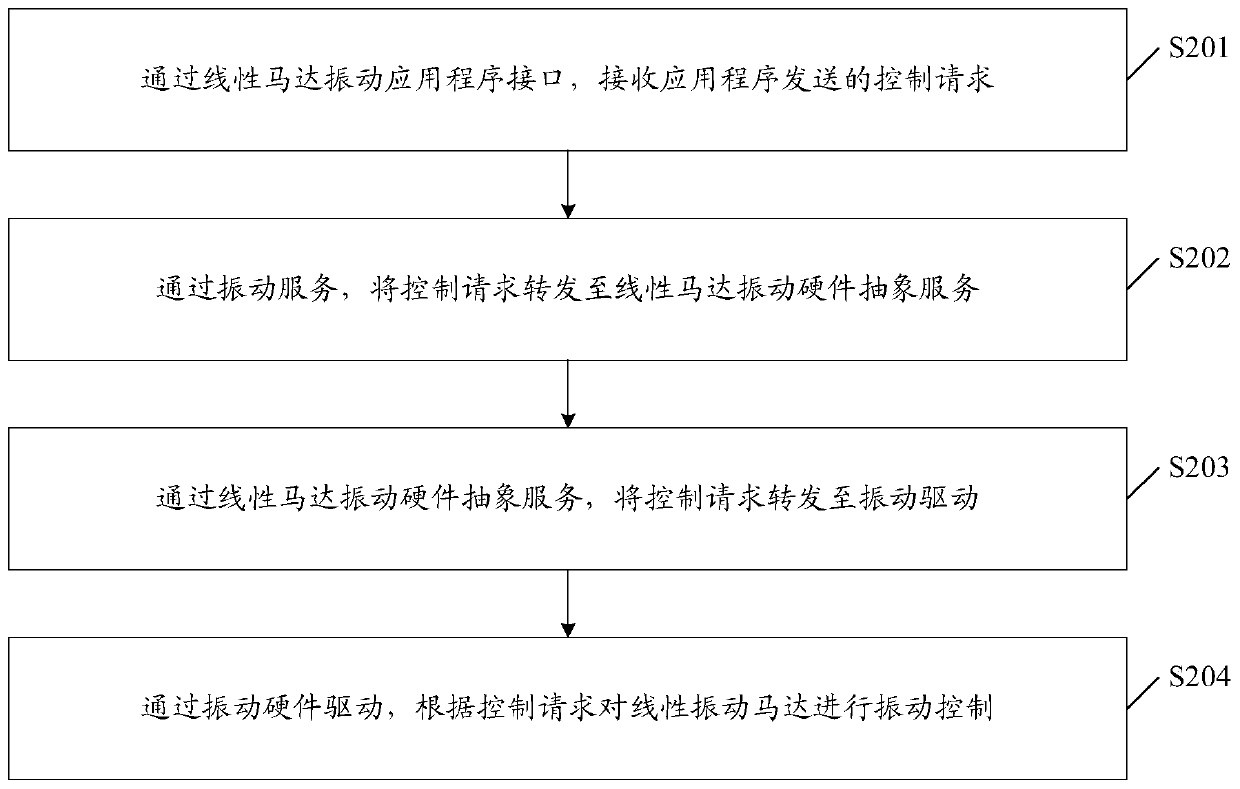

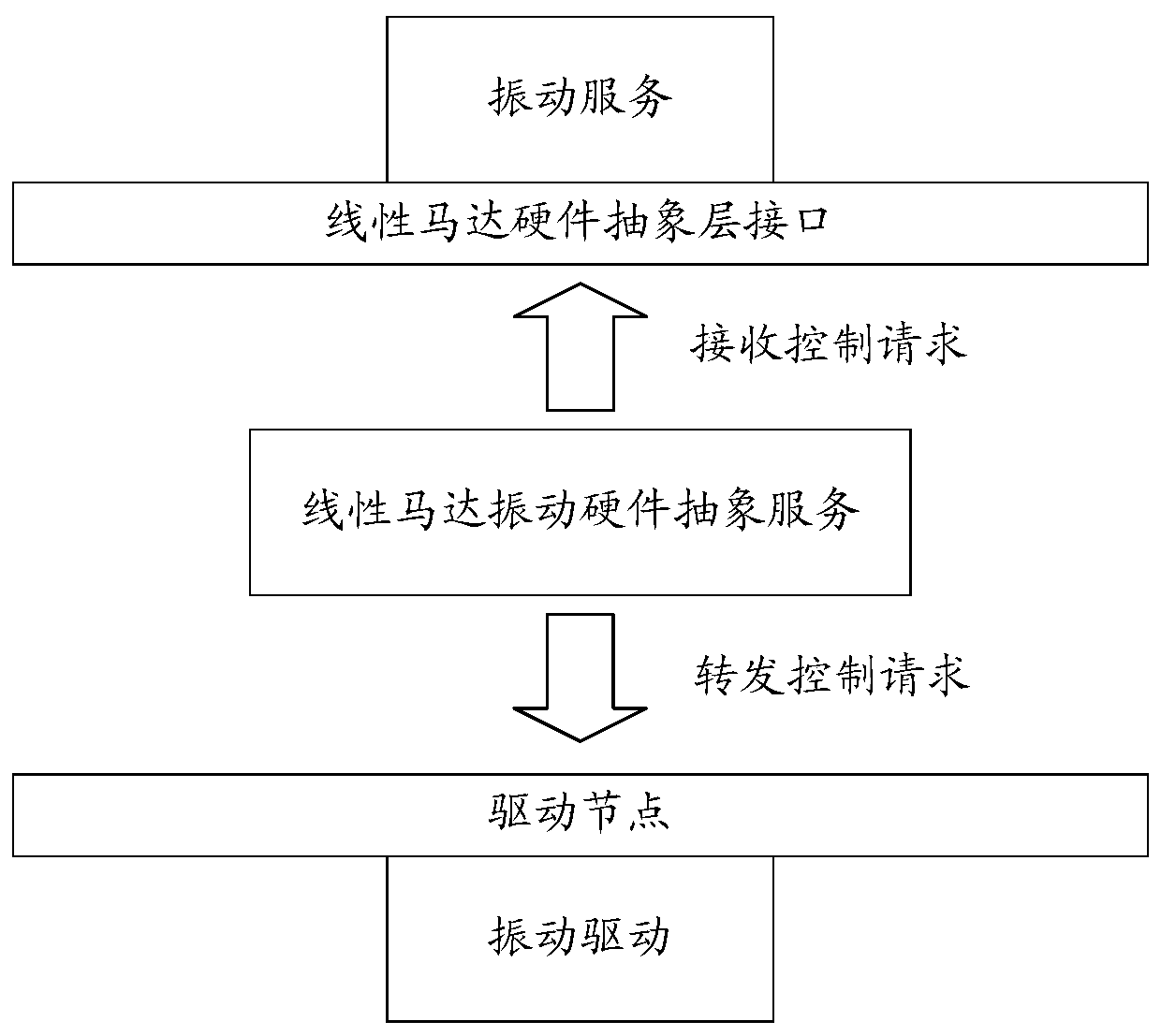

The embodiment of the invention discloses a motor vibration method, a terminal and a storage medium. The terminal comprises a linear motor vibration application program interface and a vibration service which are deployed on a framework layer, a linear motor vibration hardware abstraction service deployed on a hardware abstraction layer and a vibration drive deployed on a drive layer. The method comprises the following steps: receiving a control request sent by an application program through the linear motor vibration application program interface; forwarding the control request to the linearmotor vibration hardware abstraction service through the vibration service; forwarding the control request to a vibration drive through a linear motor vibration hardware abstraction service; and through vibration driving, performing vibration control on the linear vibration motor according to the control request.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

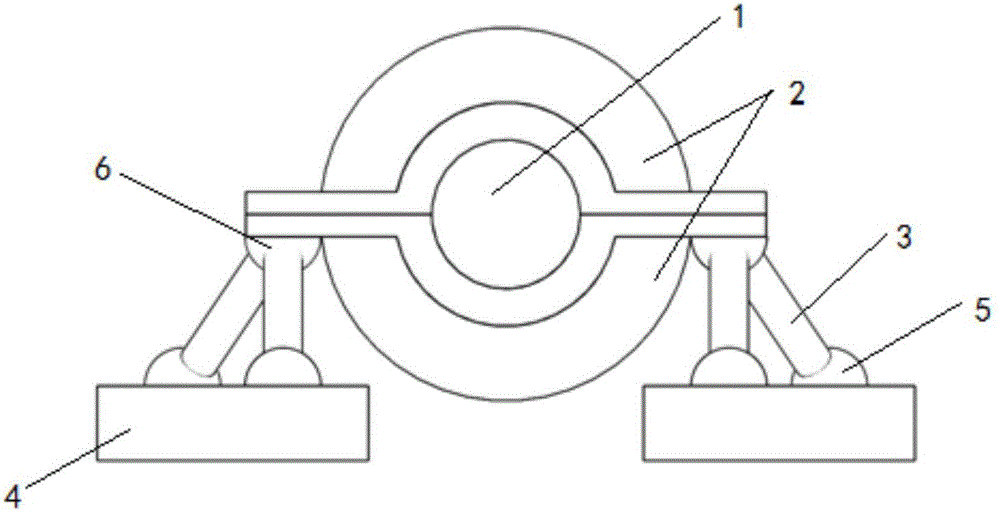

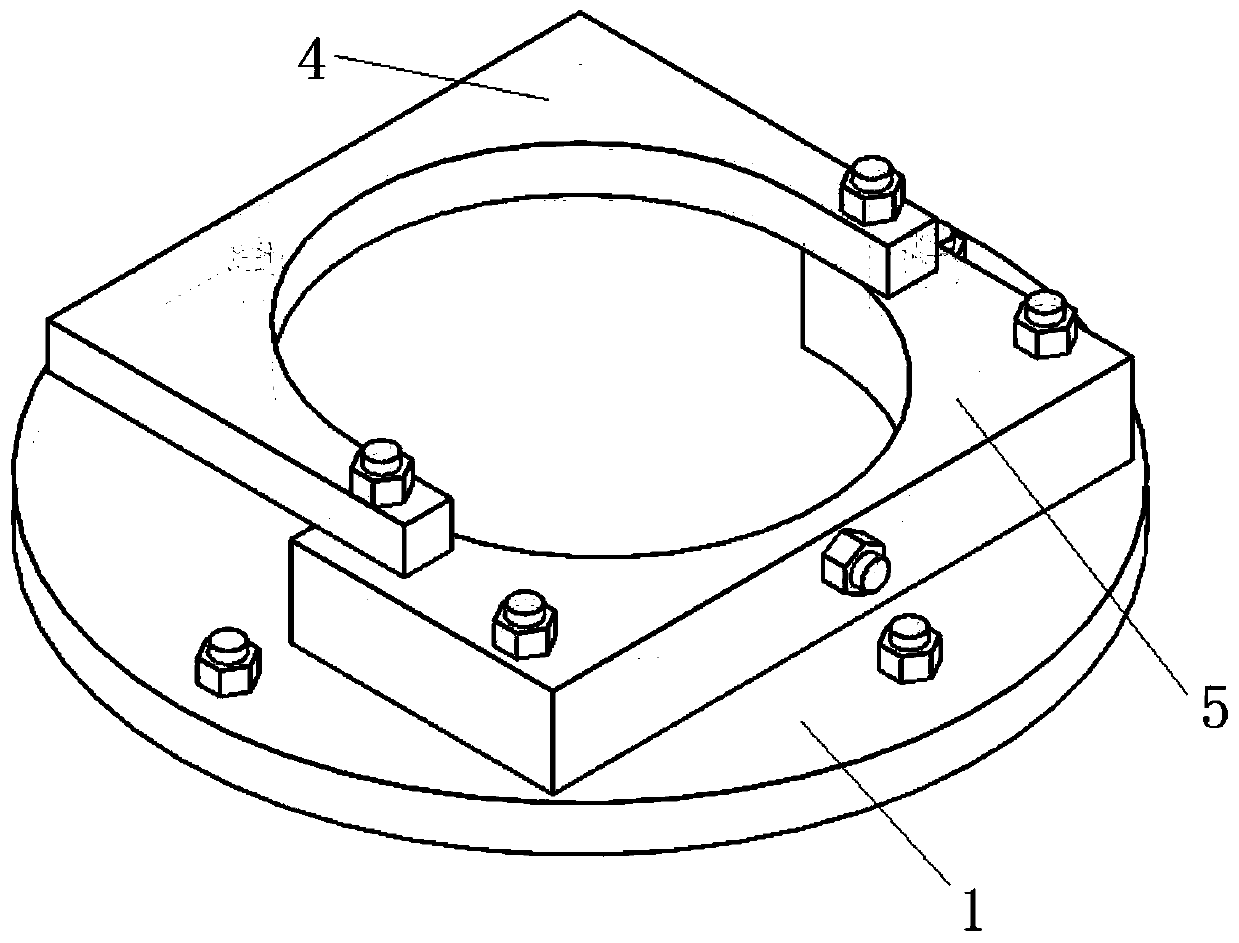

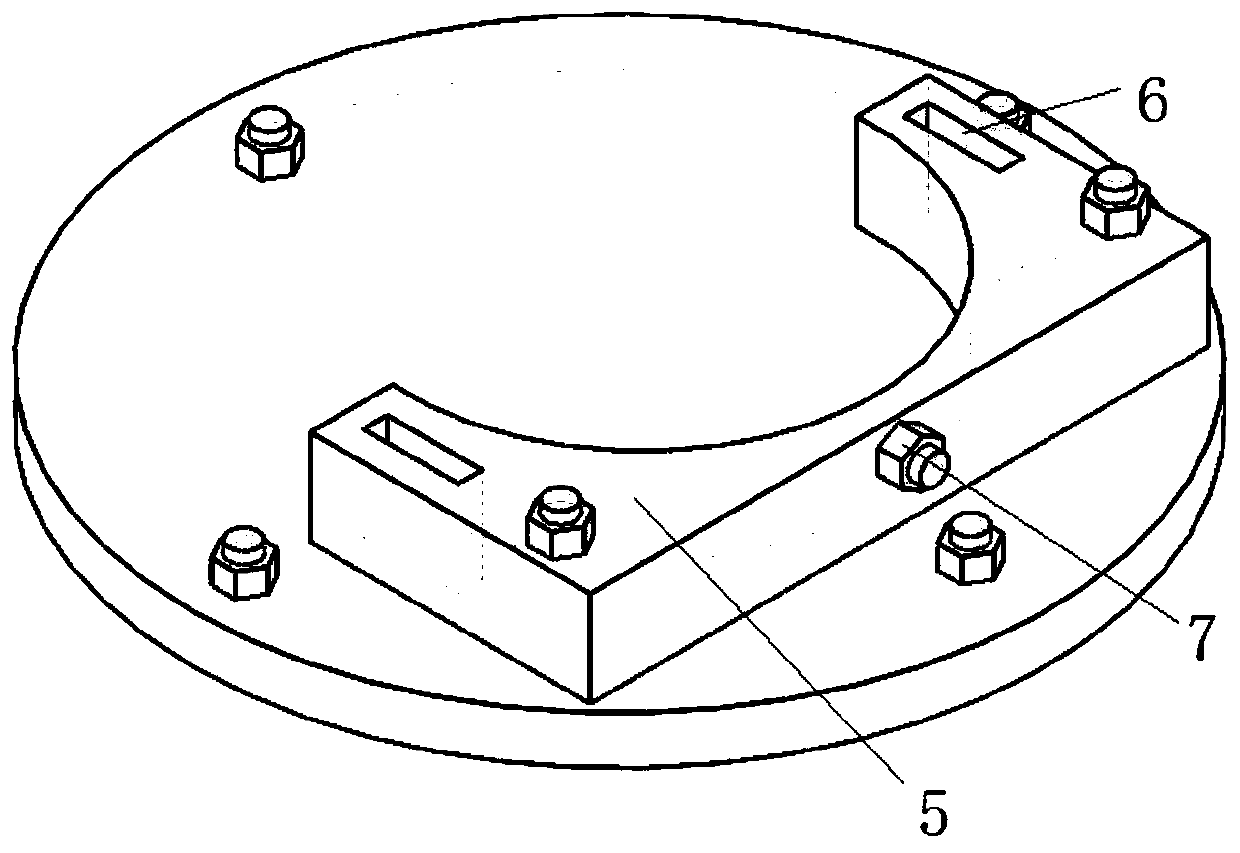

Hydraulic-driven eight-foot thrust bearing base

ActiveCN106640985AUniform load distributionReduce vibration and noisePropulsive elementsPropulsive transmissionWork performanceThrust bearing

The invention discloses a hydraulic-driven eight-foot thrust bearing base, comprising a shaft, a thrust bearing, a support assembly and a base, wherein the shaft passes through the thrust bearing; the support assembly comprises two actuator groups which are respectively and symmetrically distributed at two sides of the thrust bearing; each actuator group comprises four actuators, two upper part connecting blocks positioned at one side of the thrust bearing, and three lower part connecting blocks arranged on the base; an 'M'-shaped structure is formed by the actuators, the upper part connecting blocks and the lower part connecting blocks of each actuator group; the upper part connecting blocks, the lower part connecting blocks and the actuators are connected in a way of spherical hinge connection. The thrust bearing base provided by the invention is simple, efficient and flexible; after the design is adopted, the bearing load can be evenly distributed, the working performance of a shaft system is improved, the normal operation of the shaft system is guaranteed, and active and passive control can be also effectively carried out on the vibration of the shaft system.

Owner:SHANGHAI JIAO TONG UNIV

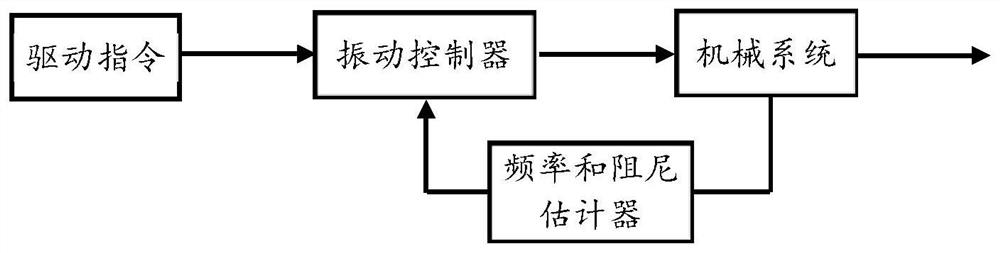

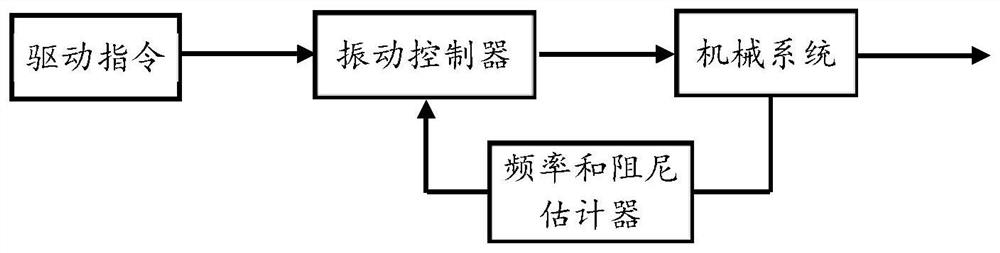

Method and system for controlling mechanical vibration

ActiveCN113157012AAchieve Vibration ControlGuaranteed work efficiencyMechanical oscillations controlVibration controlEngineering

The invention provides a control method and system for a mechanical vibration problem. A lightweight mechanical system can continuously vibrate in a movement process. The continuous vibration has a great influence on the safe operation of a mechanical system. The invention provides a novel vibration control method. Technical means can be provided for various types of mechanical vibration control problems. The vibration control method provided by the invention is essentially a complex of a notch and a low-pass filter. The notch filtering characteristic of the complex suppresses the vibration of a main vibration mode, and the low-pass filtering characteristic of the complex controls the vibration of a high mode. When the mechanical system only has one vibration mode, one vibration controller is used. When the mechanical system has a plurality of vibration modes, a vibration controller is designed by using the information of the first two vibration modes, so as to control all the vibration modes. The invention further provides an engineering implementation scheme of the method in various mechanical systems.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Damping-rigidness-controllable double-freedom-degree vibration active control platform

ActiveCN103398138BAvoid damageAchieve Vibration ControlNon-rotating vibration suppressionCounterweightsShaped beamDiagonal

A damping-rigidness-controllable double-freedom-degree vibration active control platform comprises a cross-shaped beam frame and a square base which are connected through a flexible hinge. A cross-shaped beam of the cross-shaped beam frame is distributed in the diagonal directions of the square base. A structure column is arranged at the center of the cross-shaped beam frame. Sensors and actuators are connected between the lower portions of the diagonal top ends of the cross-shaped beam frame and the square base respectively. Four limiting columns are arranged between the cross-shaped beam of the cross-shaped beam frame and the square base respectively. Prearranged gaps are reserved between the limiting columns and the cross-shaped beam frame. Four balancing weights are fixed on the lower portion of the cross-shaped beam frame between the sensors or the actuators and the limiting columns respectively. Twisting limiting spring pieces are arranged at the symmetrical positions on the lower portion of the cross-shaped beam frame between the limiting columns and the flexible hinge. The electromagnetic type sensors and the electric-damping electric-rigidness actuators are used to achieve detecting of angular speed and actuating, the flexible hinge and the spring piece with changeable thickness are combined to achieve controllable damping and rigidness in a quantifying mode, and double-freedom-degree vibration active control in the x direction and the y direction of the structure is achieved.

Owner:XI AN JIAOTONG UNIV

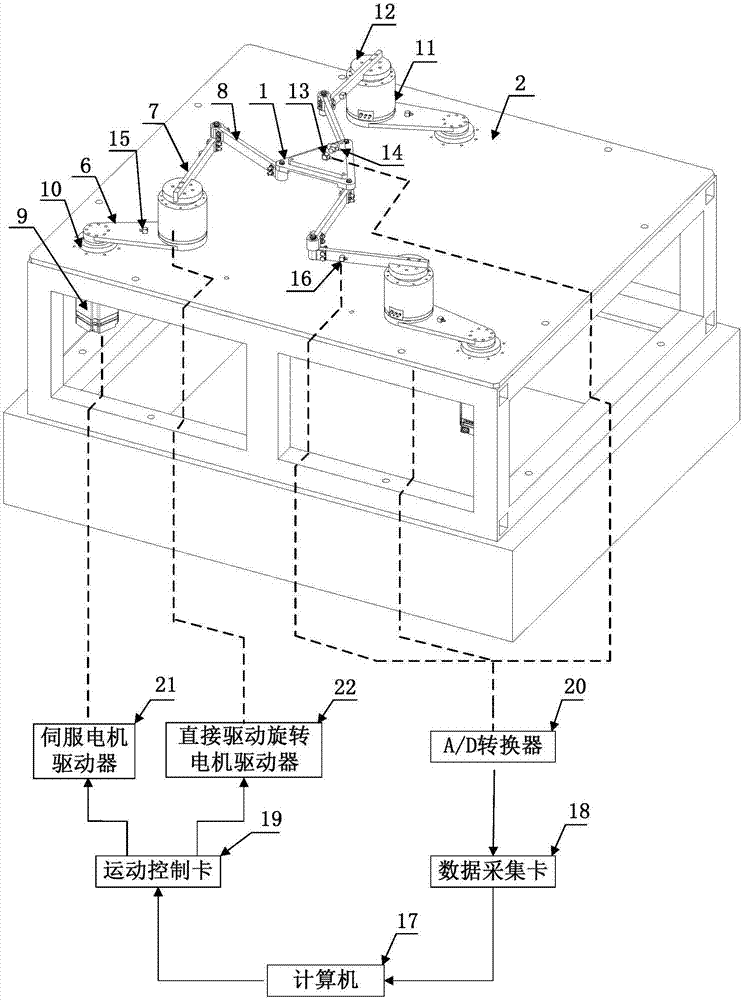

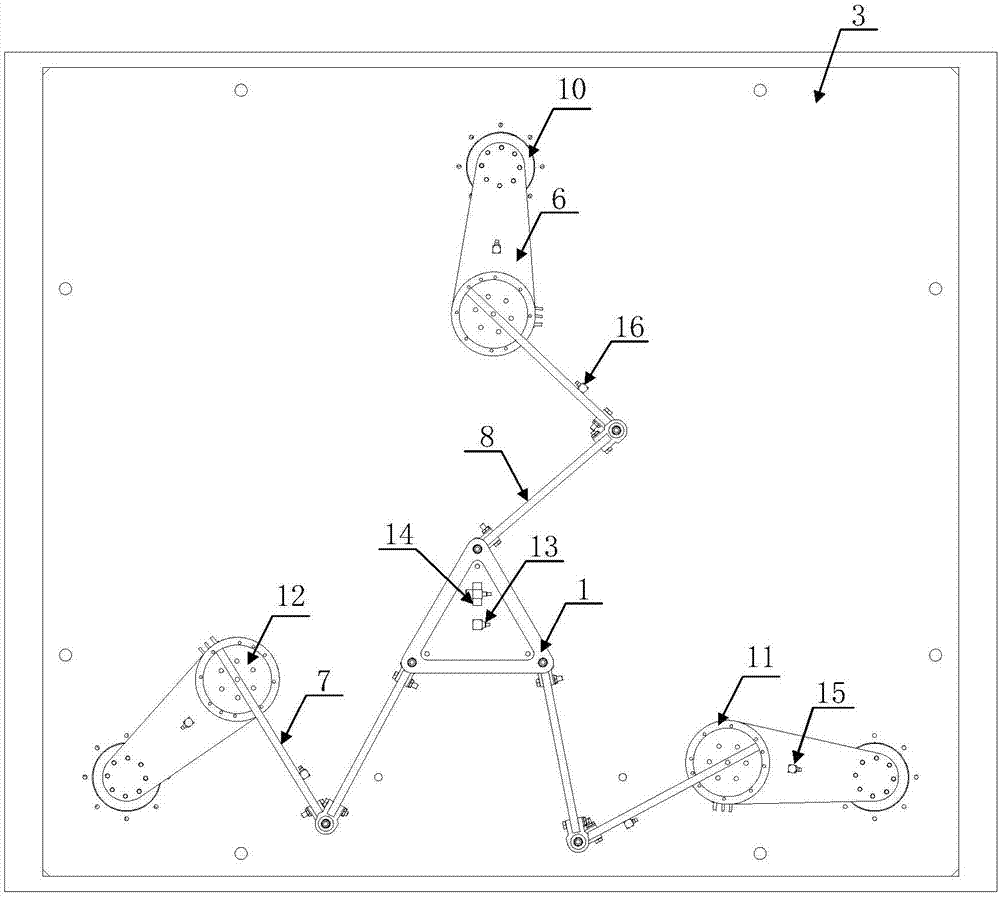

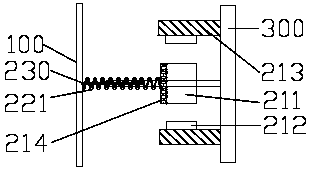

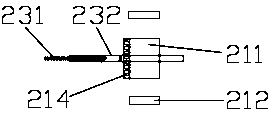

Hybrid-driven redundant plane parallel mechanism control device and method

PendingCN107263446AFlexible movementAchieve Vibration ControlProgramme-controlled manipulatorControl engineeringElectric machinery

The invention discloses a hybrid-driven redundant plane parallel mechanism control device and method. The device comprises a parallel mechanism body unit, a detection unit and a control unit. The parallel mechanism body unit comprises a mobile platform and three parallel branches. Each of the parallel branches comprises a first motor assembly, a driving plate, a second motor assembly, an active rod and a passive rod; the detection unit comprises a three-way acceleration sensor, an angular acceleration sensor, a first one-way acceleration sensor and a second one-way acceleration sensor; and the control unit is separately connected to the first motor assembly, the second motor assembly, the three-way acceleration sensor, the angular acceleration sensor, the first one-way acceleration sensor and the second one-way acceleration sensor. The device disclosed by the invention hybrid-driven by the two motor assemblies, so that the parallel mechanism works in a relatively large space and arrives a preset position stably, accurately and quickly; the plurality of sensors are used for detecting vibration information as feedback signals to quickly inhibit vibration of the parallel mechanism.

Owner:SOUTH CHINA UNIV OF TECH

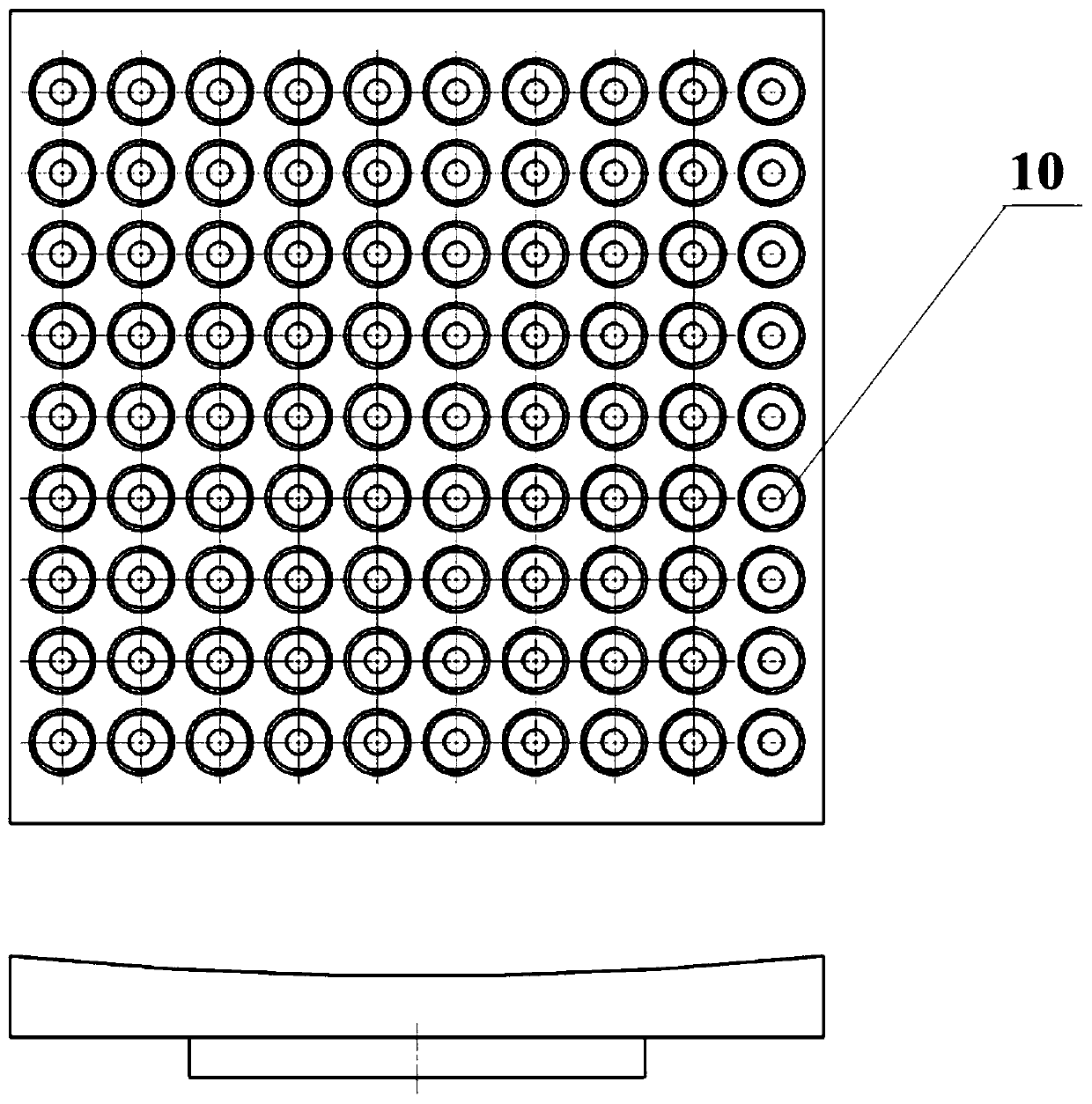

Arrayed transverse negative stiffness vibration damper

PendingCN110107643AReduce lateral vibrationAchieve Vibration ControlNon-rotating vibration suppressionMagnetic springsNegative stiffnessControl theory

The invention discloses an arrayed transverse negative stiffness vibration damper. The arrayed transverse negative stiffness vibration damper comprises a left movable plate, vibration damper substructures and a right fixed plate. The left movable plate is mounted on a machine body. Each vibration damper substructure is arranged between the left movable plate and the right fixed plate and comprisesa negative stiffness unit, a positive stiffness unit and a hydraulic damping rod. The vibration damper substructures are vertically arranged and spaced in a linear array mode. The right fixed plate is fixedly connected to the ground. The arrayed transverse negative stiffness vibration damper can control structural vibration within the broadband range by adjusting the stiffness and damping of thevibration damper structures.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Low-frequency two-degree-of-freedom swinging type TMD vibration control device for high-rise structure

PendingCN109296099ACompact designSimple installation and maintenanceProtective buildings/sheltersShock proofingLow frequency vibrationTwo degrees of freedom

The invention discloses a low-frequency two-degree-of-freedom swinging type TMD vibration control device for a high-rise structure. The low-frequency two-degree-of-freedom swinging type TMD vibrationcontrol device includes an elastic support, a two-degree-of-freedom swinging gear box, a plurality of damping energy dissipation devices, a plurality of first mass blocks, a plurality of second mass blocks, a first swinging rod and a second swinging rod, one end of the elastic support is rigidly connected with the inner wall of a barrel body, and the other end of the elastic support is flexibly connected with the inner wall of the barrel body; the two-degree-of-freedom swinging gear box is fixed to the elastic support and includes a box body and two groups of transmission units, the two groupsof transmission units are symmetrically mounted on the box body in an up-down mirroring mode, and the two transmission units contain third swinging rods with two rotational degrees of freedom in thehorizontal plane correspondingly and are connected with the first swinging rod and a second swinging rod correspondingly; and the first mass blocks are arranged on the first swinging rod in a superimposition mode, the second mass blocks are installed on the second swinging rod in a superimposition mode, and the damping energy dissipation devices are circumferentially and evenly distributed on theinner wall of the barrel body and connected with the first swinging rod correspondingly. According to the low-frequency two-degree-of-freedom swinging type TMD vibration control device for the high-rise structure, low-frequency vibration of the high-rise structure can be controlled, and the safety and functional requirements of the high-rise structure are met.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

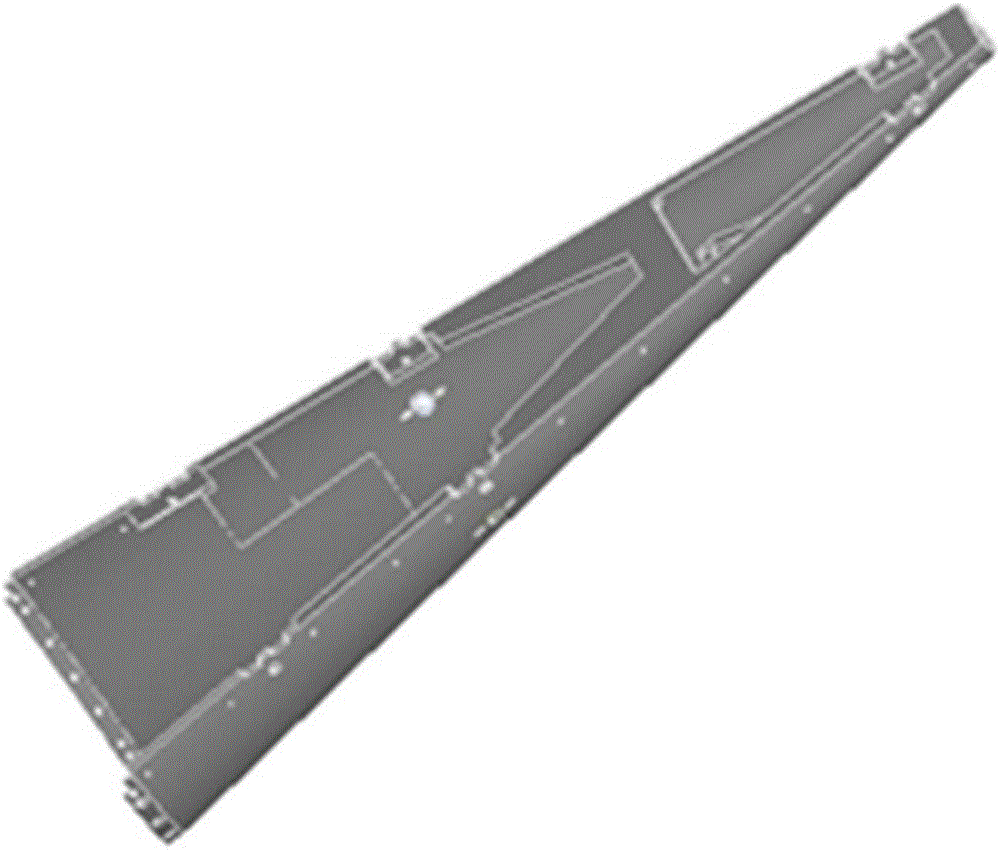

Automatic flexible mirror image clamping and damping device for numerical control machine tool

ActiveCN111015308ARealize vacuum adsorption tooling positioningQuick clampingPositioning apparatusMaintainance and safety accessoriesNumerical controlData acquisition

The invention discloses an automatic flexible mirror image clamping and damping device for a numerical control machine tool. The automatic flexible mirror image clamping and damping device comprises an automatic positioning device and a rapid clamping device; the automatic positioning device comprises a machine tool coordinate data collecting and analyzing system, a robot and a control system of the robot, wherein a one-way sliding table is arranged at the front end of the robot, and the one-way sliding table is connected with the rapid clamping device; and the rapid clamping device comprisesa vacuum adsorption tool, wherein a vibration damping device is arranged on the vacuum adsorption tool. The automatic flexible mirror image clamping and damping device is not limited to the size and the shape of a part, can meet the machining damping requirement of any thin-wall part only by replacing the front-end attaching face vacuum adsorption tool, is low in cost and short in period, and fully meets the rapid response requirement of aerospace product models and the universal applicability requirement of multiple models.

Owner:CAPITAL AEROSPACE MACHINERY +1

Device and method for non-contact measurement and non-contact control over vibration of flexible cantilever beam

InactiveCN110108347ANo change in physical propertiesReduce distractionsMechanical oscillations controlSubsonic/sonic/ultrasonic wave measurementVibration controlImage transfer

The invention relates to a device and method for non-contact measurement and non-contact control over vibration of a flexible cantilever beam. The device comprises the flexible cantilever beam, a cantilever beam bracket, binocular CCD cameras, a camera bracket, a laser pen, electromagnetic coils, a PC and an electromagnetic controller. The device is characterized in that one end of the flexible cantilever beam is fixed through the cantilever beam bracket and is called a fixed end, and the other end of the flexible cantilever beam is a free end; the binocular CCD cameras are arranged in front of the flexible cantilever beam, and the two cameras are horizontally and parallelly arranged; the binocular CCD cameras collect images of mark points of the laser pen, acquire an image sequence of bending and torsional vibration information of the flexible cantilever beam, and transmits the images to the PC through a data line; the electromagnetic coils are symmetrically arranged on the two sidesof the flexible cantilever beam and keep the same horizontal height as the flexible cantilever beam; and the PC processes the collected vibration image sequence, sends vibration control information tothe electromagnetic controller, controls the magnetism of an electromagnet, and realizes vibration control over the flexible cantilever beam. The device and method can realize non-contact measurementand control without being in contact with or changing the vibration characteristics of a measured object, and can be widely applied and studied.

Owner:ANHUI UNIV OF SCI & TECH

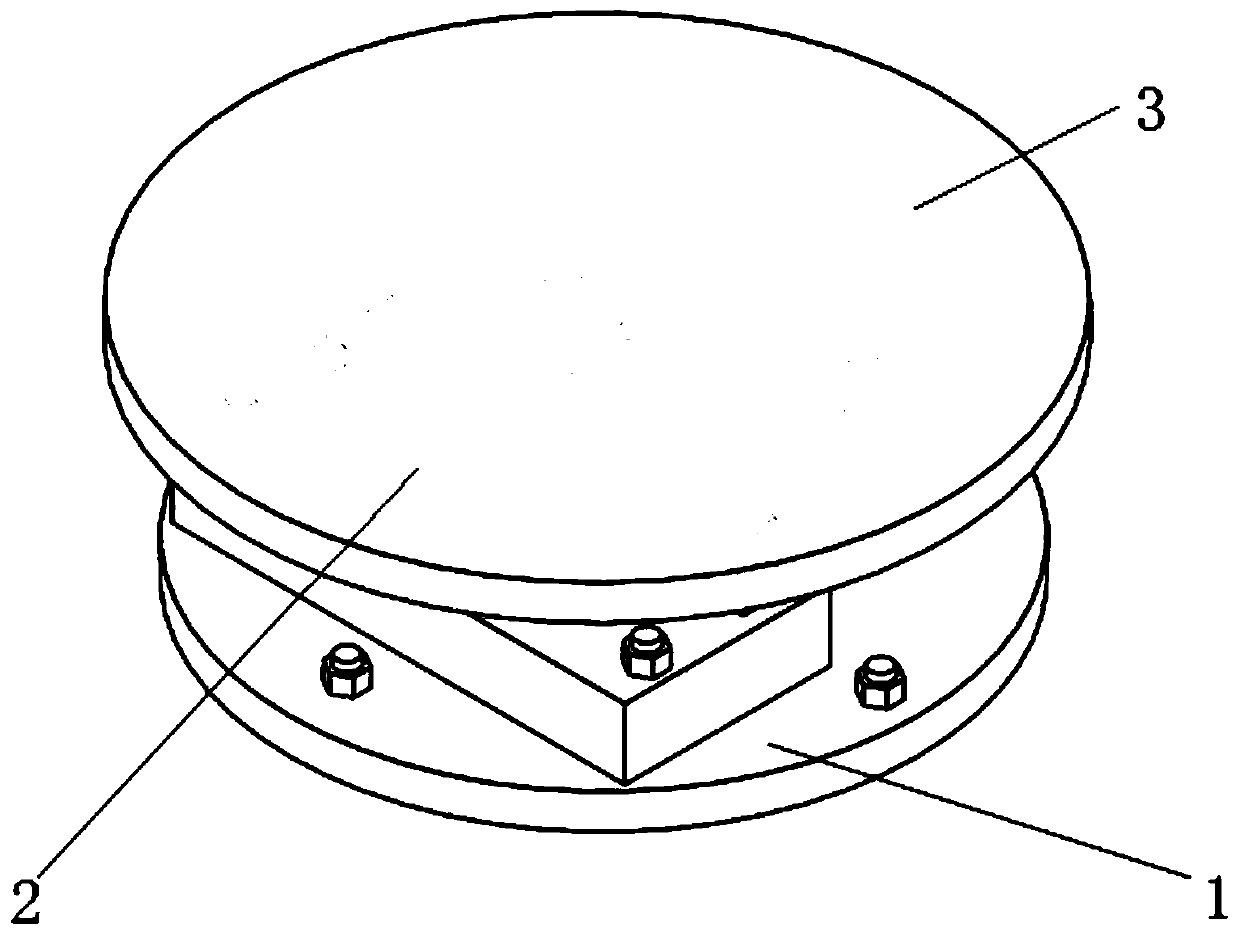

Active control system for dynamic behaviors of high-speed train

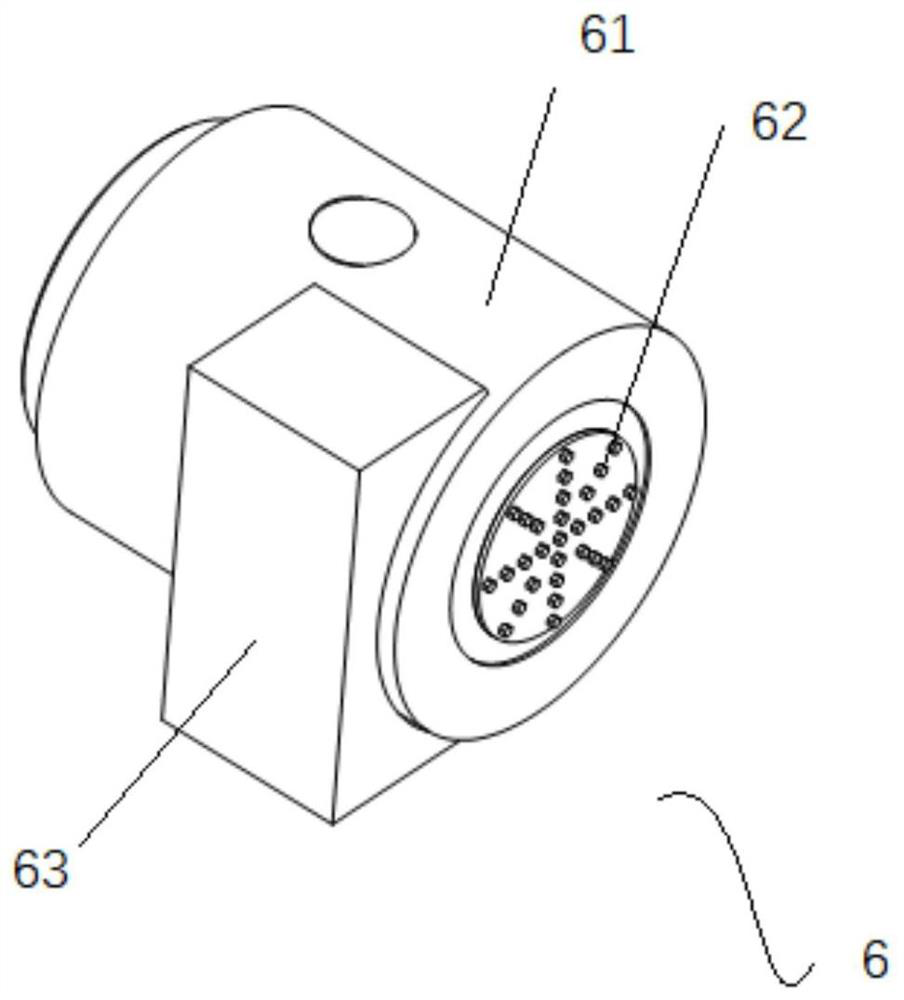

ActiveCN110778641AAchieve Vibration ControlGive full play to the output torqueNon-rotating vibration suppressionLocomotivesCircular discVibration control

The invention relates to the field of vibration control, in particular to an active control system for dynamic behaviors of a high-speed train. The active control system comprises a sensor, a controller and a control device; the sensor is installed on the controlled train, the control device comprises a base, a driving motor, an encoder, a transmission and a quality disc, the base is fixed to thecontrolled train, the driving motor is fixed to the base, the encoder is coaxially fixed to the bottom of the driving motor, the transmission is arranged at the top of the driving motor, and a rotaryshaft of the driving motor is fixedly connected with the quality disc; the controller is electrically connected with the driving motor, the sensor and the encoder. According to the active control system, the active control technology is applied, full play is given to the effect of output torque of the system, so that the output torque can directly act on the train body, the system can be adjustedto control algorithms and achieve different control effects according to actual demands, and the vibration control over compartments of the train is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

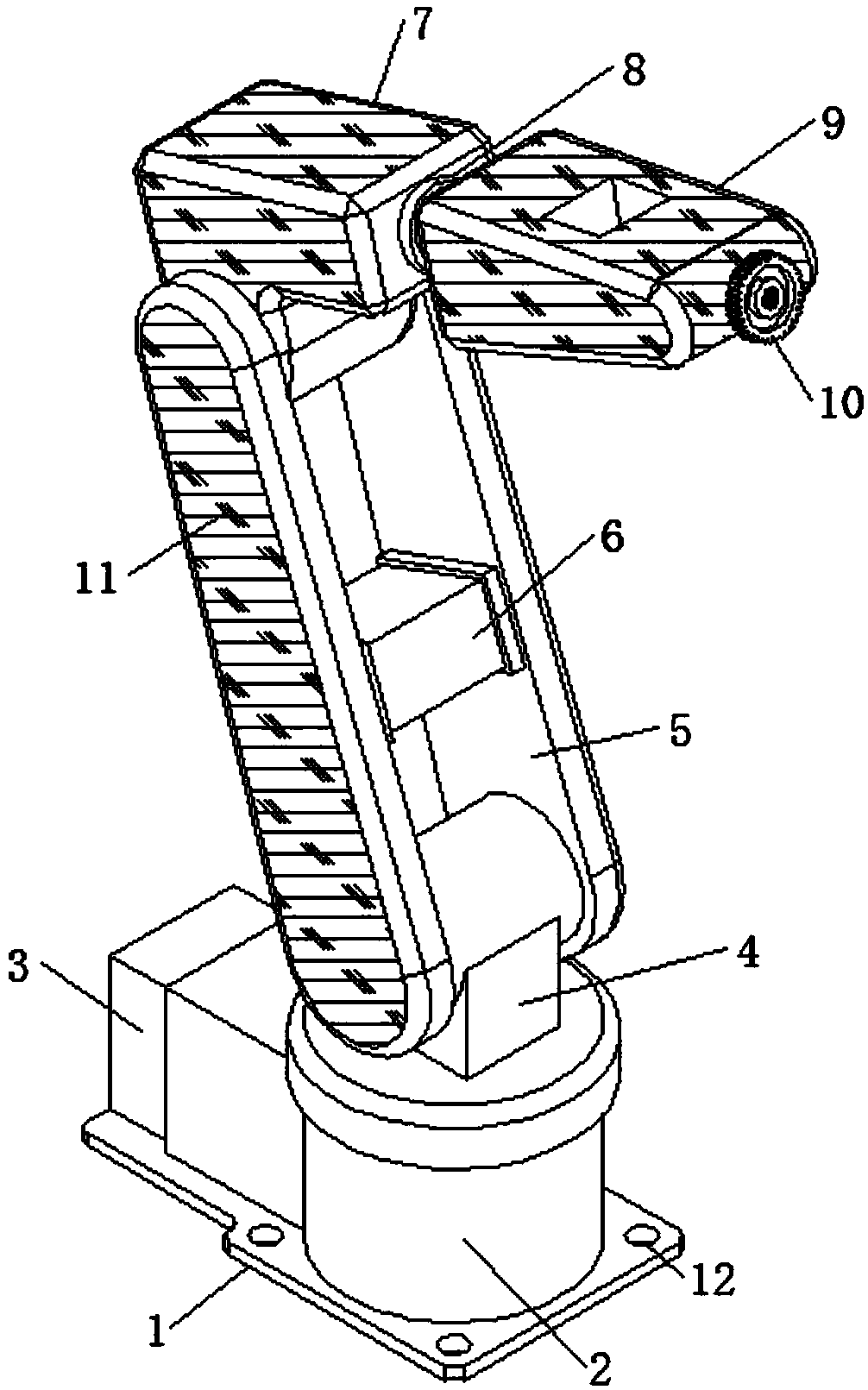

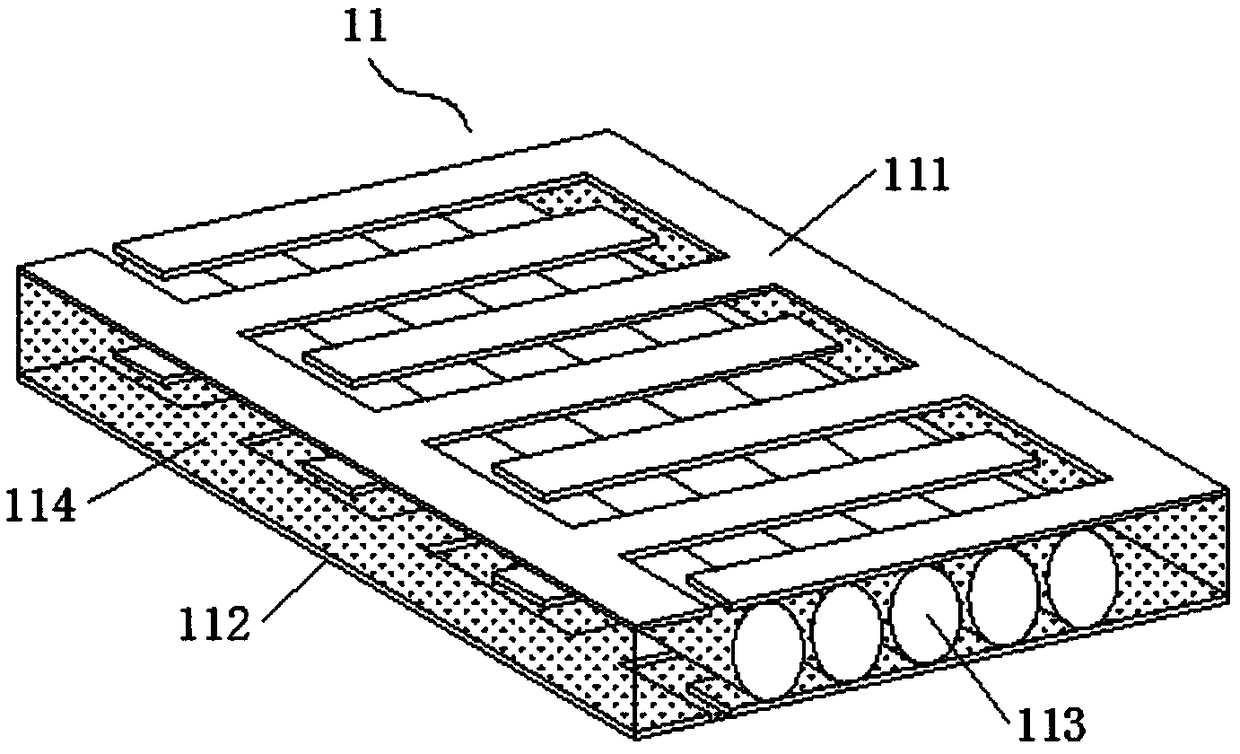

Piezoelectric-composite-based industrial robot capable of achieving vibration control

PendingCN108656091AUnderstand the purposeLearn about featuresProgramme-controlled manipulatorArmsElectricityPiezoelectric composite

The invention discloses a piezoelectric-composite-based industrial robot capable of achieving vibration control and relates to the technical field of industrial robots. The piezoelectric-composite-based industrial robot comprises a mounting base plate. A rotating base and a control device are arranged at the top of the mounting base plate. A rotating motor is arranged at the top of the rotating base. Two rotating large arms are symmetrically mounted on an output shaft of the rotating motor. A reinforcing connecting plate is arranged between the two rotating large arms. A rotating small arm ismounted between the top ends of the two rotating large arms. The side wall of the rotating small arm is provided with a torsion motor. The outer walls of the rotating large arms and the outer wall ofthe rotating small arm are each wrapped by a piezoelectric-composite vibration reduction layer. The piezoelectric-composite vibration reduction layers are electrically connected with a control devicethrough wires. By means of the piezoelectric-composite-based industrial robot, active vibration control of the industrial robot is achieved; the problem that normal work and the service life of the industrial robot are affected by vibration is reduced; and thus, industrial production efficiency is guaranteed.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

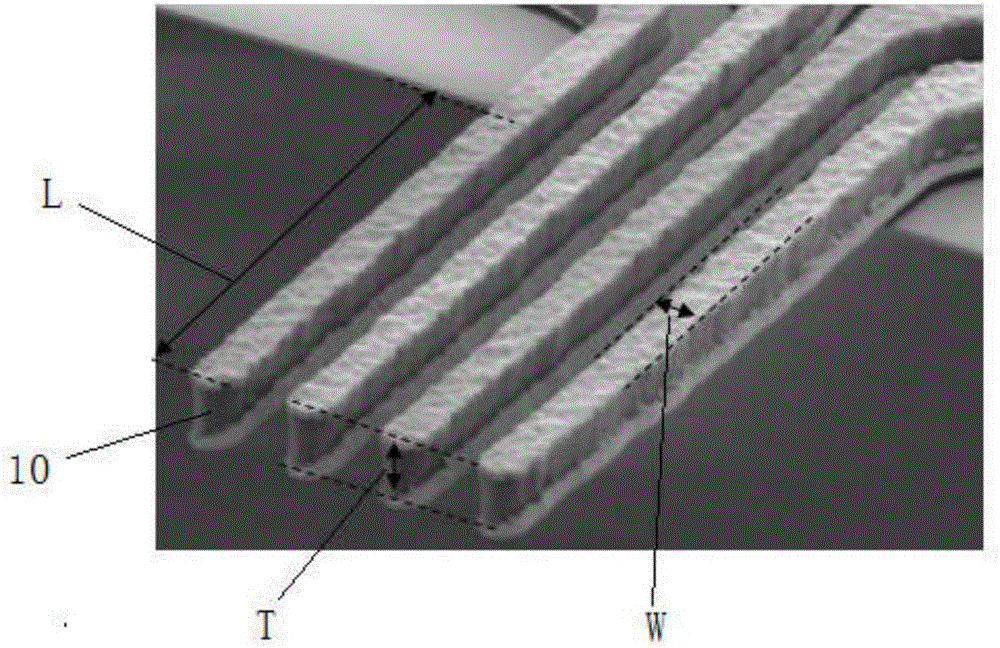

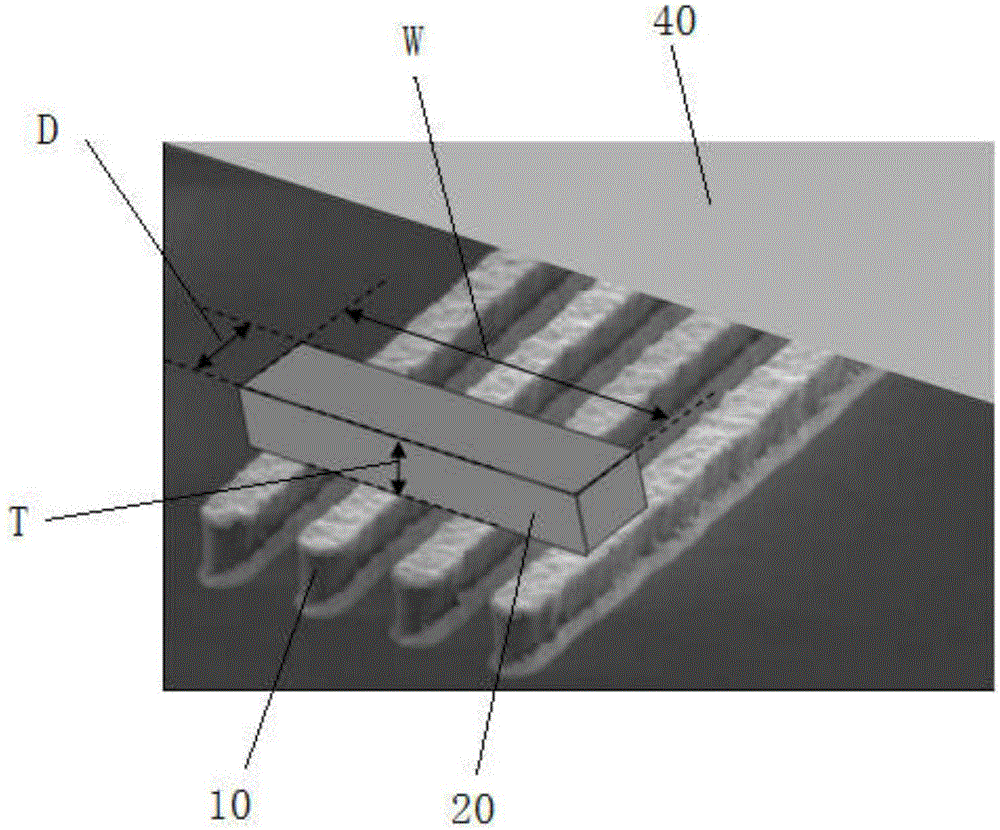

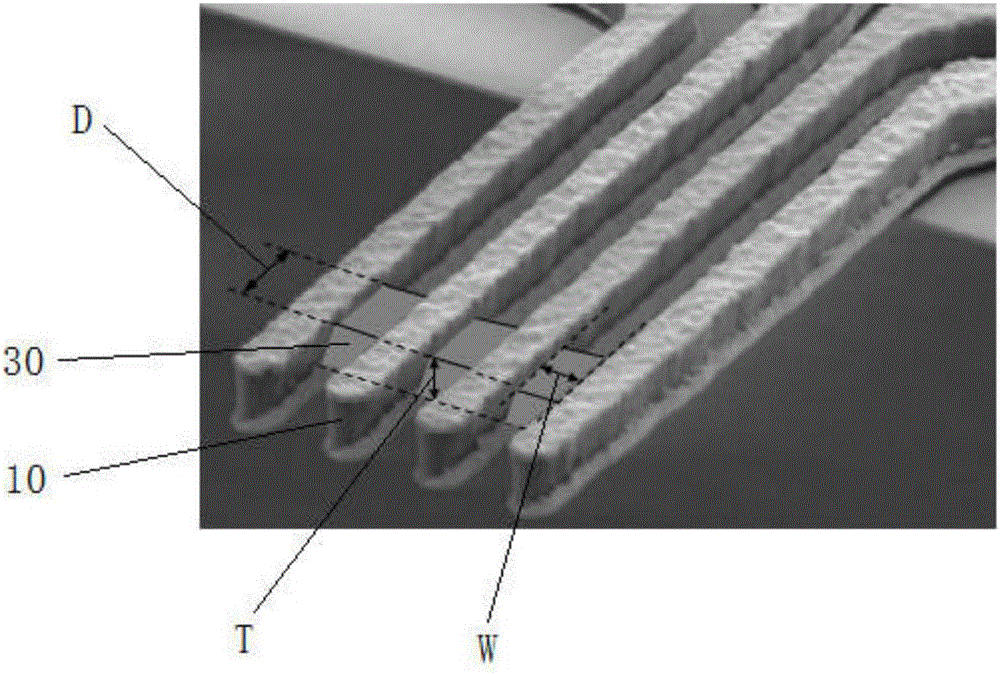

Microprobe with rake-shaped cantilever structure and preparation method thereof

ActiveCN105785083AImprove stabilityAchieve Vibration ControlElectrical measurement instrument detailsElectrical testingEngineeringCantilevered beam

The present invention discloses a microprobe with rake-shaped cantilever structure and a preparation method thereof. The microprobe comprises a set of cantilever beams and a connection structure reserved or additionally installed at the end of the set of the cantilever beams in the process of the microprobe, and the connection structure is configured to restrain side-way movement of the end of the cantilever beams. The microprobe is able to restrain the sideway jittering / vibration of each cantilever beam through a connection structure to effectively realize the jittering / vibration control of the cantilever beams and overcome the problem of unstable measurement result.

Owner:颍上县祥盛建设管理有限公司

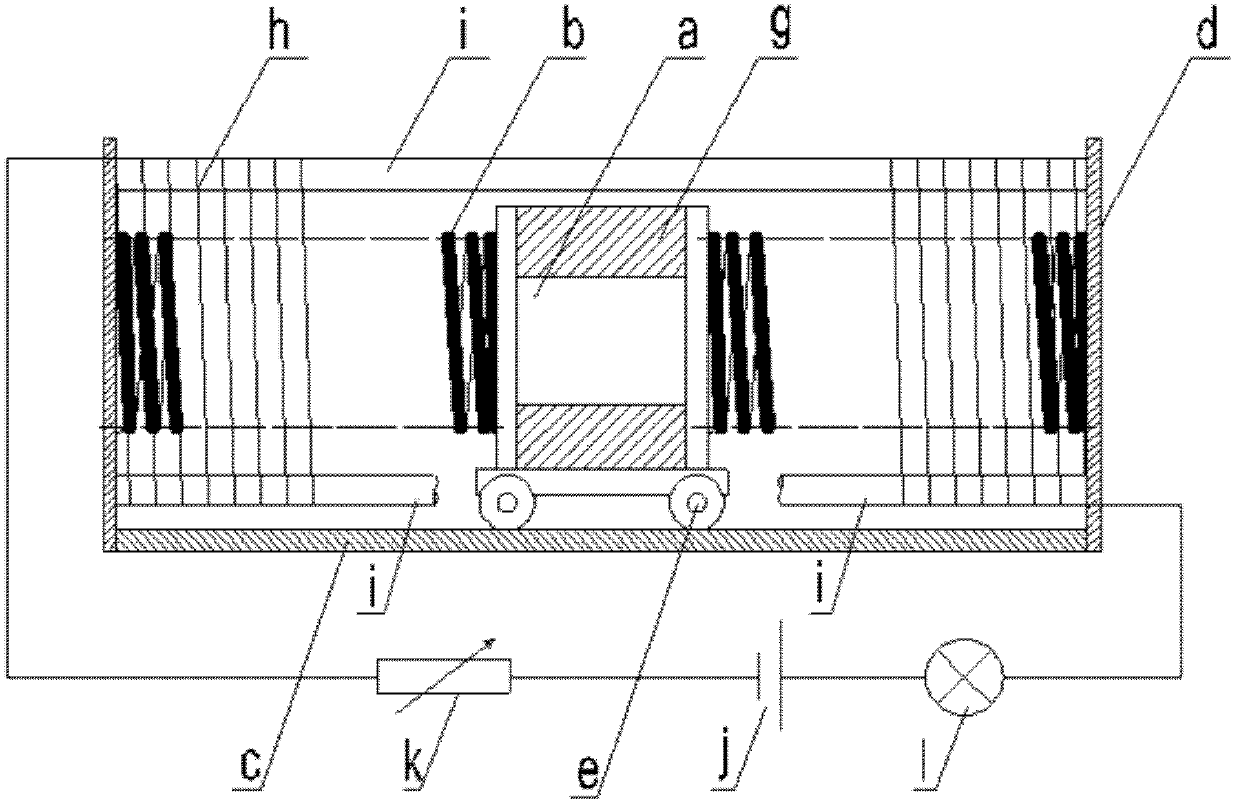

Adjustable damping energy storage type tuned mass damper and energy storage method thereof

The invention provides an adjustable damping energy storage type tuned mass damper. A damping adjusting device of a damper of consists of a permanent magnet, coils, auxiliary rods, an energy storage battery, an adjustable resistor, a light-emitting diode (LED) pre-warning indicator light; in the reciprocating motion process that the damper absorbs the vibration energy of a main structure so as to generate inertial mass, a cylindrical spiral spring provides damping, the permanent magnet generates a variable magnetic field, induced electromotive force is generated in the coils so as to generate induction current, and the induction current generates electromagnetic damping to inhibit the movement of the permanent magnet; the adjustable resistor in the damping adjusting device is adjusted, so the magnitude of the electromagnetic damping is changed, and the damping ratio of a structure reaches the optimum damping ratio; and residual energy is recovered by using the energy storage battery, the LED pre-warning indicator light provides a pre-warning indication for a pedestrian and a vehicle, and multiple effects of vibration controlling, clean energy recovery, pre-warning and alarming of vibration conditions and the like.

Owner:中铁桥研科技有限公司 +2

Conveying type vibration cleaning device based on grain production

PendingCN113210260AReduce breakage rateFalling smoothlySievingGas current separationSupport planeManufacturing engineering

Owner:ANHUI ZHENGYANG MACHINERY TECH

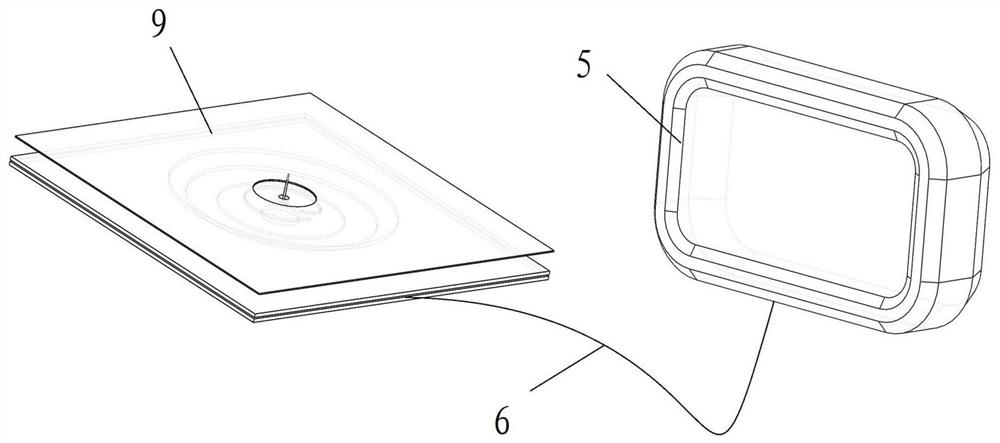

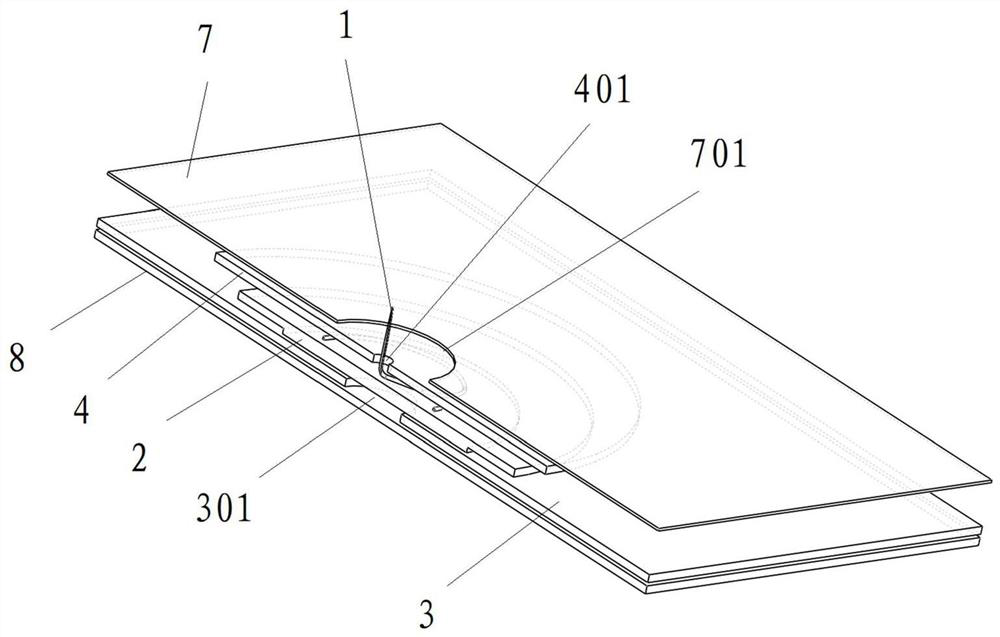

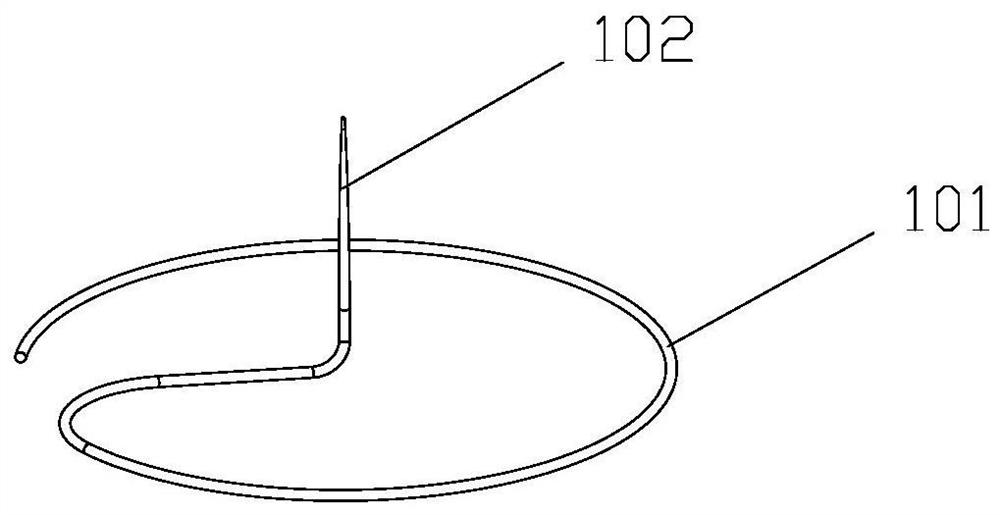

Vibration-based acupuncture point stimulation device

ActiveCN113081813BAchieve Vibration ControlSimple structureAcupunctureDevices using mechanical vibrationsPhysical medicine and rehabilitationControl power

The invention provides a vibration-based acupoint stimulating device for pressing needles, which includes pressing needles, a vibrating layer, a control unit, a first fixing tape and a second fixing tape, and the pressing needles are fixed on the first side of the vibrating layer; the control unit includes a control power supply One end of the connecting wire is fixedly connected to the vibration layer, and the other end of the connecting wire is detachably connected to the control power supply; the first fixing tape is bonded to the second side of the vibration layer, and the first fixing tape is provided for the connecting wire to pass through. through the hole through which the wire passes; the vibrating layer is located between the second fixing tape and the first fixing tape, the second fixing tape is bonded to the first fixing tape, and the second fixing tape is provided with a first through pin for the pressing pin to pass through hole. The vibration-based acupuncture point stimulation device provided by the present invention has a simple structure and is easy to operate, and can effectively transmit the vibration generated by the vibrating layer through the pressing needle, so as to increase the stimulating effect of the pressing on the acupuncture points, thereby improving the therapeutic effect.

Owner:BEIHANG UNIV

A method and system for controlling mechanical vibration

ActiveCN113157012BAchieve Vibration ControlGuaranteed work efficiencyMechanical oscillations controlVibration controlEngineering

The present application provides control methods and systems for mechanical vibration problems. There will be continuous vibration during the movement of the lightweight mechanical system. This continuous vibration can have a great impact on the safe operation of mechanical systems. This application provides a new vibration control method, which can provide technical means for various types of mechanical vibration control problems. The vibration control method invented by the present application is essentially a composite of a notch wave and a low-pass filter. Its notch filter characteristic suppresses the vibration of the main vibration mode, and its low-pass filter characteristic controls the vibration of the high mode. A vibration controller is used when the mechanical system has only one vibration mode. When the mechanical system has multiple vibration modes, the vibration controller is designed using the information of the first two vibration modes to realize the control of all vibration modes. The application also provides the engineering realization scheme of the method in various mechanical systems.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

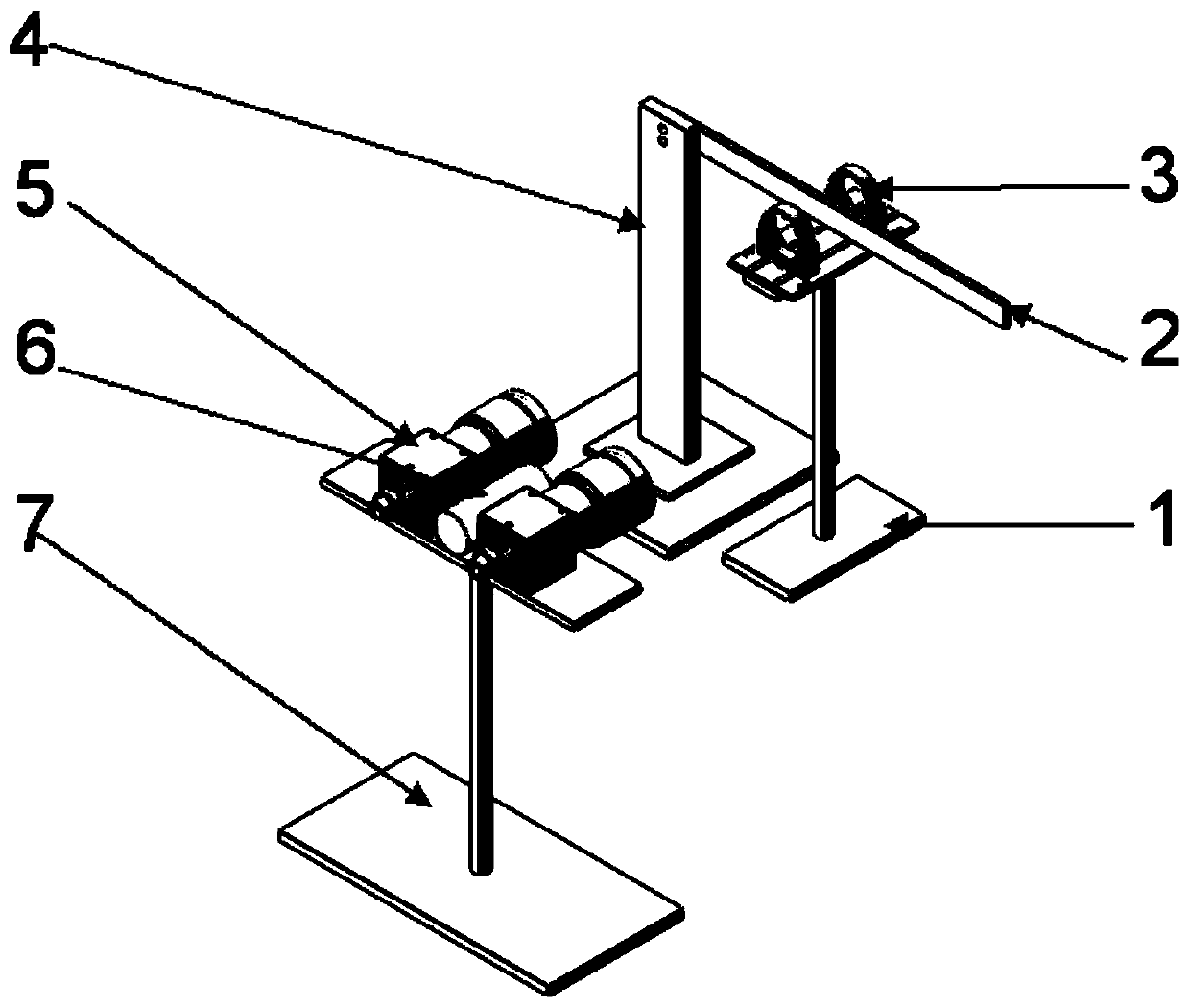

Wide frequency inertia type active vibration absorber

InactiveCN101666365BOptimize layoutEasy to installNon-rotating vibration suppressionSemi activeEngineering

The invention provides a wide frequency inertia type active vibration absorber, comprising a vibration exciter, a metal return spring, a vibration exciter fixing support, two guide shafts, a base and a regulating pressing plate. The two guide shafts are installed on the base; the regulating pressing plate is connected between the two guide shafts; the base, the guide shafts and the regulating pressing plate form a frame structure; the vibration exciter fixing support is installed on the guide shafts and can slide on the guide shafts; the vibration exciter is fixed on the vibration exciter fixing support; the metal return spring is arranged between the vibration exciter fixing support and the frame structure; and the base is provided with a vibration exciting bar. The invention overcomes the disadvantages of the prior passive vibration absorber and the semi-active vibration absorber in low-frequency vibration absorption and wide-frequency vibration so as to be conveniently applied to the vibration excitation in the horizontal direction. A detachable support enables the active vibration absorber to be flexibly arranged and installed on the basis of stably transferring the control force. A guiding mechanism enables the inertia type active vibration absorber to stably and reliably work in the horizontal direction and have the largely improved work efficiency.

Owner:HARBIN ENG UNIV

Three-axis six-degree-of-freedom vibration test device

ActiveCN110243563BAchieve Vibration ControlLarge thrustVibration testingEngineeringBearing vibration

The invention discloses a tri-axial and six-degree-of-freedom vibration test device. The device comprises a MIMO controller, a power amplifier system, a vibration platform, a vapor system and a hydraulic system; the MIMO controller generates a driving voltage signal, and then inputs the driving voltage signal into the vibration platform through the power amplifier system, and meanwhile, the response on a vibration plane is fed back to the MIMO controller; the vapor system is connected with the vibration platform, the hydraulic system is connected with the vibration platform, and the vibration platform comprises electric vibration tables, hydrostatic pressure bearings, a vibration board, trunnion brackets, a base and a ball hinge over-displacement protection device; the electric vibration tables are connected with the base through the corresponding trunnion brackets; and the electric vibration tables are connected with the vibration board through the hydrostatic pressure bearings; the electric vibration tables are connected to lower surface of the vibration board and various laterals of the vibration board through the hydrostatic pressure bearings; and the vibration board is connected with the base through the ball hinge over-displacement protection device and an auxiliary support device.

Owner:CHINA AERO POLYTECH ESTAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com