Microprobe with rake-shaped cantilever structure and preparation method thereof

A technology of cantilever beams and microprobes, applied in the direction of microstructure technology, microstructure devices, microstructure devices composed of deformable elements, etc., can solve the problems of poor accuracy and repeatability, and achieve improved stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

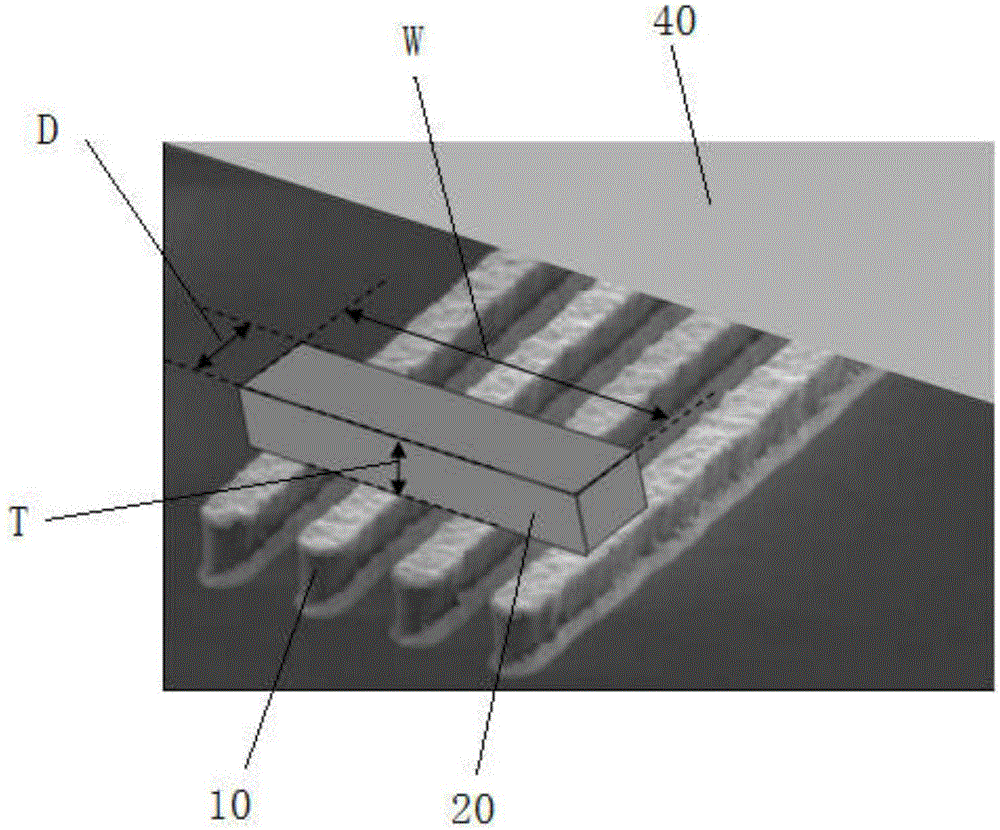

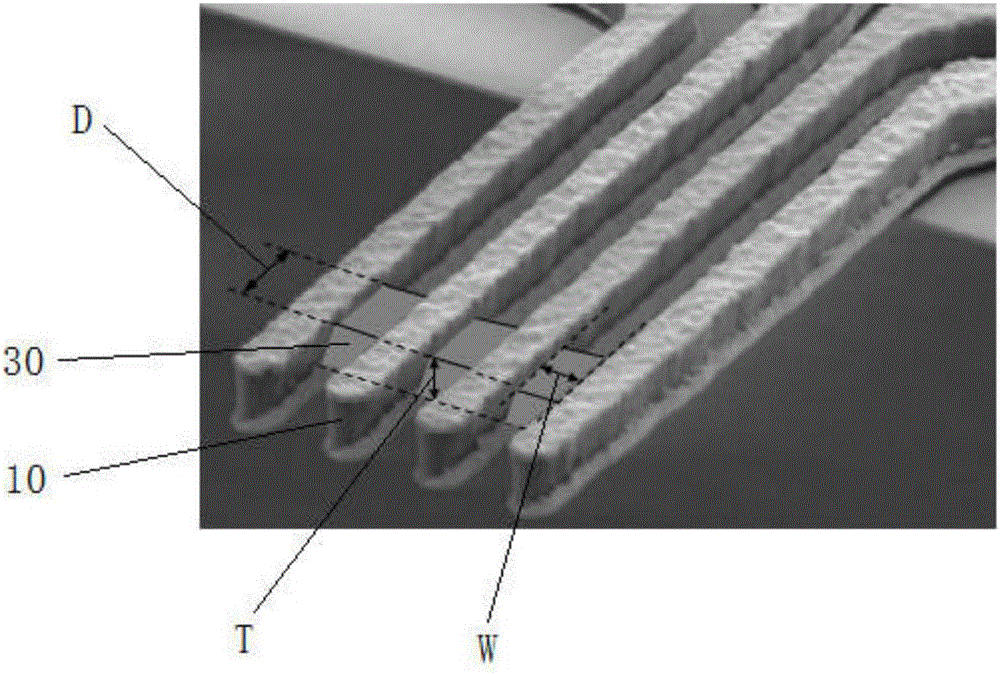

[0034] It can be understood that the essence of the microprobe (CN104931741A) disclosed in the prior art is to finely control the vibration of the cantilever beam in the measurement direction, while the vibration control of the cantilever beam in other directions is not considered. The invention utilizes the connection structure to fix the cantilever beams of the microprobes, suppresses the lateral displacement (vibration and drift) between the cantilever beams during the measurement process, and eliminates the system error introduced by the position change during the probe method measurement process.

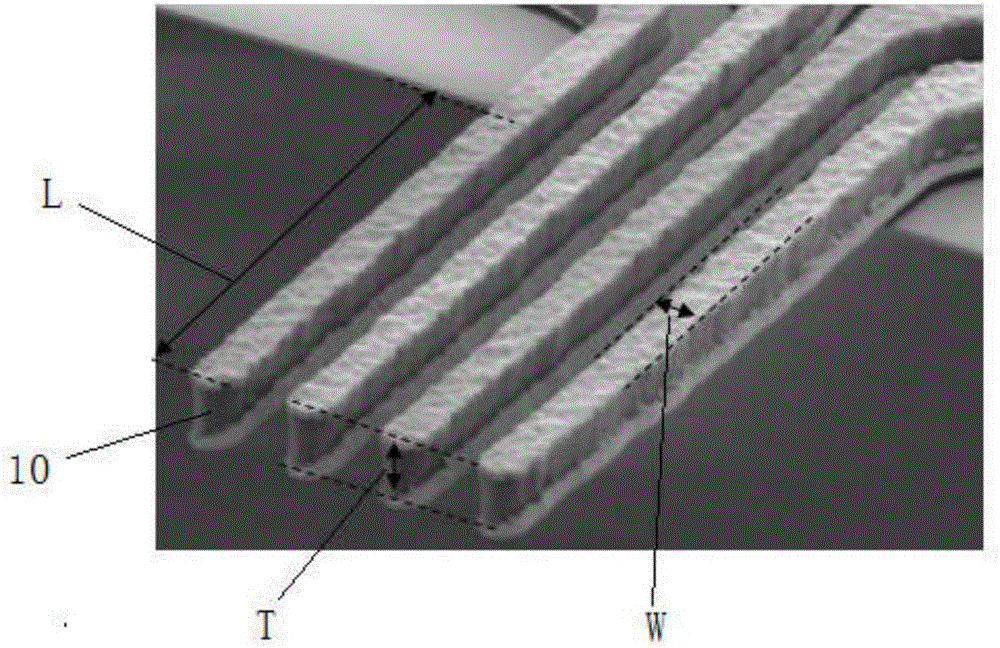

[0035] figure 1 is an enlarged view of the structure of the microprobe. The microprobe inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com